Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Improve cooling and lubrication effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

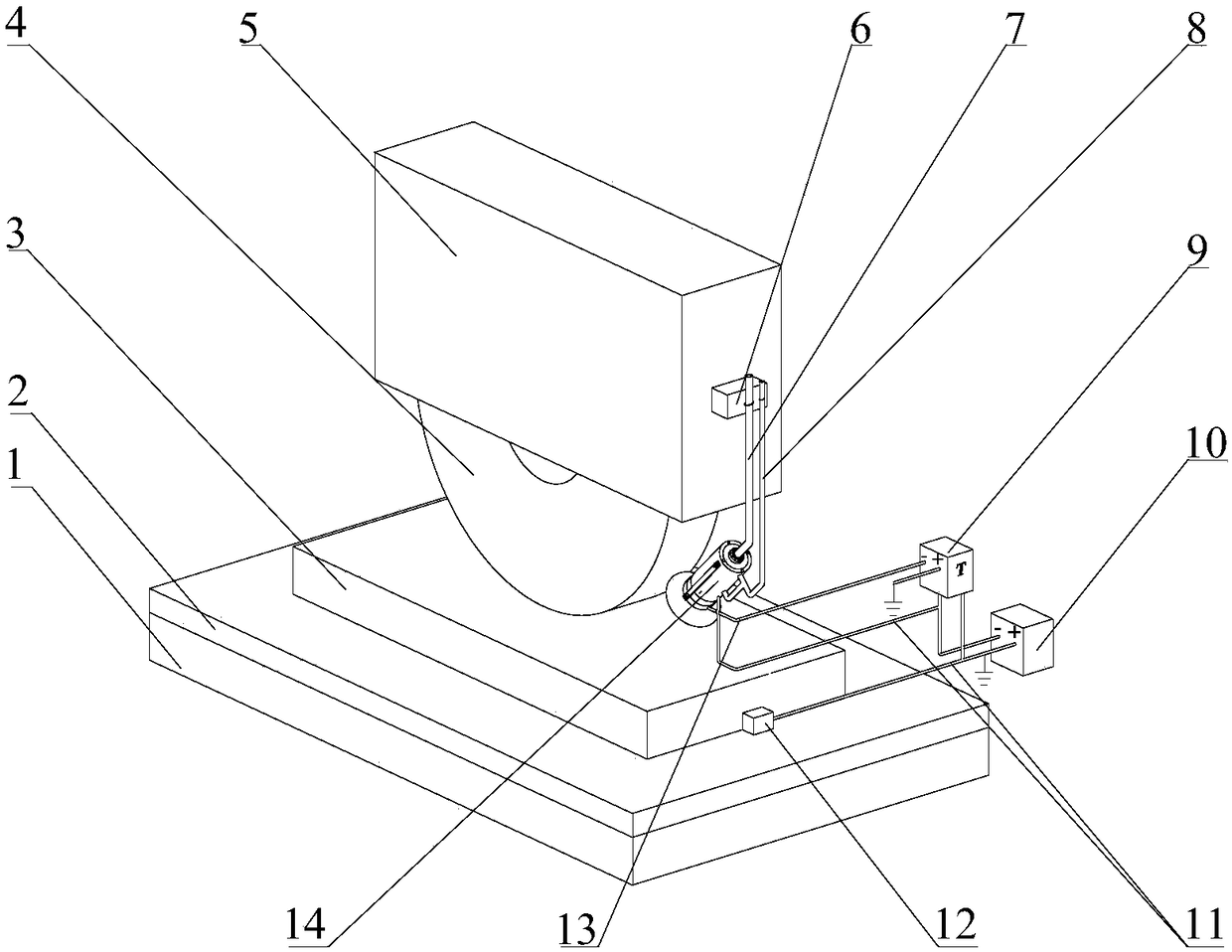

Cutting method and device capable of controlling spraying of nanometer fluid droplets

ActiveCN104029079AImprove permeabilityFull play of permeabilityMaintainance and safety accessoriesHigh pressureElectric cables

The invention discloses a cutting method and device capable of controlling spraying of nanometer fluid droplets in the field of cutting cooling and lubricating. A cutter is connected to the anode output end of an electrostatic generator with adjustable high voltage through a wire and grounded, a charging spray nozzle is connected with the cathode output end of the electrostatic generator with the adjustable high voltage through a high-voltage cable, the rear end of the charging spray nozzle is connected with a micro-injection pump through a silicon rubber tube, the micro-injection pump conveys nanometer fluid to the charging spray nozzle, the electrostatic generator with the adjustable high voltage provides direct-current negative high voltage for the charging spray nozzle, positive charges opposite to the charging spray nozzle in polarity are induced on the surface of the cutter, a high-voltage electrostatic field is built up between the spray nozzle and the cutter, the nanometer fluid droplets fully play a role in cooling and lubricating a cutting area, and the effects of cooling and lubricating the cutting area can be improved; by changing the electrostatic field between the spray nozzle and the cutter, the size, the distribution and the motion trail of the nanometer fluid droplets can be adjusted and controlled, and therefore the nanometer fluid droplets can be transported to the cutting area in a directional and controllable mode.

Owner:JIANGSU UNIV OF SCI & TECH

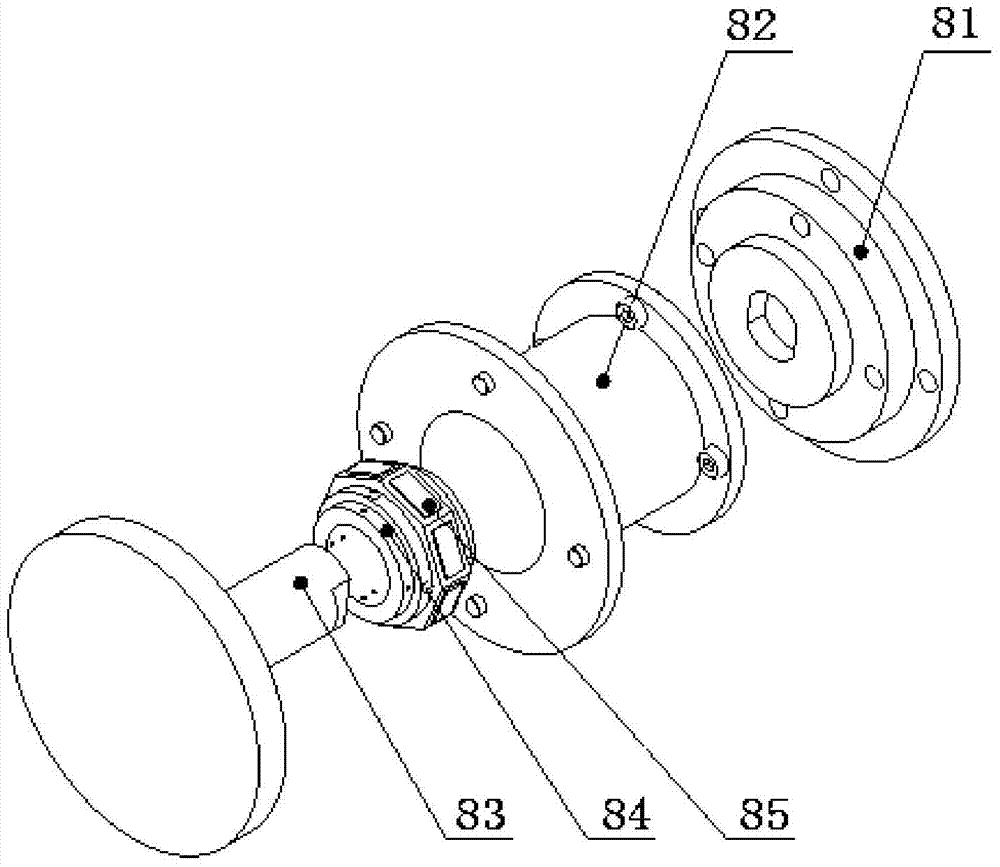

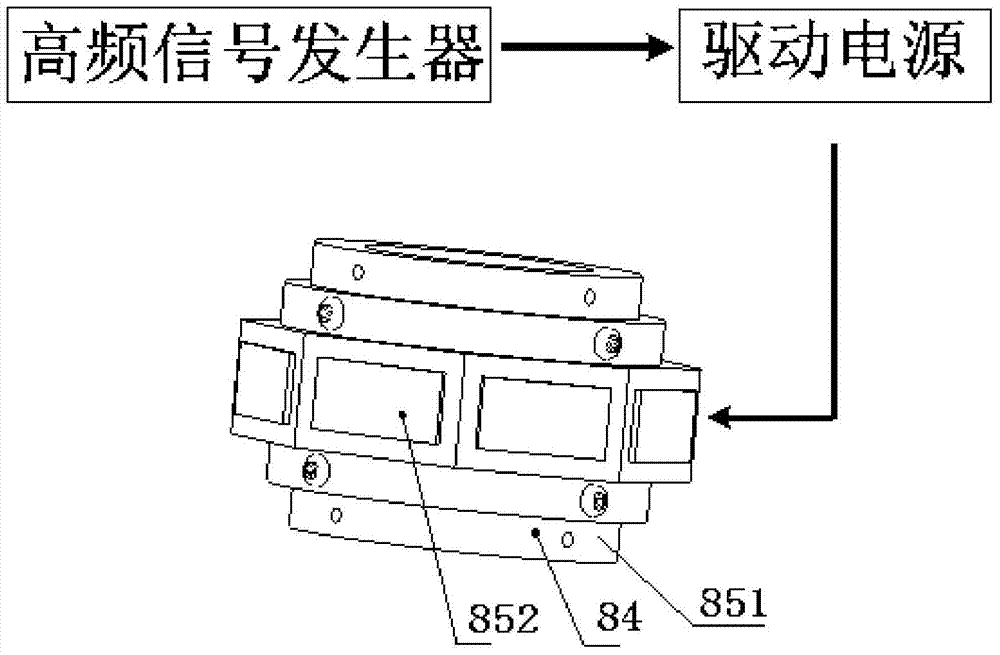

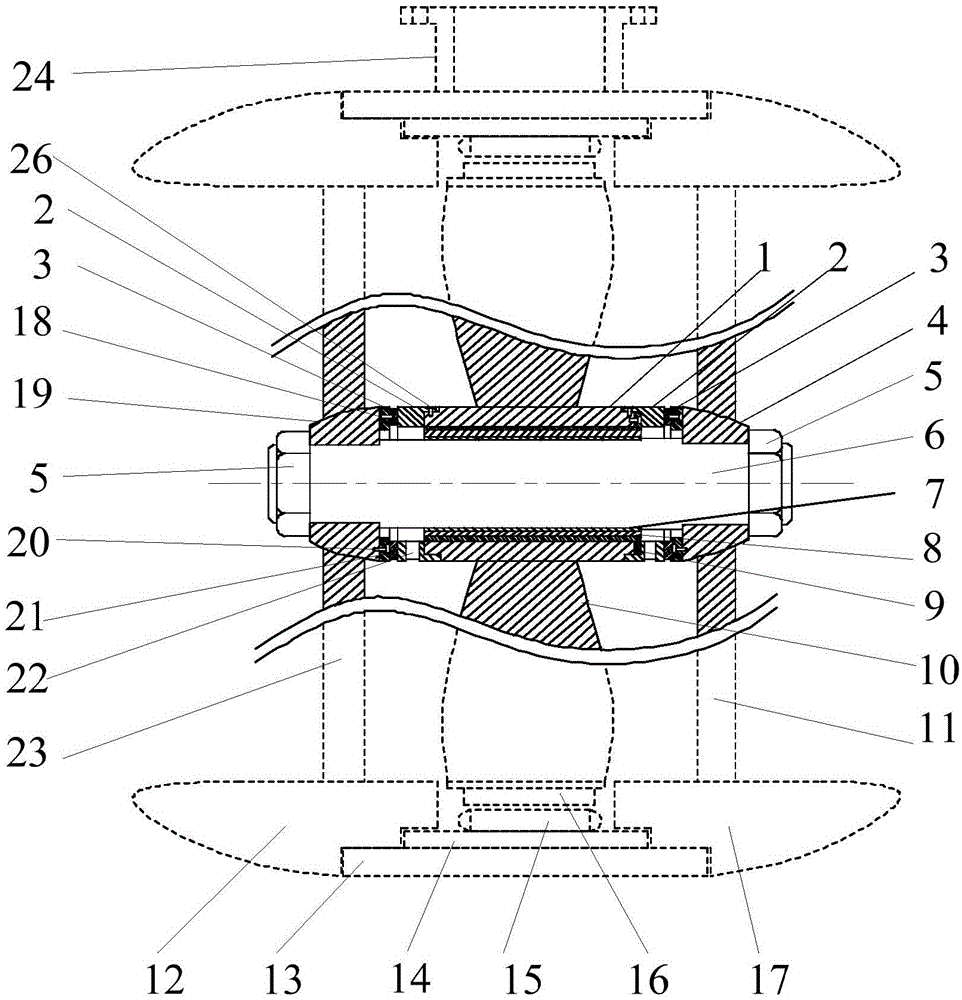

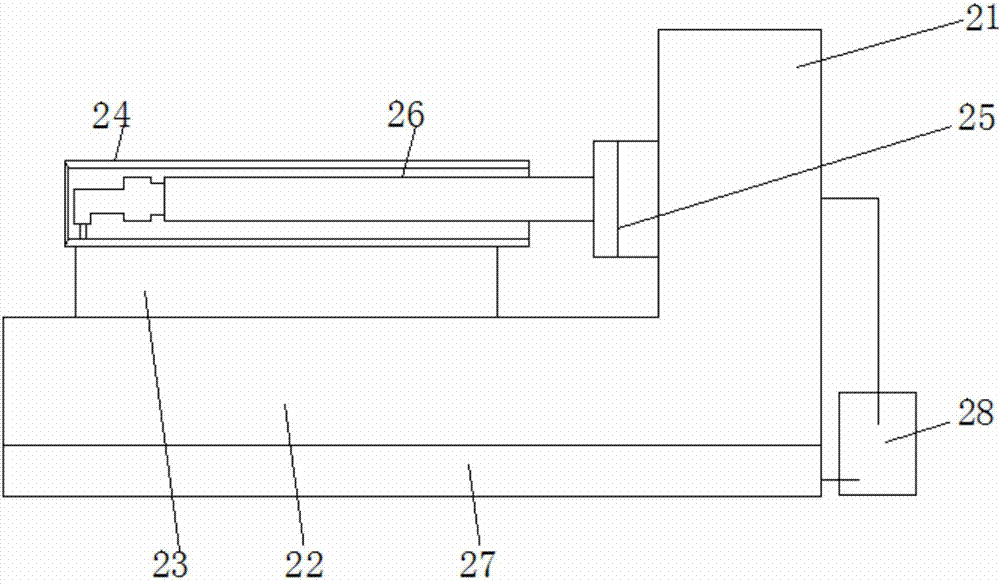

Workpiece loading device and machining device for machining tiny deep holes

InactiveCN103586504AControllable torsional vibrationReduce frictionBoring/drilling machinesEngineeringActuator

A workpiece loading device for machining tiny deep holes comprises a base, an upper cover and a protection shell, wherein the upper cover is used for bearing a workpiece to be drilled, and the protection shell is connected with the base and the upper cover. The base, the upper cover and the protection shell are coaxially arranged. A torsional vibration generating mechanism is arranged inside the protection shell and comprises a torsional actuator for generating torsional vibration and an exciting device for providing an exciting signal for the torsional vibration actuator. The torsional actuator generates the torsional vibration through intelligent materials. The machining device for machining the tiny holes comprises a drilling machine, a main shaft, a drill bit clamp, a drill bit, an intelligent material for driving the drill bit to be torsionally vibrated and a workpiece loading device, wherein the drill bit clamp is fixedly connected with the main shaft, and the drill bit and the workpiece loading device are reversely and torsionally vibrated. The workpiece loading device and the machining device have the advantages that the tiny hole machining efficiency and the machining precision can be improved.

Owner:ZHEJIANG UNIV

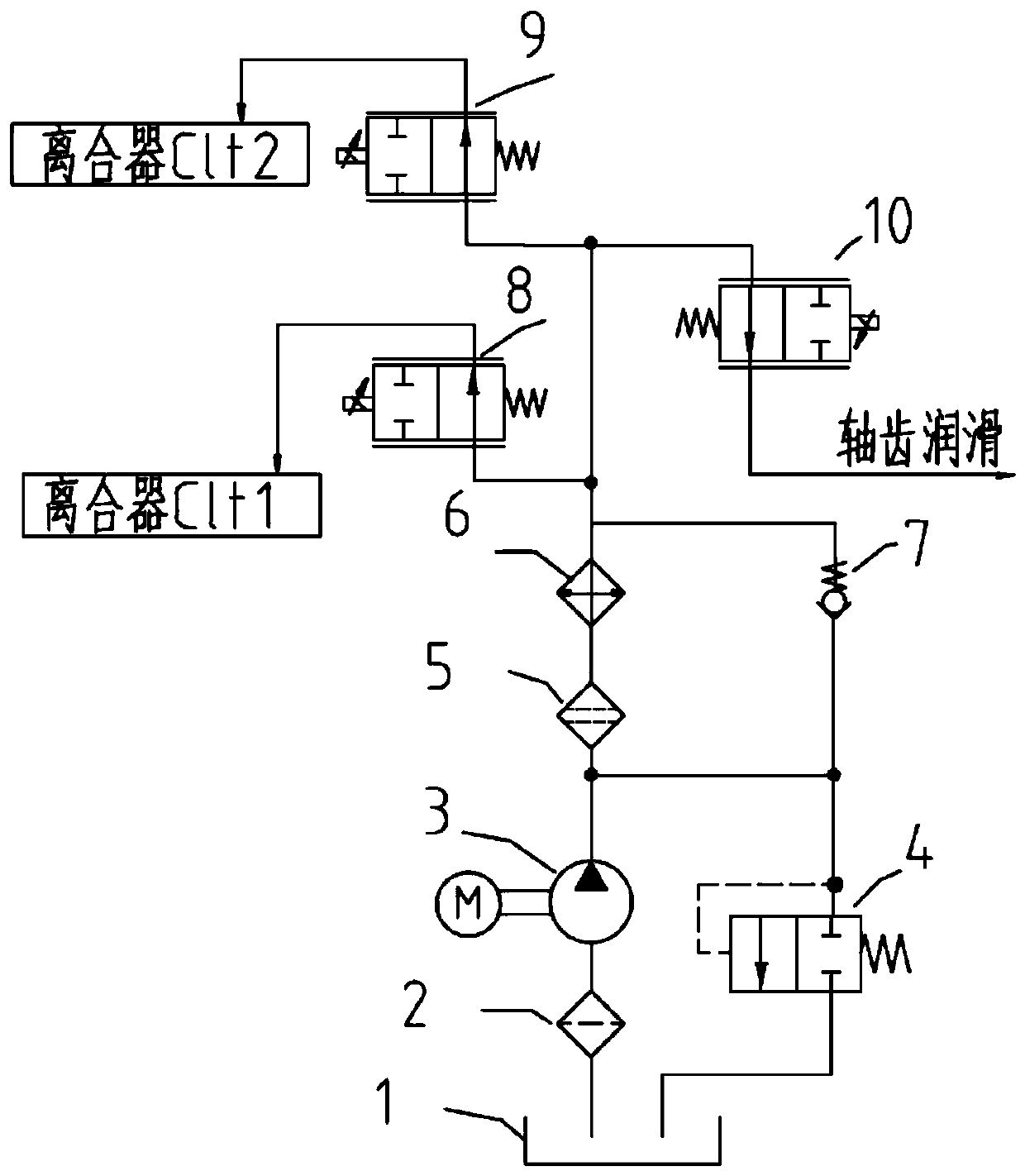

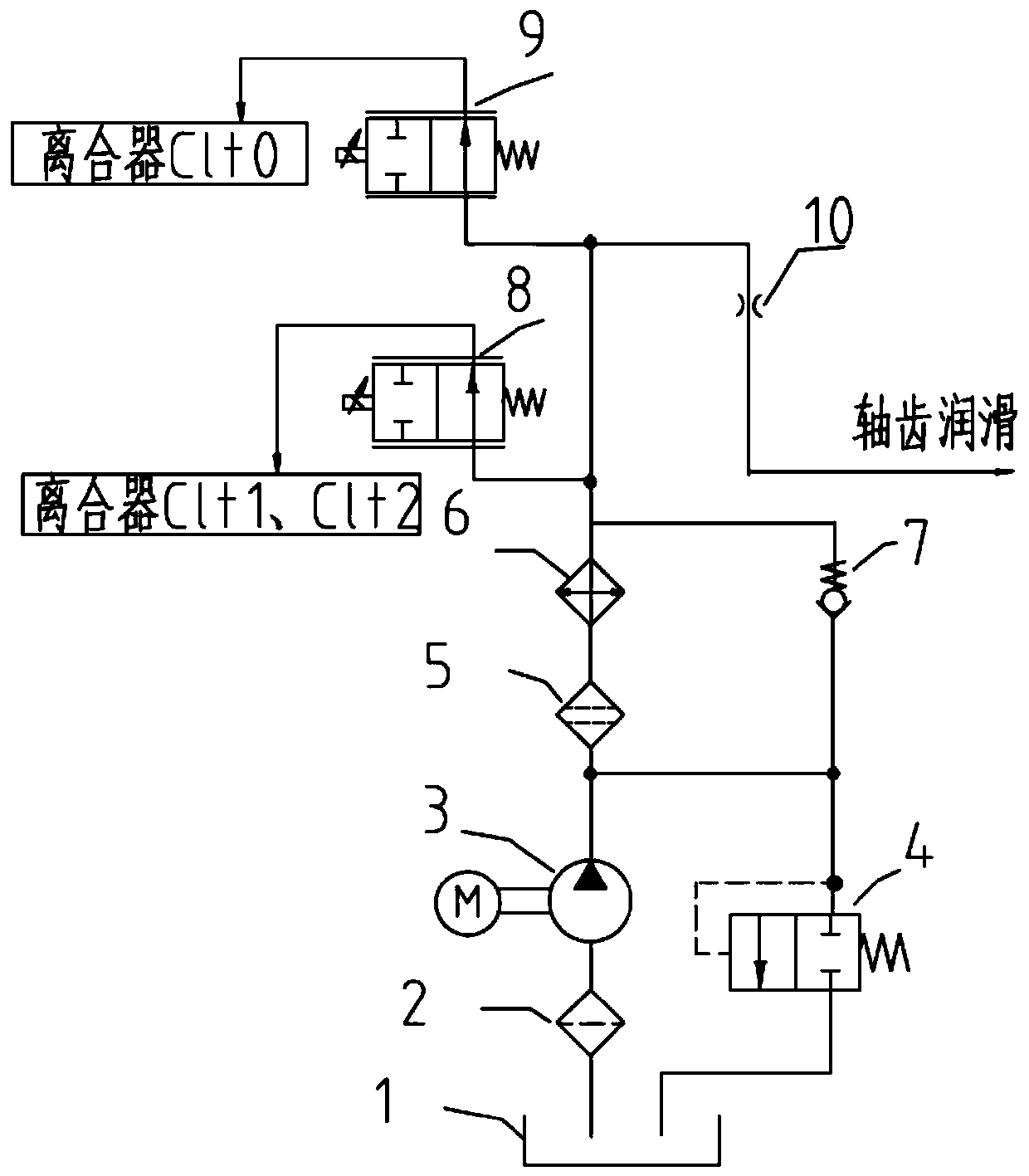

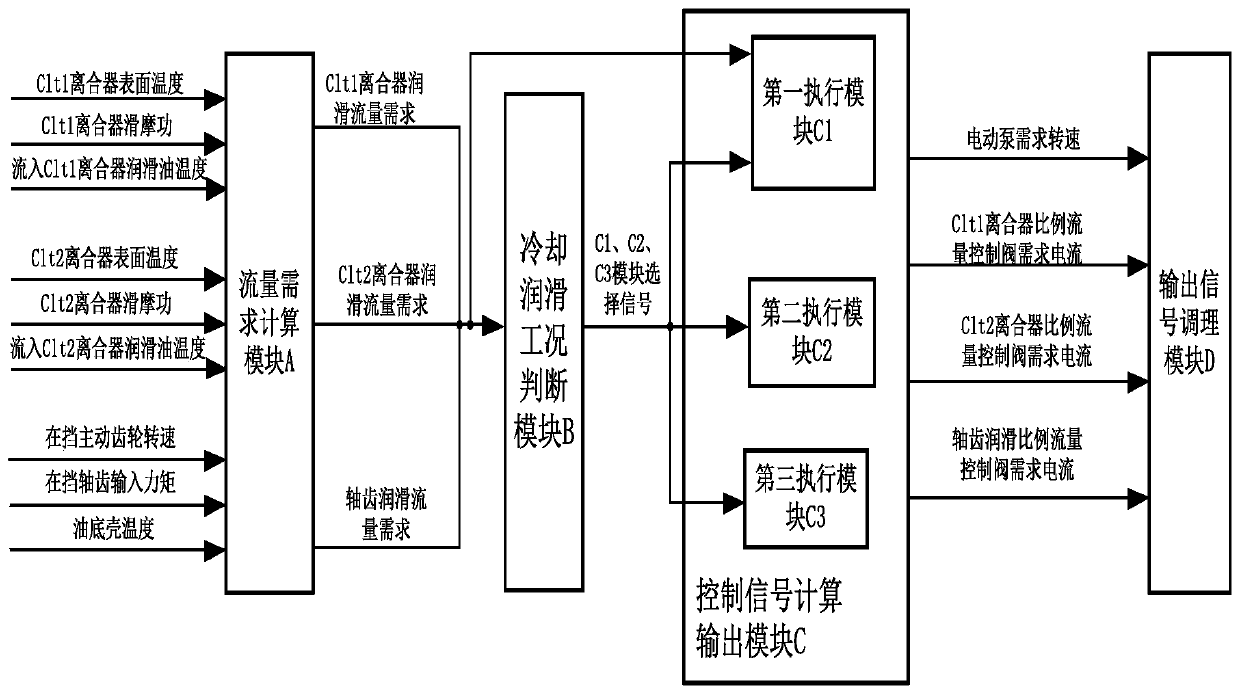

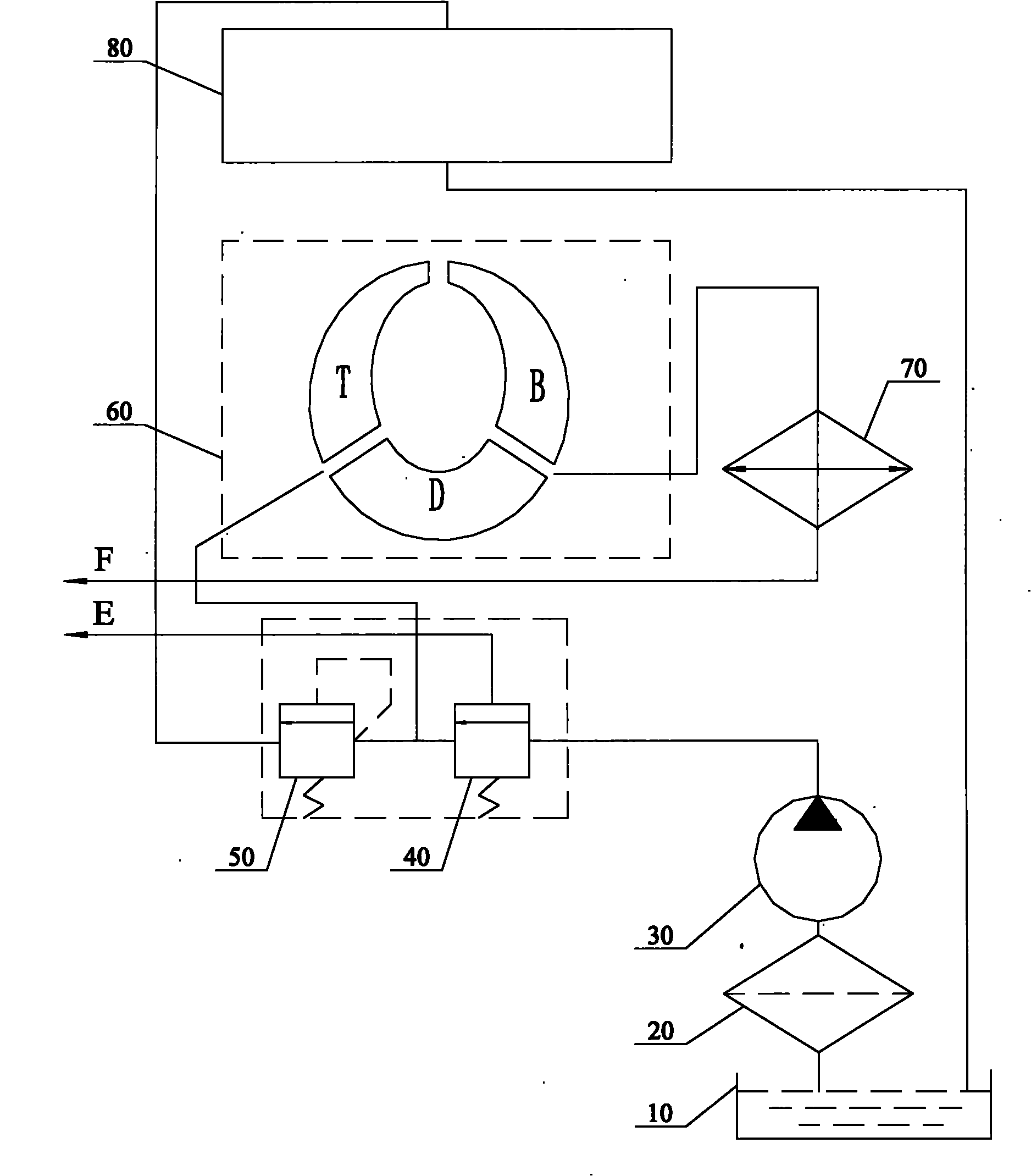

Automatic speed changer electric hydraulic cooling lubrication system and control system thereof

ActiveCN110219971AIncreased freedom of controlImprove cooling and lubrication effectGear lubrication/coolingAutomatic transmissionControl system

The invention relates to an automatic speed changer electric hydraulic cooling lubrication system. An oil inlet of an oil absorbing filter of the system is connected with an oil storage tank, and an oil outlet of the oil absorbing filter is connected with an oil suction port of an electric hydraulic pump. An oil outlet of the electric hydraulic pump is connected with an electric hydraulic pump outlet filter and an oil port in one end of an loading valve in parallel, the other end of the electric hydraulic pump outlet filter is connected with the inlet end of a cooler, and the outlet end of thecooler is connected with a plurality of clutch proportion flow control valves and the inlet end of a shaft tooth flow adjusting device in parallel; an oil port in the other end of the unloading valveis connected with the oil storage tank, and a one-way valve is connected to the outlet of the electric hydraulic pump and the outlet end of the cooler in parallel; the other ends of the clutch proportion flow control valves are connected with clutches; and the other end of the shaft tooth flow adjusting device is led to a shaft tooth cooling lubricating oil spraying pipe. The automatic speed changer electric hydraulic cooling lubrication system does not contain pressure and flow sensors, the control process can be finished without obtaining real-time system pressure and flow signals, and theoccupied space and cost of the system can be saved.

Owner:CHINA FIRST AUTOMOBILE

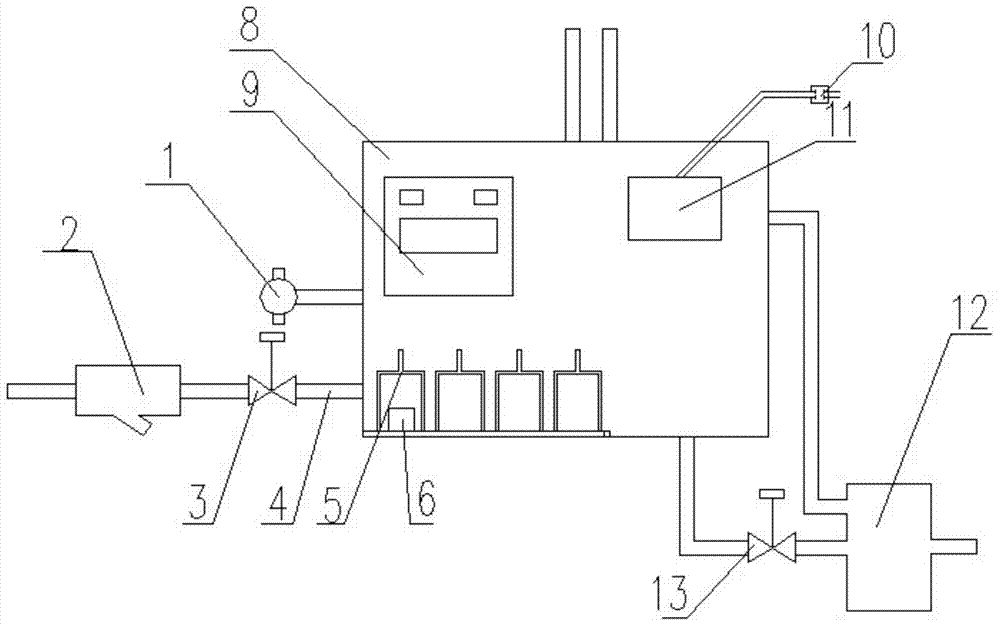

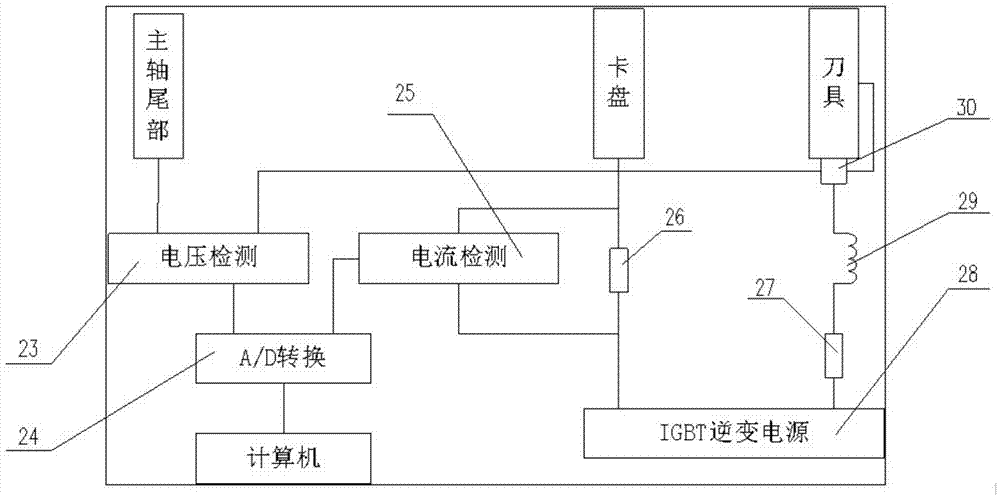

Self-starting cooling and lubricating system with low cutting fluid use level and control method for self-starting cooling and lubricating system

InactiveCN103921166AReduce dosageAvoid wastingMeasurement/indication equipmentsMaintainance and safety accessoriesCooling effectElectrical control

The invention discloses a cooling and lubricating system with a low cutting fluid use level. The cooling and lubricating system comprises an ultrasonic atomizing unit, an atomizing unit with spray nozzles, a cutting heat detecting unit and a circuit control module. The ultrasonic atomizing unit and the atomizing unit with the spray nozzles respectively comprise a plurality of atomizing assemblies which are arranged near front cutter face and rear cutter face regions of a cutter, the atomizing assemblies are integrally controlled on the basis of the temperature of a front cutter face of the cutter, the temperature of the front cutter face of the cutter is detected by the cutting heat detecting unit in real time, and accordingly various cooling and lubricating media can be flexibly compositely applied. The invention further discloses a corresponding electric control method. The cooling and lubricating system and the electric control method have the advantages that the cutting fluid use level can be greatly lowered while excellent integral cooling and lubricating effects are guaranteed; a good cooling effect can be realized, the cooling and lubricating system is convenient to control and wide in application range, accordingly, the cooling and lubricating system and the electric control method are particularly applicable to large-scale industrial production places such as machining places, and the like.

Owner:WUHAN UNIV OF SCI & TECH

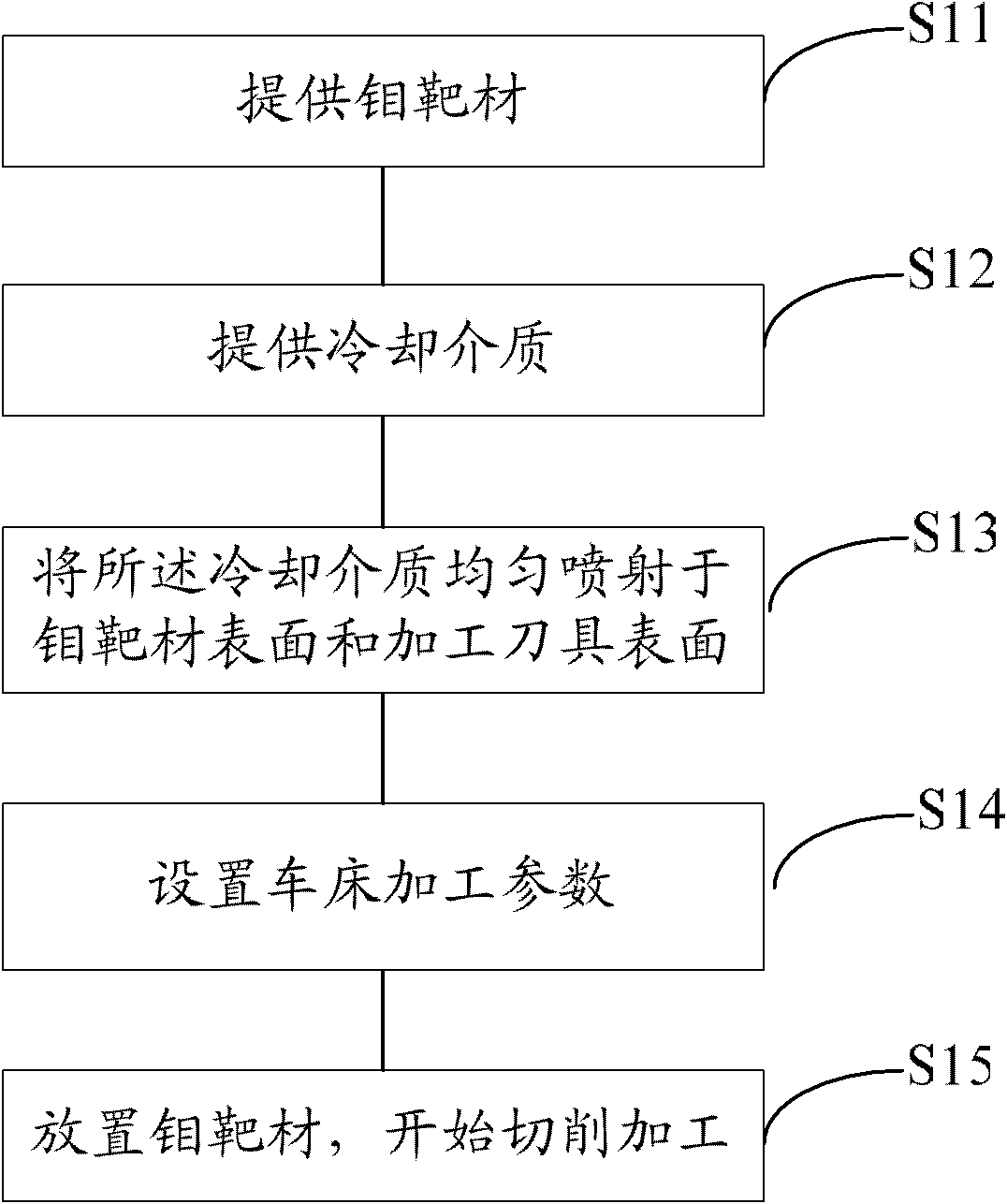

Method for processing molybdenum target material

InactiveCN102059582AReduce impactGuaranteed cutting qualityAutomatic control devicesFeeding apparatusEmulsionMachining process

The invention provides a method for processing a molybdenum target material. The method comprises the following steps of: providing a molybdenum target material; providing cooling medium which comprises emulsion and water; spraying the cooling medium on the surface of the molybdenum target material to be processed and the surface of a processing cutter evenly during the cutting process, wherein the processing cutter has the rotation speed of 2500-3000 revolutions / minute, the feed rate of less than or equal to 0.2 mm each time, the feed speed of 300-350 mm / min. The method for processing the molybdenum target material, provided in the invention, is favorable for improving a processing effect and avoid the problems of crack or burst-apart of the target material during processing.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

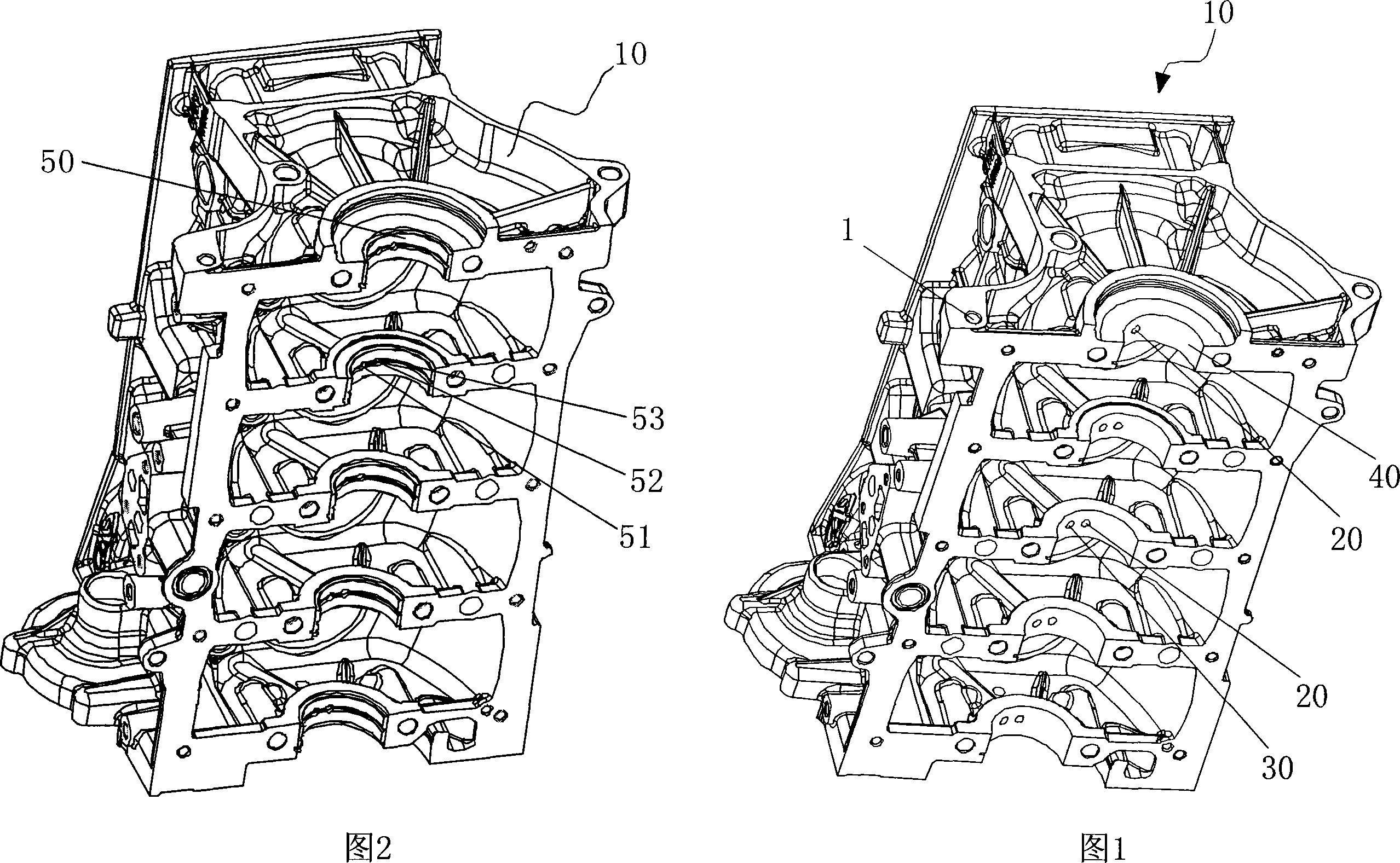

Engine cylinder block lubricant oil path

ActiveCN101158299AEasy to processReduce in quantityLiquid coolingLubricant conduit arrangementsCylinder blockHigh pressure

The invention relates to an engine cylinder body lubricant passage. The high pressure oil pumped out of an engine oil pump enters a main oil passage which runs through the front end and the rear end of an engine. The main oil passage respectively guides the engine oil into a main bearing lubricant passage which extends to a hole wall of a main bearing hole; the hole wall of the main bearing hole at the side of the main bearing lubricant passage is provided with an orifice; a main bearing arranged on the main bearing hole is provided with a first hole, a second hole and an oil trough communicated with the first hole and the second hole; the oil trough is arranged in circularity along the working surface of the main bearing; the first hole and the second hole are respectively connected with the main bearing lubricant passage and the orifice; the oil outlet direction of the orifice points at the direction of a piston. By replacing a nozzle of a check valve with the orifice and by adjusting the obliquity of the orifice, the invention causes the oil mouth direction pointing at the direction of the piston to ensure that the lubricant can be sprayed on the piston in order to reach the best lubrication effect.

Owner:CHERY AUTOMOBILE CO LTD

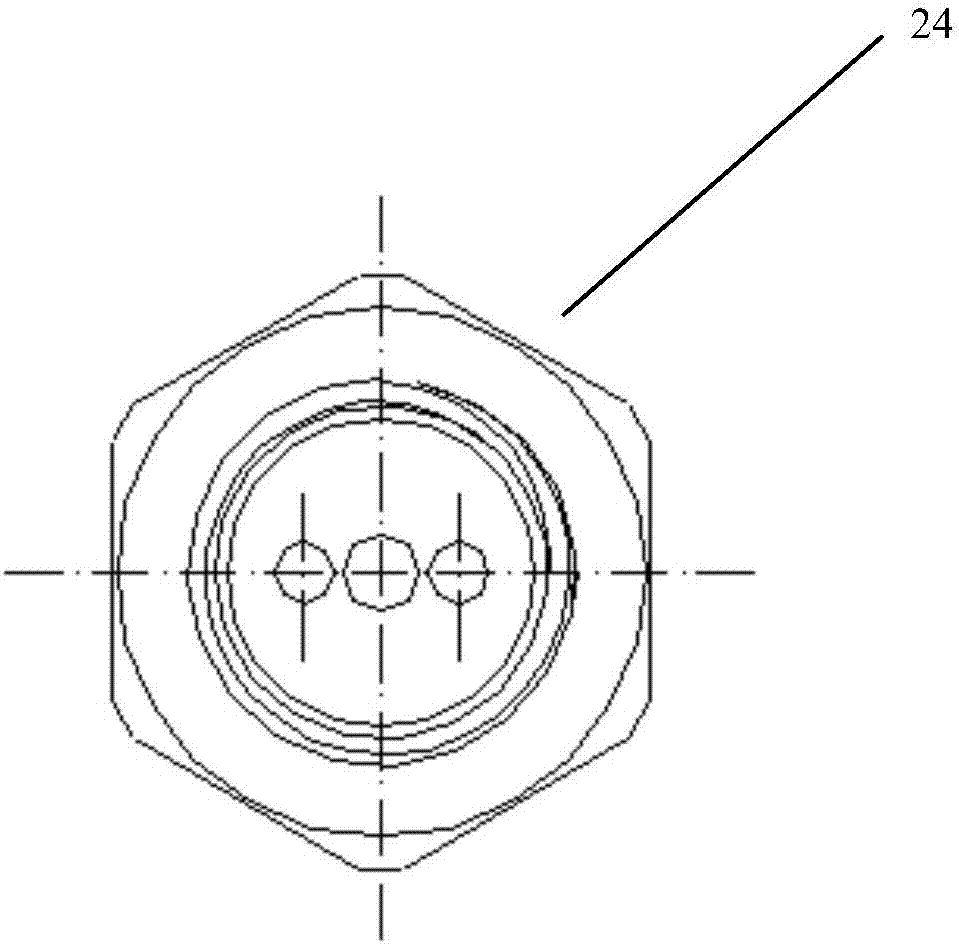

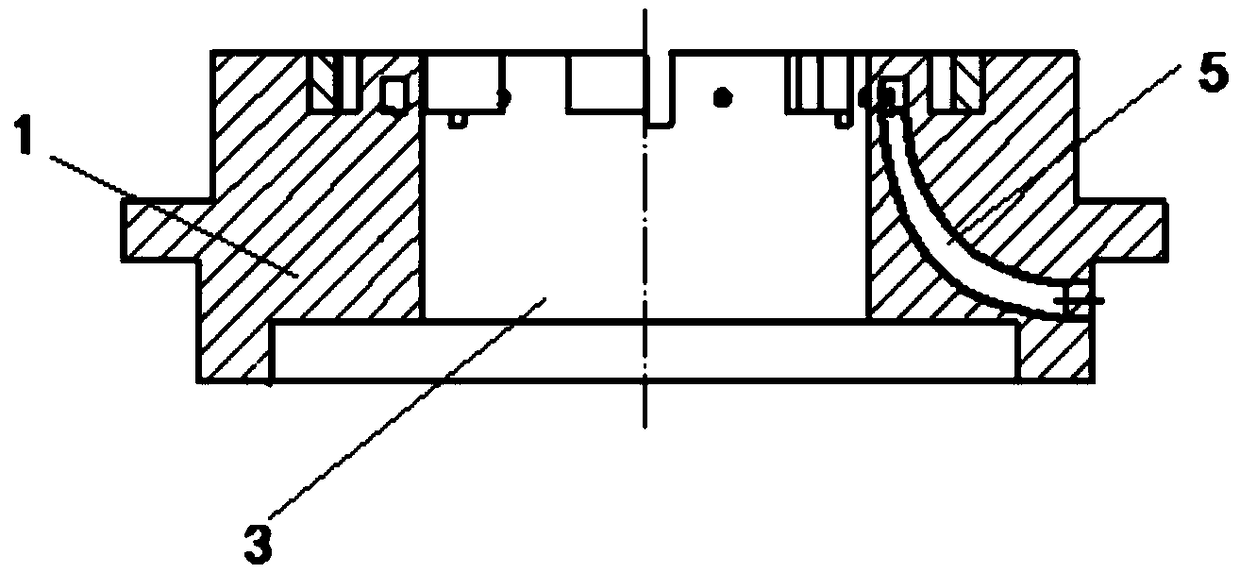

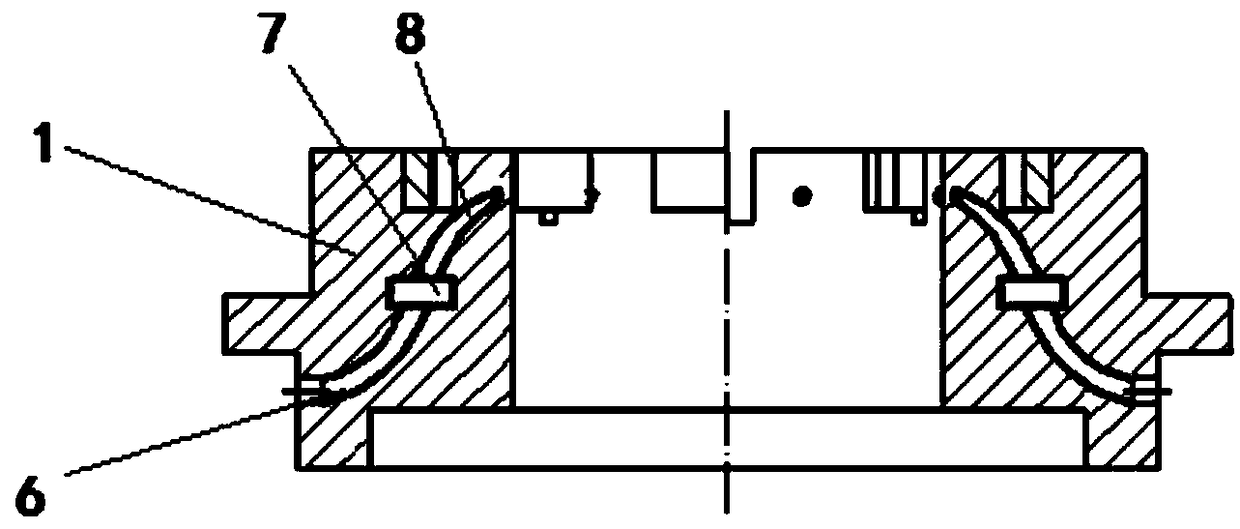

Integrated water lubrication bearing for thruster with hub flange

ActiveCN105129060AImprove cooling effectImprove carrying capacityRotary propellersPropulsive transmissionThrust bearingCooling effect

The invention discloses an integrated water lubrication bearing for a thruster with a hub flange. The integrated water lubrication bearing is mainly composed of thrust discs (2), supporting rings (3), a shaft sleeve (7), a rubber batten (8), a propeller hub copper sleeve (9) and thrust pads (21). The propeller hub copper sleeve is arranged in a propeller hub (1), the two thrust discs are installed at the two ends of the propeller hub respectively, spiral flow channels (22) are machined in the thrust discs, the two supporting rings are arranged on a front guide vane hub (4) and a rear guide vane hub (19) connected with a propeller shaft (6) respectively, and the thrust pads are assembled in fan-shaped grooves (33) in the supporting rings. The thrust pads (21), the thrust discs (2) and the supporting rings (3) form a thrust bearing. The rubber batten is vulcanized on the outer cylindrical surface of the shaft sleeve. The shaft sleeve (7), the rubber batten (8) and the propeller hub copper sleeve (9) form a combined radial bearing. The integrated water lubrication bearing has the advantages that the structure is simple and compact, the cooling effect of the radial bearing and the thrust bearing is improved, the bearing capacity of the radial bearing is improved, and the service life is prolonged.

Owner:WUHAN UNIV OF TECH +1

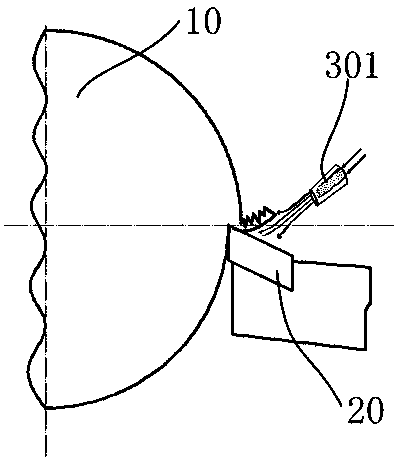

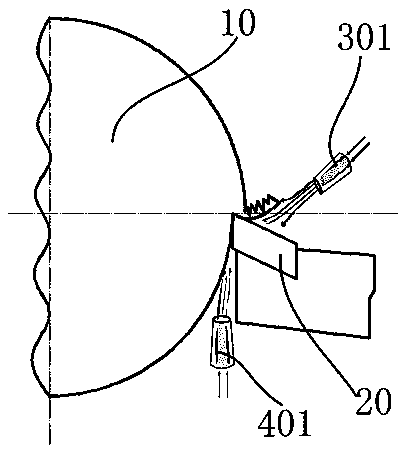

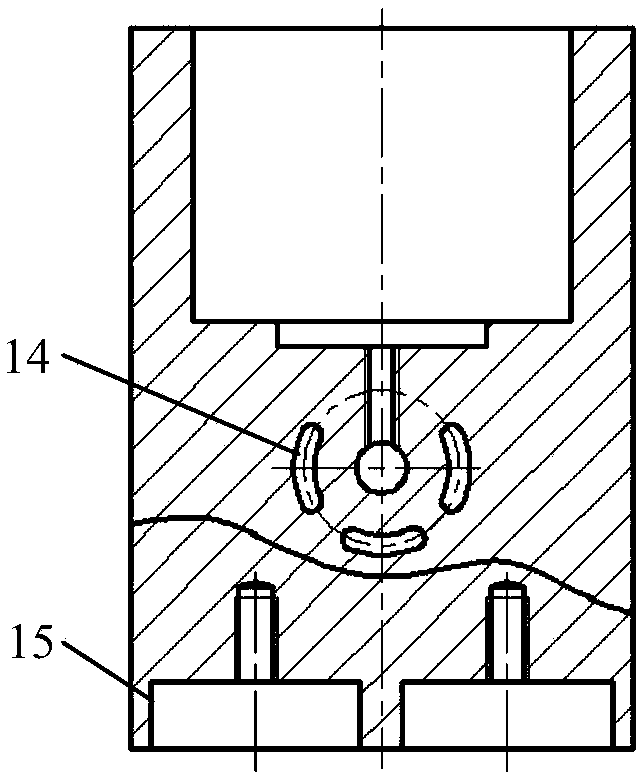

Nanofluid electrostatic atomization controllable conveying micro quantity lubricating system for auxiliary electrode focusing

InactiveCN108161750AChange the atomization cone shapeChange areaSpraying power supplyGrinding/polishing safety devicesCorona dischargeHigh-voltage direct current

The invention discloses a nanofluid electrostatic atomization controllable conveying micro quantity lubricating system for auxiliary electrode focusing. The problem that the micro quantity lubricatingliquid deposition rate is low in the prior art is solved. The system has the beneficial effects of improving the atomization cone form, deposition area and shape of fogdrop groups. According to the scheme, a nozzle for nanofluid micro quantity lubricating liquid comprises a gas-fluid mixing component, a corona discharge component and an auxiliary electrode focusing component. The nozzle is connected with a fluid supply system and a gas supply system. The corona discharge component is connected with the negative pole of an adjustable high voltage direct current power source, the positive poleis connected with a workpiece charging component and grounded, and a needle-plate negative corona discharge electric field. The auxiliary electrode focusing component is located below a corona area and connected with the negative pole of a power converter, the positive pole is grounded, and an additional electric field is formed. Under the effect of a nozzle gas-fluid mixing cavity, micro quantitylubricating fluid is atomized to spray out fogdrop groups, charged in the discharge electric field, atomized for the second time, focused towards the center axis under the effect of the auxiliary electrode focusing component, and controllably conveyed to a grinding area.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

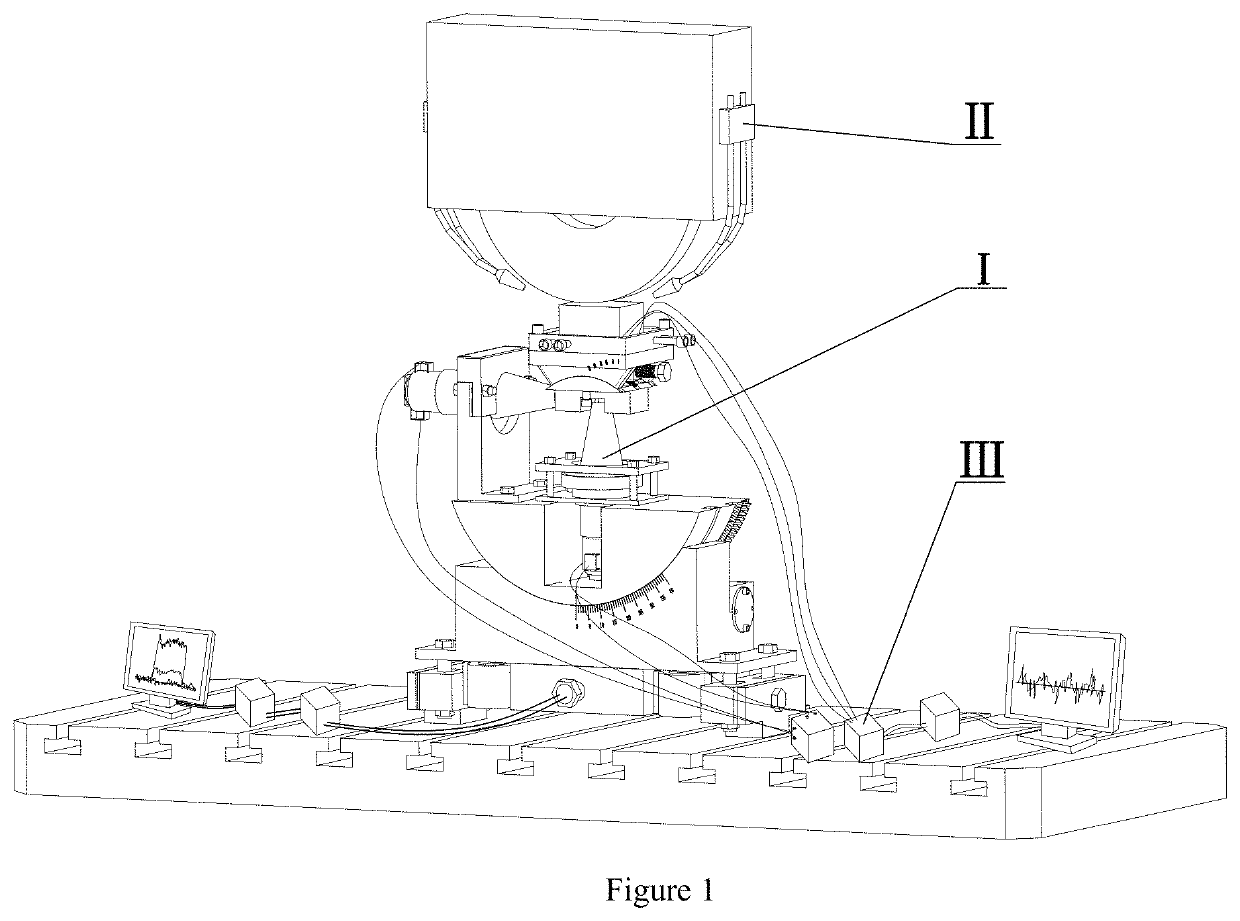

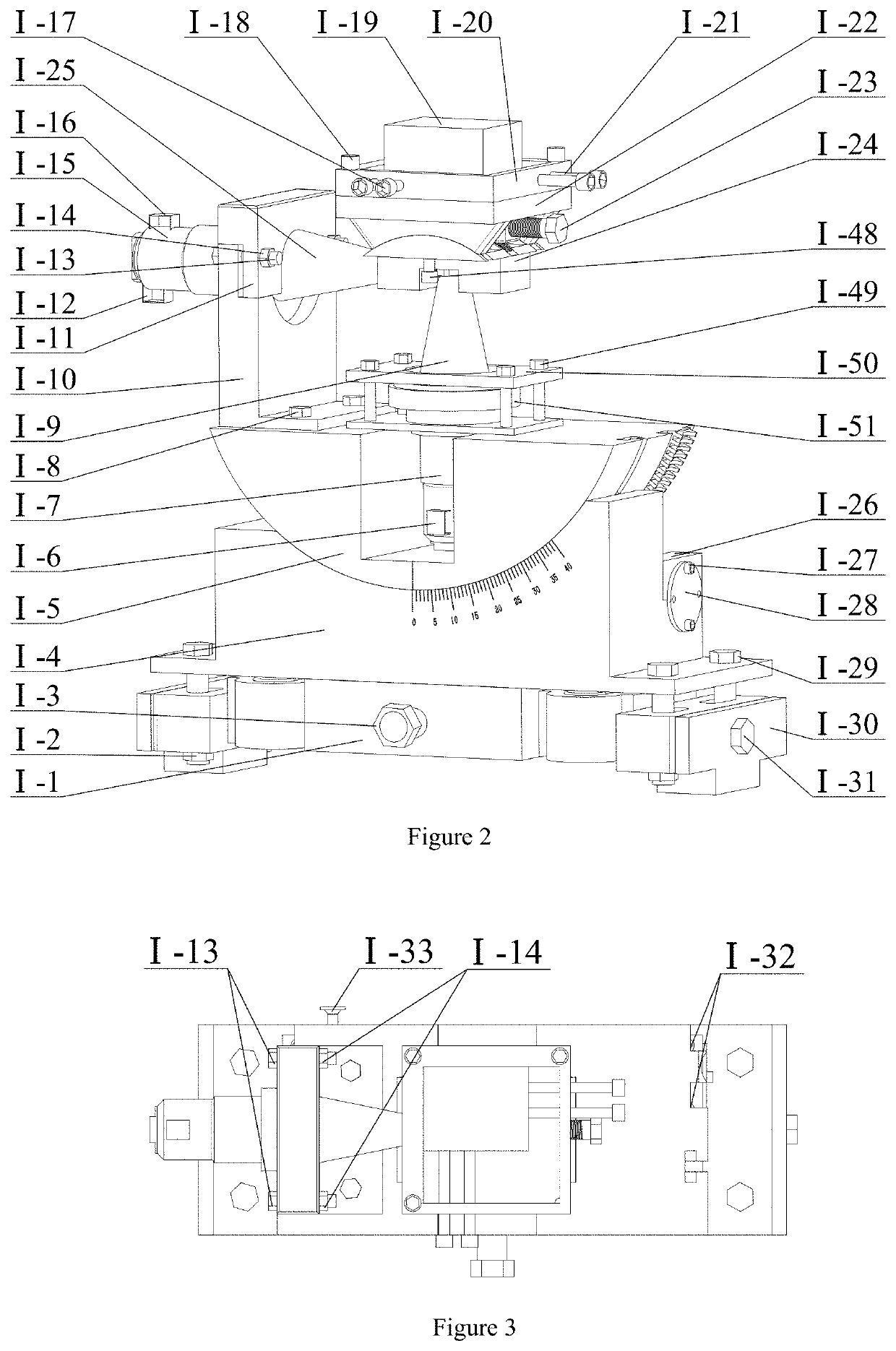

Nanofluid minimum quantity lubrication grinding device of ultrasonic vibration assisted grinding fluid micro-channel infiltration

ActiveUS20200023485A1Reduce burnImprove grinding effectGrinding work supportsGrinding/polishing safety devicesThermodynamicsMaterial removal

A NMQL grinding device of ultrasonic vibration assists grinding fluid micro-channel infiltration, and solves the problem that nanofluids are difficult to fully infiltrate the grinding zone in the prior art. Fully considers the impact of thickness of undeformed grinding debris on the grinding process and the lubrication state of single grains during material removal in the grinding process, the advantage of ultrasonic vibration assistance on improving the lubri-cooling performance of NMQL grinding is effectively achieved. According to the solution, the device includes an ultrasonic vibration mechanism capable of adjusting the spatial position of ultrasonic vibrators, the mechanism being arranged on a worktable; a NMQL grinding mechanism, arranged above a workpiece fixing table; and a grinding force measuring mechanism, including a dynamometer and a grinding force controller connected with the dynamometer, the dynamometer being arranged at the bottom of the ultrasonic vibration mechanism.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Loader and circular cooling and lubricating system of torque converter thereof

ActiveCN101870280AImprove cooling and lubrication effectSoil-shifting machines/dredgersLubricating systemTransfer caseSystem pressure

The invention discloses a circular cooling and lubricating system of a torque converter. The system comprises a pump device and a gear box overflow valve; the pump device outputs pressure oil to a system pressure oil line; a liquid inlet cavity of the gear box overflow valve is communicated with the system pressure oil line, while the liquid outlet cavity of the gear box overflow valve is communicated with an inner cavity of a three-element system through a transfer case shell of the torque converter and an oil inlet on a guide wheel seat in turn; the liquid outlet of the three-element system is connected with a radiator assembly through the guide wheel seat of the torque converter and an oil outlet on the transfer case shell in turn; the system further comprises two oil injection devices of which the oil inlets are communicated with the liquid outlet cavity of the gear box overflow valve respectively, and an oil nozzle of one oil injection device is formed above a pump wheel of the three-element system, while an oil nozzle of the other oil injection device is formed above a cover wheel of the three-element system; and the liquid outlet on a housing of the three-element system is connected with the radiator assembly. Moreover, the invention further provides a loader provided with the circular cooling and lubricating system of the torque converter.

Owner:XUZHOU XCMG DRIVELINE TECH CO LTD

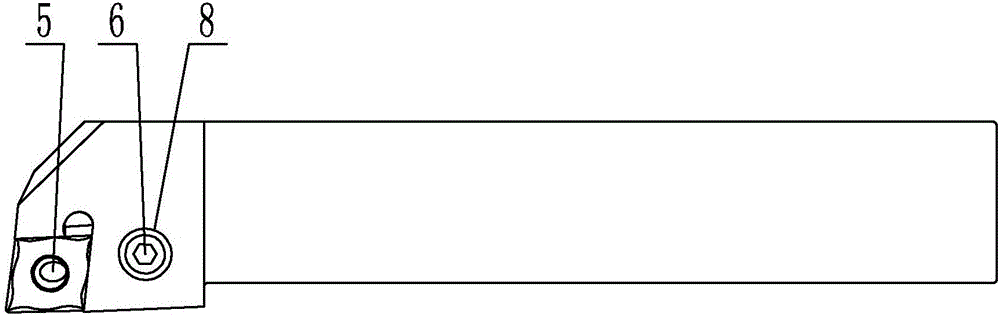

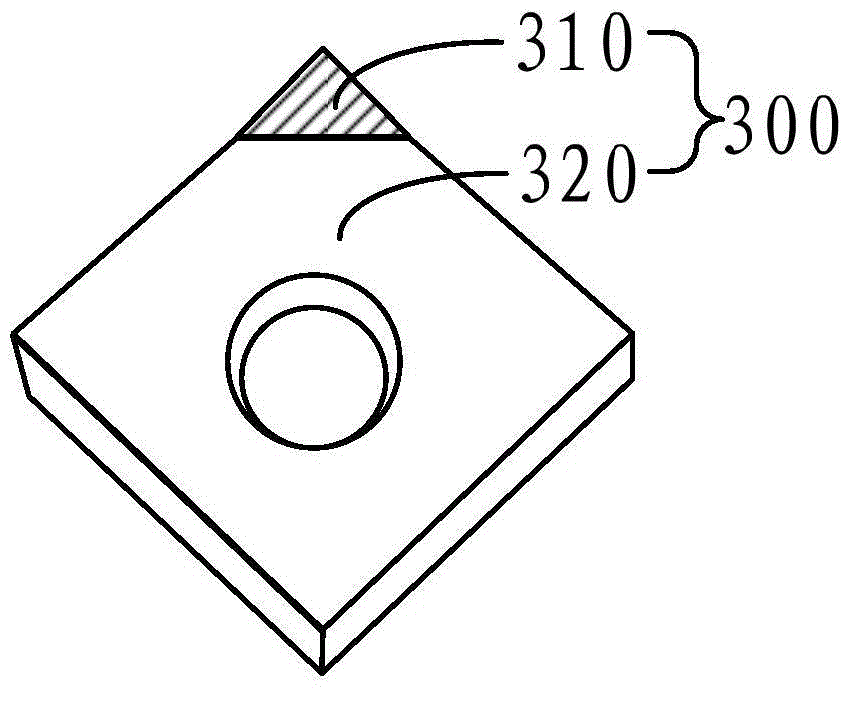

High-pressure cooling turning tool

InactiveCN106424786AImproved chip breaking performanceImprove cooling and lubrication effectCutting insertsTurning toolsInsufficient CoolingMetallic materials

The invention discloses a high-pressure cooling turning tool, relates to a turning tool, and solves the problems that when the conventional turning tool turns a difficultly-machined material, cutting fluid cannot be sufficiently sprayed to a cutting area due to insufficient cooling and lubricating capacity, and cut chip winds a workpiece and is difficultly broken off due to insufficient chip breaking capacity. The high-pressure cooling turning tool comprises a tool handle, a tool bit and a tool blade, wherein the tool bit is fixedly connected to the front end of the tool handle; the tool blade is embedded into the front end of the upper end surface of the tool bit; the tool blade is fixedly connected with the tool bit through a fastening mechanism; a threaded bind hole is formed in the lower end surface of the tool bit; the tool bit is connected with a high-pressure pipe head through the threaded bind hole; a plurality of cooling liquid passages are formed in the tool bit; one end of each of the plurality of cooling liquid passages is communicated with the threaded bind hole; the other ends of the plurality of cooling liquid passages are arranged towards the front end of the tool blade. The high-pressure cooling turning tool is used for turning a difficultly-machined metal material.

Owner:HARBIN UNIV OF SCI & TECH

Aqueous lubricating liquid for stamping, stretching and forming cell phone battery shell, preparation method and application method thereof

The invention discloses aqueous lubricating liquid for stamping, stretching and forming a cell phone battery shell, a preparation method and an application method thereof. The lubricating liquid comprises the following raw materials: 45# transformer oil, a non-ionic emulsifying agent, aqueous extreme-pressure lubricant, boric acid, an aluminum powder sinking agent, triethanolamine, isopropanolamine, synthetic petroleum sodium sulfonate, a branched chain phosphate aluminum protecting agent, a dicarboxylate based composite anti-rust agent, a butyl ether coupling agent, a hard water resistant agent, a defoaming agent and distilled water; the lubricating liquid is excellent in lubricating performance, anti-rust performance and settling performance, and the lubricating performance, the anti-corrosion performance and the cleaning performance are matched and stabilized for a long time, the antibacterial performance is good and the service life is long, the working liquid can be circularly added, the emission of the waste liquid is reduced, the environment cannot be polluted, and all indexes of 5% of diluent reach or exceed relative indexes of GB6144-2010.

Owner:AMER TECH CO LTD

Energy saving nozzle of minimum quantity lubrication system

ActiveCN107042165AUniform liquid supplyImprove cooling and lubrication effectSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The invention provides an energy saving nozzle of a minimum quantity lubrication system. The energy saving nozzle of the minimum quantity lubrication system is characterized by comprising an embedding ring and a nozzle body; the embedding ring is embedded on the outer side of the nozzle body, totally or partially covers the surface of the nozzle body, and is in clearance fit with the nozzle body; an air cavity and at least two fluid channels are formed in the nozzle body; an air hole and a hole for penetrating through the internal of the nozzle body are formed in the surface of the nozzle body; a guide groove unit is arranged on the surface of the nozzle body; and with a liquid hole as a starting point, the guide groove unit is multiple symmetric guide groove bodies scattered on the surface of the nozzle body. The nozzle structure generates fan-shaped spray to spray to a cutting area, so that the supply problem of minimum quantity lubrication cutting liquid with a machining mode as linear contact is preferably solved, the liquid supply to the cutting area is uniform, and the cooling lubrication performance of minimum quantity lubrication is improved.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH +1

Electrostatic minimum quantity lubrication device

PendingCN109986404ASmall particle sizeSmall wetting angleMaintainance and safety accessoriesElectricityEngineering

The invention provides an electrostatic minimum quantity lubrication device which comprises an electrostatic generation device, a liquid supply device, a gas-liquid electric converging device, a gas-liquid electric conveying pipe, a charging device and a nozzle. The electrostatic generation device comprises an electrostatic generator and a conveying electric wire and is powered on by a power source, and high voltages are conveyed to the gas-liquid electric converging device through the conveying electric wire. The liquid supply device is composed of a liquid storage box, a first liquid pipe and a liquid supply pump, and output lubricating liquid is conveyed to the gas-liquid electric converging device through the first liquid pipe. An outer gas source conveys high-pressure gas to the gas-liquid electric converging device through a first gas pipe. Through the gas-liquid electric converging device and the charging device, the lubricating liquid is charged, and charged fog is sprayed out.The electrostatic minimum quantity lubrication device has the advantages of being compact in structure, high in integration level, convenient to mount and the like.

Owner:ZHEJIANG UNIV OF TECH

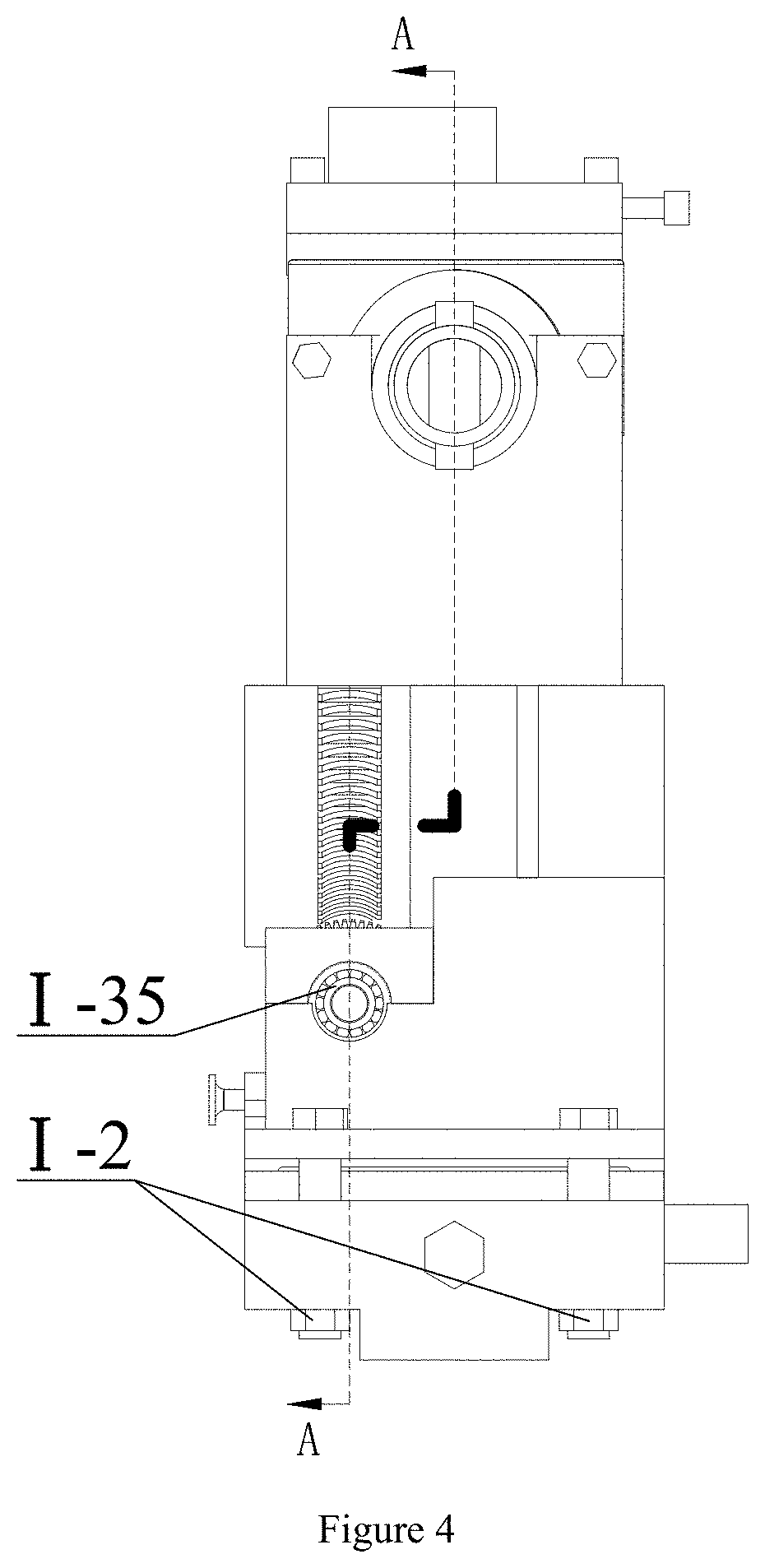

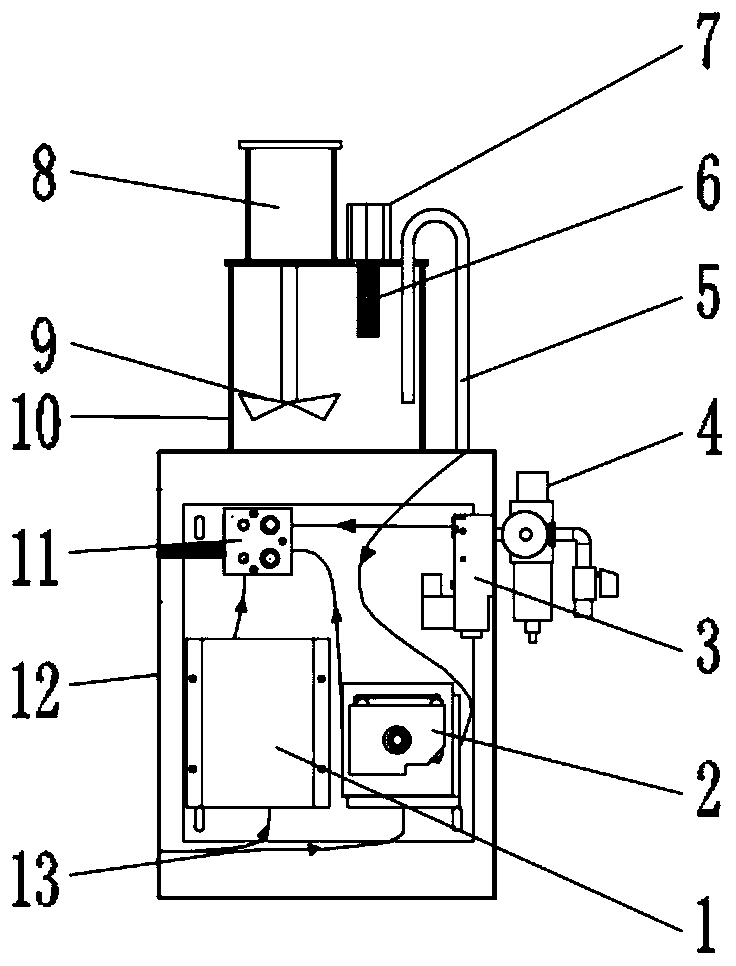

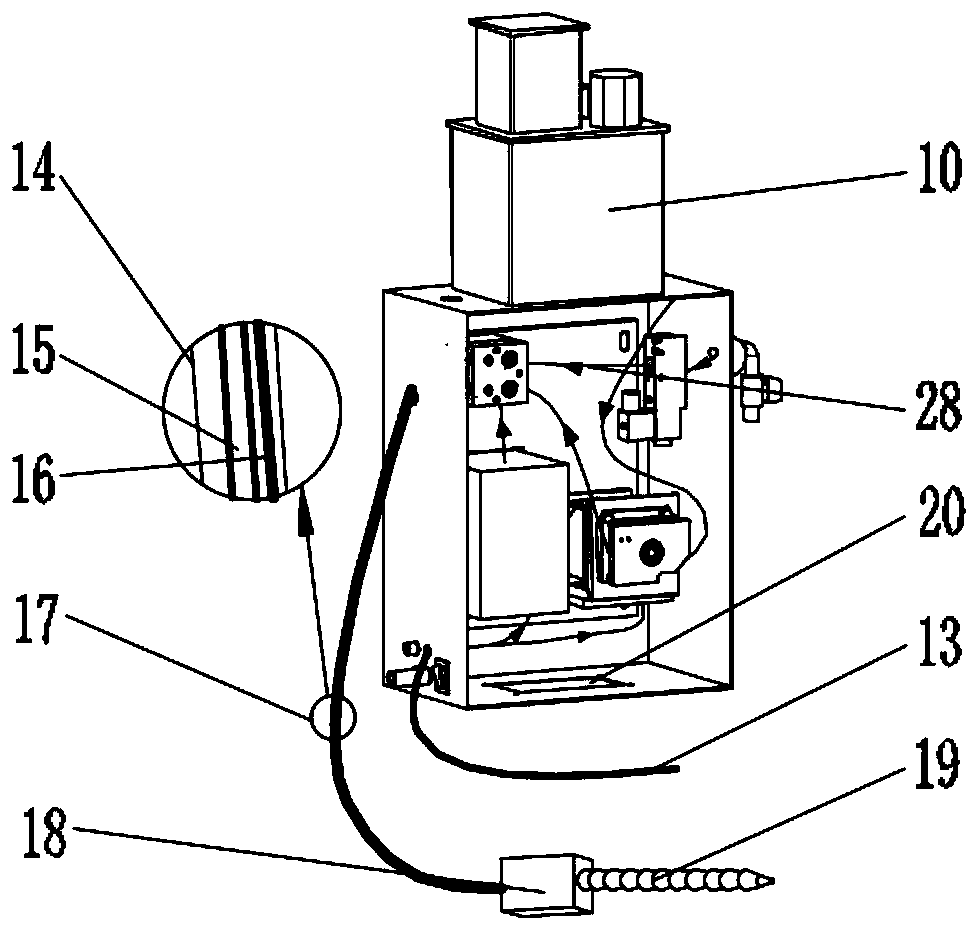

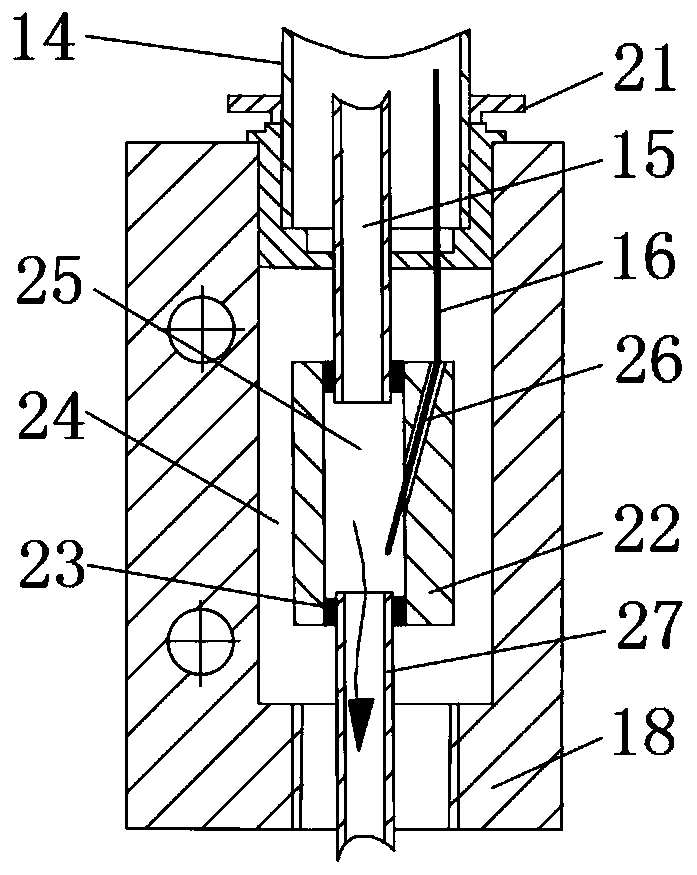

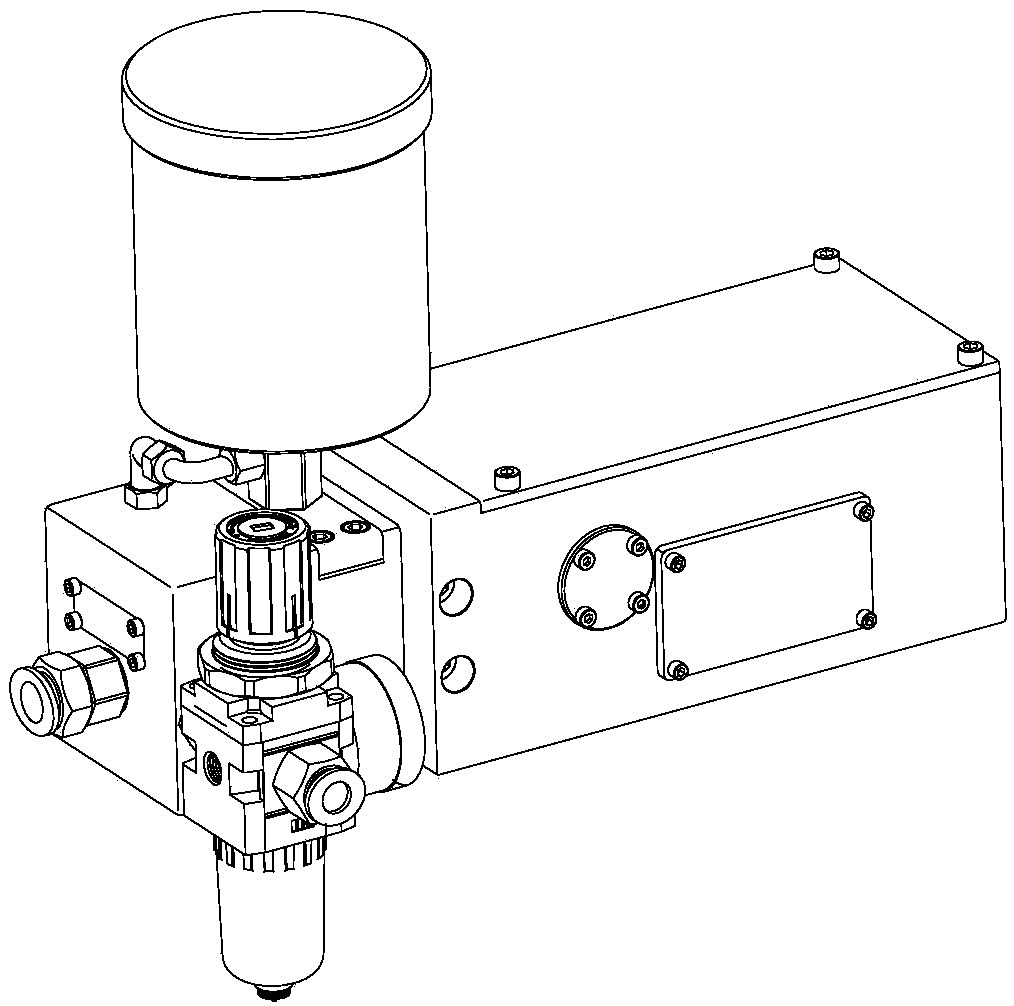

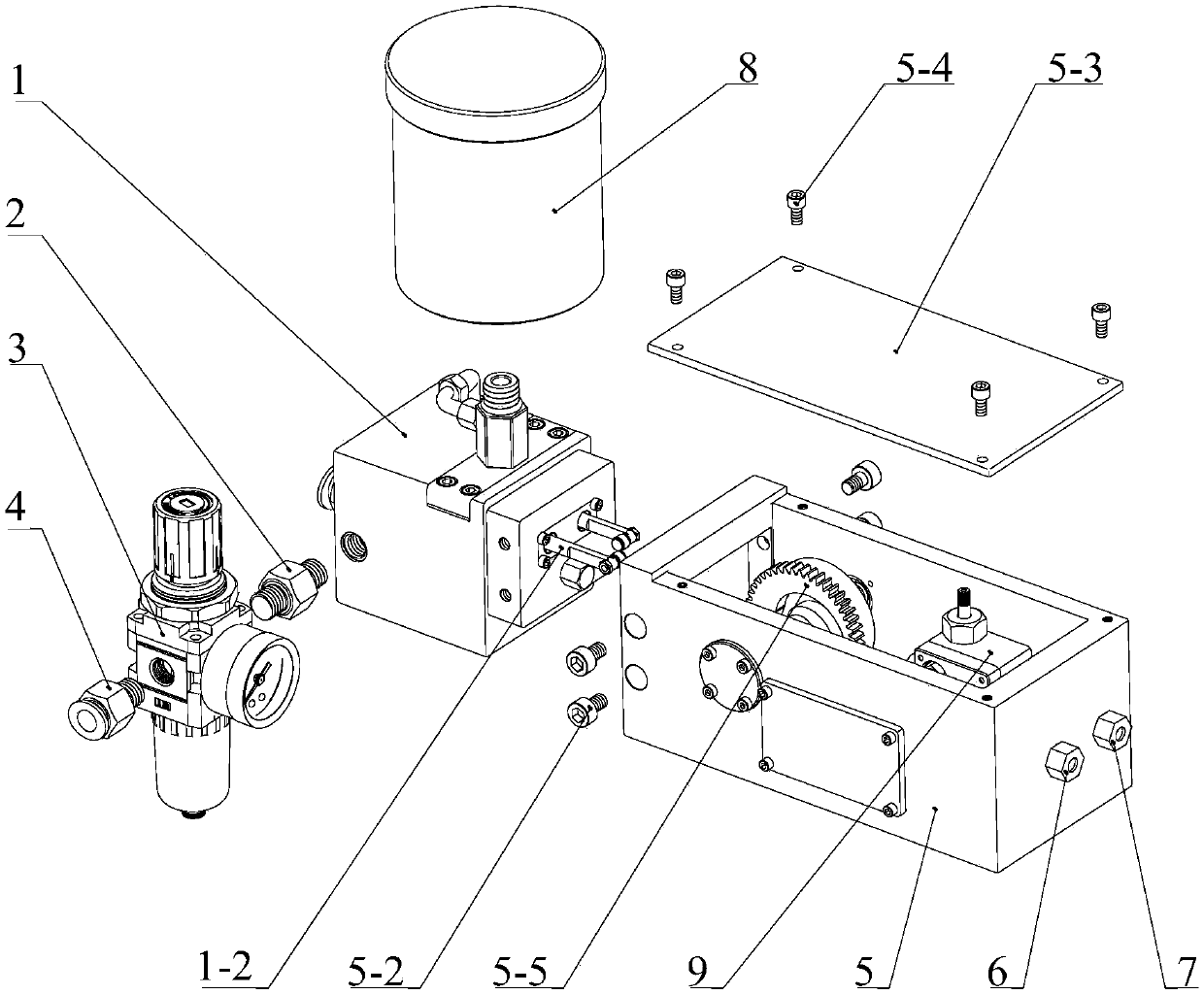

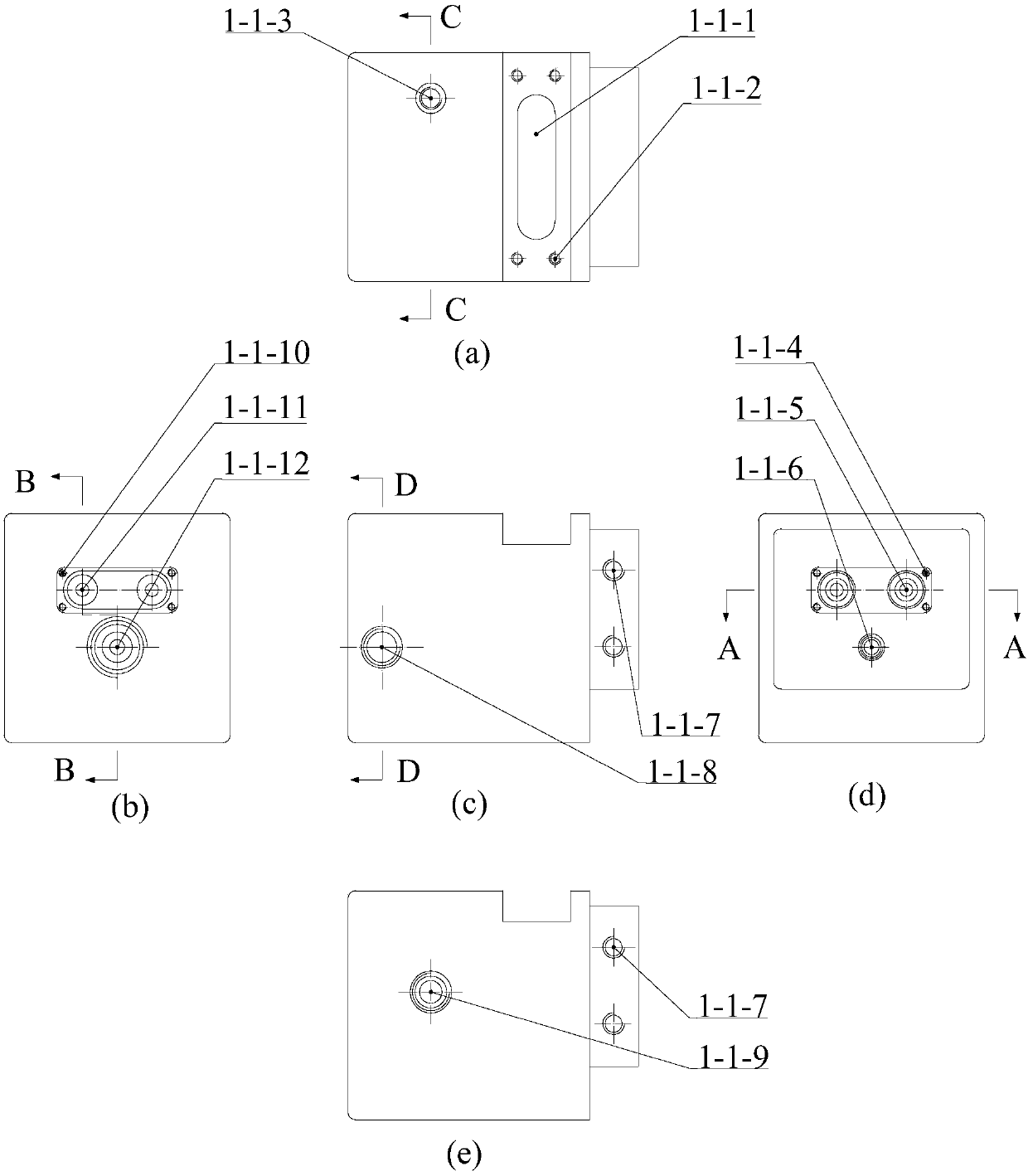

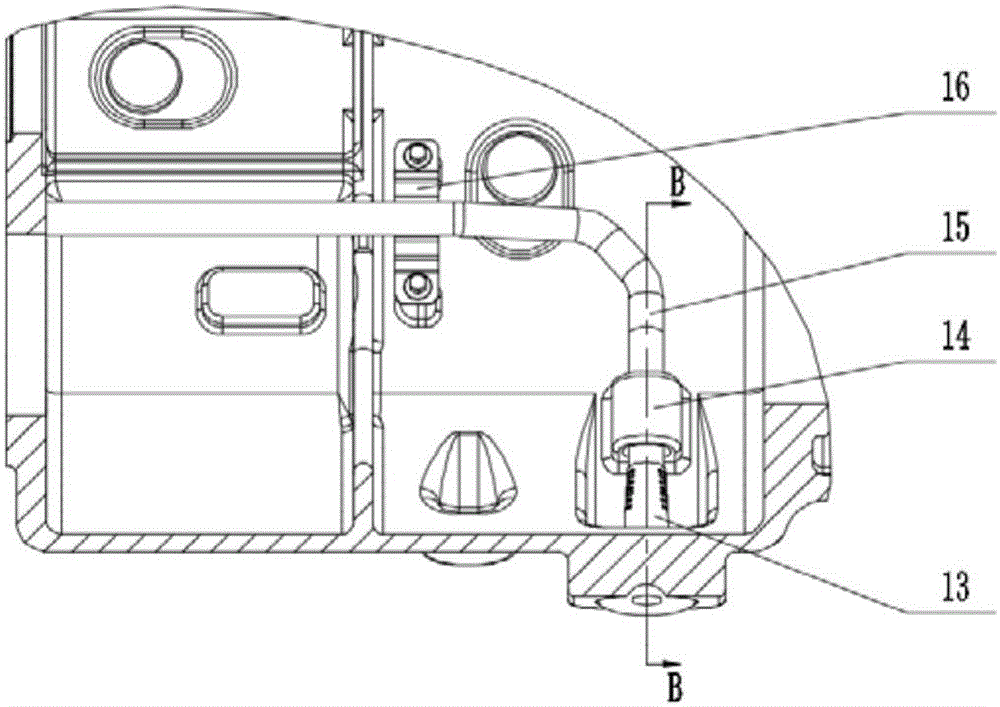

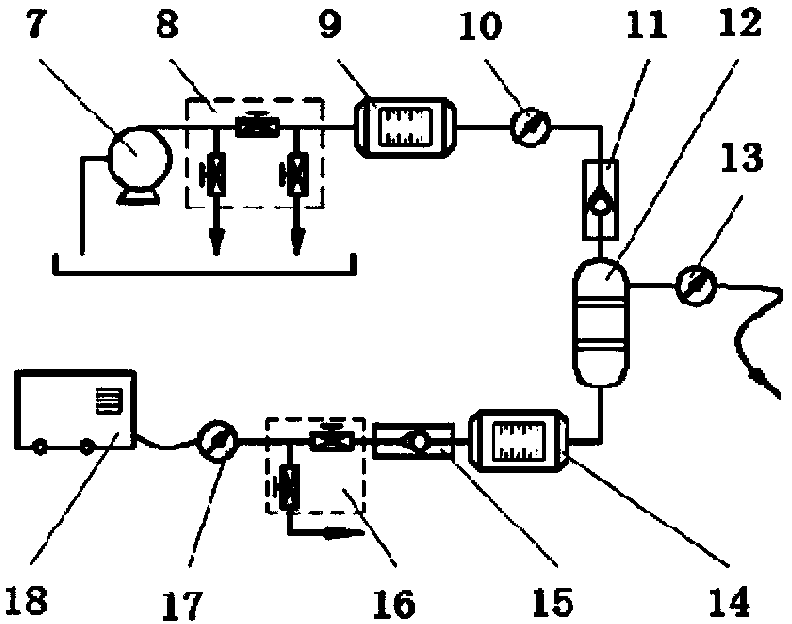

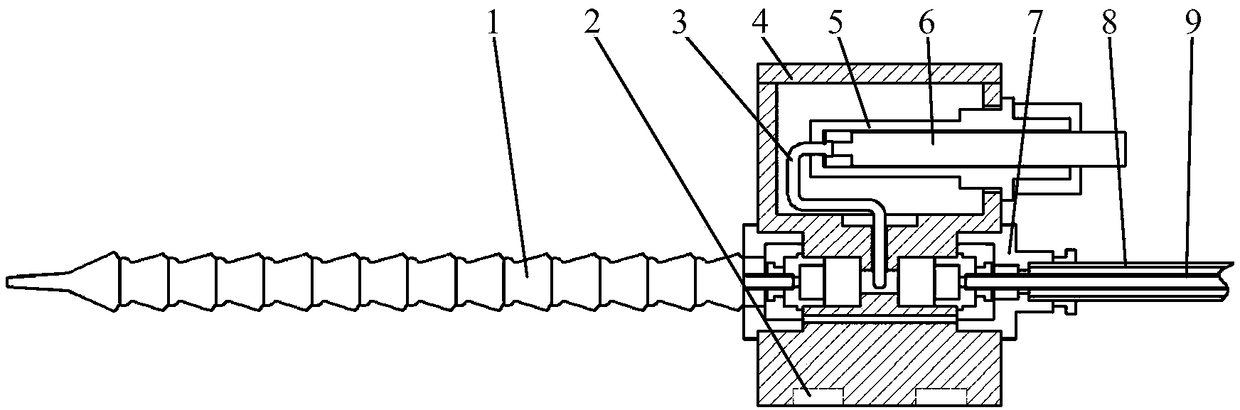

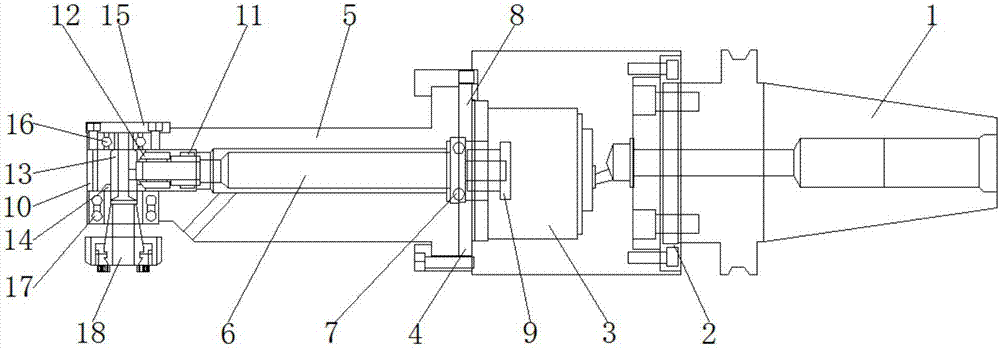

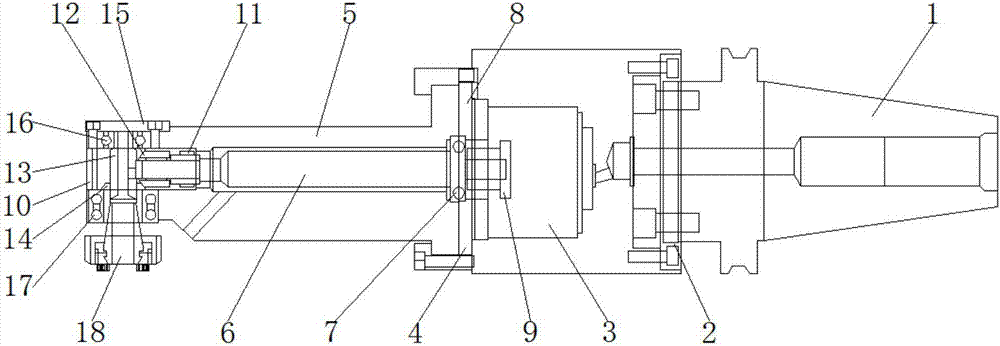

Continuous feeding precise micro-lubricating pump supporting different lubricating working conditions

InactiveCN107631158AImprove cooling and lubrication effectImprove machined surface qualityLubricating pumpsMaintainance and safety accessoriesGas phaseEngineering

The invention discloses a continuous feeding precise micro-lubricating pump supporting different lubricating working conditions. The pump comprises a pump system, a gas source treater, a driving system, an oil cup, a water pump, a two-position three-way electromagnetic valve, a water tank and an emulsifying liquid storage box. The gas source treater is connected to the pump system through a bidirectional joint; the oil cup is connected to the pump system through an oil cup joint; the water pump is mounted in a driving box body of the driving system and is connected to the pump system through ahose; the water tank and the emulsifying liquid storage box is connected to the two-position three-way electromagnetic valve; the two-position three-way electromagnetic valve is connected to the driving system; and the driving system and the water pump are separately driven by a stepping motor I and a stepping motor II. Driven by the stepping motors, the pump achieves functions of intelligent switching of various lubricating working conditions, oil, water and gas phase flow mixing ratio and flowing rate intelligent adjustment, precise and continuous feeding of a lubricant to a processing region and the like, so that the cooling and lubricating effect of the processing region is increased, the processing surface quality of a workpiece is enhanced, and equipment support is provided for intelligent feeding of micro-lubrication.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Synthetic grinding fluid and preparation method thereof

InactiveCN104342278AReduce stickingReduced edge formationLubricant compositionInorganic saltsDiluent

The invention relates to an oil product of a petrochemical product, and in particular relates to a synthetic grinding fluid and a preparation method thereof. The synthetic grinding fluid comprises the following components in parts by weight: 4% to 30% of base oil, 5% to 10% of inorganic salt corrosion inhibitor, 6% to 20% of extreme pressure additive, 30% to 60% of deionized water, 2% to 6% of pH regulator and 5% of diluent. The synthetic grinding fluid has good grinding settleability, i.e., the synthetic grinding fluid does not adhere to an abrasion wheel; and meanwhile, the synthetic grinding fluid is good in cooling performance, anti-rusting performance and cleaning performance, cannot generate a pungent smell, does not contain sodium nitrite and does not bubble, has no influence on oil paint and is long in service life.

Owner:NINGBO BAORUN PETROCHEM

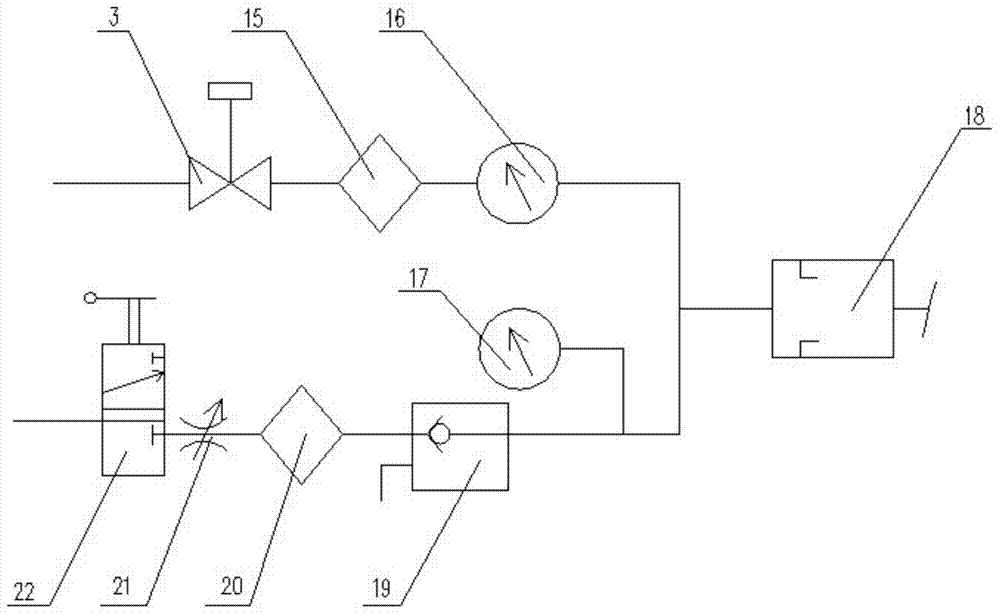

Heavy type speed changer cooling and lubricating system and cooling and lubricating method

ActiveCN106594253AGuaranteed Cooling RequirementsGuaranteed service lifeGear lubrication/coolingWind energy generationTemperature controlGear oil

The invention discloses a heavy type speed changer cooling and lubricating system and a cooling and lubricating method. The heavy type speed changer cooling and lubricating system comprises an oil pump, a filter, a temperature control valve, a radiator, an oil discharging bolt, two oil spraying pipes and an oil spraying head. When the temperature control valve is closed, a temperature control valve oil inlet pipe is communicated with a temperature control valve oil outlet pipe; when the temperature control valve is opened, the temperature control valve oil inlet pipe is communicated with a cooling oil inlet pipe, and the cooling oil outlet pipe is communicated with the temperature control valve oil outlet pipe. An input end of the oil discharging bolt is connected with the temperature control valve oil outlet pipe; three output ends of the oil discharging bolt are respectively connected with the two oil spraying pipes and the oil spraying head. Both the two oil spraying pipes extend from a primary box to a secondary box; a plurality of spraying holes are formed in each oil spraying pipe. The temperature control valve is used for determining whether gear oil enters the radiator or not. According to the heavy type speed changer cooling and lubricating system and the cooling and lubricating method, the external radiator and oil pump forced lubricating are combined, so that the lubricating and cooling requirements of shaft teeth, bearings, sealing pieces, lubricating oil and the like under special complex working conditions are ensured; meanwhile, the heavy type speed changer cooling and lubricating system and the cooling and lubricating method have the advantages of simple structure, reliable performance, and remarkable cooling and lubricating effects.

Owner:CHINA FIRST AUTOMOBILE

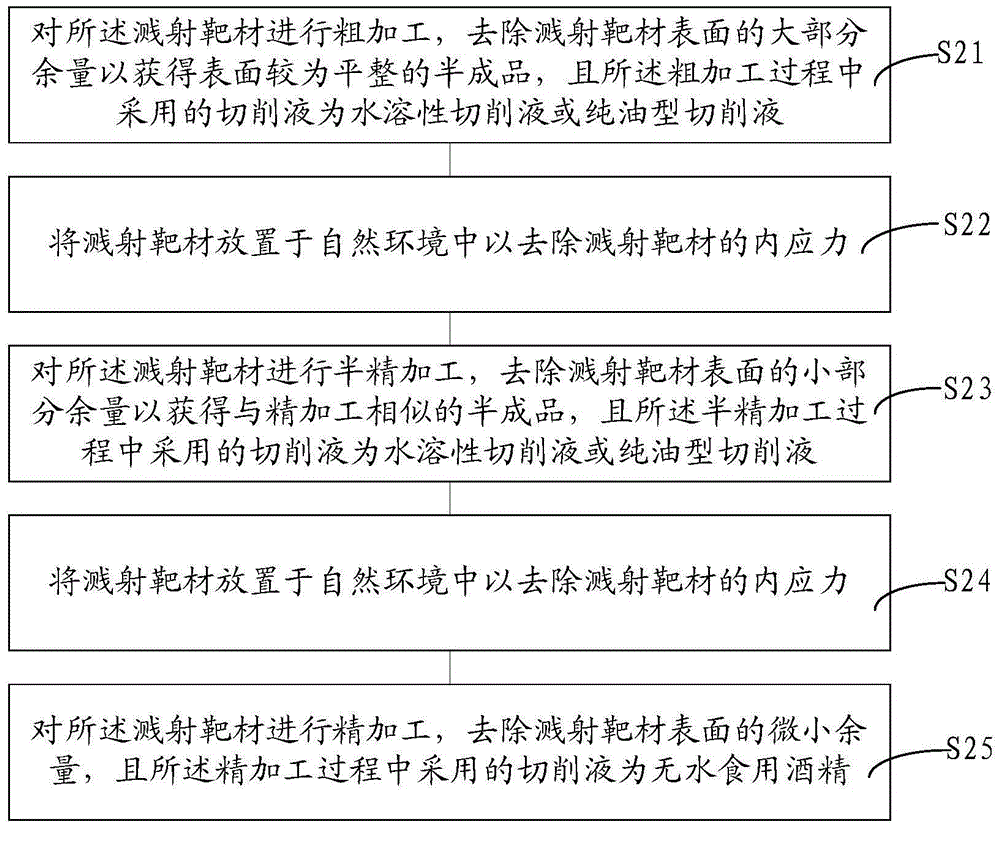

Surface treatment method for sputtering target material

The invention provides a surface treatment method for a sputtering target material. The surface treatment method comprises the following steps of: providing the sputtering target material, wherein the sputtering target material has been subjected to rough machining and semi-finishing, and the target material is pure aluminum or aluminum alloy; and adopting a turning process to carry out finish machining on the sputtering target material, and adopting anhydrous alcohol as a cutting fluid for finish machining so as to achieve effects of lubricating and cooling. The anhydrous alcohol is liable to volatilize, and does not remain on the surface of the sputtering target material after being volatized, so that high cleanliness and flatness of the surface of the finish-machined sputtering target material are met, and any requirement on other substance residues is avoided.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

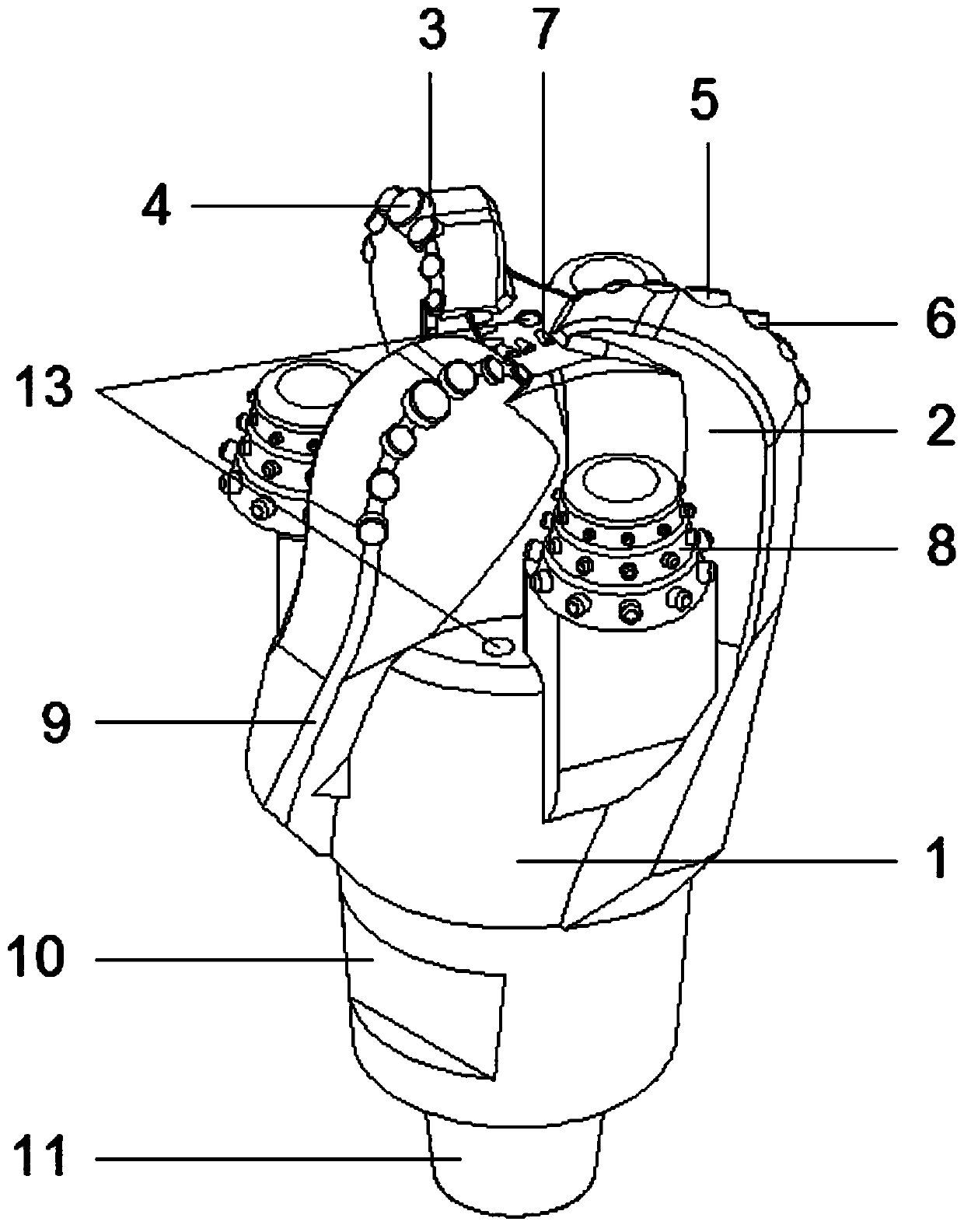

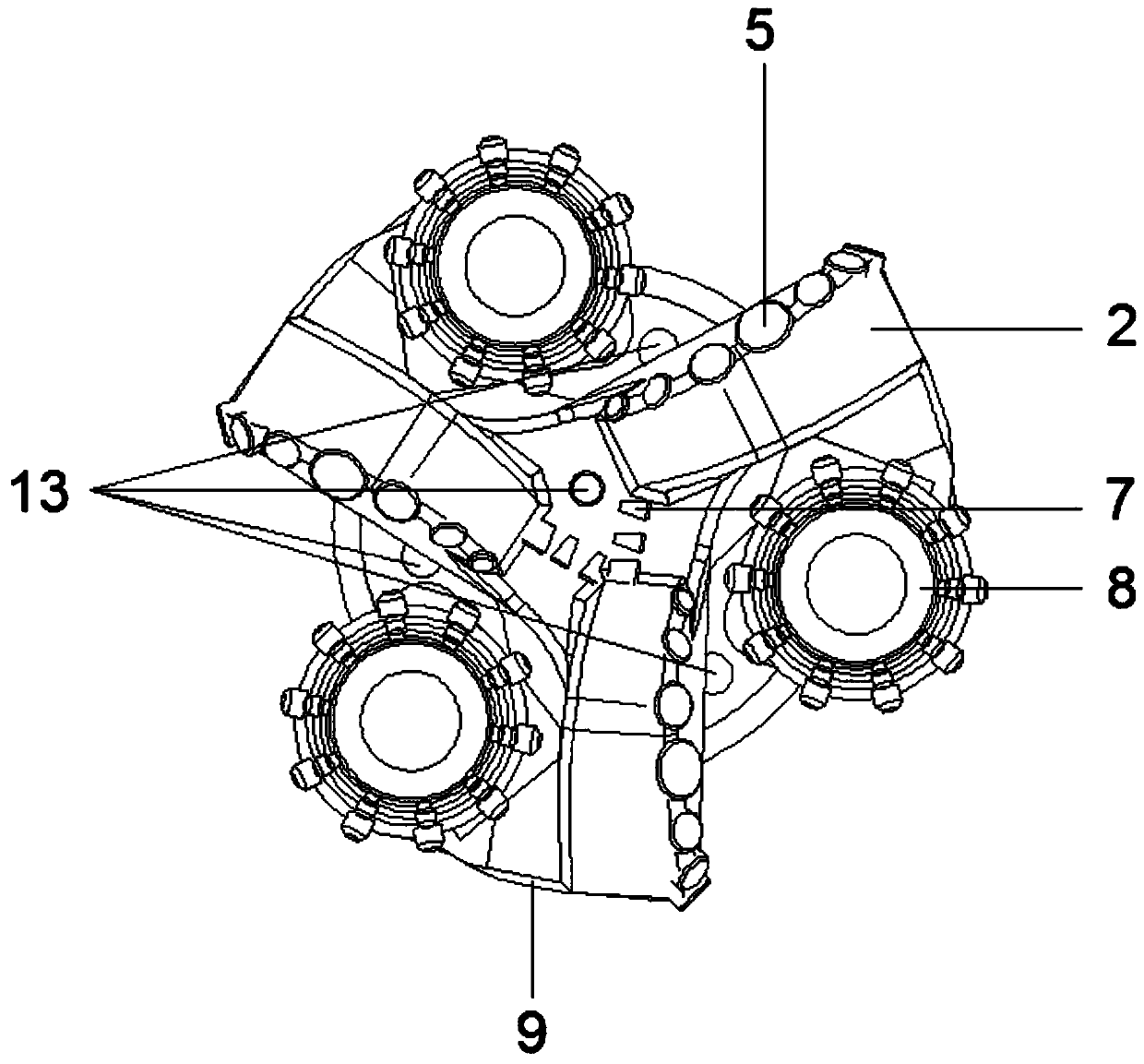

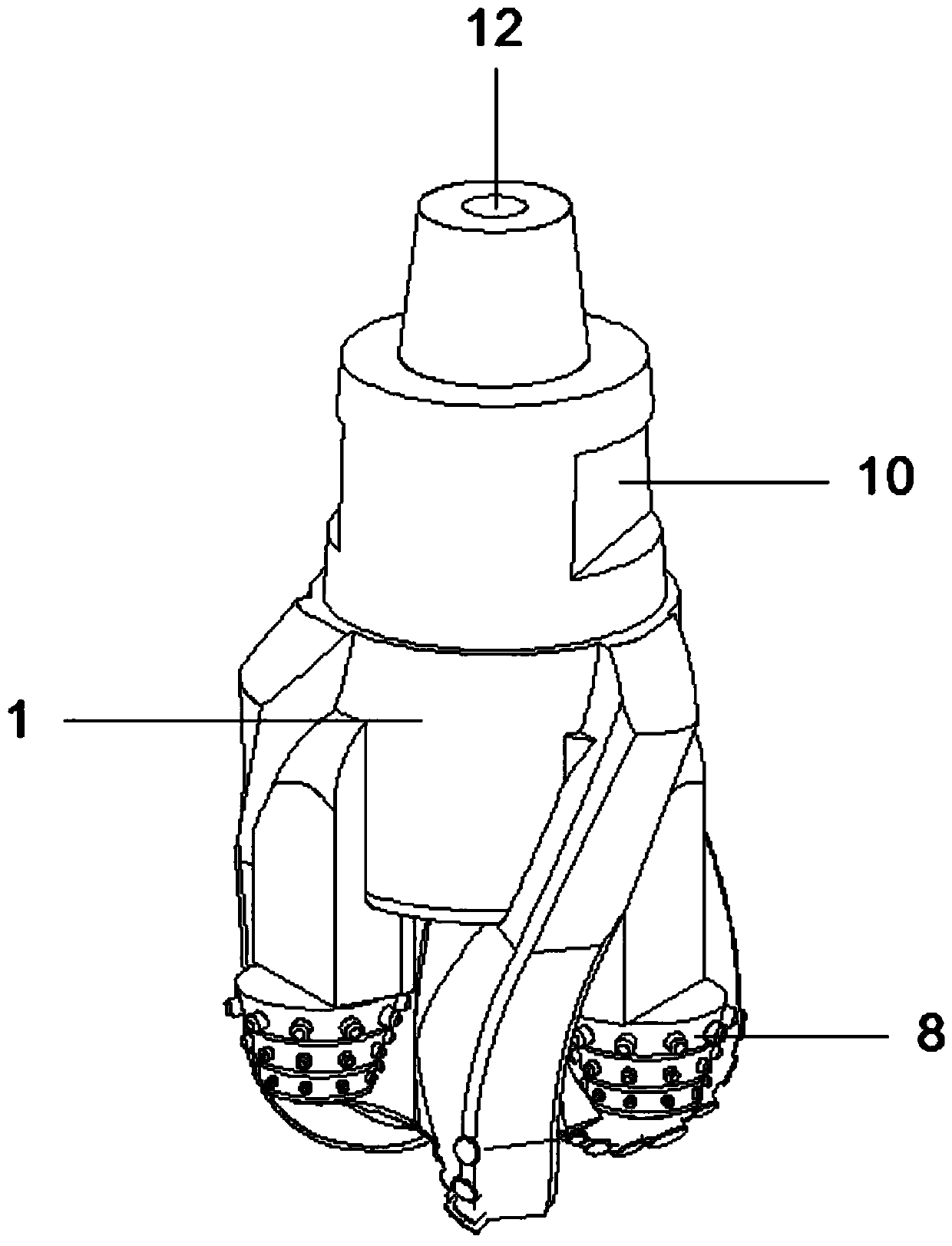

Secondary rock breaking drill bit for assisting pressurizing flow back through spiral blade

InactiveCN109898998AExtended service lifeReduce vibration amplitudeDrill bitsConstructionsWell drillingSpiral blade

The invention provides a secondary rock breaking drill bit for assisting pressurizing flow back through a spiral blade. The secondary rock breaking drill bit comprises a drill bit body, the blade anda cone; the blade is arranged at the top end of the drill bit body, and the blade and the drill bit body are of an integrated structure; and a gauge protection part is arranged on the outer wall of the blade. Through improvement for the rock breaking drill bit, primary cutting is conducted at the bottom of the drill bit to form primary rock debris, the rock debris returns to the cone under carrying flow back of a well-drilling fluid, the cone can conduct secondary breaking, the spiral blade slides in the longitudinal direction to be in surface contact with the well wall, a surface contact modeof the spiral blade is far greater than a line contact mode of a traditional straight blade, longitudinal vibration in the well-drilling process can be reduced, the rock debris generated by cutting of the drill bit flows back upwards under the action of vertical component force of the spiral face, fluid carrying the rock debris generates reactive force on the spiral blade surface, the drill bit can be pressurized, and thus the problems and deficiencies proposed in the background technology are effectively solved and overcome.

Owner:LANZHOU CITY UNIV

Electric card auxiliary inner-cooling texture turning tool and nano fluid micro-lubrication intelligent working system

InactiveCN110116223AImprove tool lifeGood dispersionCutting insertsMeasurement/indication equipmentsLubricationKnife blades

The invention provides an electric card auxiliary inner-cooling texture turning tool and a nano fluid micro-lubrication intelligent working system. The electric card auxiliary inner-cooling texture turning tool comprises an inner-cooling turning tool handle, a direction adjustable nozzle and an inner-cooling turning tool blade; the inner-cooling turning tool handle serves as a carrying device; theinner-cooling turning tool blade is arranged at one end of the inner-cooling turning tool handle; an inner-cooling turning tool shim is arranged between the inner-cooling turning tool blade and a structure, carrying the blade, of the inner-cooling turning tool handle; an inner-cooling turning tool blade compaction device is further arranged on the inner-cooling turning tool handle; the inner-cooling turning tool blade is compacted on the inner-cooling turning tool handle by the inner-cooling turning tool blade compaction device; texture is machined on the front tool surface of the inner-cooling turning tool blade; the inner-cooling turning tool blade compaction device is of a hollow structure; the direction adjustable nozzle is further arranged on the inner-cooling turning tool blade compaction device; and the inner-cooling turning tool blade compaction device communicates with an inner passage of the direction adjustable nozzle. According to the electric card auxiliary inner-coolingtexture turning tool, the design of the direction turnable inner-cooling nozzle having the atomization effect is achieved, so that the accurate and controllable supply of a slight amount of lubricating liquid is further achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

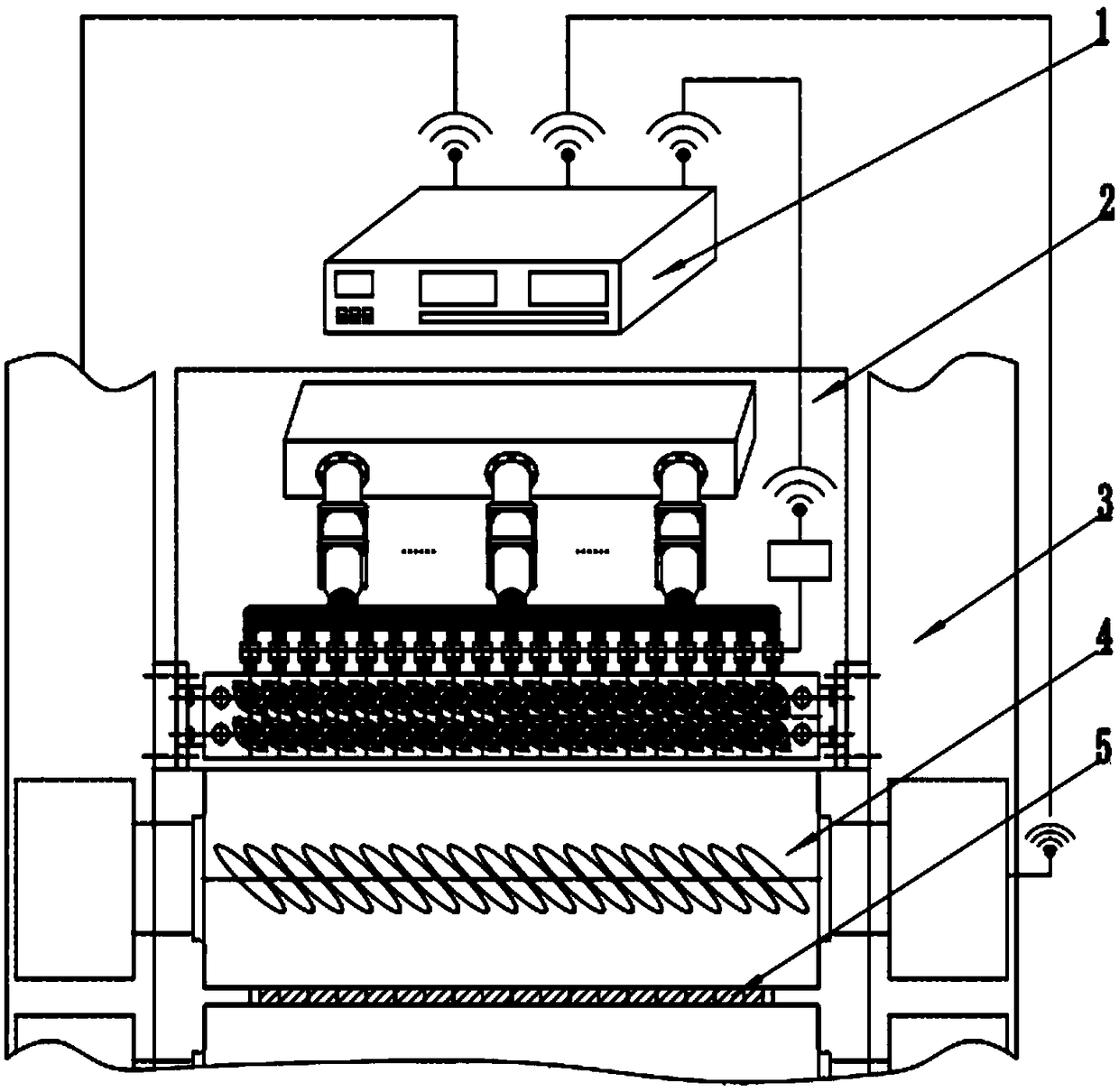

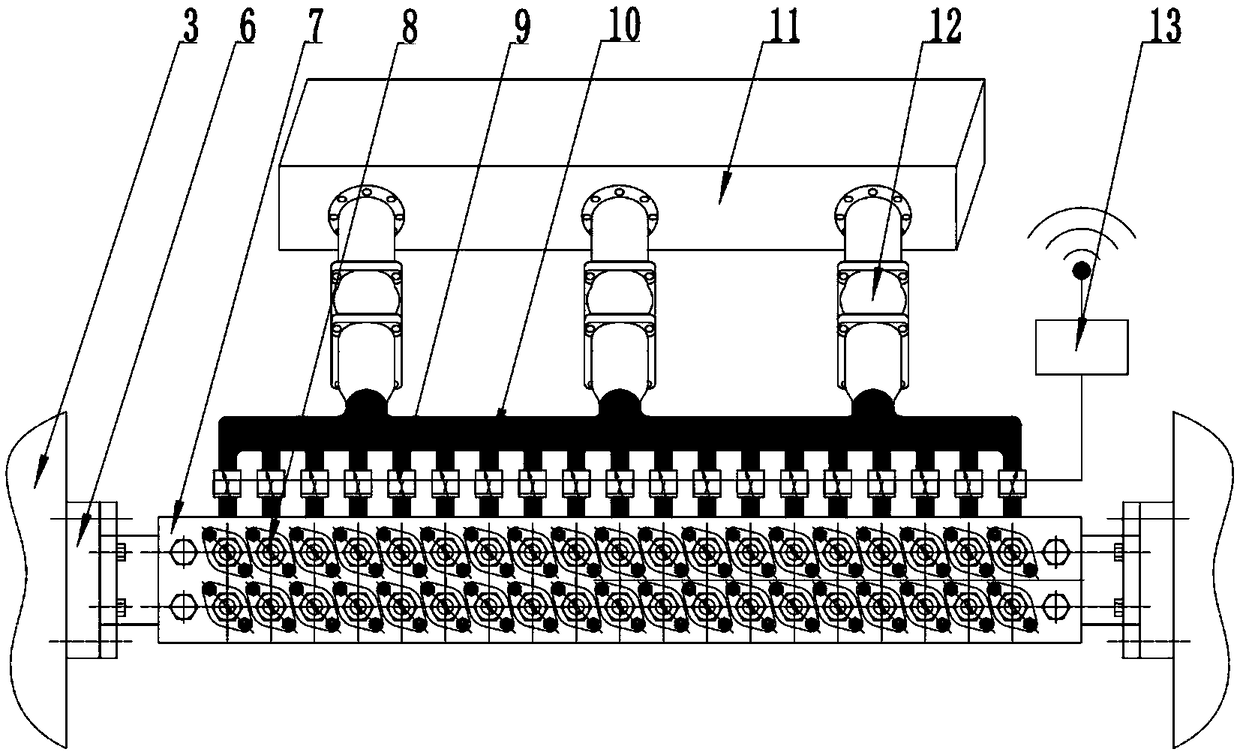

Cold rolling strip liquid nitrogen refined cooling intelligent control device

ActiveCN109351787AImprove cooling and lubrication effectImprove copy rateTemperature control deviceWork treatment devicesNanoparticleEngineering

The invention discloses a cold rolling strip liquid nitrogen refined cooling intelligent control device. A liquid nitrogen refined cooling device and a wireless intelligent control system are designedto realize point-to-point intelligent control of a roller and the strip transverse temperature during the rolling process, and the demands of asymmetrical rolling and other specific technology are met; in addition, nano-particles are added in a liquid nitrogen box to form liquid nitrogen mixed solution, the friction condition and the shape characteristic of a roll gap contact interface of a rolling deformation area are adjusted and the roller copying rate and the rolled strip surface quality are increased and improved.

Owner:唐山建龙简舟钢铁有限公司

Magnetized oil emulsion and preparation thereof

Disclosed is an emulsion treated by magnetization and a preparation method thereof, relating to the emulsion and the preparation method and solving the problems that the use amount of the existing emulsion is large, the resource is wasted, and the extreme pressure additive seriously pollutes the environment and harms the health of machine tool operators. The emulsion treated by magnetization is the emulsion which is treated through magnetization and used for metal cutting processing, cooling and lubrication. The preparation method comprises the steps: the emulsion is positioned into a magnetization treating system, and the emulsion treated by magnetization is obtained after the magnetization treatment. The use amount of the emulsion treated by magnetization and the extreme pressure emulsion is small, and not only the resource is saved, but also the discharge of the waste liquor is reduced, so the pollution to the environment and the harm to the health of the machine tool operators are reduced.

Owner:HARBIN INST OF TECH

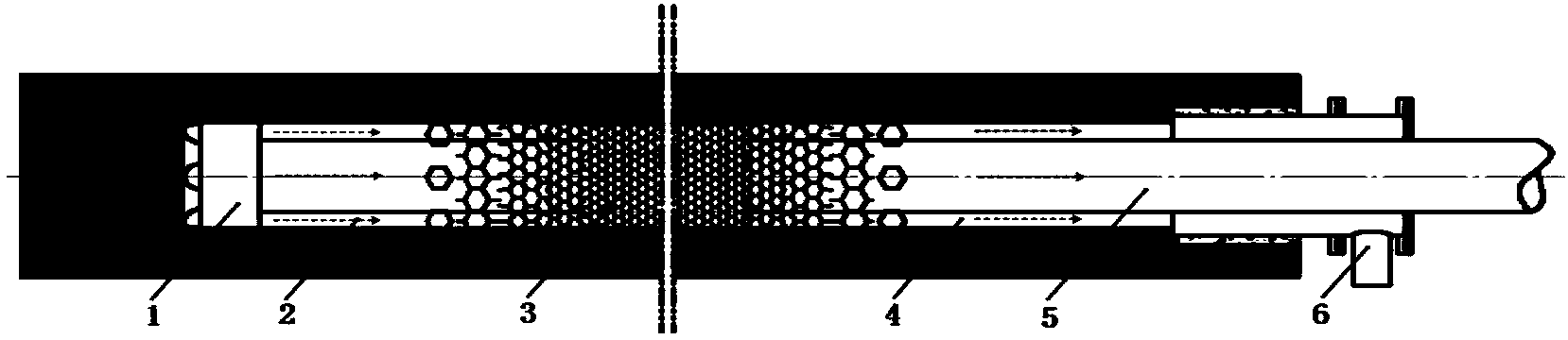

Method and device for constructing bedding gas extraction long drilled holes of soft coal seams

ActiveCN103452508ASafe and fast drillingOvercoming the Insufficiency of the Drilling TechnologyFlushingCooling effectEngineering

The invention discloses a method and a device for constricting bedding gas extraction long drilled holes of soft coal seams. The method and the device are applied to drilling the bedding gas extraction long drilled holes of the soft coal seams, and are characterized in that two types of gas-based fluid including compressed air and stable foams are used as drilled hole washing media, are alternately injected into a drilled hole, reach the bottom of the hole, then flow into annular clearance via flow channels in a drill bit, cool the drill bit and carry coal cinder dust which is generated along with drilling actions of the drill bit at the bottom of the hole, then the drilled hole washing media and the coal cinder dust return the outside of the hole, stable foam flow carries the coal cinder dust, and cools and lubricates drilling tools, and compressed air flow washes the bottom of the hole and pushes stable foam slug to flow. The method and the device have the advantages that the cinder discharge capacity is high, a drilling tool cooling effect is good, orifices are free of dust pollution, the rotation pressure of a drilling machine can be obviously reduced while the drilling capacity of the drilling machine is improved, and the drilling machine can normally drill holes in water-containing coal seams; the flow rates of gas and liquid are regulated under the control of special valve blocks by the aid of the method and the device, the device can be operated easily and conveniently, is small in size and is light, the method and the device are applicable to underground drilling construction operation environments of coal mines, and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

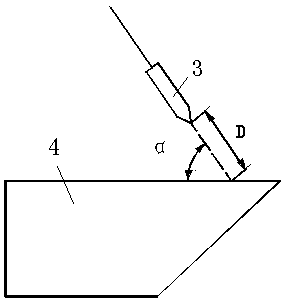

Green cast iron cutting machining method under condition of cooling and lubrication of outer cooling oils on water

ActiveCN107553206AGuaranteed lubrication effectIncrease frictionMaintainance and safety accessoriesCooling effectEngineering

The invention provides a green cast iron cutting machining method under a condition of cooling and lubrication of outer cooling oils on water. The cast iron cutting machining method comprises the following steps: S1, a workpiece is fixed on a machine tool workbench; S2, an oil-on-water device is started, and nozzles of the oil-on-water device is aligned with a cutter; S3, a cutting speed, a feeding speed and a cutting depth are set according to machining requirements of the workpiece, and the machining machine tool is started to carry out cutting machining on the cast iron workpiece; the nozzles in the S2 comprise a front cutter surface nozzle and a rear cutter surface nozzle, the distance between the front cutter surface nozzle and a cutting edge of the cutter ranges from 20 mm to 80 mm,and the included angle between the front cutter face nozzle and the horizontal direction ranges from 20 degrees to 70 degrees; and the distance between the rear cutter surface nozzle and the cutting edge of the cutter ranges from 20 mm to 80 mm. The cast iron cutting machining method has the advantages of being good in lubricating effect, good in cooling effect and timely in chip removal.

Owner:GUANGDONG UNIV OF TECH

Cyclone milling cutter with self-cooling lubrication structure

The invention relates to a cyclone milling cutter with a self-cooling lubrication structure. The cyclone milling cutter with the self-cooling lubrication structure comprises a rotating base body and aplurality of thread milling blades; a large through hole is arranged on the rotating base body along the central axis; a plurality of base body connecting screw holes are arranged on the rotating base body along the circumferential direction; the plurality of thread milling blades in a circumferential direction is arranged on one end face of the rotating base body; and further includes a plurality of cooling lubricating fluid flow passages arranged in the rotating base body in the same number as the thread milling blades; an inlet of the cooling lubricating fluid flow passage is formed in theouter surface of the rotating base body and is away from the thread milling blades; an outlet of the cooling lubricant flow passage is formed in the inner circular surface of the rotating base body and is close to the thread milling blades; and an outlet of a cooling lubricating fluid flow passage is facing a nose of a thread milling blade. The base body, and the cooling lubricating fluid flow passages are all formed by 3D printing. The cyclone milling cutter with a self-cooling lubricating structure can not only directly cool the lubricating fluid but also directly acts on a cutting area, and has good cooling uniformity and low cooling cost.

Owner:XI AN JIAOTONG UNIV +1

Cooling and lubricating system of supercharger

InactiveCN111608794AReduce resistanceReduce running timeMachines/enginesEngine componentsThermodynamicsEngineering

The invention belongs to the field of engines, in particular to a cooling and lubricating system of a supercharger. The system comprises a main circulation loop and an independent circulation branch;the main circulation loop comprises a supercharger, a one-way valve and an engine main pump arranged upstream of the supercharger; and the independent circulation branch comprises an electronic pump,a joint between electronic pump and the main circulation loop is arranged on a pipeline between the supercharger and the engine main pump, the one-way valve is arranged on a pipeline between the jointand the engine main pump, and the flow direction of the one-way valve is arranged to be consistent with the main circulation loop. The electronic pump can solve the problems of dry grinding, coking at high temperature and the like of the supercharger rotor system, running time of the electronic pump is shortened, and the service life of the electronic pump is prolonged.

Owner:GUANGXI YUCHAI MASCH CO LTD

Static minimal quantity lubrication aerial fog electric charge device

PendingCN108214090ANot easy to loseCompact structureMaintainance and safety accessoriesSpray discharge apparatusElectricityHigh pressure

The invention provides a static minimal quantity lubrication aerial fog electric charge device which comprises a box, a high-voltage static conveying line connector, a high-voltage connector base, anelectric charge electrode, an air pipe, a liquid pipe and a spraying nozzle. A liquid conveying channel and an air conveying channel are arranged inside the box, an electrode guide hole is formed in the liquid conveying channel, one end of the liquid pipe communicates with the liquid conveying channel inside the box, and the other end of the liquid pipe communicates with a minimal quantity lubrication device; and the high-voltage static conveying line connector is fixed to the high-voltage connector base of the box, the high-voltage connector base is connected with one end of the electric charge electrode, the other end of the electric charge electrode is inserted into the liquid conveying channel through the electrode guide hole and is in contact with lubricating fluid in the liquid conveying channel to achieve electric charging, the inner end of the air pipe communicates with one end of the air conveying channel, the electric charge lubricating fluid is mixed with air in the air conveying channel to be sprayed out from the spraying nozzle. The static minimal quantity lubrication aerial fog electric charge device has the beneficial effects of being compact in structure, high in integration degree, stable in electric charging and convenient to install, enabling electric charge lubricating fluid electric charge to be not prone to losing and the like.

Owner:ZHEJIANG UNIV OF TECH

Special machining machine for machining of inner cavity of crystallizer copper tube

PendingCN106965019AExtended service lifeLow resolutionMilling equipment detailsDriving apparatusProcess engineeringMachine

The invention discloses a special machining machine for machining an inner cavity of a crystallizer copper tube and belongs to horizontal special machines. The horizontal special machine comprises a machine tool workbench. A hydraulic clamp is arranged at the top of the machine tool workbench. A workpiece is arranged at the top of the hydraulic clamp. A machine tool stand column is provided with a numerical-control shaft C. The left end of the numerical-control shaft C is fixedly connected with a lengthened right-angle milling head. The lengthened right-angle milling head extends into the workpiece for cutting. According to the special machining machine, by arranging the horizontal special machine, the machine tool workbench, the hydraulic clamp, the workpiece, the numerical-control shaft C, the lengthened right-angle milling head, a cutting fluid tank and a high-pressure water supply station, the problems that the dimension precision of an inner cavity of an existing crystallizer is low, and machining is difficult are solved, the machining requirements of the inner cavity of the crystallizer copper tube for high-precision dimensions and high-fineness surfaces can be met through the mechanical cutting method, the quality of the crystallizer copper tube is greatly improved, the service life of crystallizer copper tubes in China is longer, and the quality of solidified steel billets is better.

Owner:上海司恩金属加工技术有限公司

Heavy-load high-speed main shaft cooling device

InactiveCN104329447AImprove working conditionsIncrease speedGear lubrication/coolingBearing coolingHeavy loadLubrication

Owner:柳州金盛重型数控机床有限责任公司

Hydraulic driven angle head

PendingCN106891194AImprove cooling and lubrication effectHigh cutting speedDriving apparatusBall bearingDrive shaft

The invention discloses a hydraulic driven angle head. The hydraulic driven angle head comprises a mounting handle, wherein a ball positive displacement motor is fixedly connected with the left side of the mounting handle through a first connecting flange ring; an angle head casing is fixedly connected with the left side of the ball positive displacement motor through a second connecting flange ring; a transmission shaft is arranged in the angle head casing; a ball bearing is fixedly connected with the right side of the transmission shaft; a fixed-core flange ring matched with the ball bearing for use is fixedly connected with the left side of the ball positive displacement motor. The hydraulic driven angle head is not required to be driven to rotate by a machine tool spindle motor and is mainly driven to perform rotary cutting by high hydraulic pressure, so that the cutting torque is higher, the cutting rotating speed is higher, key slots, cross holes, inclined planes and cambered surfaces of parts required to be machined in deeper, smaller and narrower space can be machined, water is introduced into the angle head for cooling, and the service time is not influenced by temperature rise. Cooling and lubricating effects of a cutting tool and a workpiece are better and precision and smooth finish of a cutting surface are better.

Owner:上海司恩金属加工技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com