Workpiece loading device and machining device for machining tiny deep holes

A loading device, deep hole technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of affecting processing efficiency and processing accuracy, limited vibration drilling efficiency, irregularity of workpieces to be drilled, etc. , to improve the processing quality, improve the life of the drill bit, and achieve the effect of good drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

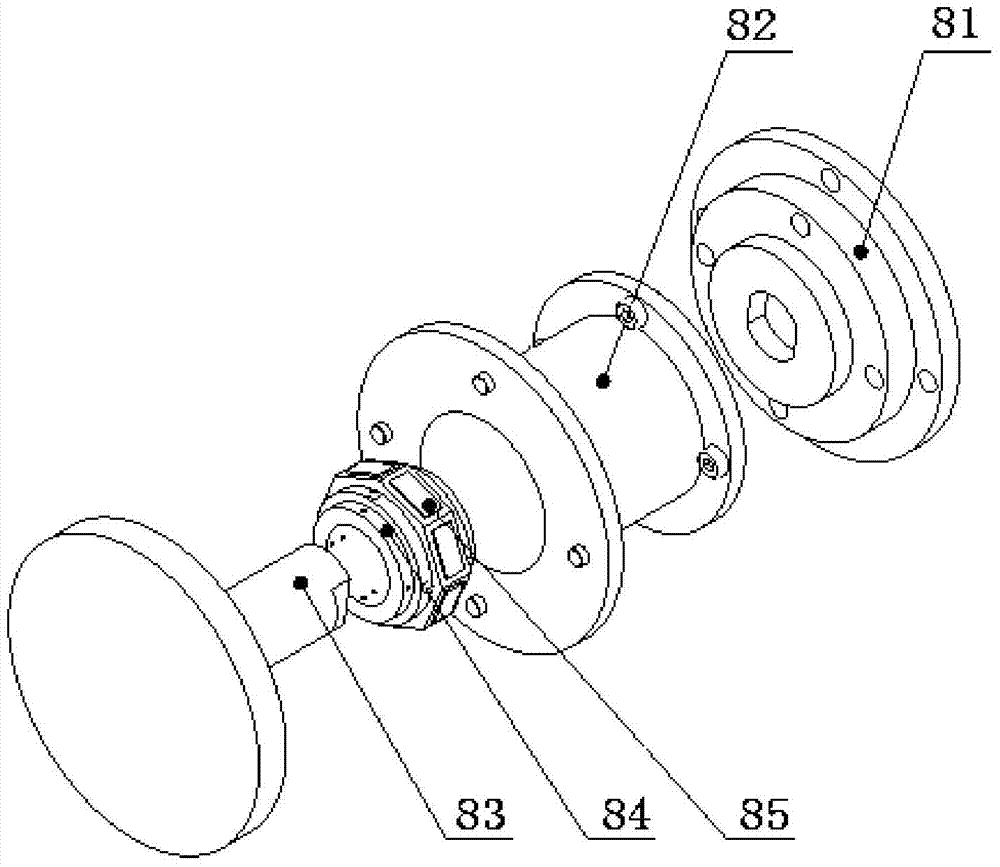

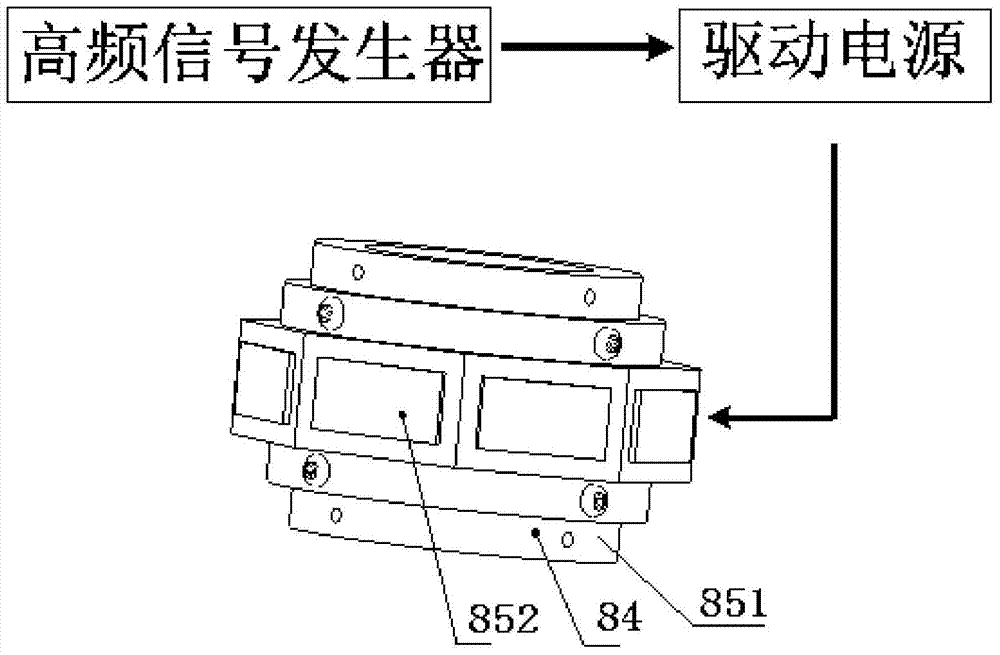

[0035] Such as figure 1 , 2 As shown, the workpiece loading device for small deep hole processing includes a base 83, an upper cover 81 for carrying the workpiece 9 to be drilled, and a protective shell 82 connecting the base 83 and the upper cover 81; the base 83 and the upper cover 81 , the protective shell 82 is coaxial, and there is a torsional vibration generating mechanism in the protective shell 82. The torsional vibration generating mechanism includes a torsional driver 85 that generates torsional vibration and an excitation device that provides an excitation signal for the torsional vibration driver; the torsional driver 85 produces torsional vibration by smart materials . Common smart materials include piezoelectric fibers, magnetostrictive materials, electrostrictive materials, shape memory aggregates, piezoelectric ceramic materials and other materials that can change the physical properties of materials in response to external signals.

[0036] Such as image 3...

Embodiment 2

[0045] Such as Figure 8 As shown, the small deep hole processing device includes a drilling machine 1, a main shaft 2, a drill bit clamp 3 fixed with the main shaft 2, a drill bit 7, an intelligent material that drives the bit 7 torsionally vibrate, and the above-mentioned workpiece loading device 8, the drill bit 7 and the workpiece loading The device 8 vibrates in reverse torsion.

[0046] Such as Figure 9 As shown, the structure that limits the torsional vibration of the driving drill bit 7 is as follows: the smart material is a plurality of torsional vibration sheets 61, the torsional vibration sheets 61 are evenly distributed on the side of the torsional actuation base 62, and the torsional actuation base 62 is fixed to the drill bit holder 3 , The slip ring 5 for applying a drive signal to the torsional vibrating sheet 61 is provided on the drill holder 3 .

[0047] The torsional actuator base 61 is in the shape of a regular prism, and the torsional vibrating sheet 6...

Embodiment 3

[0050] The difference between this embodiment and Embodiment 2 is that in order to further improve the processing efficiency and precision, the drill bit 7 is also made to produce axial high-frequency micro-vibration while torsional vibration, and the structure that produces axial high-frequency micro-vibration As follows: the drill bit 7 and the clip 3 are fixedly connected to the piezoelectric stack actuator 4 that generates axial vibration. Piezoelectric ceramics apply excitation signals, such as Figure 10 shown. All the other structures are the same as in Example 2.

[0051] Under the combined action of the axial high-frequency micro-amplitude vibration and the circumferential torsional vibration, the drill bit 7 generates combined axial and circumferential vibrations to complete the small deep hole processing of the workpiece 9 to be drilled, the processing efficiency is improved, and the processing accuracy is improved. improve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com