Preparation method for high-conductivity graphene and silver nanoparticle composite materials

A composite material and high conductivity technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of reducing the conductivity of composite materials and complicated preparation methods, and achieve enhanced conductivity, Effects of inhibiting aggregation and ensuring electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

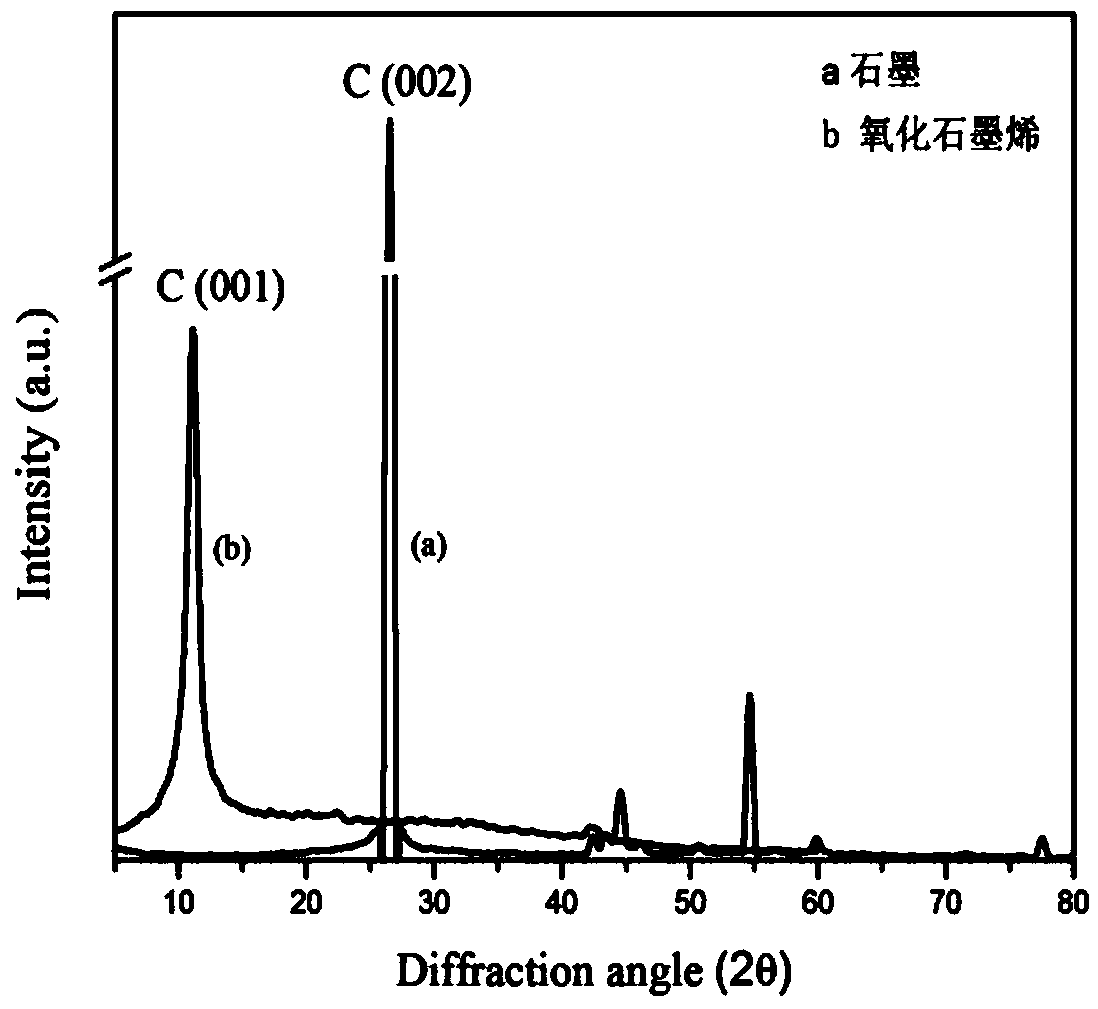

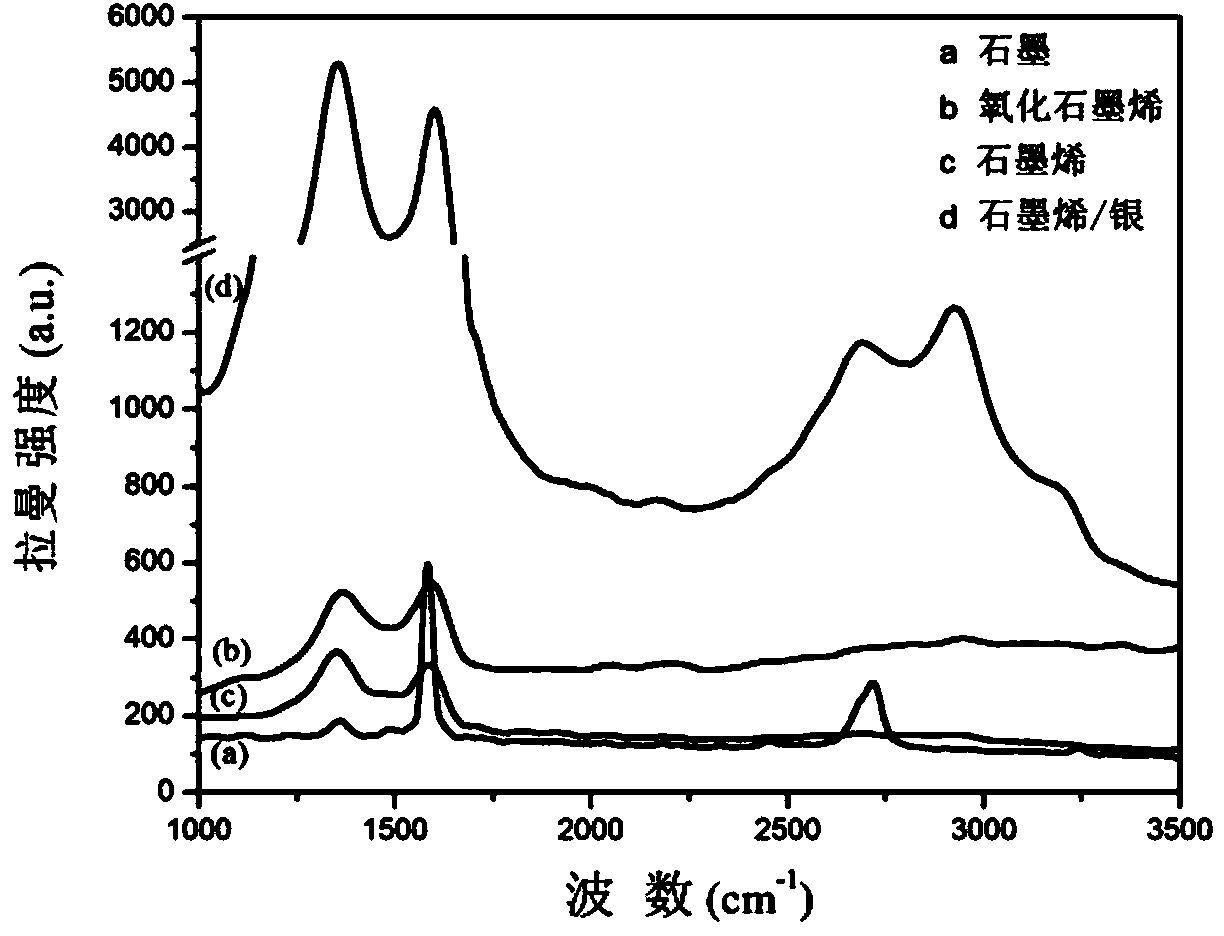

[0043] (1) Preparation of graphene oxide: Add 1g of graphite and 1g of sodium nitrate to 46ml of concentrated sulfuric acid (70%) in an ice-water bath, stir at 350rpm / min for 1h, add 6g of potassium permanganate at a temperature of 0-20°C, and heat up to React at 35°C for 60 minutes, add 90ml of deionized water dropwise, heat up to 95°C for 30 minutes, and finally add 10ml of hydrogen peroxide and 200ml of deionized water, wait until the reactant turns brown, centrifuge while hot (1000rpm for 2min, remove Precipitate, repeat 3 times; centrifuge at 8000rpm for 15min, collect the precipitate, repeat 3 times). Then wash with (5%) hydrochloric acid, ethanol and deionized water until the pH is neutral, freeze-dry in vacuum for 24 hours, and collect graphene oxide;

[0044] (2) Preparation of graphene oxide aqueous solution: 0.025g of graphene oxide was dissolved in 100ml of deionized water, and ultrasonically treated at 40KHz and 150W for 90min;

[0045] (3) Preparation of graphen...

Embodiment 2

[0048] 1) Preparation of graphene oxide: Add 2g of graphite and 2g of sodium nitrate to 92ml of concentrated sulfuric acid (98%) in an ice-water bath, stir at 350rpm / min for 1h, add 12g of potassium permanganate at a temperature of 0-20°C, and raise the temperature to 30 ℃ for 90 minutes, add 180ml of deionized water dropwise, heat up to 98℃ for 60 minutes, and finally add 20ml of hydrogen peroxide and 400ml of deionized water, wait until the reactant turns brown, and centrifuge while it is hot (500rpm for 2min to remove the precipitate matter, repeat 3 times; centrifuge at 7000rpm for 20min, collect the precipitate, repeat 3 times). Then wash with 5% hydrochloric acid, ethanol and deionized water until the pH is neutral, freeze-dry in vacuum for 24 hours, and collect graphene oxide;

[0049] (2) Preparation of graphene oxide aqueous solution: 0.025g of graphene oxide was dissolved in 100ml of deionized water, and ultrasonically treated at 40KHz and 150W for 120min;

[0050] ...

Embodiment 3

[0053] (1) Same as step (1) in implementation example 1;

[0054] (2) Same as step (2) in implementation example 2;

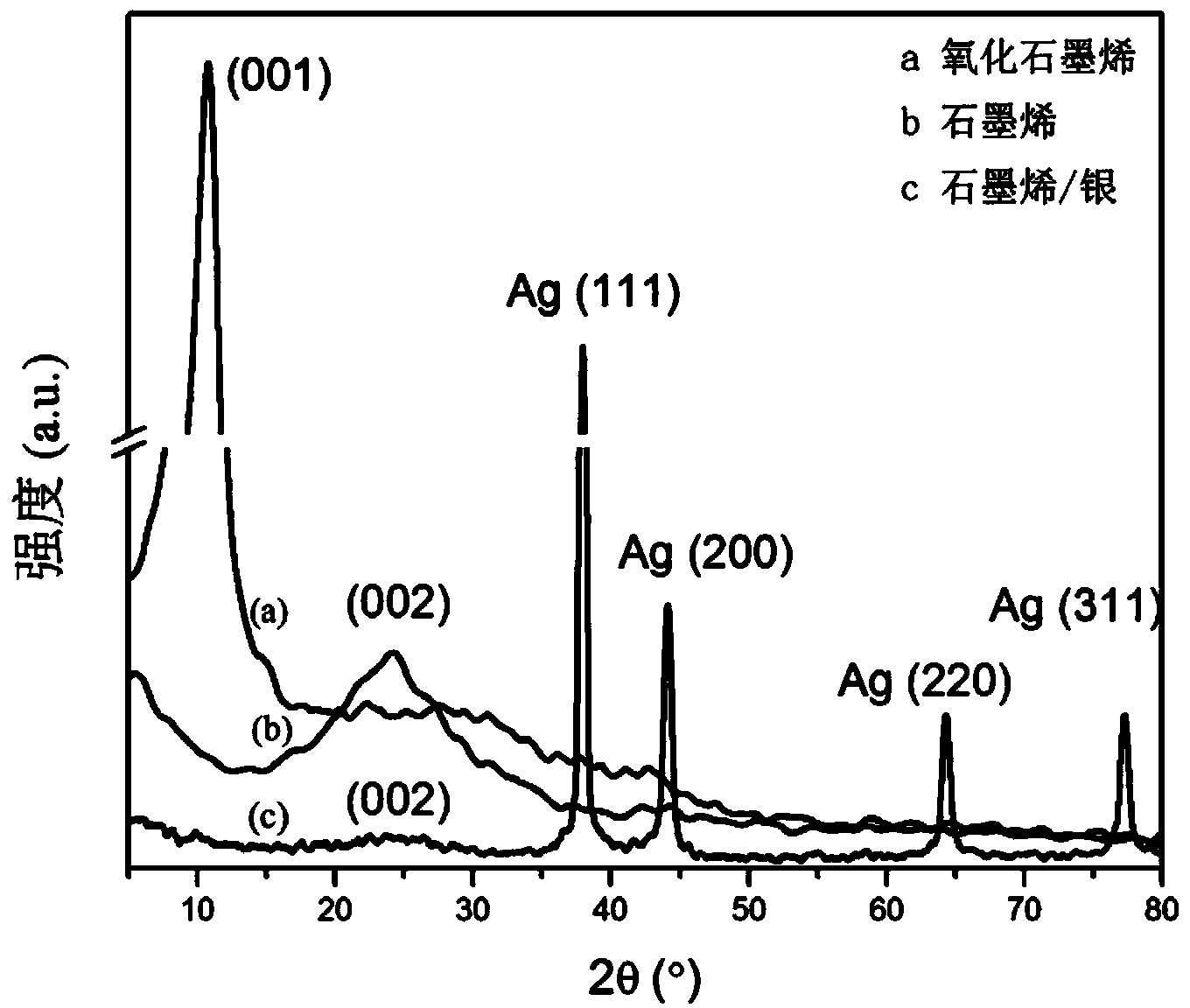

[0055] (3) Preparation of graphene / silver nanoconductive composite material: Add 0.125g of silver nitrate to the dispersion obtained in step (2), add 0.069g of sodium citrate after heating up to 98°C, stir and react at a constant temperature of 98°C for 1 hour, then add 350μl ammonia water (35%) to adjust the pH to 9, then add 27mg hydrazine hydrate (80%), stir and react at 98°C for 4h, centrifuge at 3000rpm for 5min while it is hot, and collect the precipitate; then wash it with deionized water and ethanol several times until the pH It was neutral, and finally vacuum freeze-dried for 12 hours to obtain a graphene / silver nanoconductive composite material.

[0056] The particle size of the silver nanoparticles in the graphene / silver nano conductive composite material is 10-60nm, and the distribution number is obviously more than that in Example 2; when the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com