A kind of anti-flash rust agent for water-based paint and preparation method thereof

A water-based coating and anti-flash rust technology, which is applied in polyester coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of toxicity and carcinogenicity, and does not meet the development trend of environmentally friendly coatings, and achieves good anti-flash rust performance, Low production cost, corrosion inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

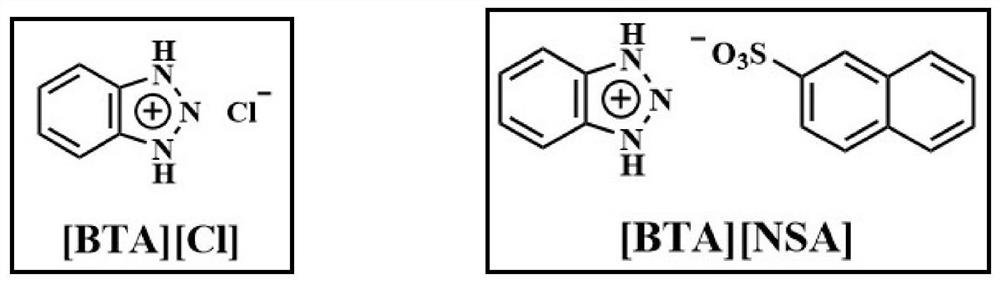

[0032] Add 20g of 1,4-butynediol and 20g of tetrasodium hydroxyethylidene diphosphonate to 1L of deionized water in sequence, stir at 25°C for 0.5h, then add 50g of [CTA][Cl] in sequence , 50g of [BTA][NSA] and 50g of [DSA][Cl], stirred at 25°C for 0.5h to obtain an anti-flash rust agent for water-based coatings.

Embodiment 2

[0034] Add 10 g of propynyl alcohol and 10 g of tetrasodium hydroxyethylidene diphosphonate to 1 L of deionized water in sequence, stir at 25°C for 0.5 h, then add 25 g of [CTA][NSA], 25 g of [BTA ][Cl] and 25g of [DSA][Cl], stirred at 25°C for 0.5h to obtain an anti-flash rust agent for water-based coatings.

Embodiment 3

[0036] Add 5 g of 1,4-butynediol and 5 g of tetrasodium aminotrimethylene phosphonate in sequence to 1 L of deionized water, stir at 25°C for 0.5 h, then add 45 g of [CTA][NSA], Stir 45g of [BTA][Cl] and 45g of [DSA][Cl] at 25°C for 0.5h to obtain an anti-flash rust agent for water-based coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com