Nanofluid electrostatic atomization controllable conveying micro quantity lubricating system for auxiliary electrode focusing

A nano-fluid and micro-lubrication technology, applied in the field of grinding, can solve the problems of inability to control the effect of droplet deposition, inflexible fixed position of the electrode ring, etc., and achieve the effect of improving deposition rate, effective utilization rate and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] As introduced in the background technology, there are deficiencies in the prior art. In order to solve the above technical problems, the present application proposes a nanofluid electrostatic atomization controllable delivery micro-lubrication system with auxiliary electrode focusing.

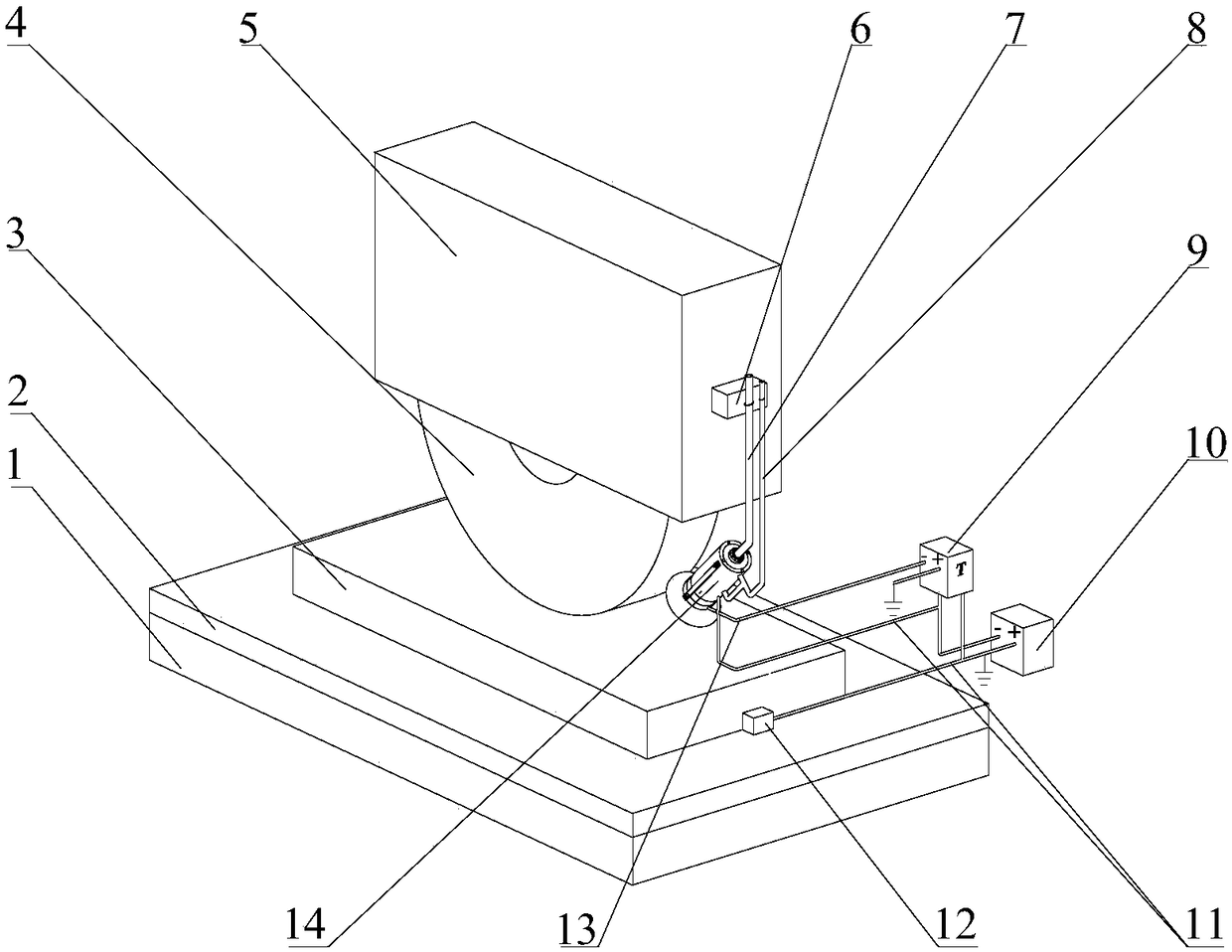

[0070] In a typical implementation of the present application, such as figure 1 As shown in the figure, a nanofluid electrostatic atomization controllable transportation micro-lubrication system focused on a tapered electrode ring, the grinding machine table 1 is covered with an insulating plate 2, and the liquid-gas serpentine tube fixing device 6 is adsorbed on the grinding wheel cover 5 The side is used to fix the nanofluid conveying serpentine tube 7 and the compressed gas conveying serpentine pipe 8 . The nanofluid conveying serpentine tube 7 is connected to the liquid inlet 16, and the compressed gas conveying serpentine pipe 8 is connected to the gas inlet I35; the L-shaped needle...

Embodiment 2

[0082] The second example is Figure 16 to Figure 20 As shown, the auxiliary electrode focusing device adopts a flat plate electrode device, and other devices are the same as the first embodiment.

[0083] Such as Figure 16 As shown, the plate electrode device includes a plate electrode connecting rod 63, a plate electrode placement plate 64, an angle positioning ring 65, and a plate electrode 72. The plate electrode 72 is installed in a plate electrode placement frame 79, and can be wound around the connection center with the plate electrode placement plate 64. Rotate to adjust the angle with the central axis; the plate electrode placement plate 64 can move up and down with the plate electrode connecting rod 63 to adjust the distance between the plate electrode 72 and the L-shaped needle electrode 23.

[0084] Such as Figure 17 As shown, the angle positioning ring 65 has an arc-shaped chute 75 along the circumferential direction, and is flexibly connected with the flat el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com