A kind of self-lubricating non-stick aluminum-melting environment-friendly coating and coating film and preparation method thereof

An environmentally friendly coating and self-lubricating technology, applied in coatings, manufacturing tools, casting molding equipment, etc., can solve the problems of cast aluminum release agent toxicity, harsh application process conditions, complex preparation process, etc., to achieve excellent results and easy The effect of preparation, temperature resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

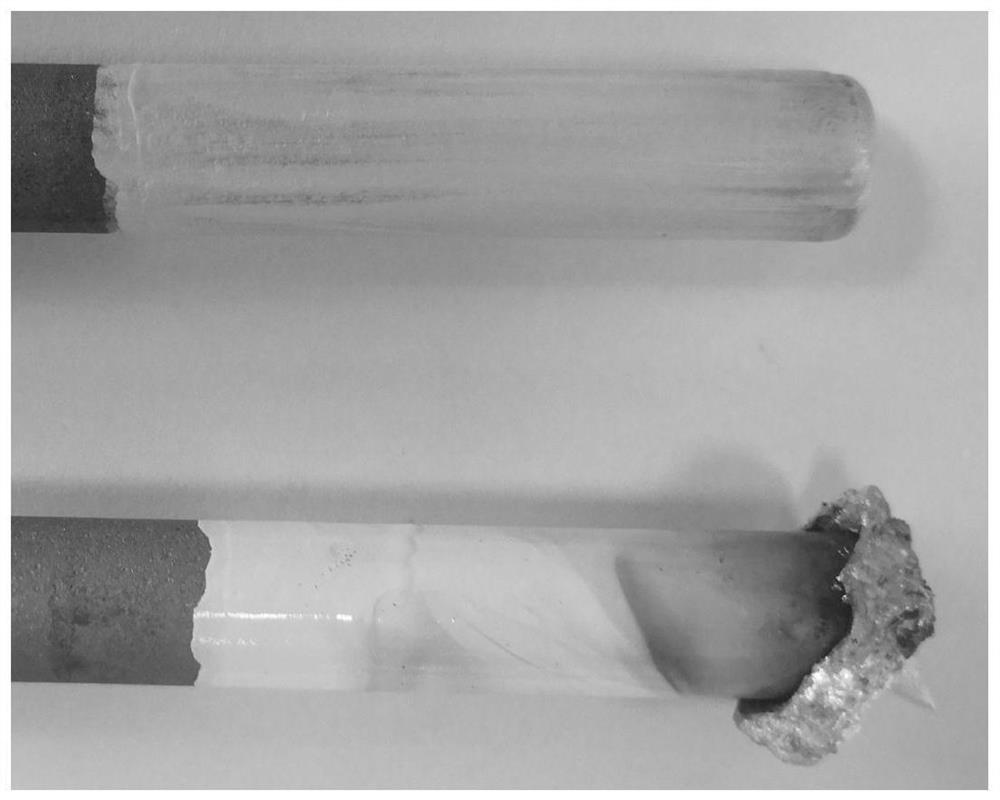

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing an environmentally friendly paint that is self-lubricating and does not stick to molten aluminum, comprising:

[0043] 1) Mix the silane coupling agent containing amino group or epoxy group, deionized water and tetramethylammonium hydroxide according to the mass ratio of (20~60):(30~50):(0.1~1), Ultrasonic dispersion for 30 minutes, hydrolysis at room temperature for 7 days, and preparation of polysiloxane oligomer aqueous solution I with a viscosity lower than 100 mPa·S;

[0044] Among them, silane coupling agents containing amino groups include 3-aminopropyltrimethoxysilane, N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, 3-ureapropyltrimethoxysilane, Bis-[3-(methoxysilyl)-propyl]-amine or 3-anilinopropyltrimethoxysilane.

[0045] Silane coupling agents containing epoxy groups include 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 3-(2,3-epoxypropoxy)propyltrimethoxysilane or 3-(2,3-Glycidoxy)propylmethyltrimethoxysilane....

Embodiment 1

[0053] (1) Prepare 3-aminopropyltrimethoxysilane, deionized water (DI), and tetramethylammonium hydroxide (TMAH) according to the mass ratio of 20:30:0.2, disperse them with ultrasonic waves for about 30 minutes, and then It was hydrolyzed for 7 days at normal temperature (23±2° C.) to prepare polysiloxane oligomer aqueous solution I with a viscosity lower than 100 mPa·S.

[0054] ⑵Put 20 parts of deionized water (DI) into the beaker, add 10 parts of BYK-190 dispersant to it at the speed of 100rpm / min, disperse for 8min, and add 2 parts of dipropylene glycol butyl ether, 30 10 parts of boron nitride, 10 parts of talcum powder, 10 parts of low temperature glass powder, 5 parts of Al 2 o 3 Disperse it for 25min.

[0055] (3) After dispersion, add 3 parts of gas phase SiO 2 , and then dispersed for 5 minutes to prepare the aqueous slurry II.

[0056] (4) Mix polysiloxane oligomer aqueous solution Ⅰ and slurry Ⅱ according to different ratios of 10:90, ultrasonically disperse f...

Embodiment 2

[0059] (1) N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, deionized water (DI), tetramethylammonium hydroxide (TMAH) and other materials are mixed according to the mass ratio of 30:35:0.2 Proportional configuration, ultrasonic dispersion for about 30 minutes, and then hydrolysis at room temperature (23±2°C) for 7 days to prepare polysiloxane oligomer aqueous solution I with a viscosity lower than 100mPa·S.

[0060] ⑵Put 60 parts of deionized water (DI) into the beaker, add 2 parts of BYK-190 dispersant to it at the speed of 200rpm / min, disperse for 5min, add 5 parts of dipropylene glycol butyl ether, 40 Parts of boron nitride, 15 parts of talcum powder, 15 parts of low temperature glass powder, 5 parts of Al 2 o 3 Disperse it for 30min.

[0061] (3) After dispersion, add 2 parts of gas phase SiO 2 , and then dispersed for 10 minutes to prepare the aqueous slurry II.

[0062] (4) Mix polysiloxane oligomer aqueous solution I and slurry II according to different ratios of 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com