Process for preparing sulfuric acid by sulfurated hydrogen stepwise reaction

A hydrogen sulfide and sulfuric acid production technology, which is applied in the field of coal chemical industry, can solve the problems of complex process, difficult to use hydrogen sulfide to prepare sulfuric acid process, difficult operation and increased investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

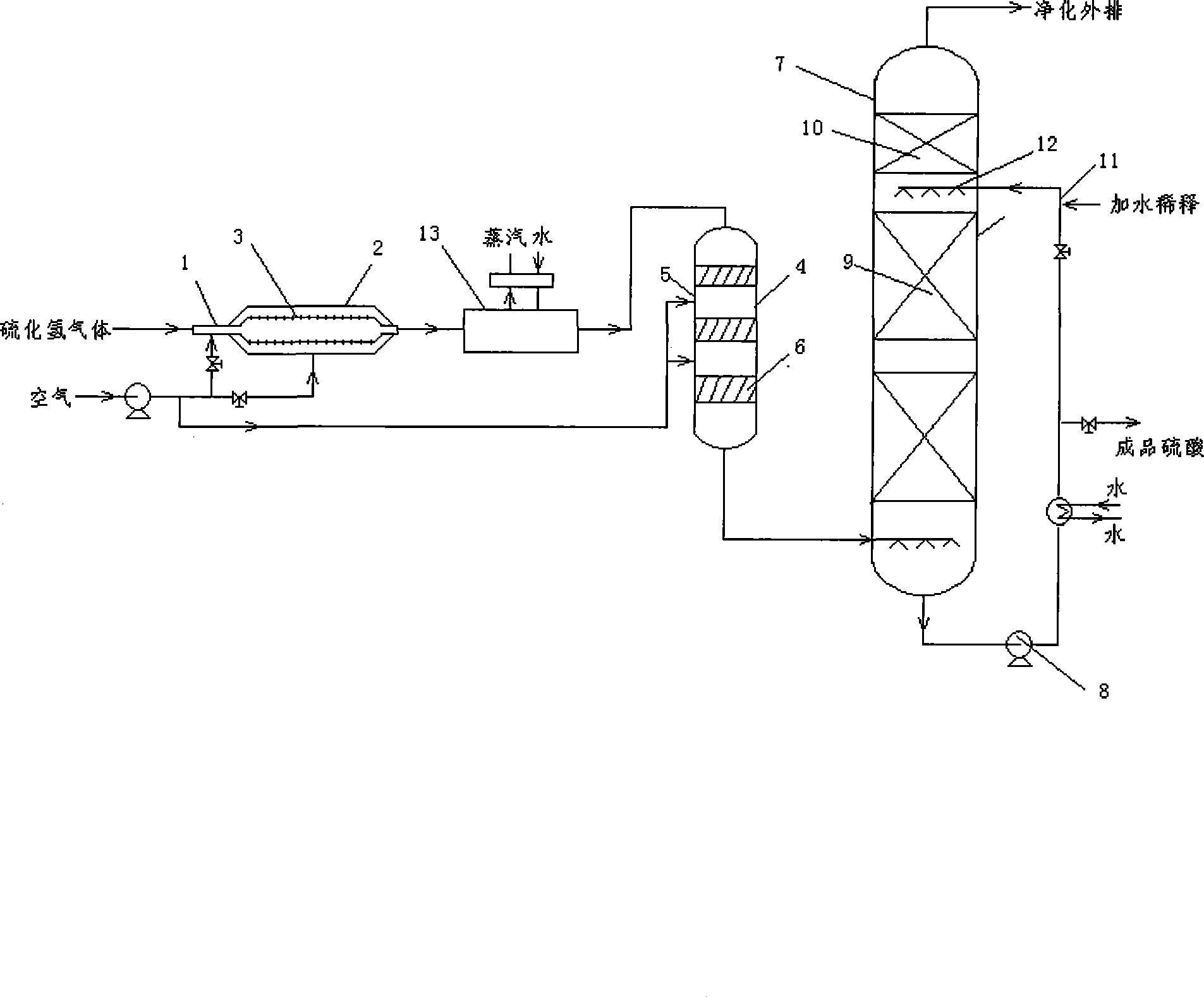

[0010] The present invention is described in detail below in conjunction with accompanying drawing: raw material hydrogen sulfide gas and the air that is about 40% hydrogen sulfide gas combustion to generate sulfur dioxide pass burner 1 and incomplete combustion takes place at the front of air-cooled reactor 2, and the mixed gas that produces Further reaction and combustion with the cooling air entering along the inner wall 3 of the air-cooled reactor, the hydrogen sulfide is completely converted into sulfur dioxide; the sulfur dioxide product gas passes through the waste heat boiler 13 to generate high-pressure steam to recover heat, and then enters the converter 4; the sulfur dioxide product gas passes through the converter 4 The 3-stage or 4-stage catalyst bed layer 6 catalytically oxidizes to generate sulfur trioxide, and the heat released by each layer of reaction is diluted and cooled by air from 2 or 3 quenching air inlets 5 between the layers to keep the reaction tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com