Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Conductivity controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

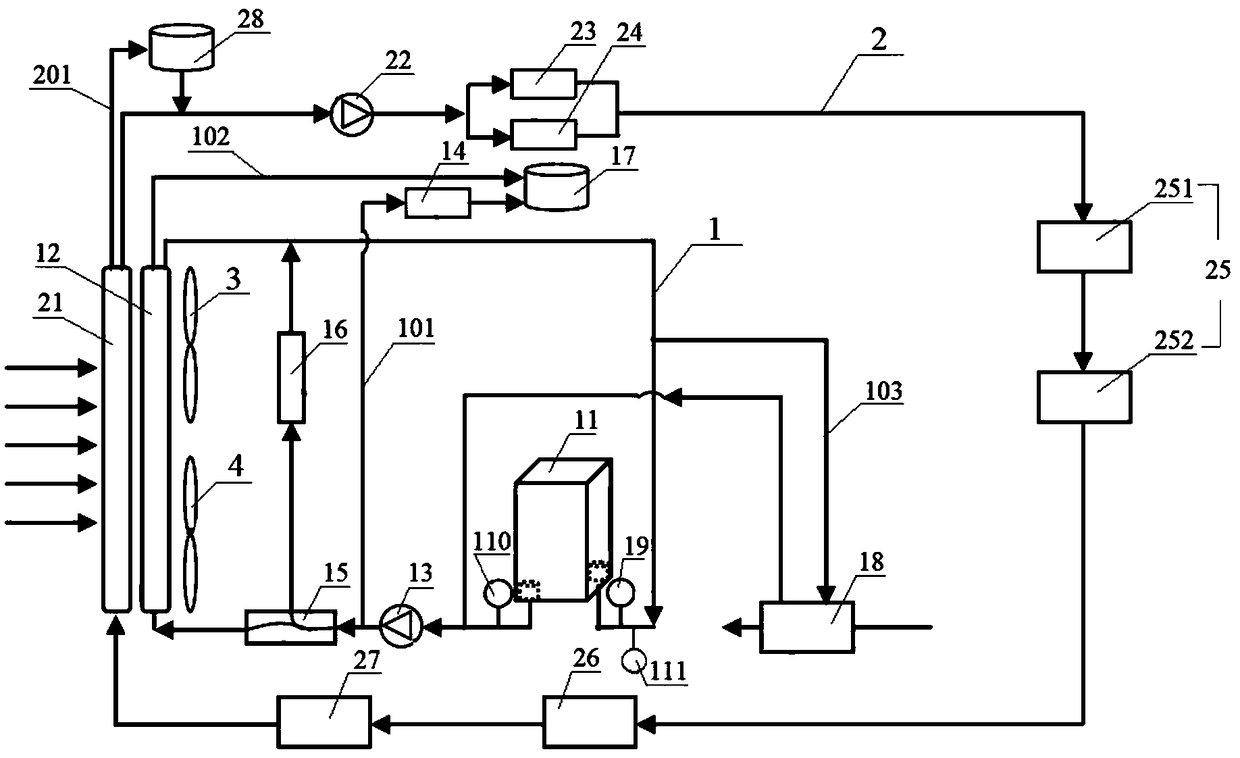

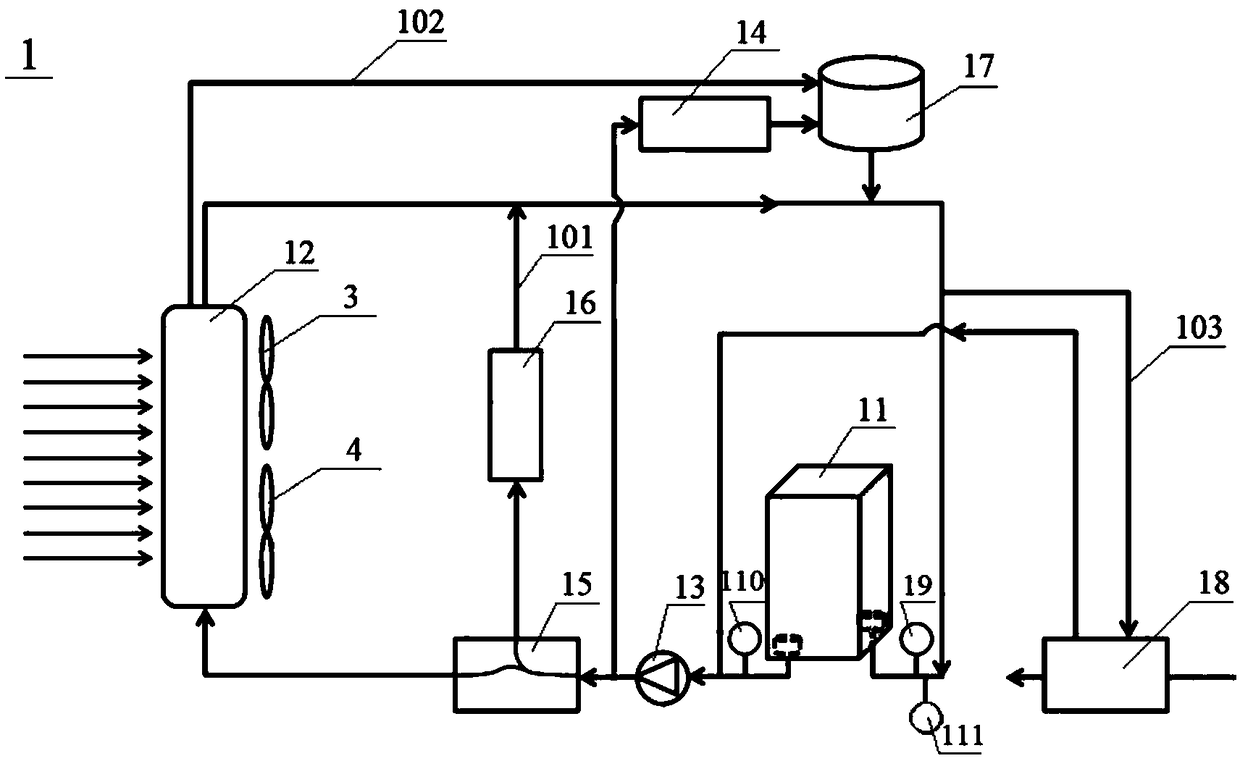

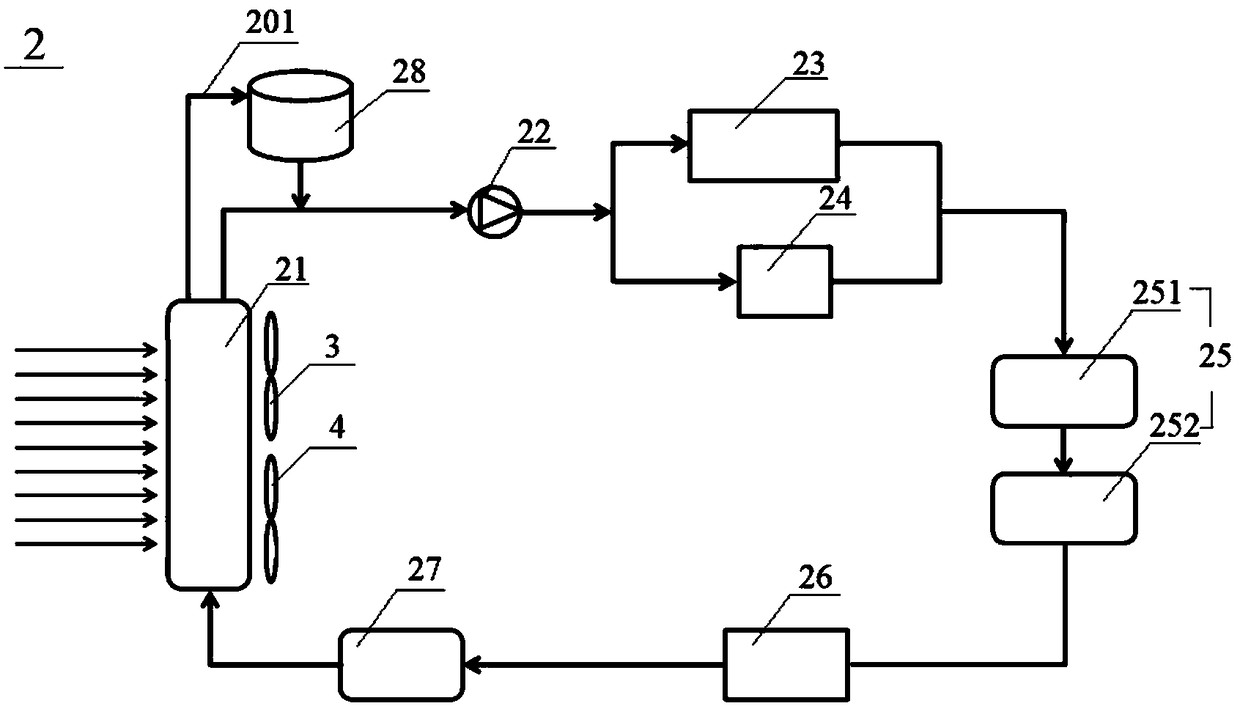

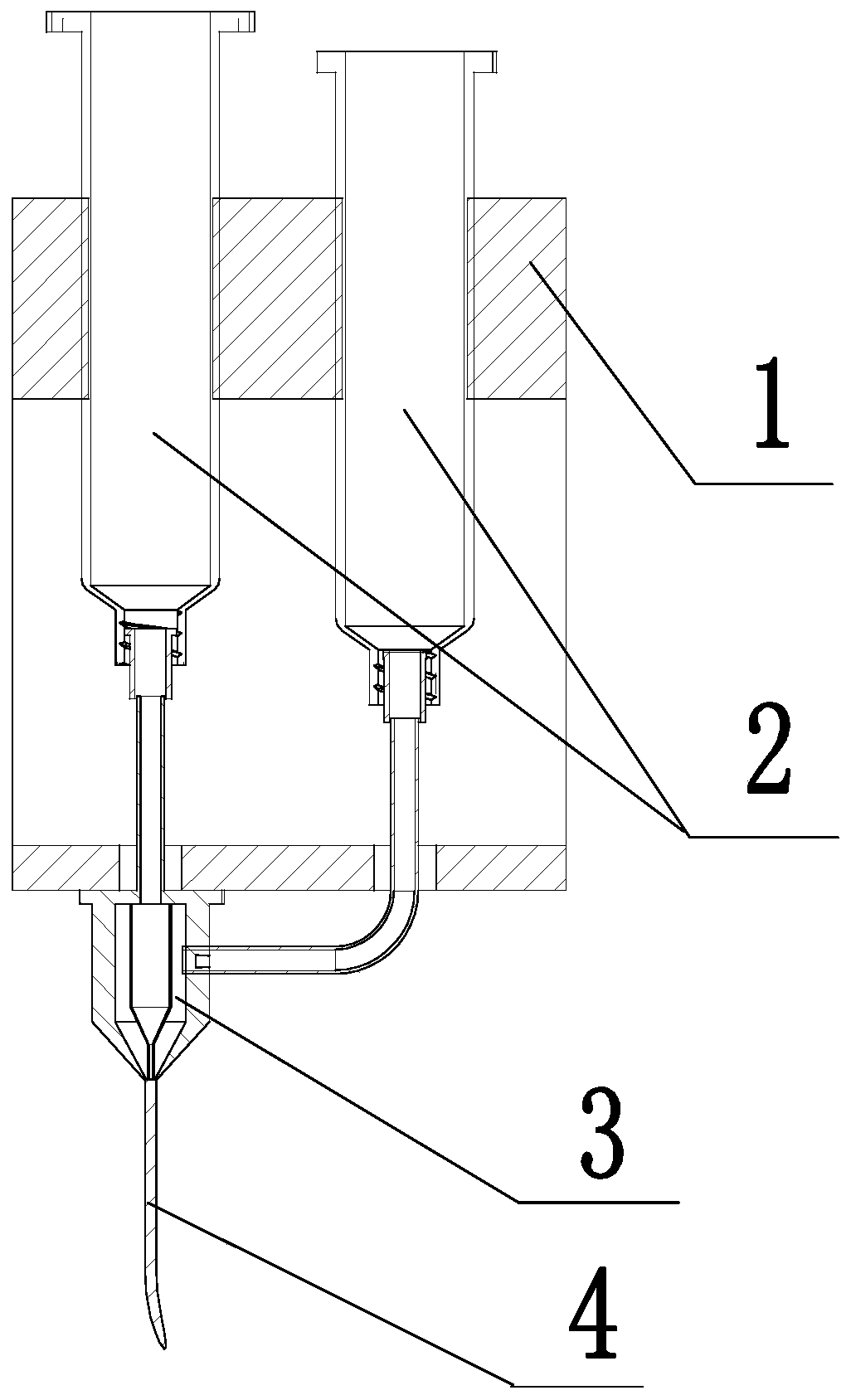

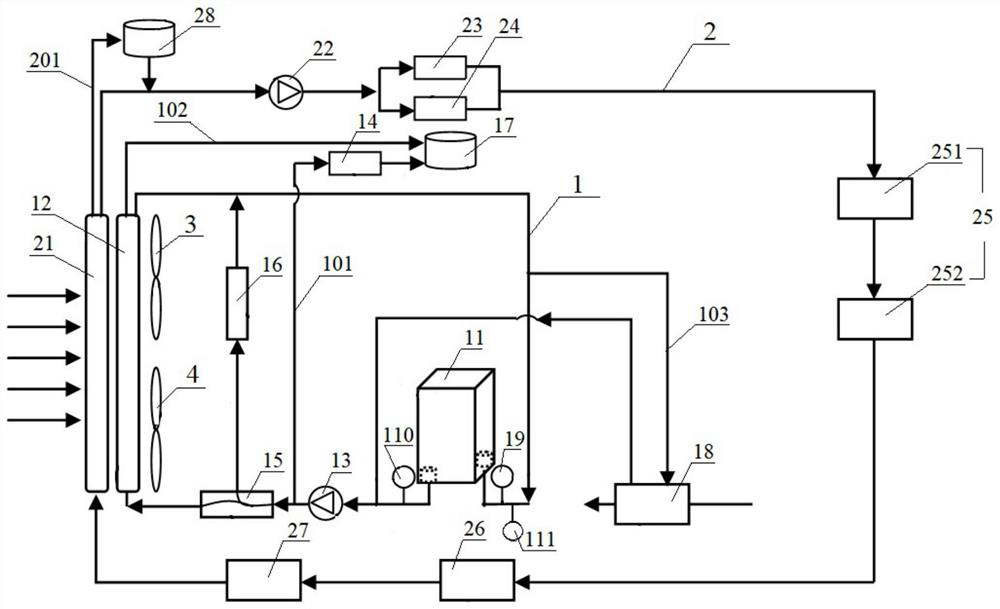

Hydrogen fuel cell automobile thermal management system

ActiveCN109278590AConductivity controllableReduce energy consumptionElectric energy managementFuel cellsElectro conductivityElectric drive

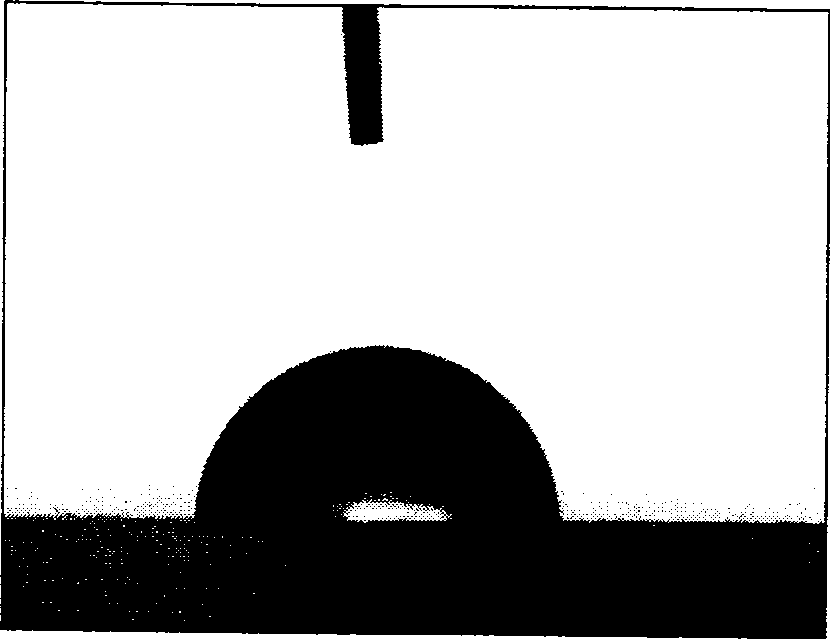

The invention discloses a hydrogen fuel cell automobile thermal management system. The hydrogen fuel cell automobile thermal management system comprises a first cooling loop (1) and a second cooling loop (2); the first cooling loop (1) cools a hydrogen fuel electric reactor (11); a first radiator (12), the hydrogen fuel electric reactor (11) and a circulating pump (13) are arranged on the first cooling loop (1); the first cooling loop (1) comprises a first branch (101) with a deionizater (14); the second cooling loop (2) cools a hydrogen fuel cell auxiliary system and an electric drive system;a second radiator (21), an electronic water pump (22), an air compressor driving motor (23), an air compressor controller (24), a DC / DC converter (25), a motor controller (26) and a vehicle driving motor (27) are arranged on the second cooling loop (2); and the first radiator (12) and the second radiator (21) are placed in the vehicle running direction in series. The hydrogen fuel cell automobilethermal management system has the characteristics of good heat radiation effect and controllable hydrogen fuel cell cooling liquid electrical conductivity.

Owner:CHERY AUTOMOBILE CO LTD

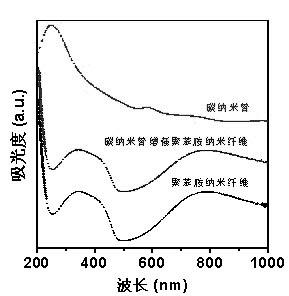

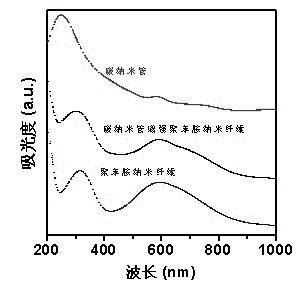

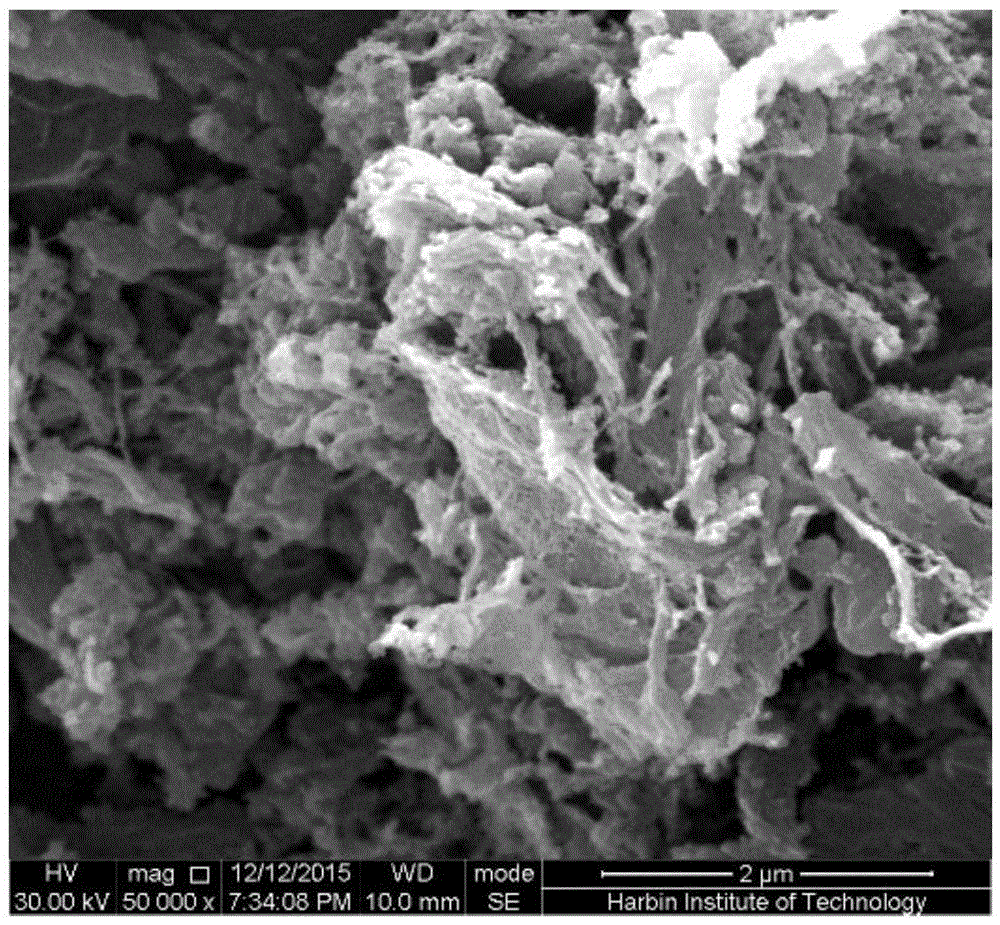

Carbon nano tube reinforced polyaniline nano-fiber and preparing method thereof

InactiveCN102558554AConductivity controllableOvercome the technical problem of not being able to conduct electricity under alkaline conditionsFiberPolymer science

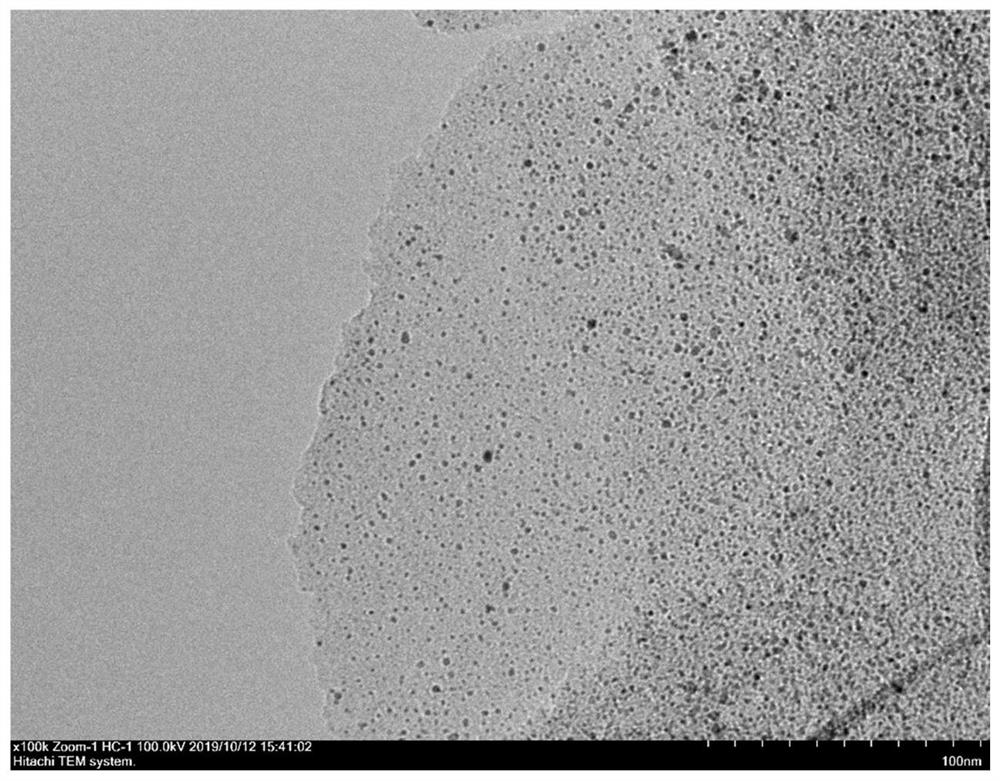

The invention discloses carbon nano tube reinforced polyaniline nano-fiber and a preparing method thereof. The preparing method includes steps of: adding aniline monomers and carbon nano tubes into dilute acid for ultrasound treatment to obtain carbon nano tube and aniline monomer blend solution; dissolving initiators into ethanol to form initiator solution and dissolving oxidants in dilute acid to form oxidant solution; and adding the initiator solution into the carbon nano tube and aniline monomer blend solution, then adding the oxidant solution, severely swinging for a moment, performing centrifugation, washing, redispersion and the like after standing reaction is complete so as to finally obtain the carbon nano tube reinforced polyaniline nano-fiber. The preparing method is simple, efficient and high in controllability. The carbon nano tubes can be uniformly dispersed on a polyaniline matrix. The mean diameter of the obtained carbon nano tube reinforced polyaniline nano-fiber is 30-60 nm, the length is 1-2 mu m, and electric conductivity is 10(-8)-10(2) S / cm, and the carbon nano tube reinforced polyaniline nano-fiber can be used in the application fields such as sensors, actuating devices, ultra-capacitors, electrochromatic windows, functional coatings and ultrafiltration membranes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method and application of polypyrrole/graphene/bacterial cellulose conducting film material

ActiveCN105609326AQuality improvementChemically stableHybrid capacitor electrodesHybrid/EDL manufactureElectrolytic agentCapacitance

The invention provides a preparation method and application of a polypyrrole / graphene / bacterial cellulose conducting film material. The invention relates to a preparation method and preparation of a conducting film material. A conducting film material prepared according to the existing method has poor stability, cycling performance and mechanical property and electrolyte adopted when the conducting film material is used as an electrode corrodes the conducting film material and a device. With adoption of the preparation method disclosed by the invention, all these problems can be solved. The method comprises the following steps: preparing bacterial cellulose pulp; preparing a graphene / bacterial cellulose composite material; preparing a polypyrrole coated graphene / bacterial cellulose composite material; directly carrying out vacuum filtering on the reaction solution of the polypyrrole coated graphene / bacterial cellulose composite material to form a film; and finally drying. The polypyrrole / graphene / bacterial cellulose conducting film material is applied to a supercapacitor. The polypyrrole / graphene / bacterial cellulose conducting film material can load high active matter mass in unit area, can be synthesized simply, has controllable electrical conductivity and good rate capability, can be put into large-scale production and can be used for preparing a symmetric supercapacitor with high capacitive character. The invention belongs to the technical field of nanomaterial.

Owner:HARBIN INST OF TECH

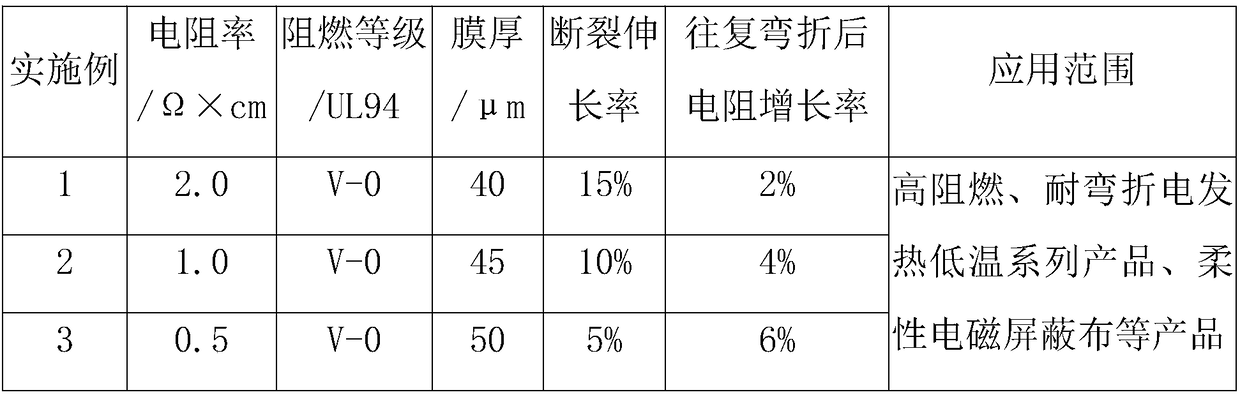

Graphene flame-retardant elastic composite, composite film and preparing method of composite film

The invention provides a graphene flame-retardant elastic composite. The composite is characterized by being prepared from, by mass, 0.5-10% of graphene microchips, 20-35% of fire retardant, 10-30% ofthermoplastic elastomer, 30-60% of solvent and 0.1-1.5% of auxiliaries. In addition, the invention further provides a composite film containing the graphene flame-retardant elastic composite and a preparing method of the composite film. The composite obtained with the thermoplastic elastomer, the fire retardant and the solvent with different elasticity moduli as the film forming materials and thegraphene microchips as the conductive filler has the advantages of flame retardance, high conductivity, bendability, high adhesiveness and the like, and therefore the composite film prepared from thecomposite also has the advantages of flame retardance, high conductivity, bendability, high adhesiveness and the like, and the composite film can be applied in the fields of electromagnetic shielding, far infrared electric heating products, flexible conductive electrodes and the like, is wide in application range, and effectively overcome the problems that an existing electric heating film product is poor in bending resistance and potential safety hazards such as spontaneous combustion are caused by local overheating.

Owner:中金态和(武汉)石墨烯科技股份有限公司

Conductive fiber preparation method and product thereof

The invention discloses a conductive fiber preparation method and a product thereof. The method comprises a step of uniformly coating a prepared conductive material comprising mixed solution of conductive particles or conductive polymer and photosensitive polymer and comprising uniform solution or suspension on the surface of a fiber by a dipping or spraying method, wherein a coating is cured under the irradiation of ultraviolet light, the conductive material is fixed on the surface of the fiber and the fiber is endowed with conductive performance; ultraviolet lamp light is used for irradiation, and the temperature of a lamp box is 25 to 125 DEG C; and in the curing process, the wavelength of the ultraviolet light source is controlled at 280 to 350 nanometers, the power is 150 to 250mW / cm2, and the irradiation time is 2 to 15 seconds. Compared with the prior art, the conductive fiber has the advantages of difficult drop of conductive components, durable conductivity, low resistance, soft handfeel, wearing comfortableness and the like; and the preparation method has simple process and low cost.

Owner:RONGSHENG PETROCHEM +2

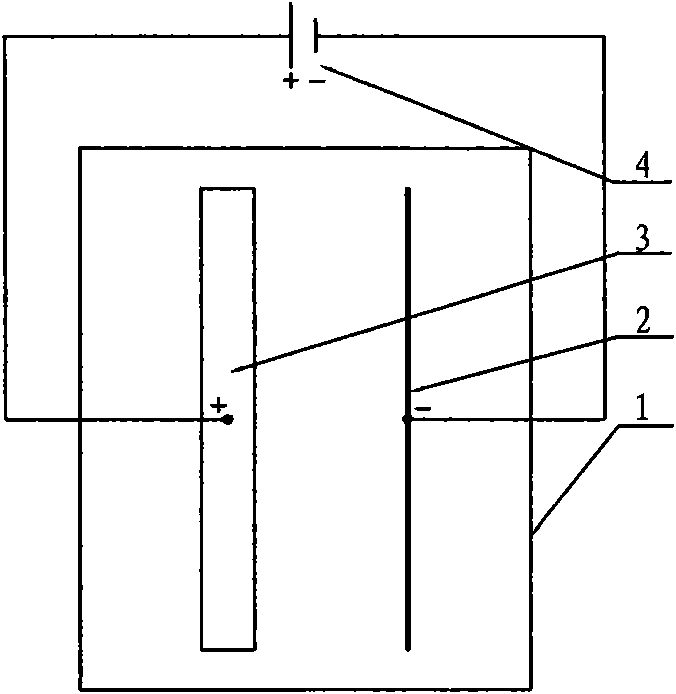

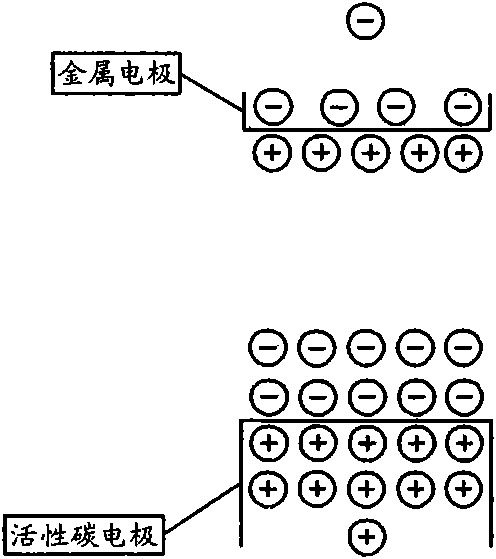

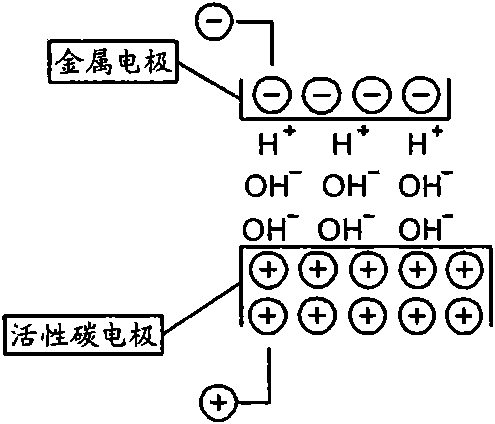

Reductive water non-diaphragm electrolysis device

InactiveCN102020341ARealize popularization of commercializationReduce consumptionWater/sewage treatmentActivated carbonStable state

The invention relates to a reductive water non-diaphragm electrolysis device belonging to the technical field of electrolysis of water and comprising an electrolyzer, a pair of negative electrode and positive electrode arranged in the electrolyzer, and a power supply electrically connected with the negative electrode and the positive electrode; one of the negative electrode and the positive electrode is an activated carbon electrode mainly made of activated carbon, and the other electrode is a metal electrode made of metal; the distance delta between the negative electrode and the positive electrode is not greater than 5m but is greater than 0. The device can adapt to various kinds of raw water and can prepare reductive water with wide pH range and a stable state without adding any substance directly by electrifying; moreover, compared with various water electrolysis devices, the reductive water non-diaphragm electrolysis device has lower power consumption and manufacturing cost, and thereby, the commercial popularization of the non-diaphragm electrolysis device can be implemented.

Owner:李国梅 +2

Graphene conductive fabric and preparation method thereof

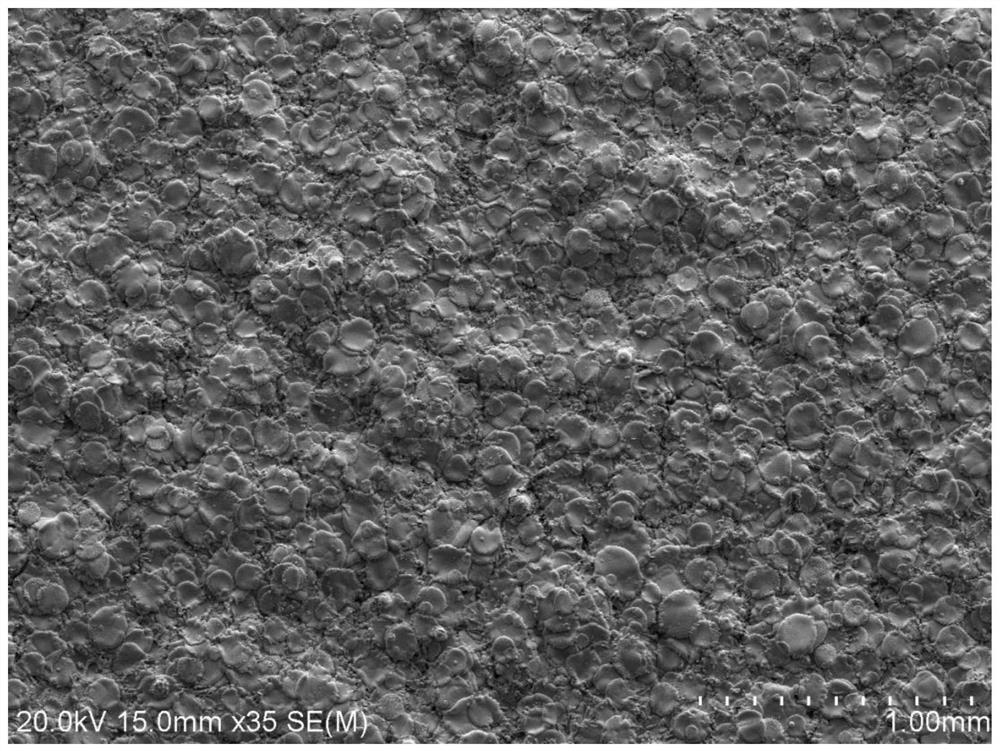

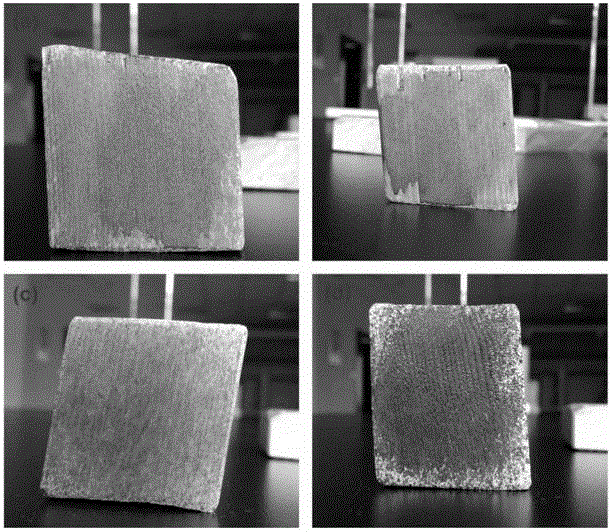

ActiveCN109944059AContributes to conductivityContributes to durabilityPhysical treatmentElectromagnetic shieldingLow temperature plasma

The invention provides a preparation method of a graphene conductive fabric. The method comprises the following steps of fabric pretreatment, plasma treatment, graphene oxide adsorption and reductiontreatment. The preparation method has the advantages that a low-temperature plasma surface treatment technology is adopted for grafting ammonium radical ions or branch ammonia radical ions onto the surface of a fabric, the adhesion force and uniform adsorption effect of graphene oxide rich in carboxyl functional groups on the surface of the fabric are improved, and the conductivity, durability andwater washing resistance of the fabric are improved; the operation is simple, the consumed time is short, and the batch production is facilitated; by controlling the concentration of the graphene oxide, the light antistatic fabric to the dark black conductive fabric can be prepared, and the conductivity is controllable; the graphene conductive fabric has bacterial resistance, electromagnetic shielding and other characteristics.

Owner:福建赛纤新材料有限公司

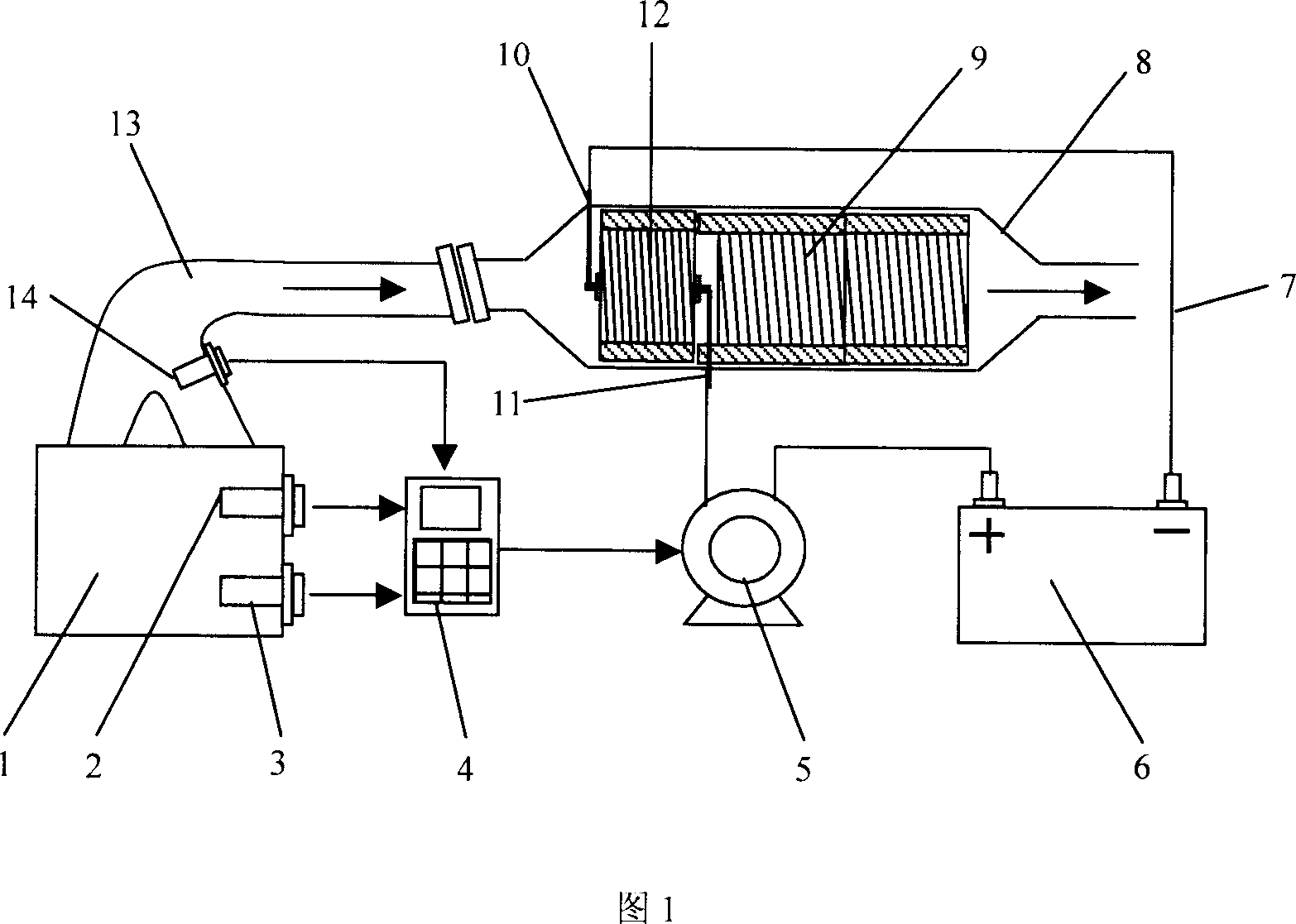

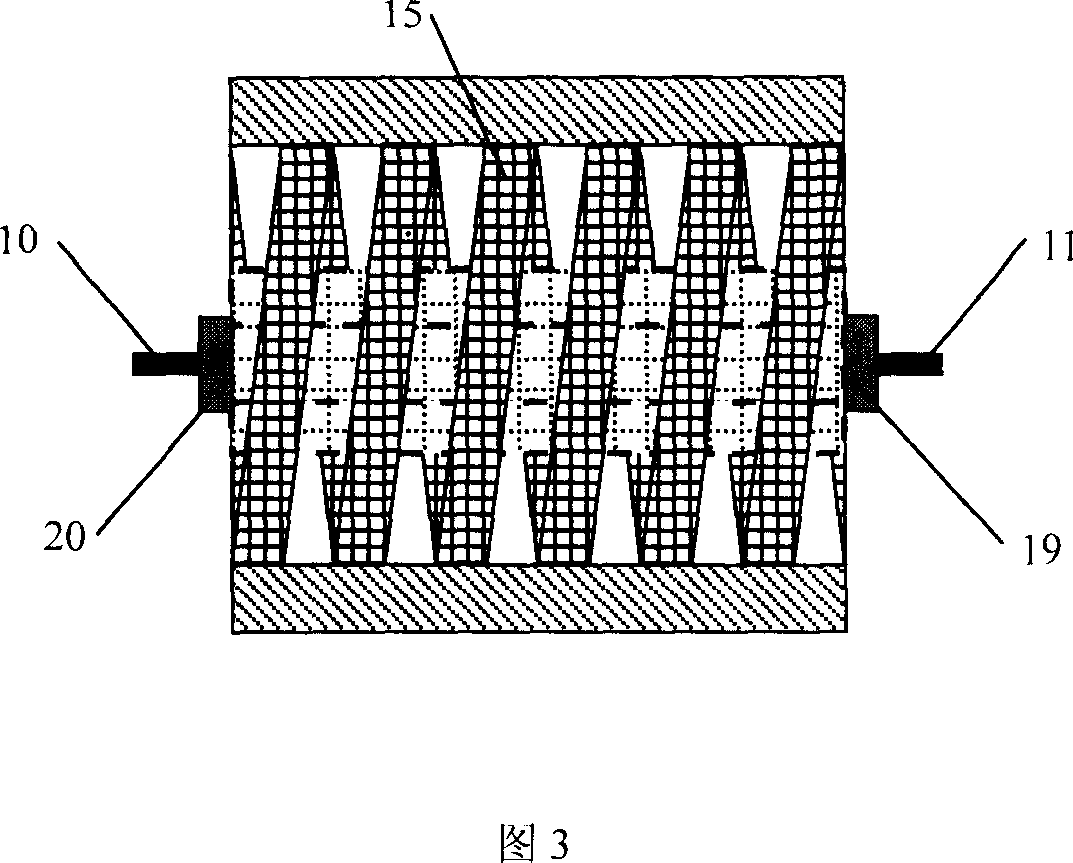

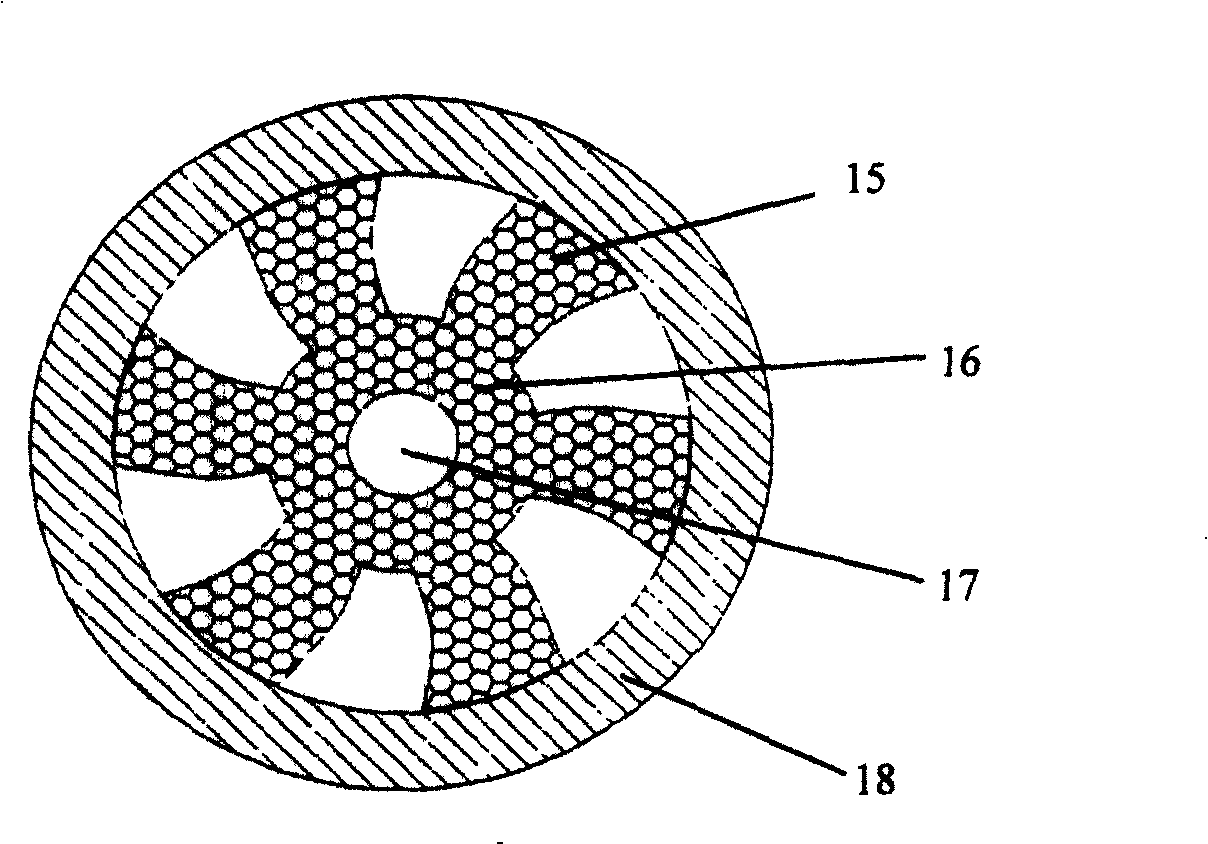

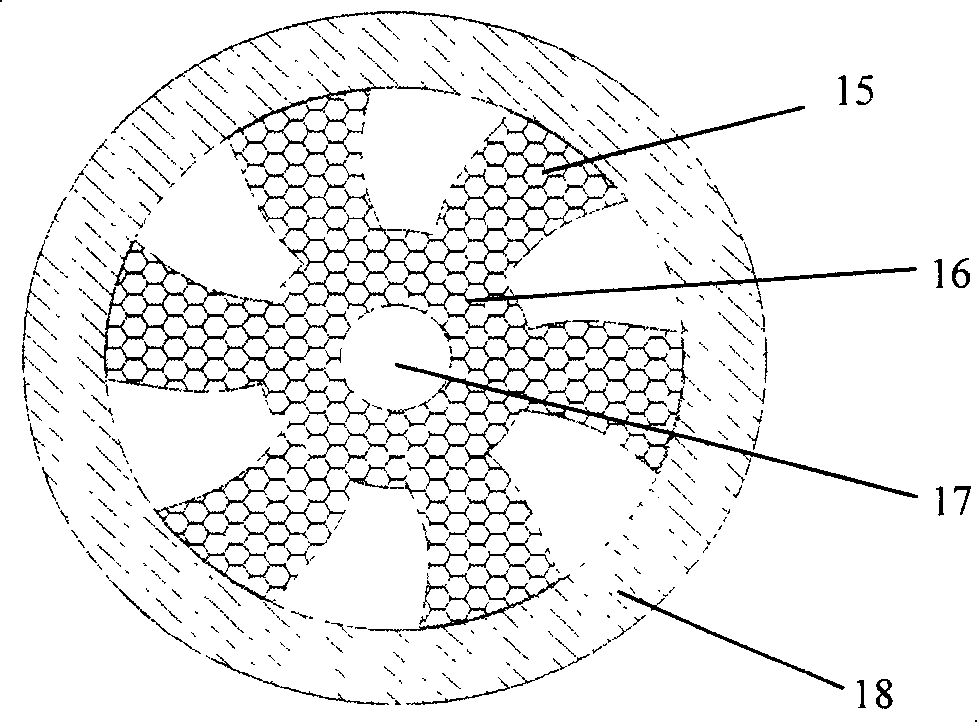

Spiral type filtering-regeneration device for particulates in exhaust gas from diesel vehicle

InactiveCN1966942AFast heat conductionUniform temperature distributionExhaust apparatusSilencing apparatusParticulatesElectricity

The particle filter and regeneration system of diesel engine comprises power, electric and nonelectric heat spiral particle filter made of carbide ceramics installing together inside the housing of the purifier connected with the exhaust of the diesel engine. It is highly efficient in purification and controllable in conductivity, and fine durability. Apart from that, it is low in cost, simple in structure and easy for assembly.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of cellulose-based composite material with high adsorption property

InactiveCN106824125ALarge specific surface areaImprove adsorption capacityOther chemical processesCongo redLithium chloride

The invention discloses a preparation method of a cellulose-based composite material with a high adsorption property. The method comprises the steps: firstly swelling straw cellulose powder, adding the straw cellulose powder to a lithium chloride / N,N-dimethylacetamide solution, dripping the straw cellulose solution into deionized water by using an injector under the stirring condition so the drops form cellulose microspheres with diameters of about 2mm, thus forming cellulose hydrogel microspheres; dispersing the cellulose hydrogel microspheres into a 1mol / L hydrochloric acid solution, adding a pyrrole monomer for stirring, wherein the temperature is 20-25 DEG C and the dispersing time is 2h which stirring at 50-100r / min; dripping the prepared ammonium persulfate water solution and continuously stirring; and washing surface ions by using the deionized water for multiple times to prepare the polypyrrole / cellulose-based composite microspheres. The obtained composite microspheres have excellent adsorption property on a negative dye congo red; and meanwhile, the method is simple in process, mild in reaction conditions and beneficial to massive production.

Owner:SOUTHWEST JIAOTONG UNIV

Application of conductive ink in electronic tag antenna

InactiveCN102437422ALow costThe production process is simpleRadiating elements structural formsLow temperature curingUltra fine

The invention relates to an application of conductive ink in an electronic tag antenna, belonging to the technical field of an electronic tag. Based on improvement in the structure and manufacturing of the existing electronic tag antenna, the application is mainly characterized in that an antenna pattern is printed on a substrate through a large roller printing machine with silver paste conductive ink, the silver paste conductive ink mainly comprises ultra-fine silver powder, is liquid thermosetting ink and has the characteristics of strong adhesion, low temperature curing, controllable conductivity, low resistance and the like, and the electronic tag antenna can be manufactured in a printing process, the film printed with the silver paste conductive ink is thin, uniform and smooth and has an excellent performance. The production cost is greatly reduced, the manufacturing process of the electronic tag antenna is simplified, the production efficiency is increased, the total thickness of the antenna is only one sixth of that of an aluminum etched antenna, and the applications of the manufactured electronic tag can be expanded due to the low cost and thin film.

Owner:ARIZON RFID TECH YANGZHOU

High-temperature-resistant enameled wire prepared by 3D printing and preparation method thereof

ActiveCN110322988AConductivity controllableFlexible designPlastic/resin/waxes insulatorsApparatus for heat treatmentSlurryGraphite

The invention relates to a high-temperature-resistant enameled wire prepared by 3D printing and a preparation method thereof, and belongs to the technical field of enamelled wires. The method is characterized in that conductive object powder is prepared into slurry or commercial conductive slurry is directly printed into a conductive inner core in a 3D printing mode, a high-temperature insulatingmaterial is prepared into thick slurry and then a high-temperature insulating material outer layer is obtained in the 3D printing mode; the conductive slurry or the powder is one or several kinds of graphene, graphite powder, carbon paste, conductive metal or modified ceramic; and the high-temperature-resistant insulating material is high-temperature-resistant insulating polyimide. The enameled wire prepared by the preparation method disclosed by the invention is excellent in mechanical property, chemical property, electrical property and thermal property; and the preparation method greatly simplifies the manufacturing process, the path can be designed, and the size can be customized, quick manufacturing is realized, and the method is particularly suitable for preparation of a small-diameter and micron-sized diameter enameled wire in batches, and provides a brand-new method for preparing the enameled wire.

Owner:烟台润创工业科技有限公司

Composite filtering-regeneration device for particulates in exhaust gas from diesel vehicle

InactiveCN100419227CFast heat conductionUniform temperature distributionExhaust apparatusSilencing apparatusParticulatesCarbide

It relates to the particle filter and regeneration system of the diesel engine, made of carbide ceramics, comprising the power and particle filter. His particle filter and regeneration system of diesel engine comprises power, electric and nonelectric heat spiral particle filter made of carbide ceramics installing together inside the housing of the purifier connected with the exhaust of the diesel engine. It is highly efficient in purification and controllable in conductivity, and fine durability. Apart from that, it is low in cost, simple in structure and easy for assembly.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of graphene organic silver conductive ink and preparation method thereof

The invention discloses a graphene organic silver conductive printing ink and a preparation method thereof. The conductive printing ink comprises a conductive function unit precursor, an organic silver complexing agent, an adhesive, a solvent and auxiliaries. The preparation method comprises the following steps: (A) stirring and ultrasonically dispersing the organic silver, the solvent and the organic silver complexing agent under a lucifugal condition to obtain an organic silver complexing solution; and (B) putting the graphene, the resin adhesive, the auxiliaries and the organic silver complexing solution in the lucifugal condition and stirring and ultrasonically dispersing in an environment lower than 10 DEG C, wherein the obtained uniform mixture is the graphene organic silver conductive printing ink. The graphene organic silver conductive printing ink prepared by the method disclosed by the invention is low in solid content, good in stability, good in printing performance and wide in application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Aminocarbazole/aniline copolymer and synthesis method thereof

InactiveCN102634018AThe polymerization method is simpleAggregation method is efficientOrganic chemistryLuminescent compositionsCarbazoleConductive polymer

The invention discloses an aminocarbazole / aniline copolymer and a synthesis method thereof. The synthesis method comprises the following steps: dissolving 3-amino-9-ethylcarbazole and aniline in different mol ratios in a first solvent to form a comonomer solution; dissolving a certain amount of oxidant in a second solvent to form an oxidant solution; and after blending the oxidant solution and the comonomer solution, shaking intensely for some time, standing, and reacting completely to obtain the aminocarbazole / aniline copolymer. The invention has the advantages of simple synthesis steps, high efficiency and high controllability; and the obtained carbazole / aniline conducting polymer can be used in the fields of electrodes, electron screening, electrostatic prevention, electrochromic materials, fluoroscopic examination and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

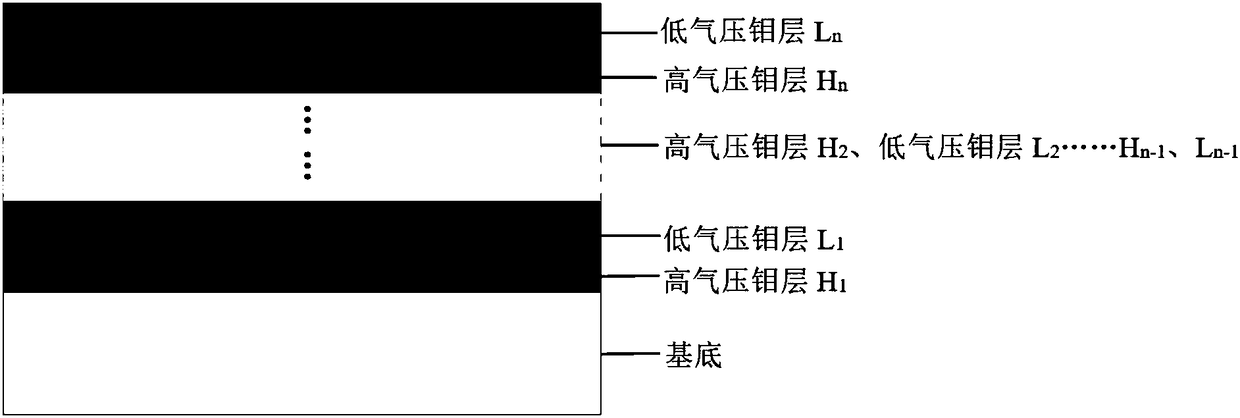

Solar cell back electrode, solar cell and preparation method of solar cell back electrode

ActiveCN108735825AConductivity controllableStrong adhesionPhotovoltaic energy generationSemiconductor devicesElectrical batterySolar battery

The invention provides the field of a solar cell, and particularly discloses a solar cell back electrode, a solar cell and a preparation method of the solar cell back electrode. The preparation methodof the solar cell back electrode comprises the step of sequentially and alternatively depositing high-atmospheric pressure molybdenum layers and low-atmospheric pressure molybdenum layers on a surface of one side of a substrate as a bottom electrode by a magnetron sputtering method, wherein the thicknesses of different high-atmospheric pressure molybdenum layers are respectively 30-200 nanometers, the thicknesses of different low-atmospheric pressure molybdenum layers are respectively 40-300 nanometers, the pressures of depositing different high-atmospheric pressure molybdenum layers are respectively 0.7-3.0Pa, and the pressures of depositing different low-atmospheric pressure molybdenum layers are respectively 0.01-0.5Pa. A periodic multi-layer alternative molybdenum-layer structure is prepared under high- and low- atmospheric pressures, the solar cell back electrode can have favorable electrical property, adhesive force and high-temperature stability, and the residual stress of thesolar cell back electrode is simultaneously reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Novel PCB/CCL waste regenerated resistance pulp and preparing method thereof

InactiveCN106847370AImprove performanceConductivity controllableNon-conductive material with dispersed conductive materialCable/conductor manufactureMaterials science

The invention discloses a novel PCB / CCL waste regenerated resistance slurry and a preparation method thereof. The novel PCB waste regenerated resistance slurry includes a conductive phase, a bonding phase and an organic carrier, wherein the conductive phase includes graphite and ultrafine metal alloy powder Alloy, PP, substrate mixed dust, binder phase includes inorganic filler, phenolic resin and benzomelamine, organic carrier includes hydrogenated castor oil, etc. PCB / CCL enterprise side materials are processed and crushed to replace the raw materials in existing products and reuse resources, which is in line with the development direction of China's national policy for solid waste reduction, harmlessness and resource utilization.

Owner:惠州新联兴实业有限公司

Spiral type filtering-regeneration device for particulates in exhaust gas from diesel vehicle

InactiveCN100392213CFast heat conductionUniform temperature distributionExhaust apparatusSilencing apparatusParticulatesElectricity

The particle filter and regeneration system of diesel engine comprises power, electric and nonelectric heat spiral particle filter made of carbide ceramics installing together inside the housing of the purifier connected with the exhaust of the diesel engine. It is highly efficient in purification and controllable in conductivity, and fine durability. Apart from that, it is low in cost, simple in structure and easy for assembly.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Graphene conductive coating with light-emitting function

ActiveCN109206964AImprove qualitySimple production processLuminescent paintsElectrically-conductive paintsConductive coatingCvd graphene

The invention discloses a graphene conductive coating having a light-emitting function, and the graphene conductive coating comprises the following components by weight: 1 part of a graphene dispersion; and 1 to 30 parts of a UV-curable glue; wherein the graphene dispersion is further composed of the following components by weight: 1 part of graphene and 1 to 100 parts of deionized water; the graphene conductive UV glue obtained by the manufacturing process has stable quality, simple production process and controllable conductivity, has the function of illuminating, can be sprayed on non-conducting objects that need to be electrically conductive to allow the non-conducting objects to produce electrical conductivity, can also be used for spraying on some heat-resistant materials, and can beconnected with electrodes to be used in electrothermal low-temperature heating materials.

Owner:中科国思生命健康科技(广州)有限公司

High obstructive polyaniline composite film and its preparation method and use

InactiveCN100506893CImprove barrier propertiesImprove waterproof performanceComposite filmMicrosphere

The invention relates to a polyaniline composite film with high barrier property, which is a film composed of polyaniline and polyvinylidene chloride copolymer microspheres with a diameter of 100-1000 nanometers. After mixing the aniline solution and the polyvinylidene chloride copolymer solution, put it into the liquid supply device of the electrospray device, spray the mixed liquid from the spray device, and then the solvent volatilizes to obtain solidified intrinsic state polyaniline on the receiving device Composite film; then obtained by irradiating under a 45W ultraviolet lamp for 1 to 30 minutes. The composite film can be formed on any material and any shape of substrate, and the thickness and conductivity of the film are adjustable. It has the properties of electromagnetic shielding, antistatic, waterproof, acid and alkali resistance, and high gas barrier. It can be widely used in military affairs. , navigation, aerospace, mining engineering, medicine and health, hardware, electromechanical, packaging and other industries.

Owner:INST OF CHEM CHINESE ACAD OF SCI

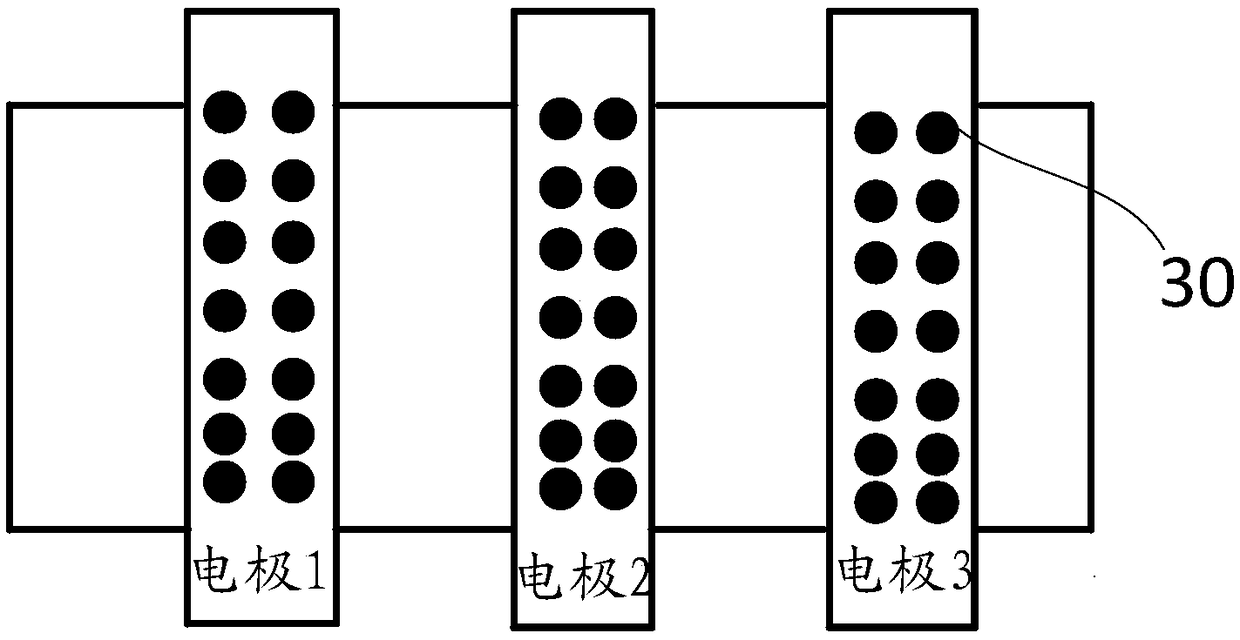

Method for improving activity of carbon fiber felt for vanadium battery

ActiveCN114068959AHigh activityImprove performanceCell electrodesRegenerative fuel cellsFiberCarbon fibers

The invention discloses a method for improving the activity of a carbon fiber felt for a vanadium battery, and belongs to the technical field of vanadium batteries. The method comprises the following steps: putting the carbon fiber felt into a sulfuric acid solution for ultrasonic treatment; immersing the upper end and the lower end which account for 1 / 4-1 / 3 of the total thickness of the felt into pyrrole-acetone liquid for modification; respectively putting the upper end and the lower end of the modified carbon fiber felt into nickel powder liquid and hydrogen peroxide for ultrasonic treatment, adjusting the height, and respectively carrying out ultrasonic treatment on the upper end and the lower end accounting for 1 / 3-3 / 4 of the thickness of the treated part; and carrying out calcining in nitrogen and acetylene, and finally soaking in mixed acid to obtain the electrode for the vanadium battery. Carbon nanotubes are introduced into the upper and lower ends of the carbon fiber felt by using a vapor deposition method, so that the pore diameters of the carbon fibers at the upper and lower ends are changed, the purposes of improving the activity of the carbon fiber felt and improving the performance of the vanadium battery are achieved, and the problem that the performance of the vanadium battery is influenced by non-uniform pore diameters of the carbon fiber felt due to physical extrusion stress during vanadium battery assembly is solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Method for preparing conductive coating on surface of composite material through plasma spraying

PendingCN113355627AHigh densityImprove bindingMolten spray coatingSurface engineeringConductive coating

The invention relates to the technical field of surface engineering, and provides a method for preparing a conductive coating on the surface of a composite material through plasma spraying. The method comprises the steps that a composite material base body is sequentially subjected to cleaning and sand blasting treatment, then the composite material base body is fixed to a workbench of plasma spraying equipment, and compressed air is adopted for cleaning the surface of the composite material base body; and the cleaned surface of the composite material base body is preheated, conductive metal powder is sprayed on the preheated surface of the composite material base body through a plasma spraying method, and the conductive coating is formed. The plasma spraying method is adopted for preparing the conductive coating on the surface of the composite material, the method is easy to operate, high in stability and controllability and suitable for spraying of large structural parts, and the prepared conductive coating is high in density, good in combination with the base body and controllable in conductivity.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A graphene conductive coating with luminescent function

ActiveCN109206964BImprove qualitySimple production processLuminescent paintsElectrically-conductive paintsConductive coatingAdhesive glue

Owner:中科国思生命健康科技(广州)有限公司

A ruthenium-modified sulfur-doped graphene two-dimensional material and its preparation and application

ActiveCN111068717BHigh yieldSimple processCatalyst activation/preparationElectrodesDoped graphenePtru catalyst

A ruthenium-modified sulfur-doped graphene two-dimensional material and its preparation and application. RuCl 3 ·6H 2 O and graphene oxide are added to deionized water, adjust the pH value to 0 to 6, disperse evenly with ultrasonic vibration, and then freeze-dry to remove the solvent to obtain a solid; the solid is roasted at high temperature in an inert atmosphere, cooled to room temperature, acid leached, and washed with water , dried to obtain a ruthenium-modified sulfur-doped graphene two-dimensional material. The ruthenium element-modified sulfur-doped graphene two-dimensional material prepared by the present invention has good conductivity, and the ruthenium element is evenly distributed as an active center; such ruthenium element-modified sulfur-doped graphene two-dimensional material can be used as electrocatalytic moisture Analytical hydrogen catalyst has the characteristics of low overpotential, high catalytic activity and long catalytic life.

Owner:NORTHWEST UNIV

zno conductive covariant substrate vertical structure type gan ultraviolet led

A ZnO conductive covariant substrate vertical structure type GaN UV LED uses a nano-pattern (PPS) sapphire as an epitaxial substrate, uses a MOCVD method to grow a ZnO low temperature buffer layer and a ZnO high temperature epitaxial layer, uses a ZnO epitaxial layer as a high quality conductive substrate, a GaN UV LED epitaxial is formed in a following step, and an LED chip is peeled and transferred, thus forming the ZnO conductive covariant substrate vertical structure type GaN UV LED. The novel vertical structure type GaN UV LED can reduce the device cost, and can improve the luminous efficiency of the GaN UV LED. The ZnO conductive covariant substrate vertical structure type GaN UV LED is simple in peeling technology, low in cost, and can be applied to the flexible substrate luminous project.

Owner:NANJING UNIV

A kind of graphene conductive fabric and preparation method thereof

ActiveCN109944059BContributes to conductivityImprove adsorption capacityPhysical treatmentReduction treatmentLow temperature plasma

The inventor provides a preparation method of a graphene conductive fabric, comprising the following steps: fabric pretreatment, plasma treatment, graphene oxide adsorption, and reduction treatment. The above technical scheme adopts low-temperature plasma surface treatment technology to graft ammonium ions or ammonium ions on the surface of the fabric, which enhances the adhesion and uniform adsorption effect of graphene oxide rich in carboxyl functional groups on the surface of the fabric, and helps the fabric Excellent conductivity, durability and washability; simple operation, short time-consuming, conducive to mass production; by controlling the concentration of graphene oxide, light-colored antistatic fabrics to dark black conductive fabrics can be prepared to achieve controllable conductivity ; Graphene conductive fabric also has antibacterial, electromagnetic shielding and other characteristics.

Owner:福建赛纤新材料有限公司

A kind of preparation method of the water-based coating that adjusts high insulation surface resistance

InactiveCN104152036BImprove adhesionConductivity controllableElectrically-conductive paintsWater basedHigh surface

The invention relates to a preparation method of a water-based paint for adjusting high insulating surface resistance. The steps are as follows: adding a dispersant into pure water to completely dissolve the dispersant to obtain an aqueous solution of the dispersant; adding aniline monomer and protonic acid to the above dispersant In the aqueous solution, stir evenly to obtain solution A; add the oxidant to pure water and stir until completely dissolved to obtain solution B; place solution A and solution B in a constant temperature tank, quickly mix solution A and solution B and stir until uniform, Polymerize at a constant temperature of -10 to 20°C for 10 to 20 hours to obtain a mixed solution; mix the mixed solution with pure water and stir until uniform to obtain a water-based coating with adjusted high insulation surface resistance. The water-based paint that the inventive method prepares can adjust the surface resistance of wood, plastics, pottery and glass to 10 3 ~10 10 Ωcm -2 , not limited by ambient humidity and temperature, the resistance of the high-insulation surface can be kept in the required range for a long time, and can be kept stable for two years, which has wide application value and industrial prospects.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

Anode material of electric/high pressure coupling elastic press and its installation and use method

ActiveCN106277694BExtended service lifeReduce loss costsSpecific water treatment objectivesElectrochemical sludge treatmentElectro conductivityCarbon fiber composite

The invention discloses an anode material of an electric / high-voltage coupled elastic press. It is a braided fabric obtained by mixing 30-60% carbon fiber and 40-70% polypropylene fiber or polypropylene fiber, that is, carbon fiber composite material cloth; the resistivity of carbon fiber is 36-144 ohm meters, and the tensile strength is 3530 Carbon fiber with ‑4410Mpa, denier 400‑700g / 1000m, flammability UL94V‑0, halogen content Cl<900, Br<900, Cl+Br<1500. The carbon fiber composite cloth can be installed behind the filter cloth of the anode filter frame of the conventional plate and frame filter, or the carbon fiber composite cloth can be directly replaced by the filter cloth of the anode filter frame, connected to the positive power supply, and used as an anode. In the present invention, the carbon fiber composite material is used as the anode material, and the electric conductivity is controllable, the cost is low, the service life is long, the energy utilization rate is high, and the installation mode is flexible.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

Conductive fiber preparation method and product thereof

The invention discloses a conductive fiber preparation method and a product thereof. The method comprises a step of uniformly coating a prepared conductive material comprising mixed solution of conductive particles or conductive polymer and photosensitive polymer and comprising uniform solution or suspension on the surface of a fiber by a dipping or spraying method, wherein a coating is cured under the irradiation of ultraviolet light, the conductive material is fixed on the surface of the fiber and the fiber is endowed with conductive performance; ultraviolet lamp light is used for irradiation, and the temperature of a lamp box is 25 to 125 DEG C; and in the curing process, the wavelength of the ultraviolet light source is controlled at 280 to 350 nanometers, the power is 150 to 250mW / cm2, and the irradiation time is 2 to 15 seconds. Compared with the prior art, the conductive fiber has the advantages of difficult drop of conductive components, durable conductivity, low resistance, soft handfeel, wearing comfortableness and the like; and the preparation method has simple process and low cost.

Owner:RONGSHENG PETROCHEM +2

A thermal management system for a hydrogen fuel cell vehicle

ActiveCN109278590BMeet thermal requirementsConductivity controllableElectric energy managementFuel cellsHydrogen fuel cellThermal management system

Owner:CHERY AUTOMOBILE CO LTD

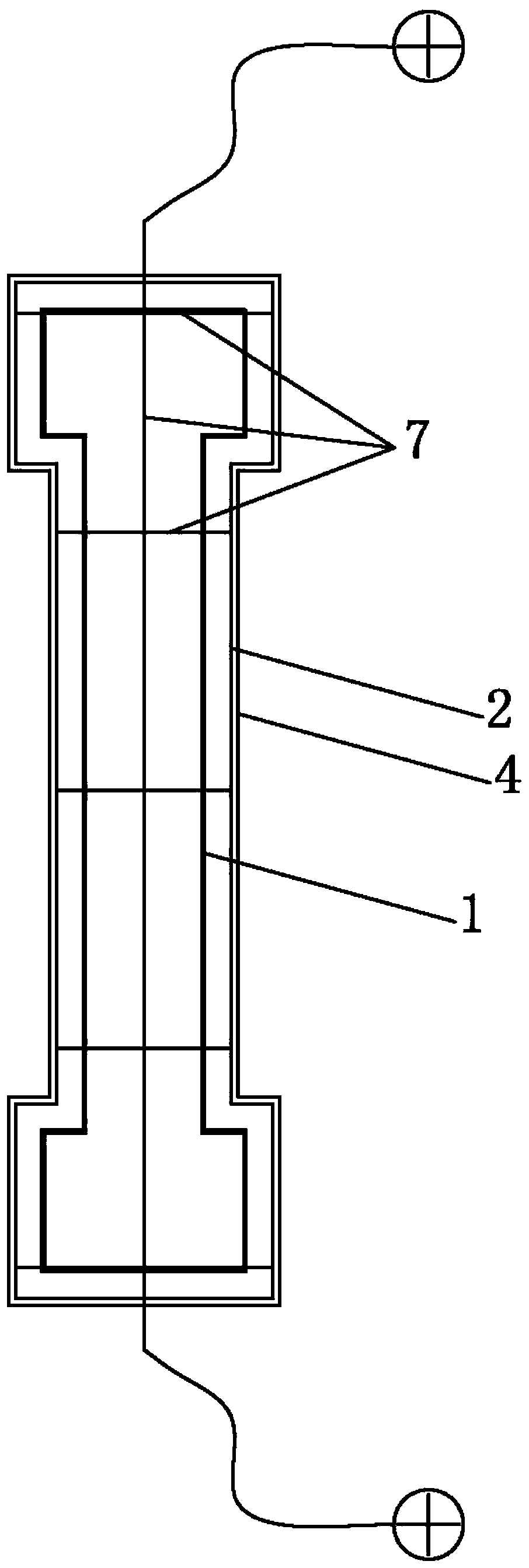

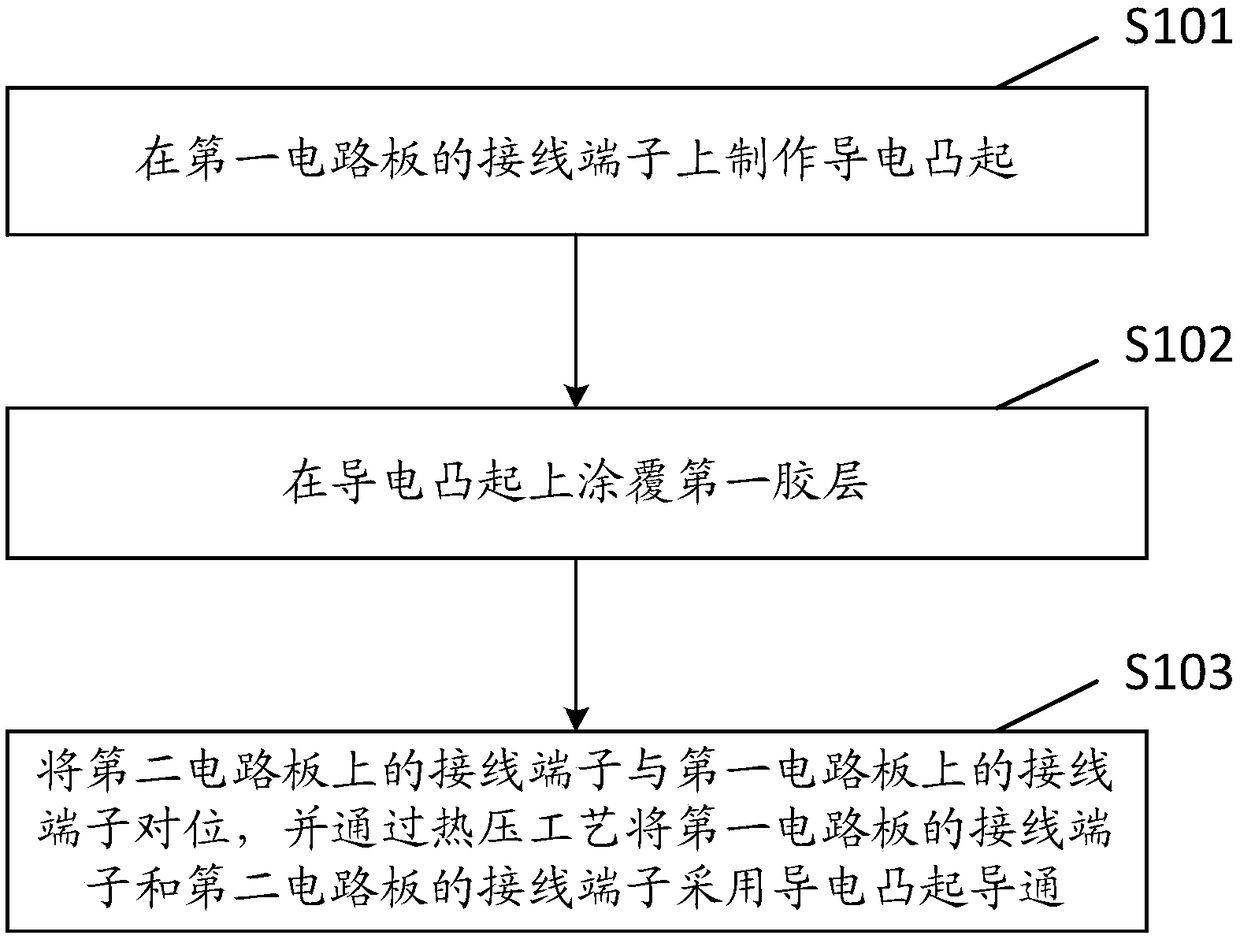

Binding method of display device, display panel and display device

InactiveCN109270716AConductivity controllablePrinted circuit assemblingNon-linear opticsDisplay deviceElectrode

The invention discloses a binding method of a display device, a display panel and the display device. The method is used for making the conduction condition of electric conduction particles of a peripherical electrode of a glass substrate. The binding method of the display device comprises the steps that an electric conduction protrusion is made on a wiring terminal of a first circuit board; the electric conduction protrusion is coated with a first glue layer; a wiring terminal of a second circuit board is aligned with the wiring terminal on the first circuit board, and the wiring terminal ofthe first circuit board and the wiring terminal of the second circuit board are conducted through the electric conduction protrusion and a hot press technology.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com