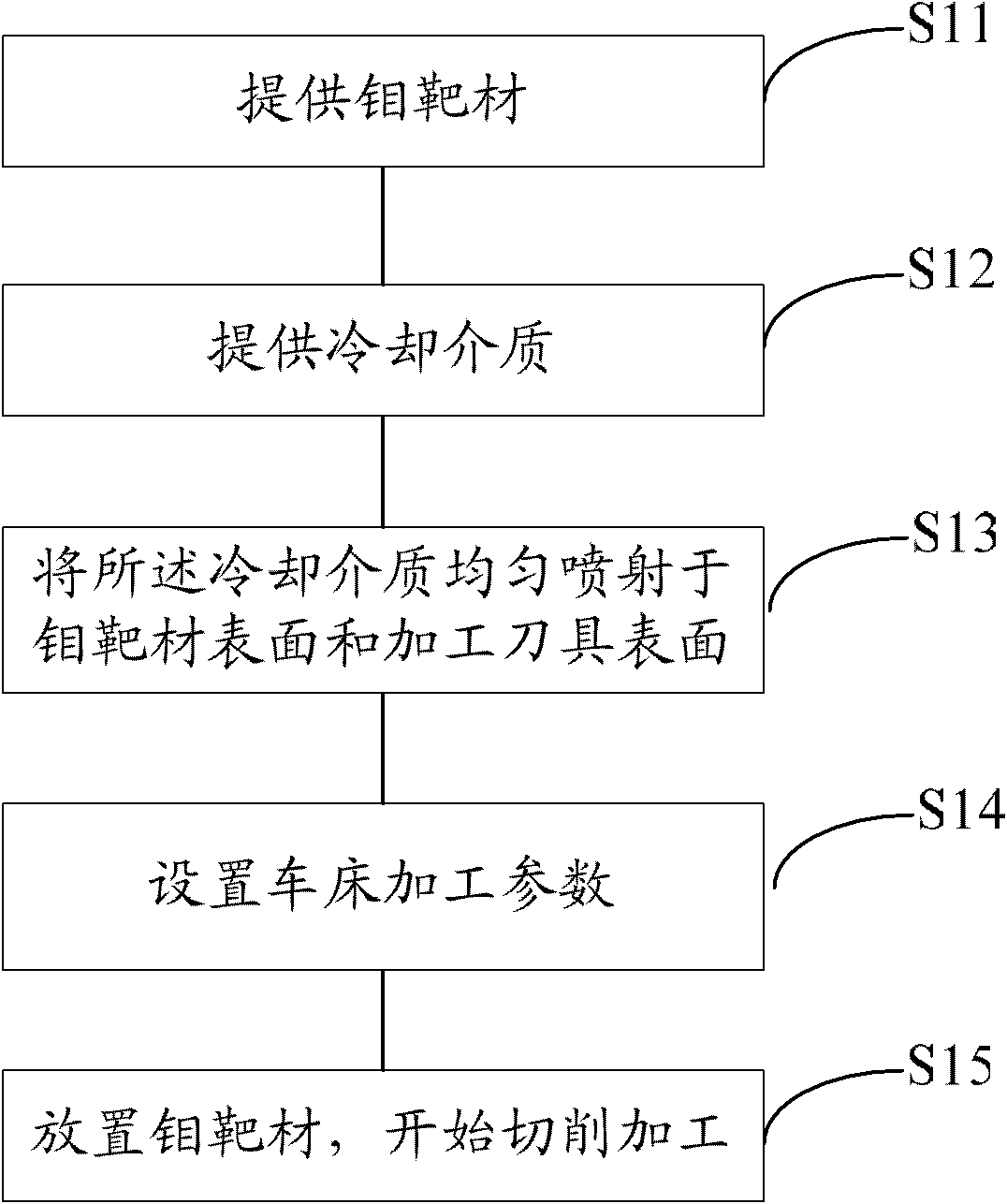

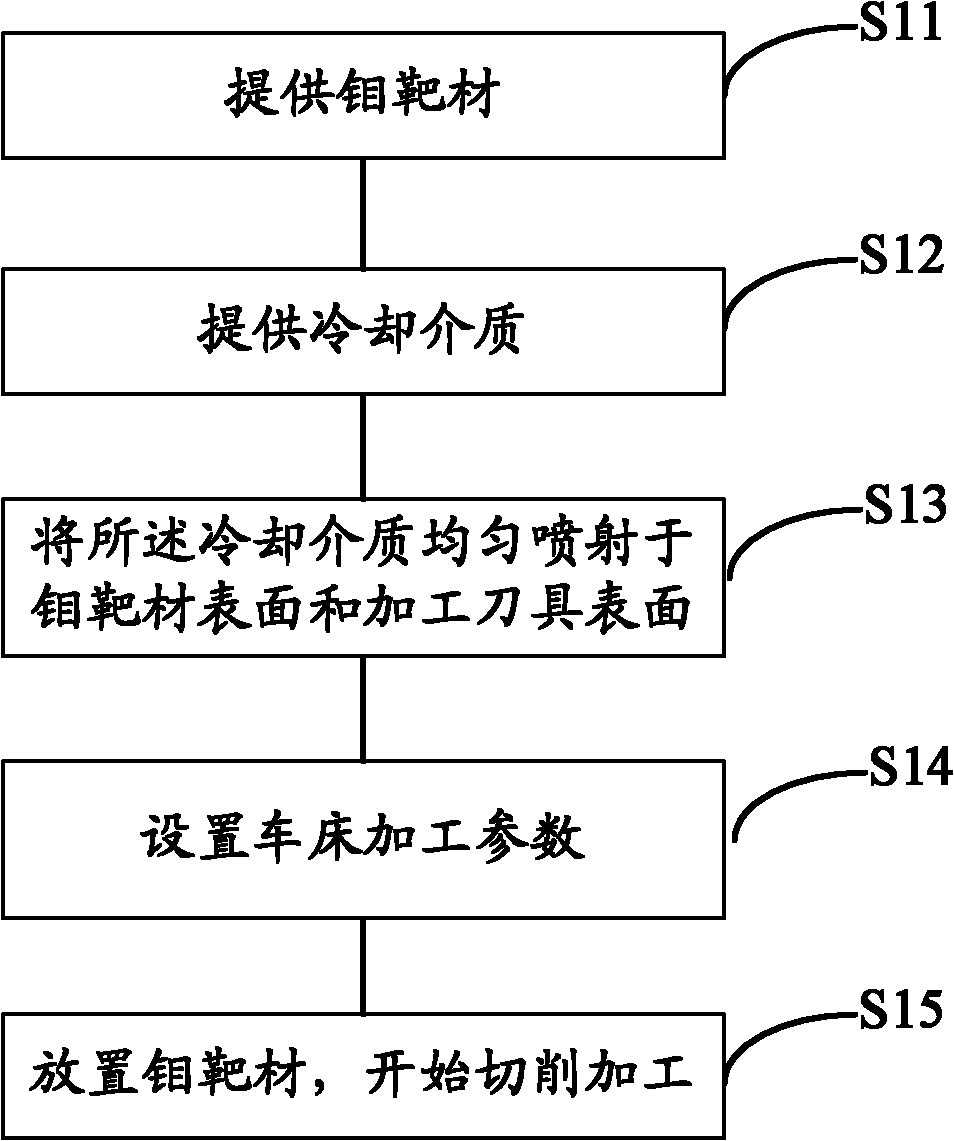

Method for processing molybdenum target material

A processing method and molybdenum target technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of molybdenum material cracking and cracking, and achieve the effect of avoiding stress, reducing impact force and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The inventor found in the process of processing molybdenum targets that the domestic processing of molybdenum targets generally adopts the ordinary milling method, and there is no special research on the processing parameters, and the settings are relatively random, which are generally the same as processing other targets such as chromium targets and titanium targets. ; For example, the processing tool speed is 450-550 rpm, the feed rate is 0.8-1.0 mm / time, the feed speed is 50-100 mm / min, and the ratio of emulsion to water in the cooling medium is 1:10-1 : 20. However, due to the high hardness and high brittleness of the molybdenum target at room temperature, it is easy to generate large stress when using the existing technology to process the molybdenum target, and the cooling and lubrication effect of the cooling medium cannot be guaranteed, which may easily cause the molybdenum target to crack or even crack. , resulting in decreased productivity and increased costs....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com