A process method for anticorrosion by spraying oil casing with black uv paint

A process method, oil casing technology, applied in the device, coating, pretreatment surface, etc. of the surface coating liquid, can solve the problems of erosion, curing, peeling, etc., to ensure full absorption, good film formation, good effect on neutral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

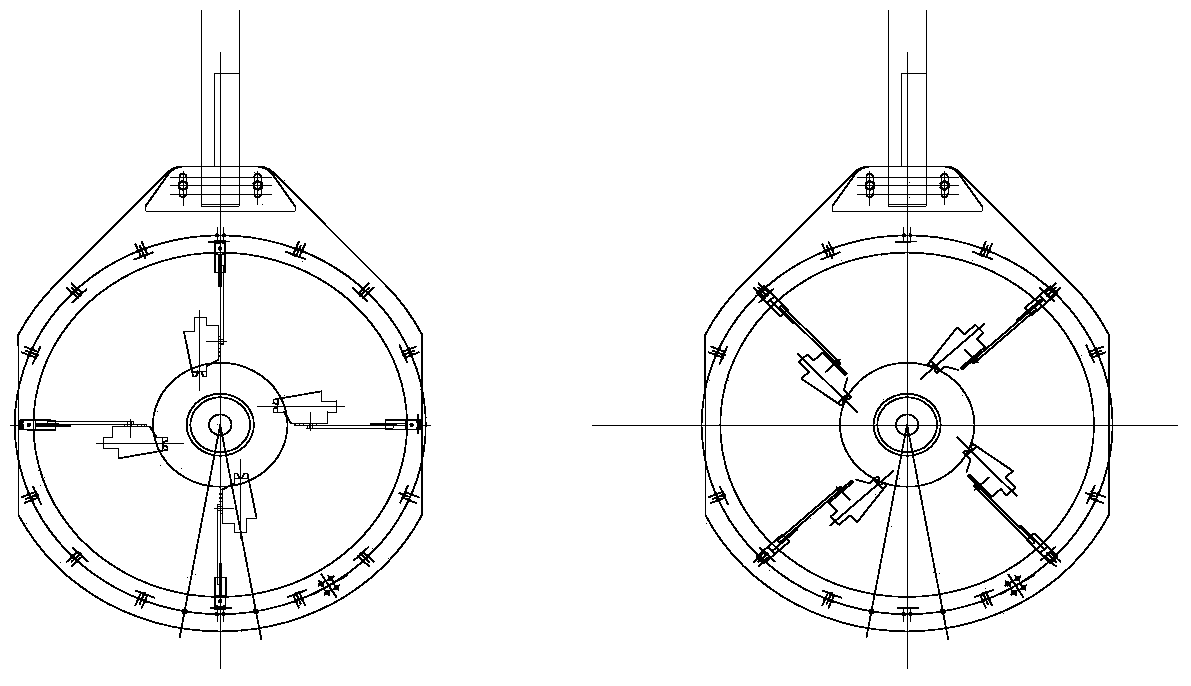

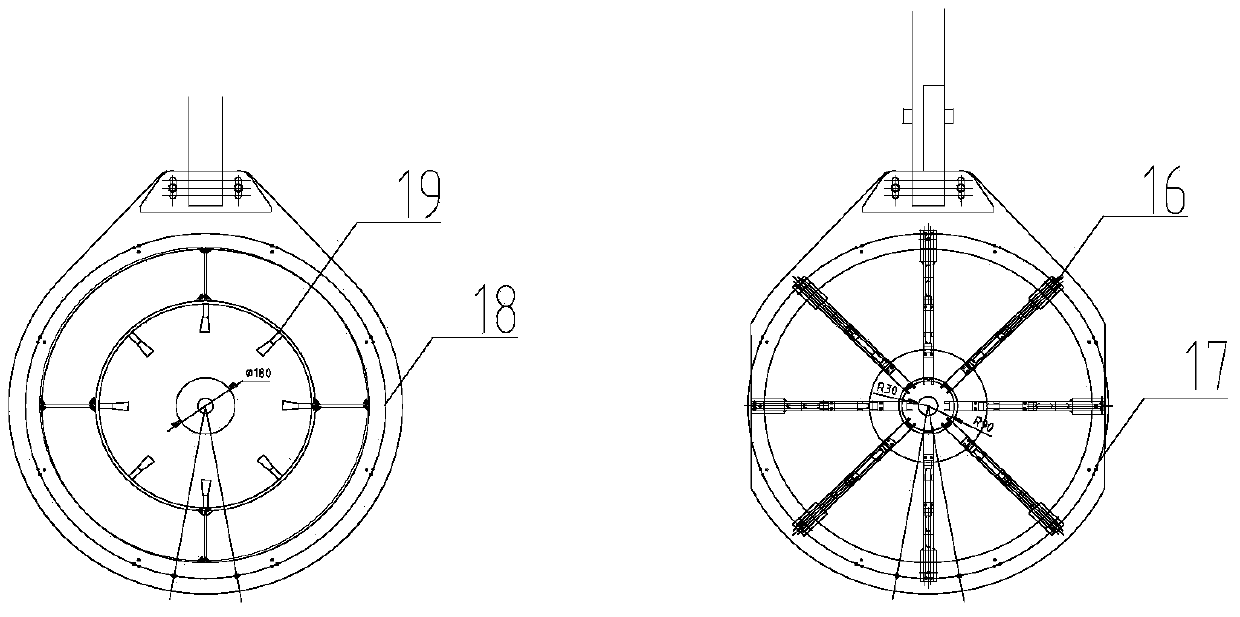

[0025] This process plan is to use black UV paint for UV curing spraying. Spraying adopts pneumatic spray gun 16 to carry out atomized spraying, from figure 2 and image 3 : It can be seen that the four spray guns fixed on the spray ring are different from the four spray guns used in the original spray gun. The eight pneumatic spray guns 16 are all fixed on the front spray ring 17, so that the spray guns have good centering and are easy to control. The spray gun delay time, the air knife 19 installed on the rear spray ring 18 and the pneumatic spray gun 16 of the front spray ring 17 blow against each other to prevent the paint mist from entering the curing chamber 21 and play a safety role; the pneumatic spray gun 16 includes two air intake lines, one The compressed air opens the gun needle, and the paint is shot out; one way of compressed air passes through the four small holes next to the gun head to break up the jet, and atomizes the broken jet through the four atomizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com