Method for separating scheelite from fluorite

A scheelite and fluorite technology, which is applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of excessive residual chemicals on the surface, high energy consumption of full flotation, and environmental impact of chemicals, and achieve good application. and promotion prospects, effective use of mineral resources, and the effect of less consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

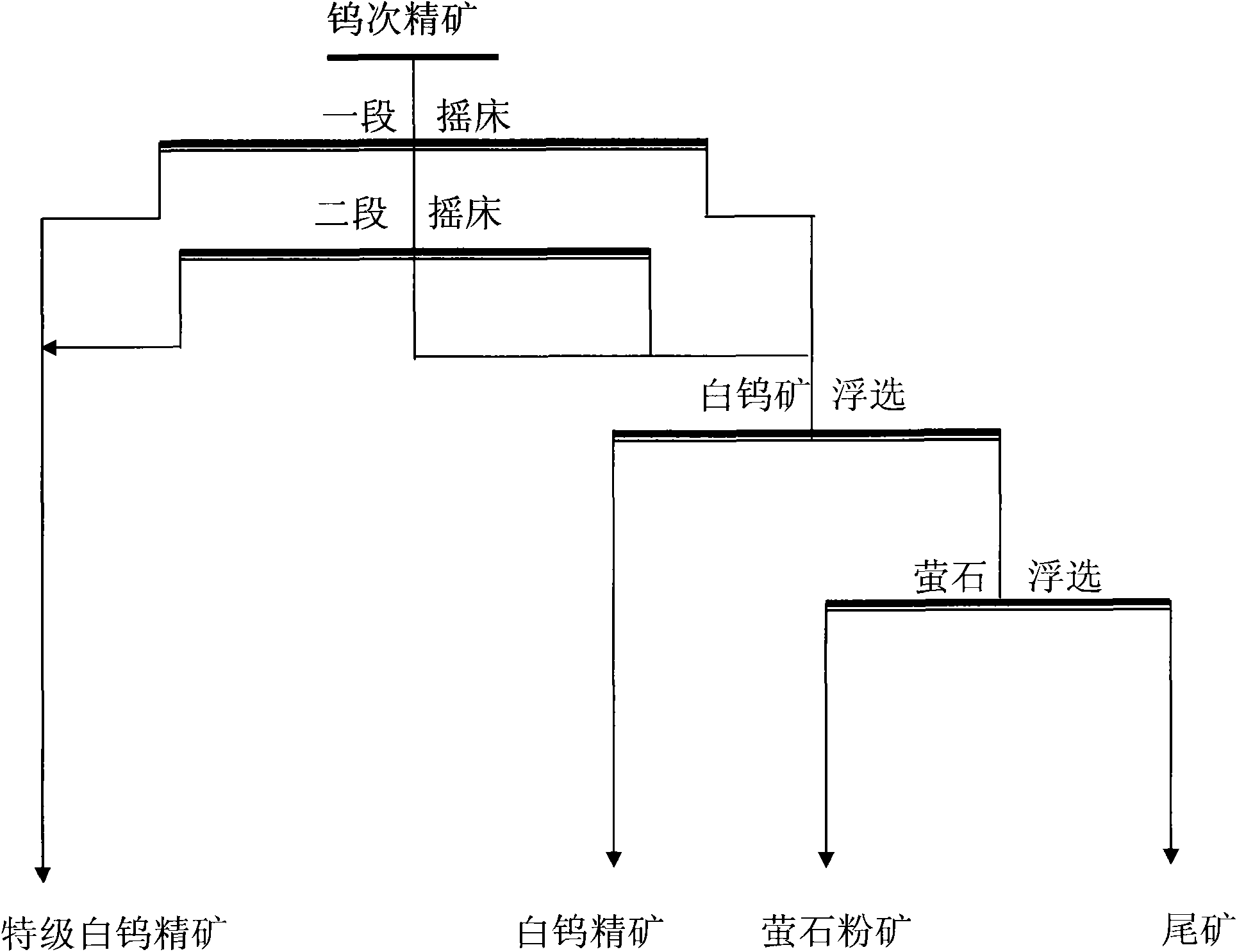

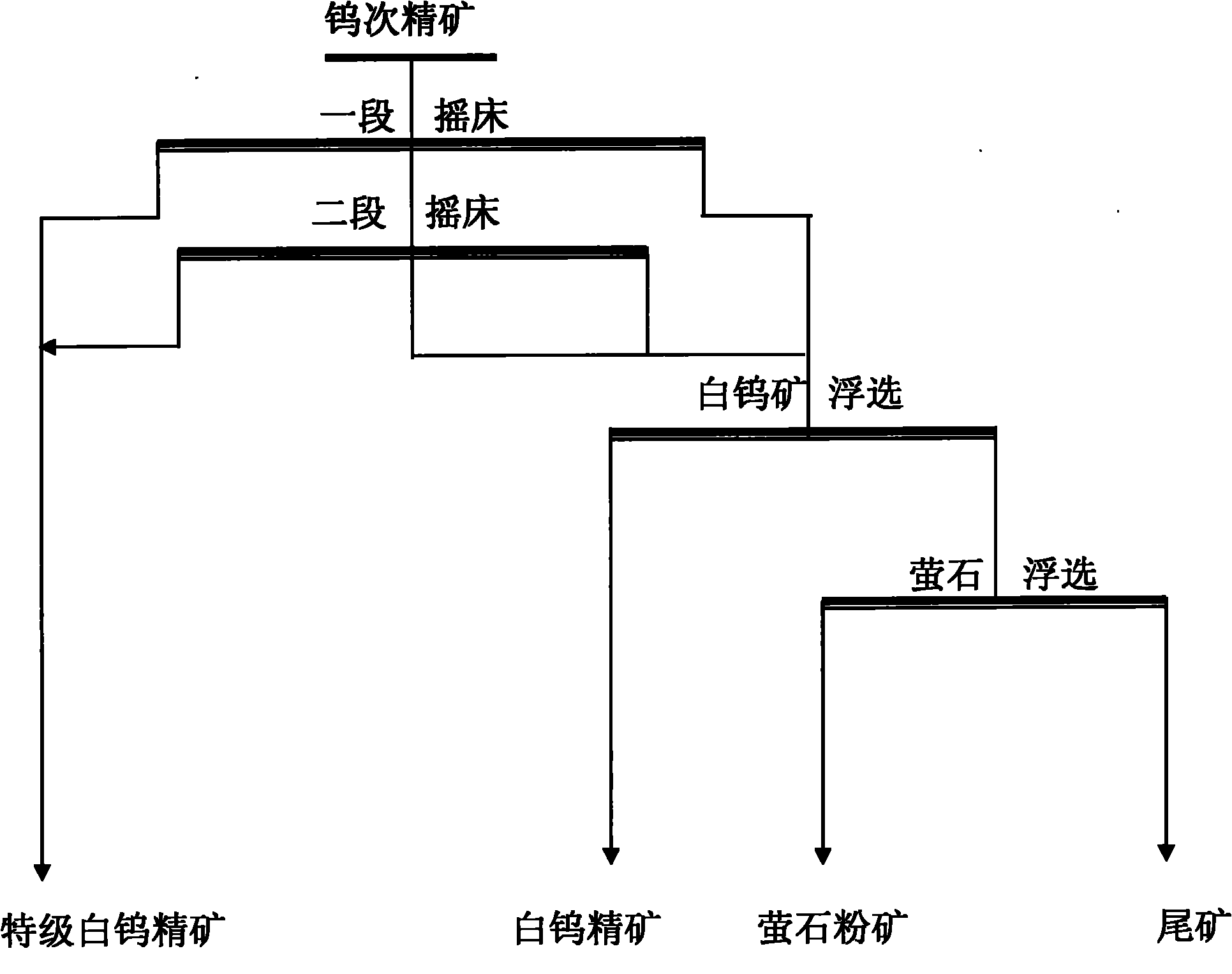

[0013] Example 1:

[0014] Raw materials contain WO 3 46.96%, Ca23.30%, F12.53%, after two stages of shaker separation, the output contains WO 3 71.70%, F1.29% super-grade scheelite concentrate, the recovery rate of tungsten is 80.5%, and the removal rate of fluorine is 95.02%. The tailings in the shaker are added with 100 kg of water glass and 10 kg of TN per ton of raw materials. After concentration, Warm and stir for 1 hour, dilute to 25% by mass, adjust the pH of the slurry to 9, add 500 grams of inhibitor KJ per ton of raw materials, add 500 grams of collector YY, and go through primary roughing and secondary sweeping , one selection, the output contains WO 3 65.5% scheelite concentrate, flotation tailings further flotation output containing CaF 2 85.09% fluorite powder mineral products. The recovery rate of tungsten in the whole process reaches 95.78%, and the removal rate of fluorine in scheelite concentrate is 90.30%.

Embodiment 2

[0016] Raw materials contain WO 3 48.79%, Ca22.76%, F12.04%, after two stages of shaker separation, the output contains WO 3 72.68%, F1.23% super-grade scheelite concentrate, the recovery rate of tungsten is 82.0%, and the removal rate of fluorine is 96.45%. The tailings in the shaker are added with 90 kg of water glass and 8 kg of TN per ton of raw materials. After concentration, Warm and stir for 1 hour, dilute to 25% by mass, adjust the pH of the pulp to 10, add 400 grams of inhibitor KJ per ton of raw materials, add 400 grams of collector YY, and go through primary roughing and secondary sweeping , one selection, the output contains WO 3 66.64% scheelite concentrate, flotation tailings further flotation output containing CaF 2 86.32% fluorite powder ore products. The recovery rate of tungsten in the whole process reaches 96.34%, and the removal rate of fluorine in scheelite concentrate is 91.55%.

Embodiment 3

[0018] Raw materials contain WO 3 34.13%, Ca25.97%, F25.53%, after two stages of shaker separation, the output contains WO 3 70.36%, F1.62% super-grade scheelite concentrate, the recovery rate of tungsten is 81.78%, and the removal rate of fluorine is 93.34%. The tailings in the shaker are added with 120 kg of water glass and 12 kg of TN per ton of raw materials. Warm and stir for 1 hour, dilute to a concentration of 25% by mass, adjust the pH of the pulp to 9.5, add 800 grams of inhibitor KJ per ton of raw materials, and add 300 grams of collector YY. Second selection, the output includes WO 3 65.54% scheelite concentrate, flotation tailings further flotation output containing CaF 2 88.54% fluorite powder ore products. The recovery rate of tungsten in the whole process reaches 94.33%, and the removal rate of fluorine in scheelite concentrate is 89.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com