Waste to hydrogen conversion process and related apparatus

a technology of waste to hydrogen and conversion process, which is applied in the direction of cell components, sustainable manufacturing/processing, and final product manufacturing, etc., can solve the problems of high energy consumption, high cost, and inability to cleanly separate hydrogen from steam reforming process, and achieve the effect of efficient steam reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

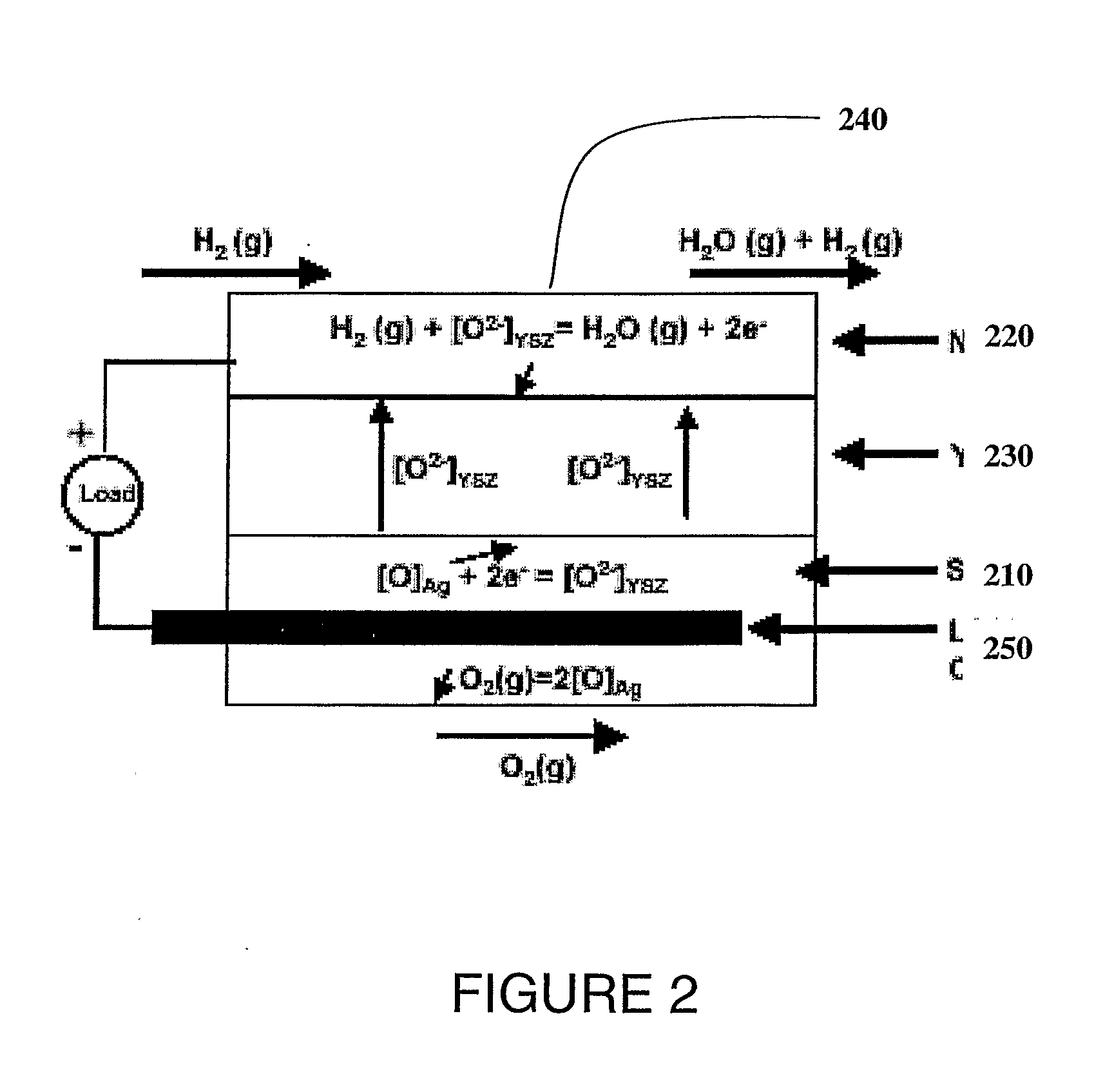

[0026]In one or more embodiments, carbon-based reversible and regenerative solid oxide fuel cell system is provided that can be operated at zero to near zero pollution emission and within environmental hazard reduction goals. The device when operated as an electrolyzer can produce hydrogen at high throughputs from steam and carbon feed and the same device can be operated in the reverse mode as a fuel cell to produce electricity from hydrogen and air / oxygen.

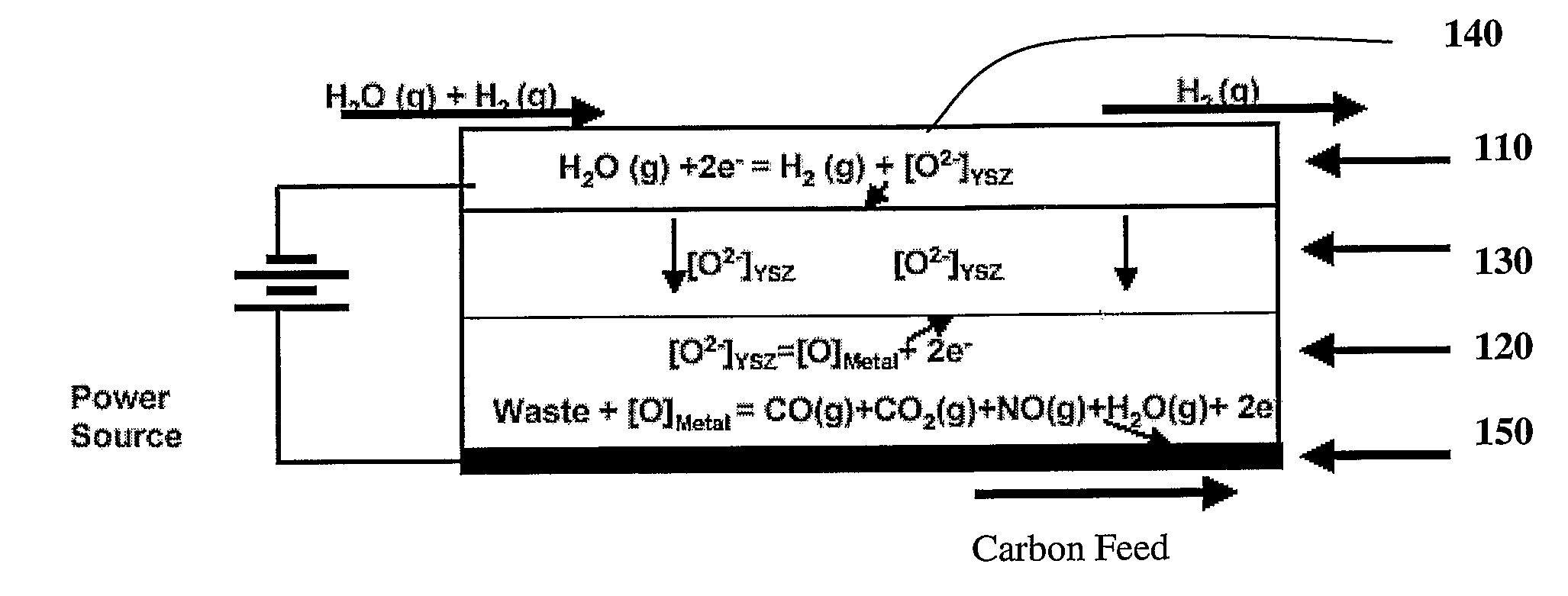

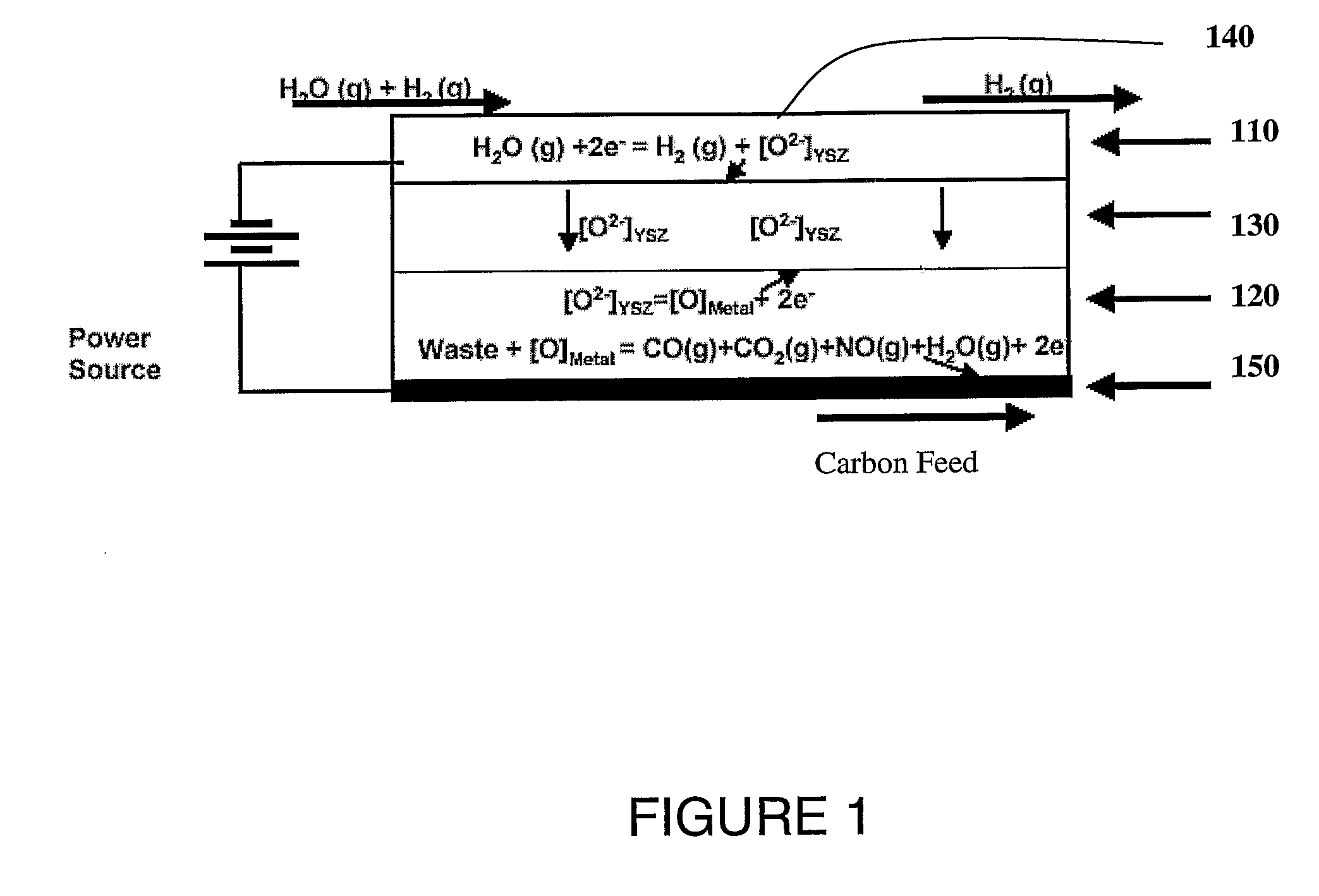

[0027]Operation of the electrochemical device for synthesizing and separating hydrogen is shown in FIG. 1. The cell is constructed with two porous electrodes that sandwich an electrolyte. The device includes a cathode 110 that is capable of stably operating at high temperatures and a liquid metal anode 120, separated by a solid oxide electrolyte 130, e.g., an oxygen ion conducting membrane. The system further includes appropriate current collectors 140, 150 for the cathode and anode, respectively. This system, operating at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Polarity | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com