Mineral separation technique for fine-grain tungsten-tin associated minerals

An associated ore, tungsten-tin technology, applied in flotation, magnetic separation, solid separation, etc., can solve the problem of low recovery rate of ore dressing, and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

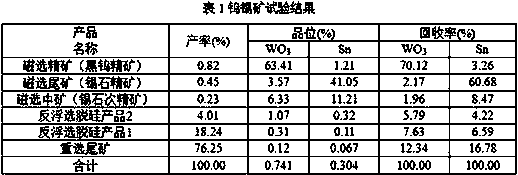

Embodiment 1

[0019] A fine-grained tungsten-tin co-associated ore beneficiation process, the specific steps are as follows:

[0020] (1) The secondary slime part produced during the crushing and grinding process of quartz vein-type tungsten-tin co-associated ore or the tailings part after flotation of sulfide ore with polymetallic ore is crushed to a particle size of less than 0.03mm;

[0021] (2) Gravity separation and enrichment: use at least one of shaking table, centrifugal concentrator, Nelson concentrator, Falcon concentrator, hydrocyclone, and spiral chute to carry out gravity separation and tailings, and the amount of gangue tailings in 60%-85%;

[0022] (3) Reverse flotation desilication: the regulator is 20-500g / t of sodium carbonate solution with a mass concentration of 1-5%, 10-200g / t of a starch solution with a mass concentration of 1-5%, and the collector is mass One or several of the etheramine solution with a concentration of 1-5%, the dodecylamine solution with a mass con...

Embodiment 2

[0026] A fine-grained tungsten-tin co-associated ore beneficiation process, the specific steps are as follows:

[0027] (1) The secondary slime part produced during the crushing and grinding process of quartz vein-type tungsten-tin co-associated ore or the tailings part after flotation of sulfide ore with polymetallic ore is crushed to a particle size of less than 0.03mm;

[0028] (2) Gravity enrichment: use a shaker to carry out gravity separation and throw tailings, and the amount of gangue tailings is 60%;

[0029] (3) Reverse flotation desulfurization: primary roughing, the pulp concentration is 25%, the activator uses sulfuric acid solution with a mass concentration of 1%, the dosage is 10g / t, pH=6, and the collector uses a mass concentration of 1% Butyl xanthate solution, the dosage is 1g / t, the foaming agent is 1% methyl isobutyl carbinol solution, the dosage is 1g / t, and the flotation time is 3 minutes;

[0030] (4) Reverse flotation desiliconization: primary roughing...

Embodiment 3

[0034] A fine-grained tungsten-tin co-associated ore beneficiation process, the specific steps are as follows:

[0035] (1) The secondary slime part produced during the crushing and grinding process of quartz vein-type tungsten-tin co-associated ore or the tailings part after flotation of sulfide ore with polymetallic ore is crushed to a particle size of less than 0.03mm;

[0036] (2) Gravity separation and enrichment: adopt centrifugal concentrator to carry out gravity separation and throw tailings, and the amount of gangue tailings is 65%;

[0037] (3) Reverse flotation desulfurization: primary roughing, the pulp concentration is 26%, the activator uses sulfuric acid solution with a mass concentration of 2%, the dosage is 50g / t, pH=5.8, and the collector uses 2% sulfuric acid solution Butyl xanthate solution, the dosage is 10g / t, the foaming agent adopts pinitol oil solution with a mass concentration of 2%, the dosage is 5g / t, and the flotation time is 4 minutes;

[0038] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com