A kind of marine anti-corrosion inorganic coating and preparation method thereof

An inorganic coating and marine anti-corrosion technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of easy aging and peeling of organic coatings, inconvenient coating protection implementation, limited corrosion resistance, etc., to achieve Excellent volume stability, good chemical corrosion resistance, and good coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

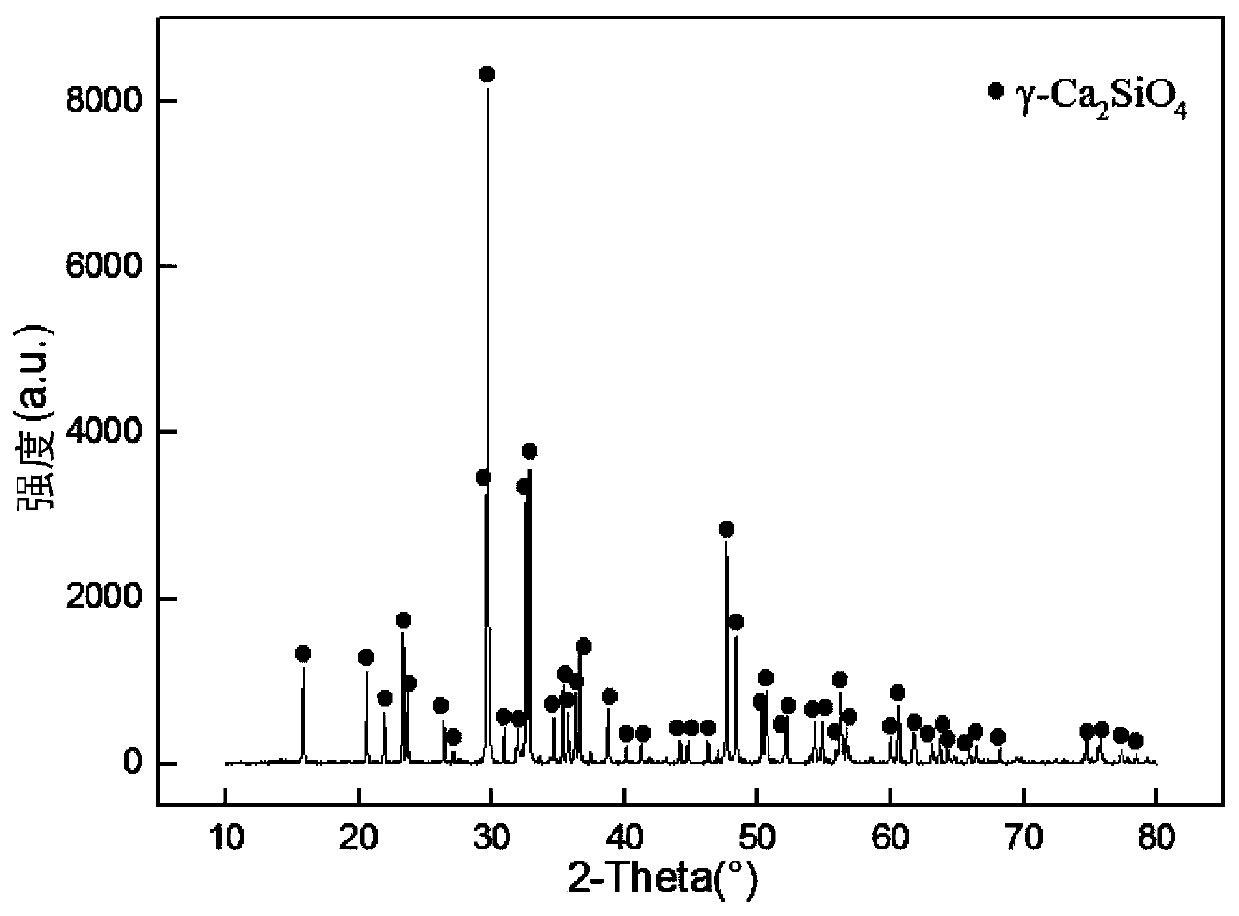

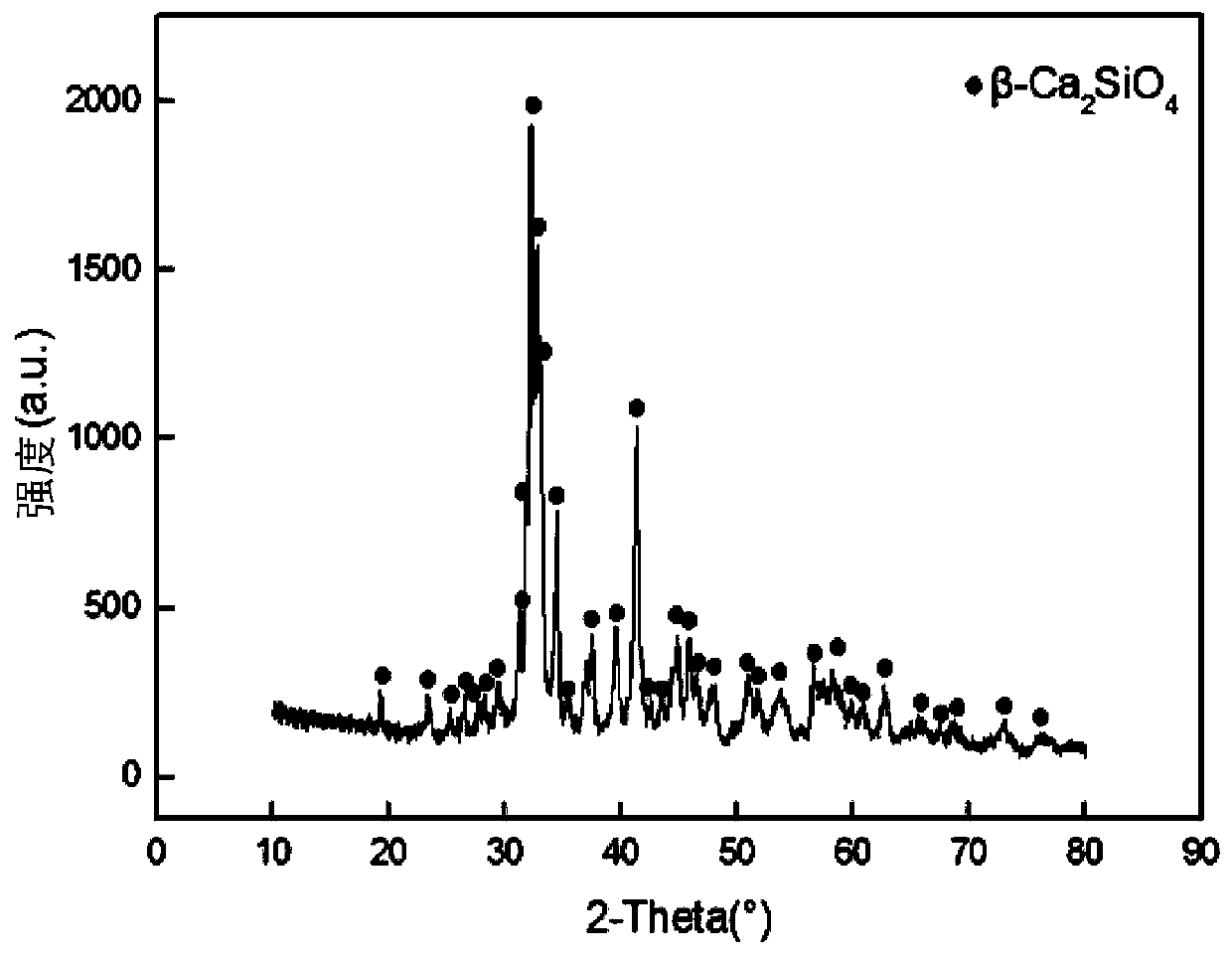

[0046] (1) Mix analytically pure calcium carbonate and silicon dioxide at a molar ratio of 2:1, heat at 1400°C for 3 hours, and synthesize γ-dicalcium silicate through solid-state reaction;

[0047] (2) Sieve the gamma dicalcium silicate powder, take the powder with a particle size of 30-50 μm, and reserve it for spraying;

[0048] (3) The metal substrate is a 304 stainless steel rectangular test piece with a size of 30mm×15mm×1.25mm. Pretreatment of the surface of the metal substrate to be sprayed: sandblasting, ultrasonic cleaning, compressed air drying;

[0049] (4) Atmospheric plasma spraying: The atmospheric plasma spraying process is used to spray a 20 μm NiCr transition layer and a 130 μm dicalcium silicate coating on the surface pretreated metal substrate, and the process parameters for spraying the NiCr transition layer are: The flow rate of plasma gas argon gas is 57slpm, the flow rate of plasma gas hydrogen gas is 8slpm, the spraying current is 600A, the voltage is...

Embodiment 2

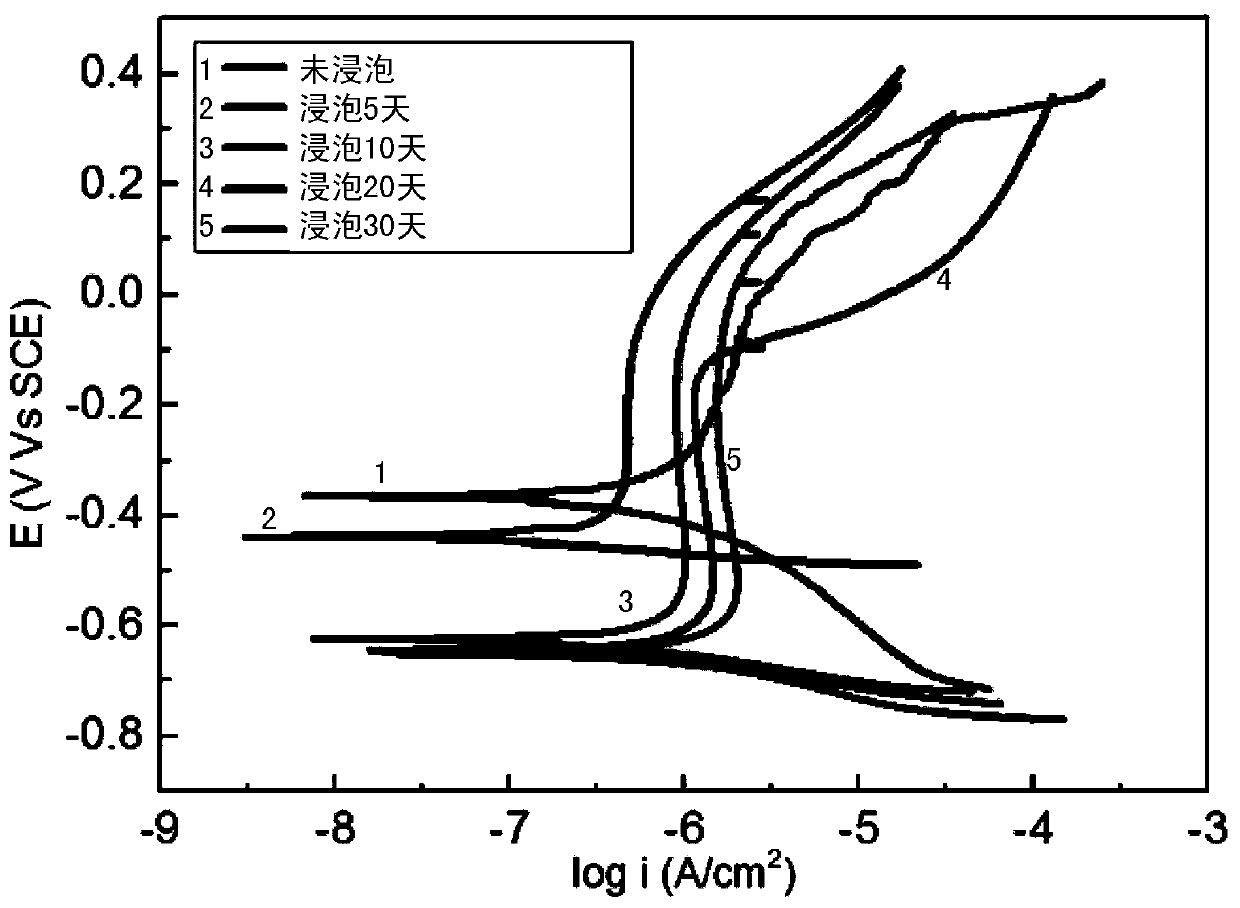

[0052] After soaking the samples obtained in Example 1 in 3.5wt% NaCl solution for different periods of time, the polarization curves were detected. The detection method of the polarization curve is: Ametek 1287&1260 test system is used, the saturated calomel electrode is used as the reference electrode, the electrolyte is 3.5wt% NaCl solution, the voltage test range is -0.5~0.6V (reference open circuit voltage), and the scan rate is 0.5mV / s.

[0053] image 3 Table 1 and Table 1 respectively show the polarization curve and corrosion parameters of the sample obtained in Example 1 after soaking in 3.5wt% NaCl solution.

[0054] Corrosion parameters of the sample obtained in Table 1 Example 1 soaked in 3.5wt% NaCl solution

[0055]

[0056] From image 3 It can be seen from Table 1 that after immersion for 30 days, the corrosion current density of the sample remained at 1.61×10 -6 (A / cm 2 ).

Embodiment 3

[0058] The sample obtained in Example 1 was corroded by 5.0wt% NaCl solution for 24 hours with alternating wet and dry salt spray. Figure 4 Photo for salt spray corrosion. It can be seen that after the dicalcium silicate coating sample was corroded for 42 days in the dry-wet alternating salt spray chamber, the coating surface did not appear corrosion characteristics such as blistering, peeling, and rust spots. The surface white matter in the figure is the soaking product of dicalcium silicate in sodium chloride solution, namely calcium carbonate and calcium carbonate monohydrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com