Preparation method of ultra-thin titanium dioxide nanosheet

A technology of titanium dioxide and nanosheets, which is applied in the field of ultra-thin single crystal titanium dioxide nanosheets, can solve the problems of large particles, and achieve the effects of simple preparation process, high ratio and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

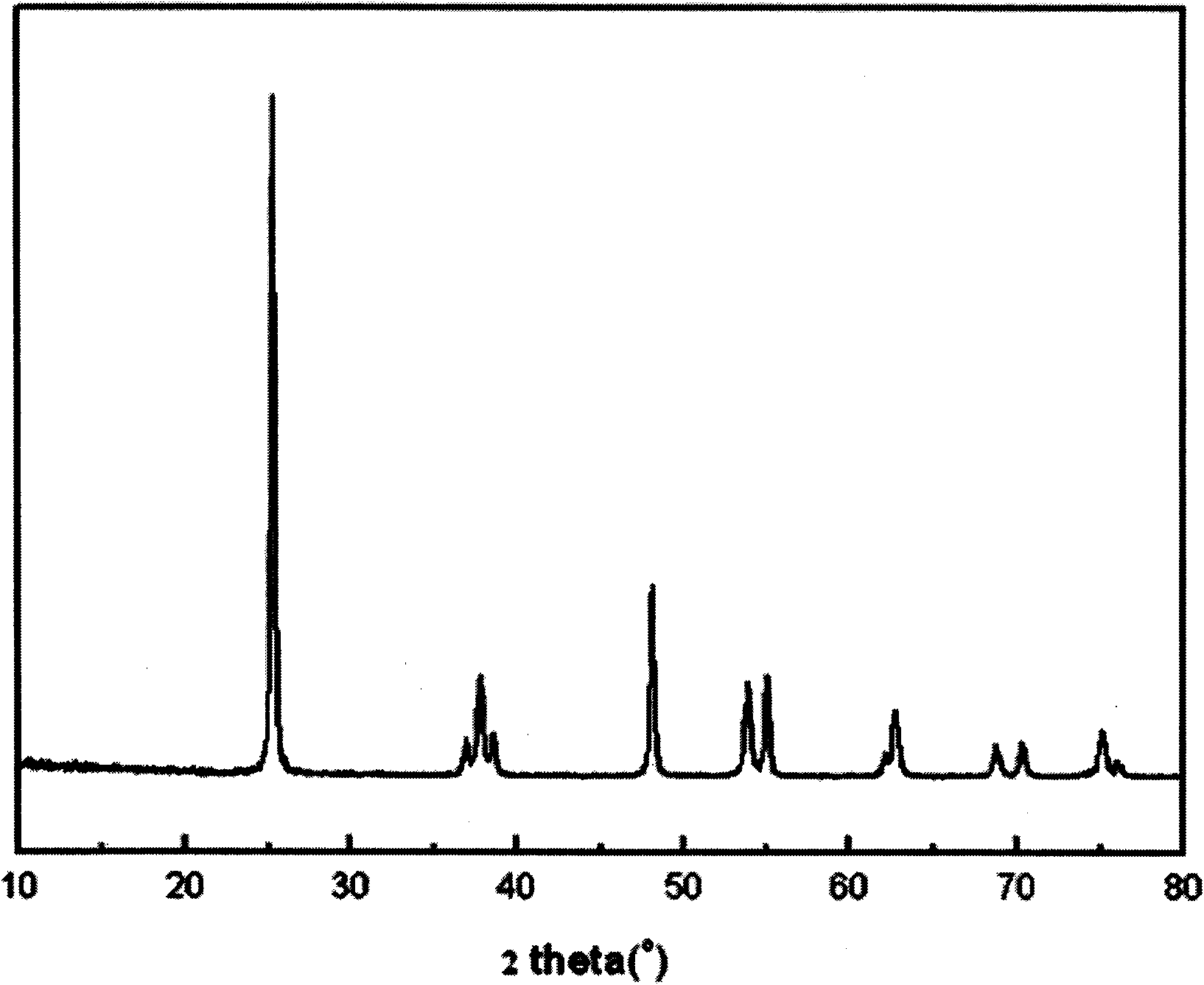

[0030] Inject 25ml of n-butyl titanate and 4.0ml of hydrofluoric acid into a 50ml polytetrafluoroethylene reactor sequentially, put them in a stainless steel container, press tightly, seal, and keep at 170°C for 20h. After the reaction, the supernatant was removed, and the white or blue product at the bottom was washed with alcohol several times, washed with water, and then vacuum-dried for 12 hours to obtain the target product. Picture 1-1 with Figure 1-2 It is a transmission electron microscope photo of the target product. It can be seen that titanium dioxide is a sheet structure, mainly rectangular and square, with a thickness of 4.4nm. Depend on Figure 1-3 It can be seen that the flaky titanium dioxide is anatase.

Embodiment 2

[0032]Inject 25ml of n-butyl titanate and 3.0ml of hydrofluoric acid into a 50ml polytetrafluoroethylene reactor sequentially, put them in a stainless steel container, press tightly, seal, and keep at 170°C for 20h. After the reaction, the supernatant was removed, and the white or blue product at the bottom was washed with alcohol several times, washed with water, and then vacuum-dried for 12 hours to obtain the target product. diagram 2-1 with Figure 2-2 It is a transmission electron microscope photo of the target product. It can be seen that the titanium dioxide is a sheet structure, mainly rectangular and square, with a small amount of irregular shape, and the thickness is 3.2nm.

Embodiment 3

[0034] Inject 25ml of n-butyl titanate and 3.0ml of hydrofluoric acid into a 50ml polytetrafluoroethylene reactor in sequence, put them in a stainless steel container, press tightly, seal, and keep at 160°C for 20h. After the reaction, the supernatant was removed, and the white or blue product at the bottom was washed with alcohol several times, washed with water, and then vacuum-dried for 12 hours to obtain the target product. Figure 3-1 with Figure 3-2 It is a transmission electron microscope photo of the target product. It can be seen that titanium dioxide is a sheet structure, mainly rectangular and square, with an increase in the number of irregularly shaped nanosheets compared to Example 2, and a thickness of 2.5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com