Method for extracting tungsten from wolframite or scheelite and wolframite mixed ores

A technology of black and white tungsten and mixed ore, which is applied in the extraction of metal tungsten, and efficiently extracts tungsten from wolframite or black and white tungsten mixed ore. It can solve the problems that tungsten leaching cannot be realized and it is difficult to implement in industry. It is easy to operate, Easy to industrialize and realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

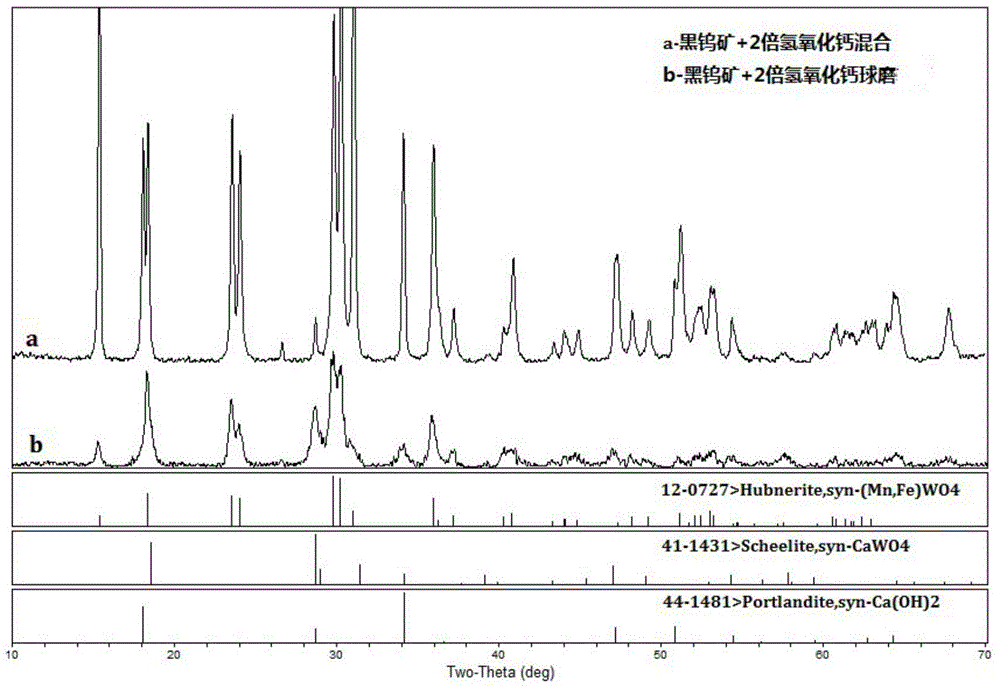

[0032] Wolframite concentrate (containing WO) with a particle size of less than 250 μm 3 71.3%) and calcium hydroxide by Put it into the grinding cylinder, add water according to the liquid-solid ratio of 0.5:1mL / g, and then ball mill for 2 hours. After the reaction is terminated, filter the tungsten-containing ore and dry it for 24 hours and perform X-ray diffraction analysis on it. The results are as follows: figure 1 shown. From figure 1 It can be seen that the characteristic spectral lines of scheelite appear after the reaction, and the diffraction peaks of wolframite broaden.

[0033] At 80°C, the above tungsten ore was treated with H 2 SO 4Concentration is 250g / L, H 3 PO 4 The mixed acid solution with a concentration of 350g / L was leached for 4h, the liquid-solid ratio was 10:1mL / g, and the leaching rate of tungsten was 99.2%.

Embodiment 2

[0035] Wolframite concentrate (containing WO) with a particle size of less than 250 μm 3 56.3%) and calcium hydroxide by Put it into the grinding cylinder, add water according to the liquid-solid ratio of 0.5:1mL / g, and then ball mill for 2 hours. After the reaction is terminated, use H 2 SO 4 Concentration is 250g / L, H 3 PO 4 The mixed acid solution with a concentration of 350g / L was leached for 4 hours, the liquid-solid ratio was 10:1mL / g, the reaction temperature was 80°C, and the leaching rate of tungsten was 98.7%.

Embodiment 3

[0037] Wolframite concentrate (containing WO) with a particle size of less than 250 μm 3 34.2%) and calcium oxide by Put it into the grinding cylinder, add water according to the liquid-solid ratio of 1:1mL / g, and then ball mill for 2 hours. After the reaction is terminated, the slurry is 2 SO 4 Concentration is 250g / L, H 3 PO 4 The mixed acid solution with a concentration of 350g / L was leached for 4 hours, the liquid-solid ratio was 10:1mL / g, the reaction temperature was 80°C, and the leaching rate of tungsten was 98.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com