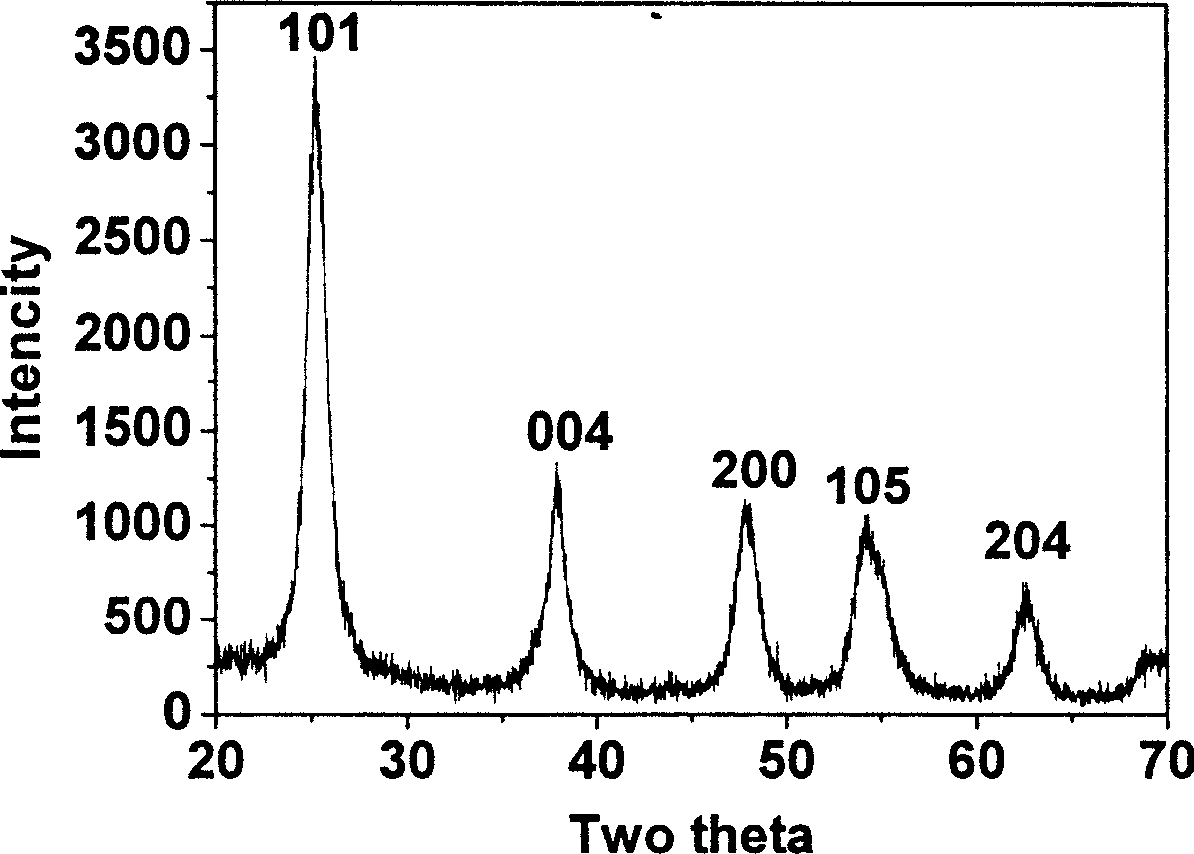

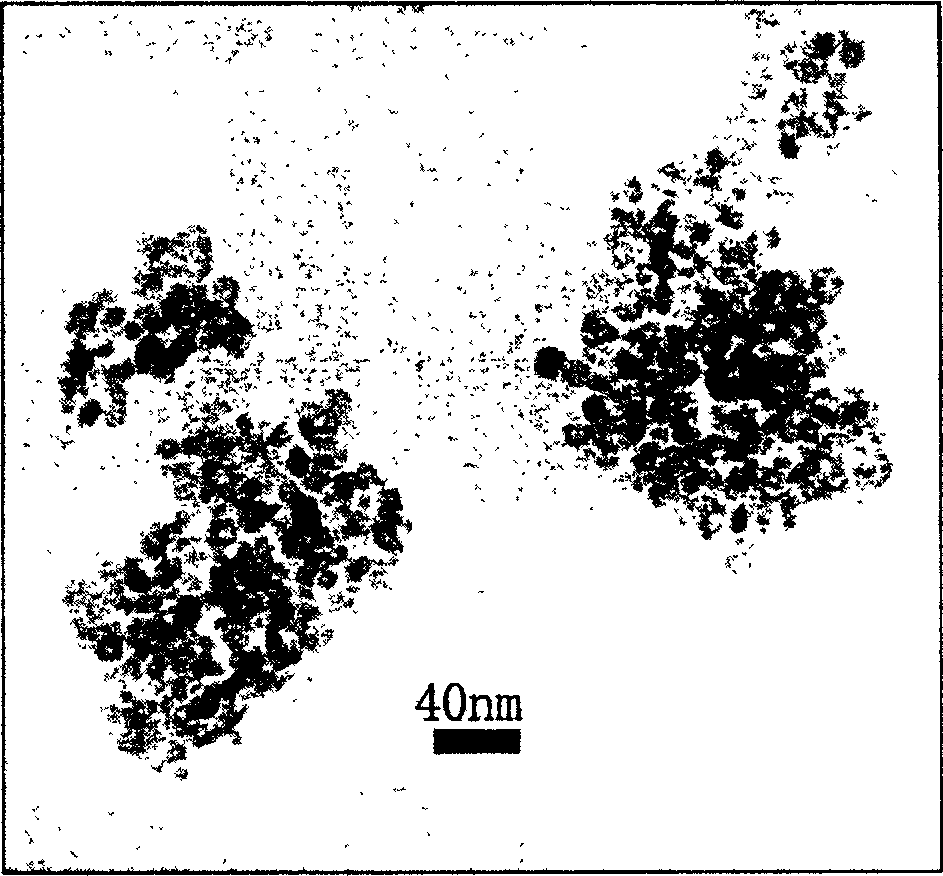

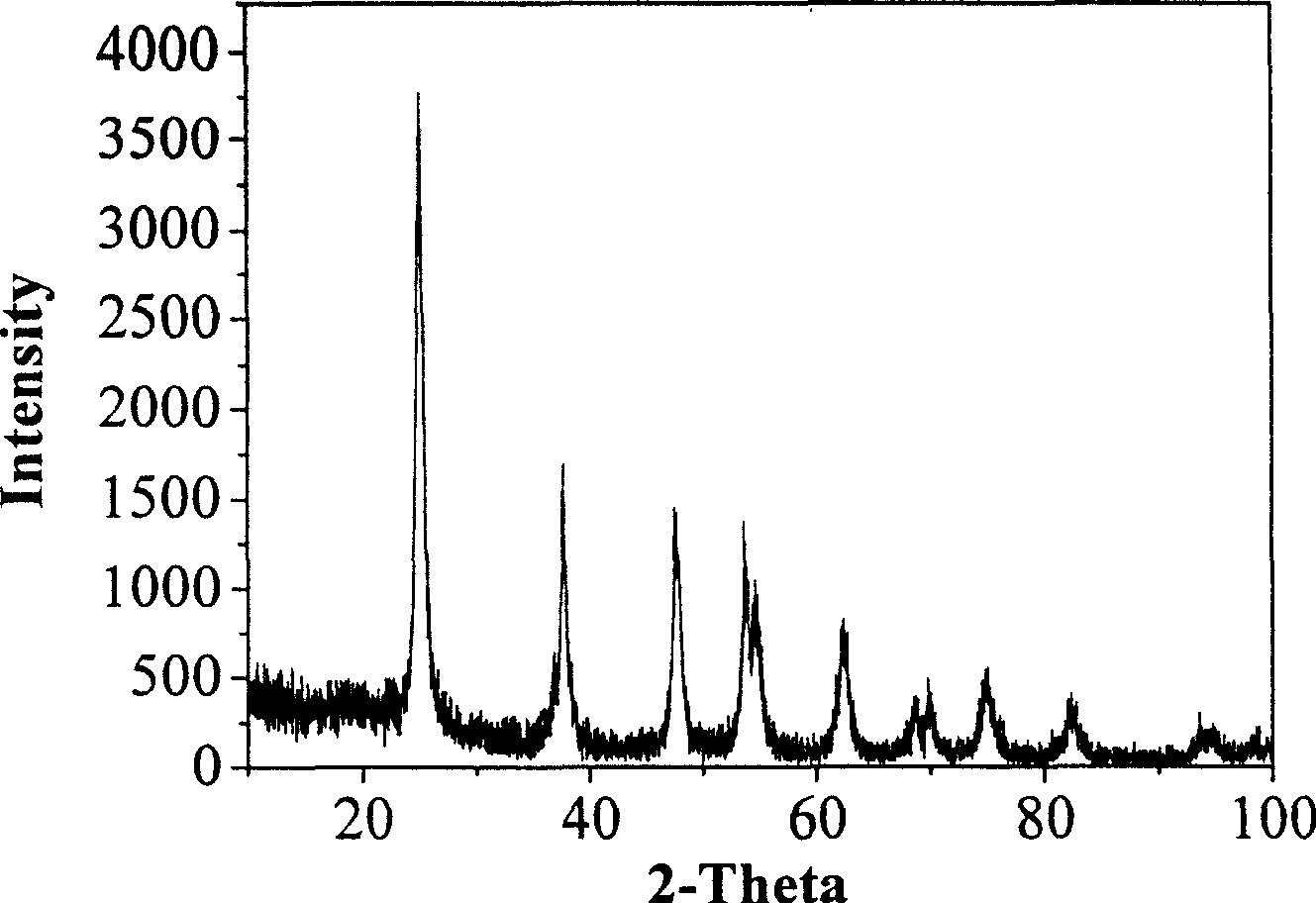

Production of nitrogen-doped anatase-type nanometer titanium dioxide

A nano-titanium dioxide, anatase-type technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effects of controllable grain size and high specific surface area of nano-TiO2 powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] With 1.3L deionized water as solvent, 0.25M industrial grade TiOSO 4 The solution is used as a precursor, 0.5M urea is added as a precipitating agent, 1.3L deionized water is added at 25°C, and they are dissolved by mechanical stirring. , kept at 110°C for 2h, then filtered with distilled water until Ba(NO 3 ) 2 The solution does not detect SO 4 2- After ionization, wash with absolute ethanol 5-8 times, and then dry in a water bath at 60°C for 12 hours.

Embodiment 2

[0018] With deionized water as] solvent, with 0.25M industrial grade TiOSO 4 The solution is used as a precursor, and 0.5M urea is added as a precipitating agent. The volume of the solution is 1.3L, and they are dissolved by mechanical stirring at 25°C. Insulate at 110°C for 24 hours, then filter with distilled water until Ba(NO 3 ) 2 The solution does not detect SO 4 2- After ionization, wash with absolute ethanol 5-8 times, and then dry in a water bath at 60°C for 12 hours.

Embodiment 3

[0020] Precursor industrial grade TiOSO 4 The concentrations of urea and precipitating agent are 0.25M and 0.5M respectively, add deionized water to make the solution volume 1.3L, add deionized water at 25°C, and dissolve them with mechanical stirring. , with a stirring speed of 300r / min, heat preservation at 110°C for 8 hours, and then filter with distilled water until the Ba(NO 3 ) 2 The solution does not detect SO 4 2- After ionization, wash with absolute ethanol 5-8 times, and then dry in a water bath at 60°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com