Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Controllable grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-toughness ultrafine-grained high-entropy alloy and preparation method thereof

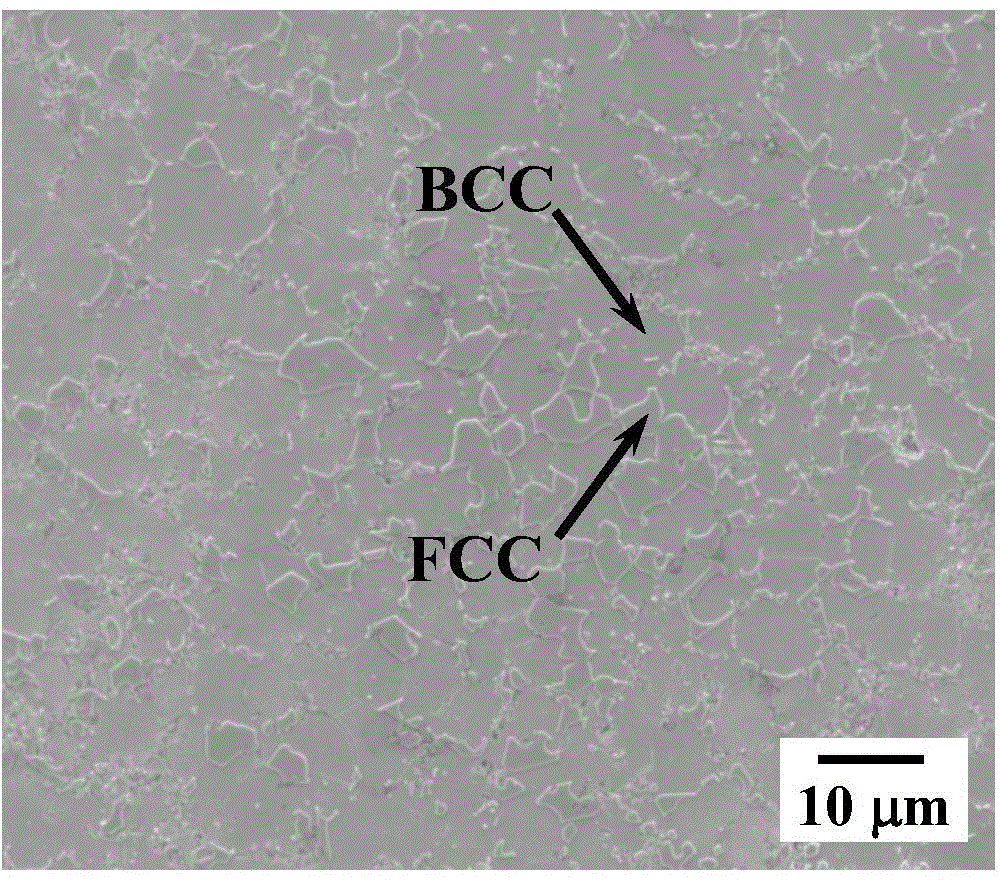

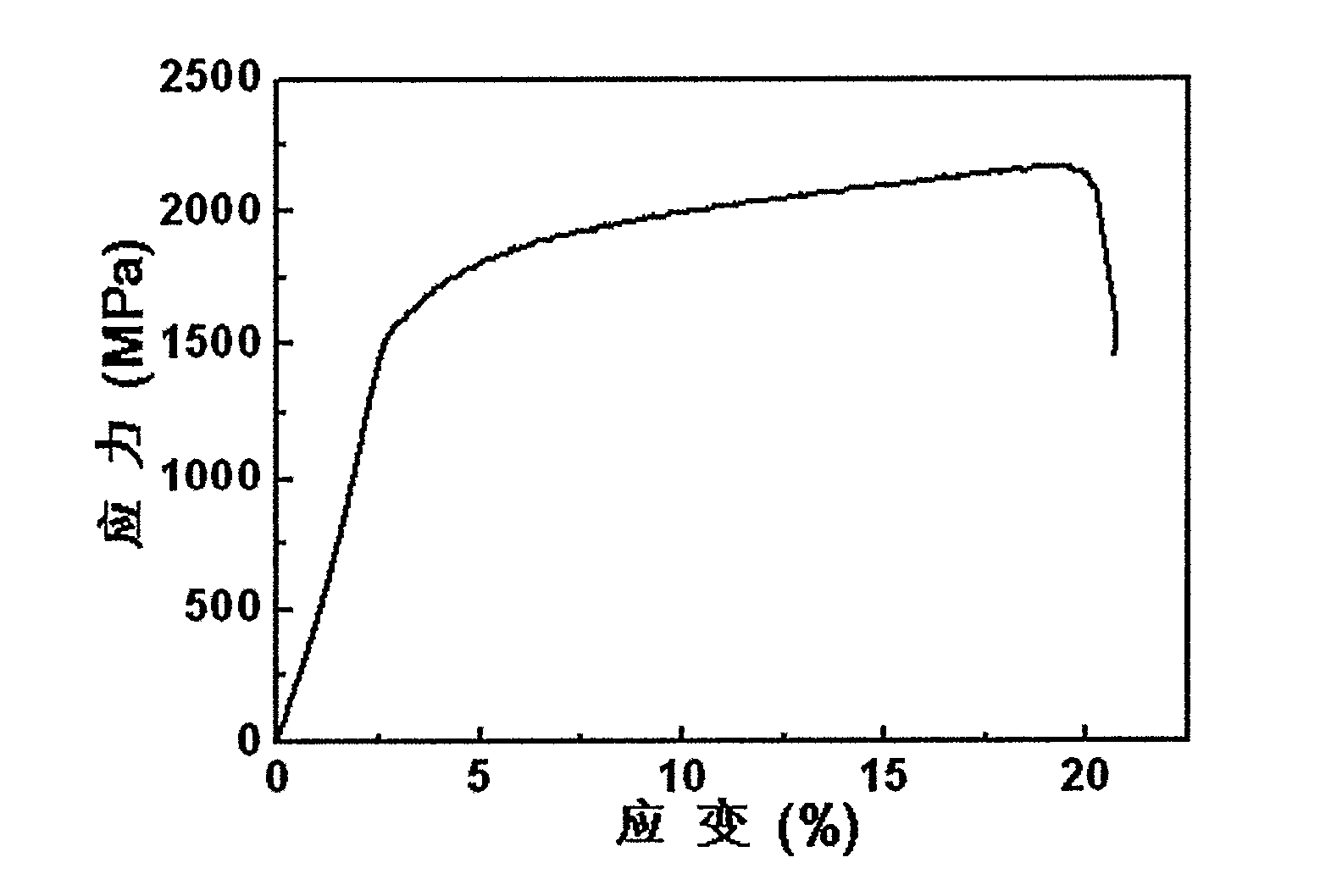

The invention belongs to the technical field of alloy material, and discloses a high-strength high-toughness ultrafine-grained high-entropy alloy and a preparation method thereof. The high-strength high-toughness ultrafine-grained high-entropy alloy is composed of the following elements according to the atomic percentage: 20%-25% of Ni, 18%-20% of Fe, 18%-22% of Co, 18%-20% of Cr, and 20%-24% of Al; the microstructure takes a body-centered cubic disordered solid solution phase rich in Ni and Al elements as a matrix phase, and takes a face-centered cubic disordered solid solution phase rich in Fe and Cr elements as a reinforcing phase. The preparation method of the alloy comprises the steps: elemental powders with the atomic percentages are subjected to powder mixing and high-energy ball milling to prepare an amorphous composite powder, and the amorphous composite powder is sintered to obtain the high-strength high-toughness ultrafine-grained high-entropy alloy. The prepared high-entropy alloy has the advantages of large size and good comprehensive mechanical properties, and can be used in the fields of aeronautics and astronautics, military industry, electrons, instruments and apparatuses and the like.

Owner:SOUTH CHINA UNIV OF TECH

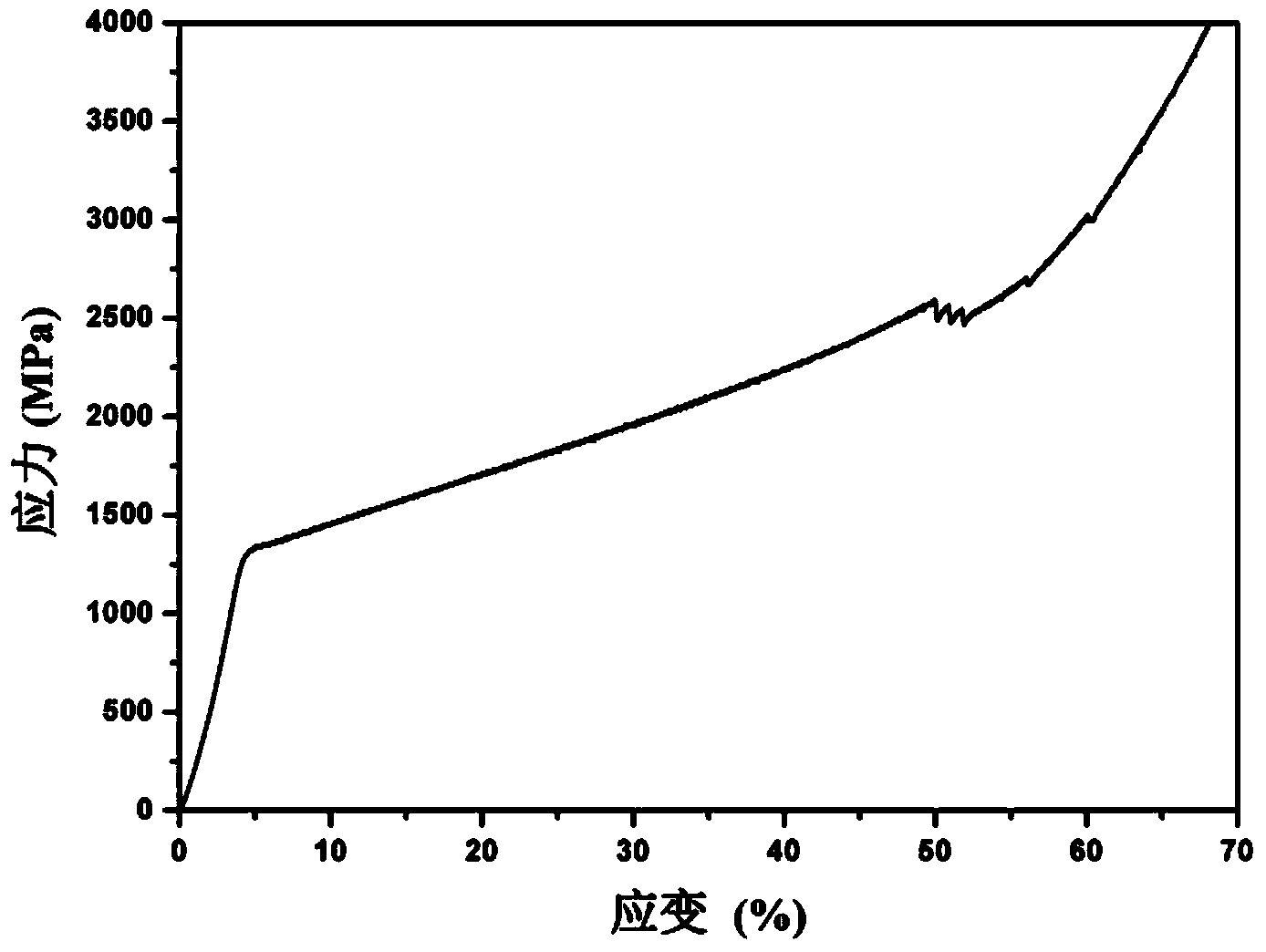

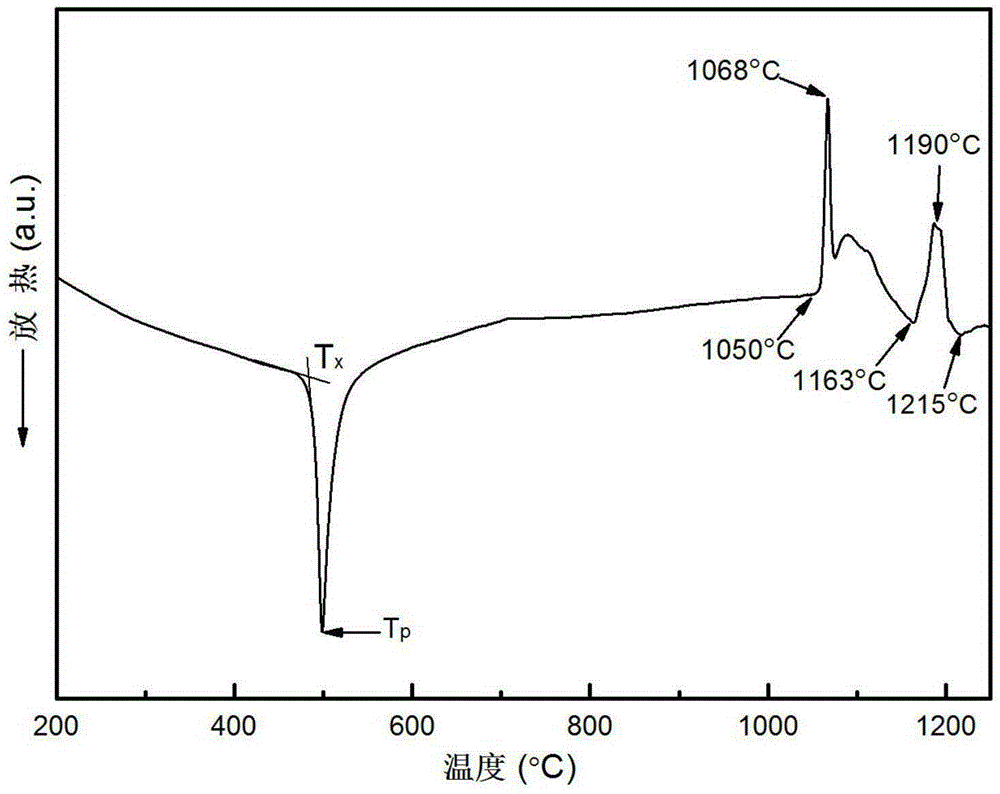

High-ductility titanium based ultra-fine crystal composite material and method for producing the same

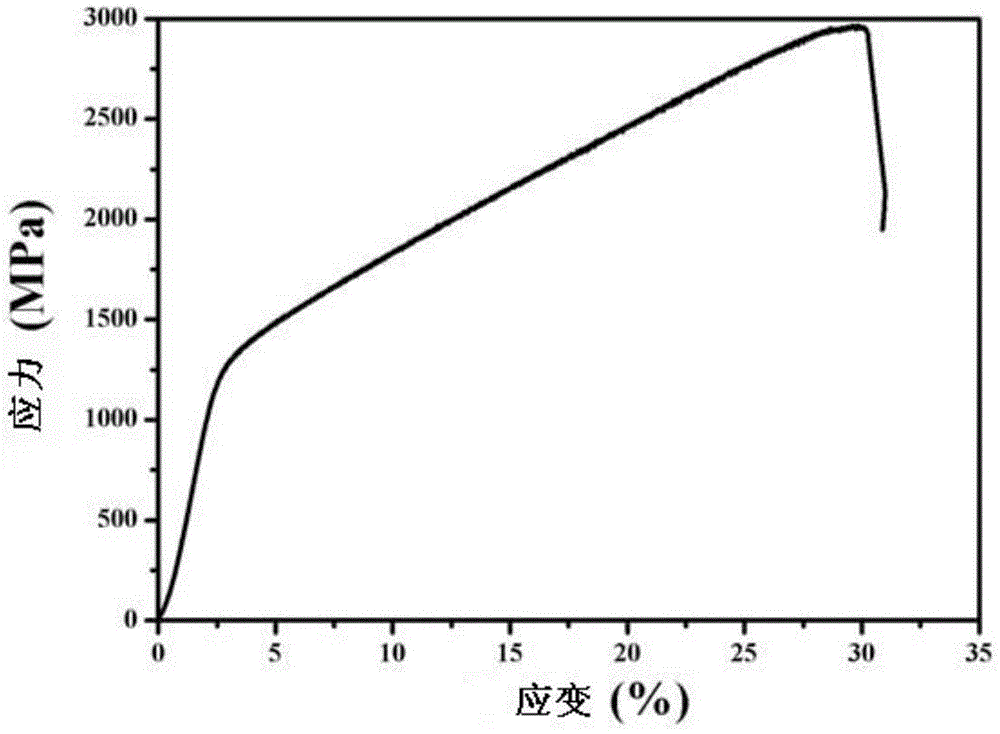

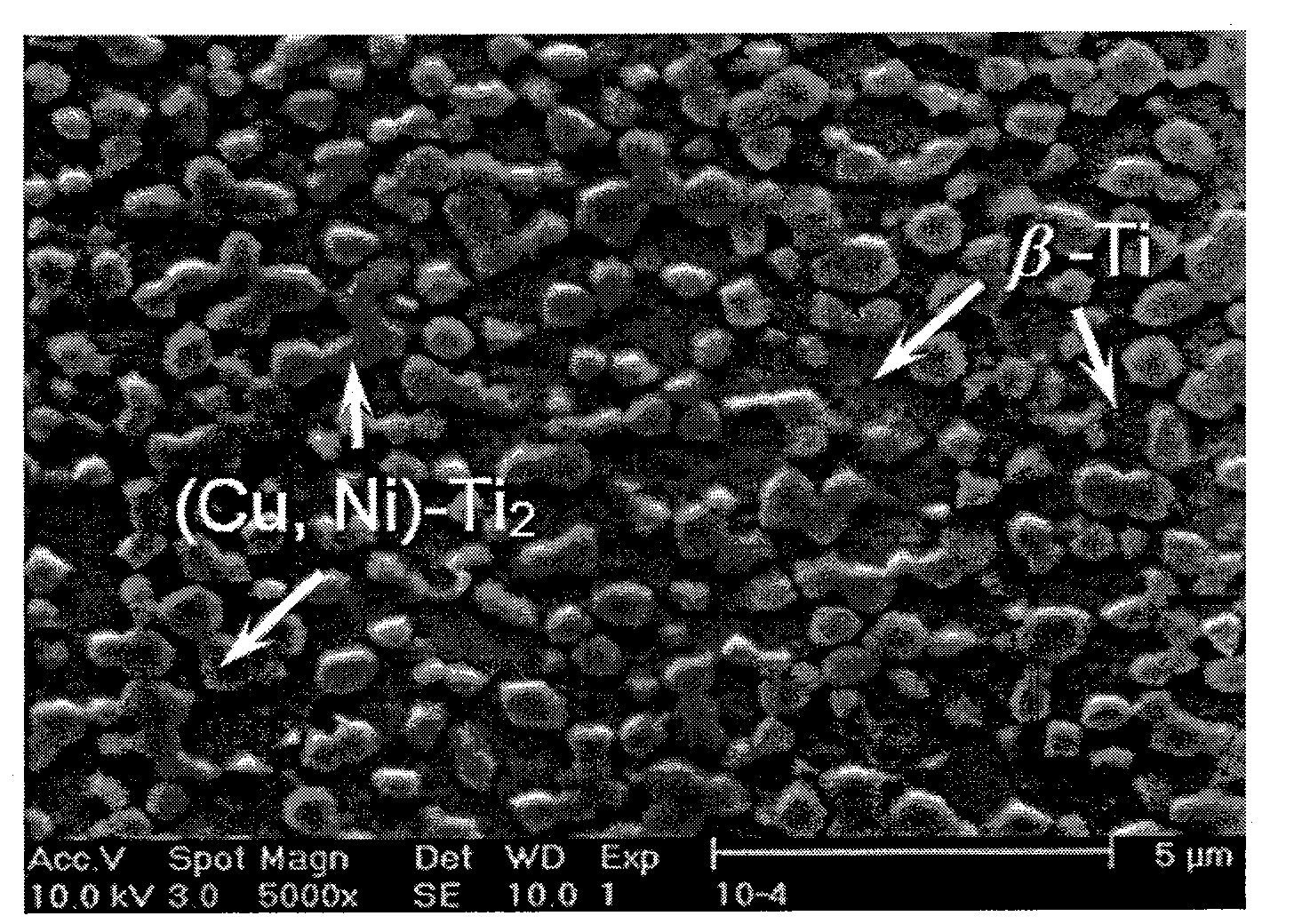

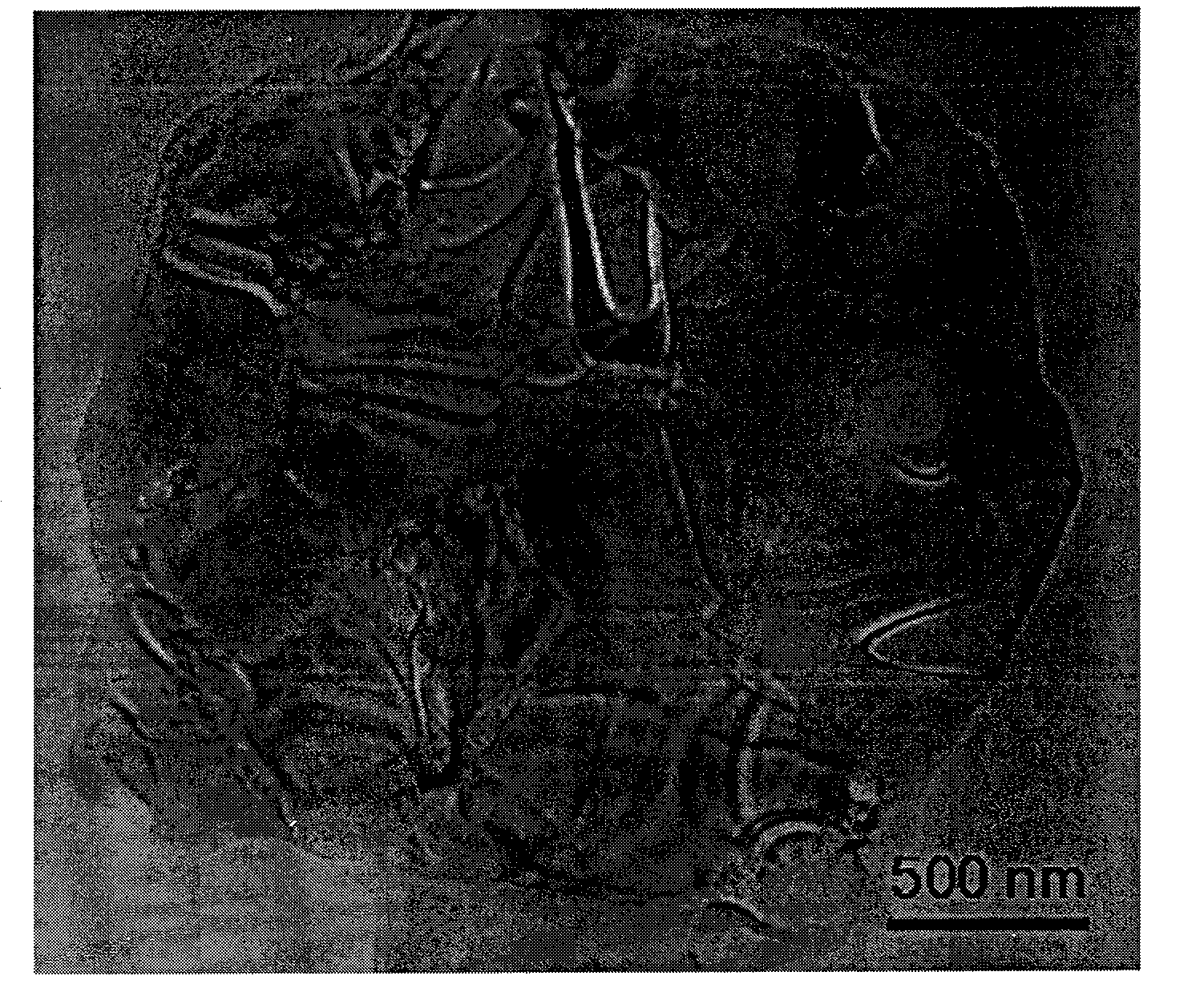

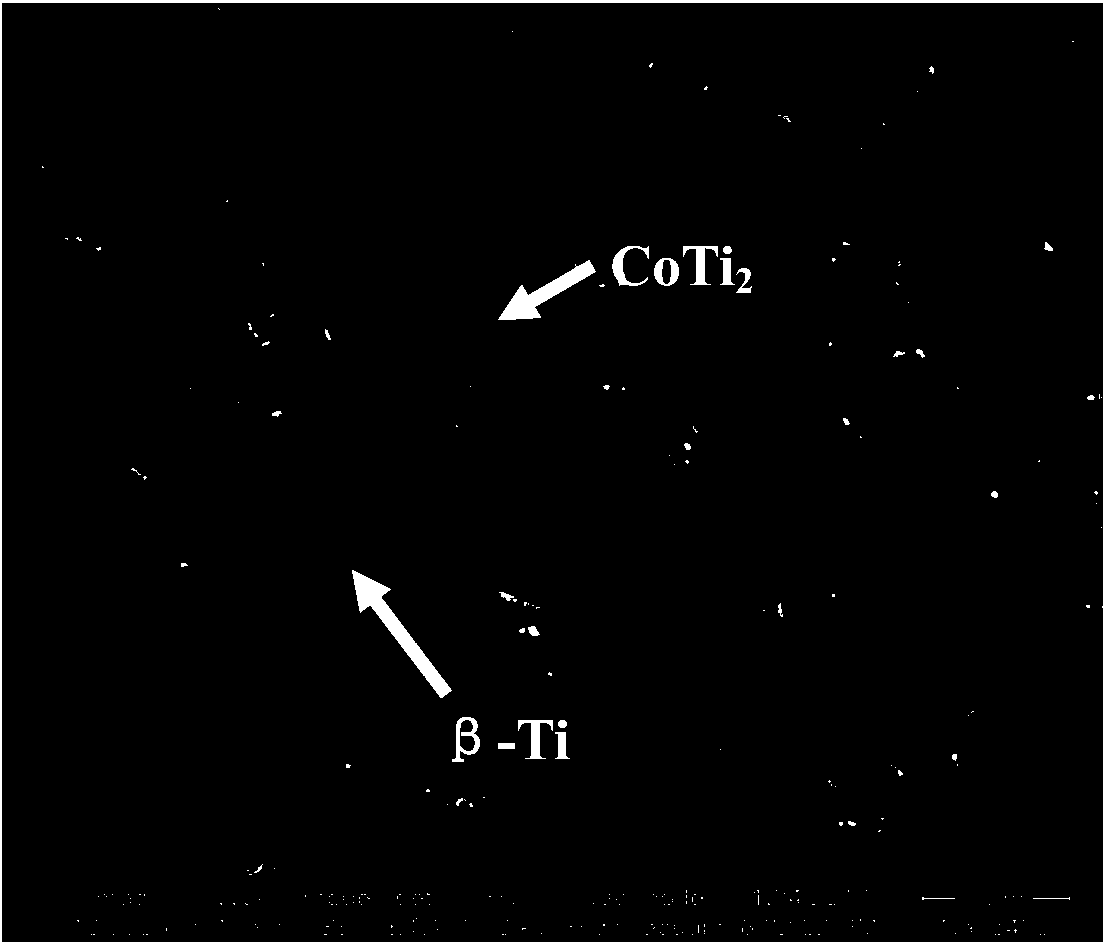

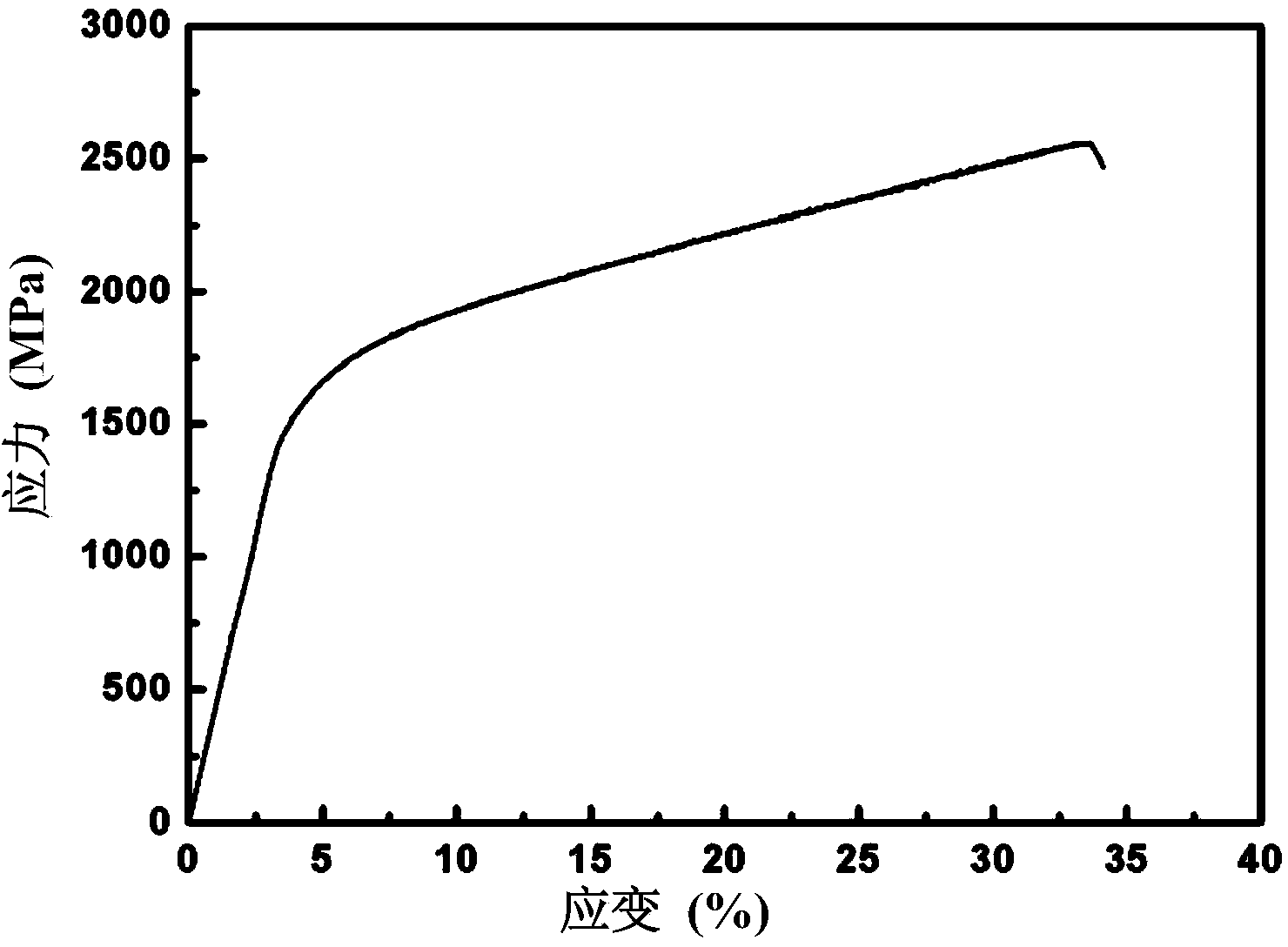

The invention relates to a high-plasticity ultrafine-grained Ti-based composite material and a preparation method thereof. The high-plasticity ultrafine-grained Ti-based composite material of the invention takes Beta-Ti as matrix phase, and the (Cu, Ni)Ti2 as wild phase. The preparation method of the composite material is a combined method of the pulse current sintering technology and the amorphous crystallization method, and comprises steps of mixing powder and high-energy ball milling, and the obtained powdered alloy has wide super-cooled liquid phase region and the amorphous phase accounts for at least 90% of the volume, then rapidly sintering with a discharging plasma sintering system at a sintering temperature Ts which is more than or equal to amorphous alloy powder crystallization temperature +200K and is less than or equal to the melting temperature -100k of the amorphous alloy powder, and at 40-500MPa for 1-20 minutes. Mixture ratio of elements in the invention is reasonable, and the obtained large-size ultrafine-grained Ti-based composite material has excellent comprehensive mechanical property and good prospects for popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

Lightweight periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. According to the scheme, the preparation method comprises the following steps of: uniformly dispersing 0.2 to 4wt% of magnesite micro powder and 0.2 to 4wt% of active alpha alumina micro powder into 5 to 8wt% of binding agent to obtain a modified binding agent; adding 50 to 70wt% of porous periclase-magnesium aluminate spinel ceramic particles to a vacuum agitating machine; vacuumizing to be below 2.5kPa; maintaining the constant pressure for 3 minutes; adding the modified biding agent to the vacuum agitating machine; agitating for 10 minutes; closing a vacuumizing system; then adding 10 to 25wt% of porous periclase-magnesium aluminate spinel ceramic fine powder, 4 to 20wt% of fine magnesia powder, and 1.5 to 4wt% of magnesium aluminate spinel fine powder to the vacuum agitating machine; uniformly agitating; mechanically pressing and modeling; drying; and maintaining the temperature of 1,500 to 1,650 DEG C for 2 to 10 hours. The lightweight periclase-magnesium aluminate spinel refractory material for the rotary cement kiln has the advantages of being low in heat conductivity, high in intensity, high in thermal shock resistance, high in kiln coating performance, and high in resistance to medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

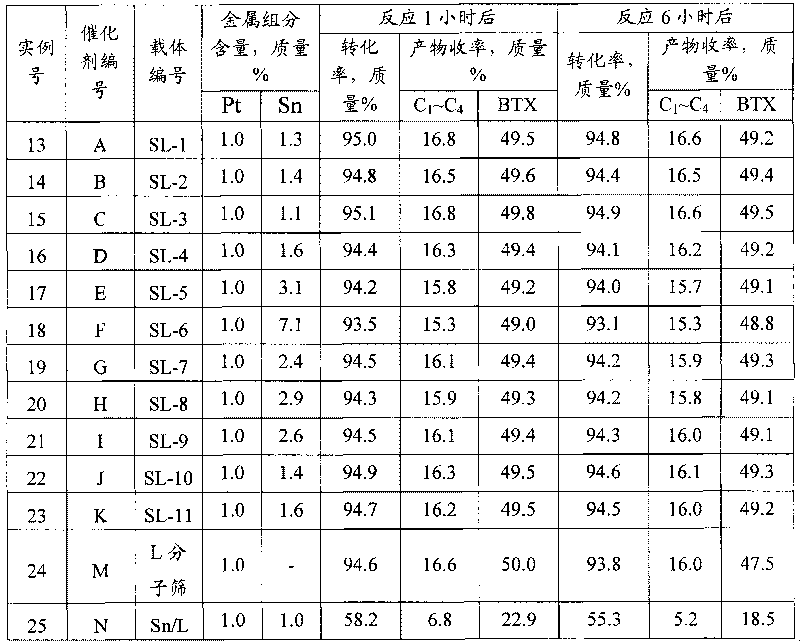

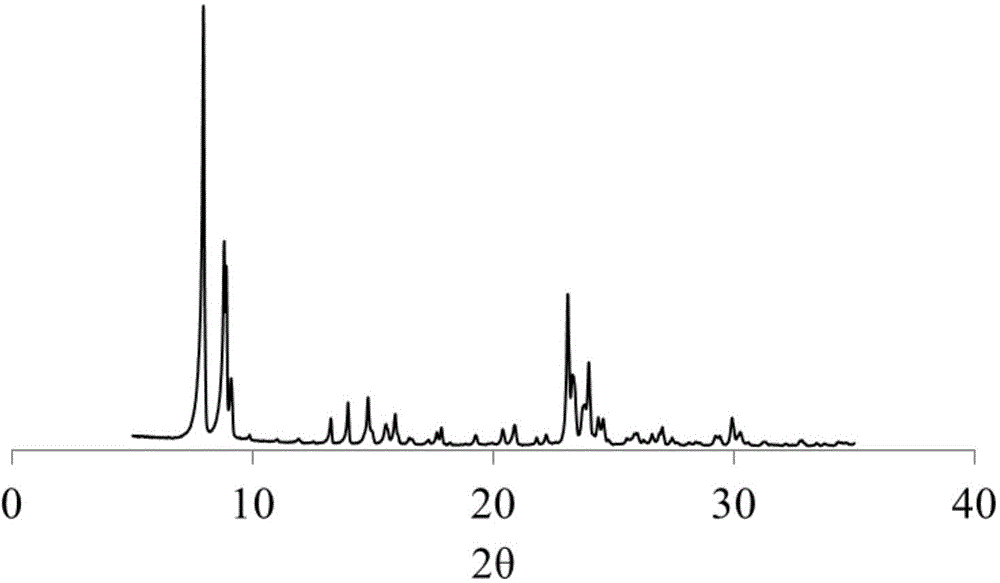

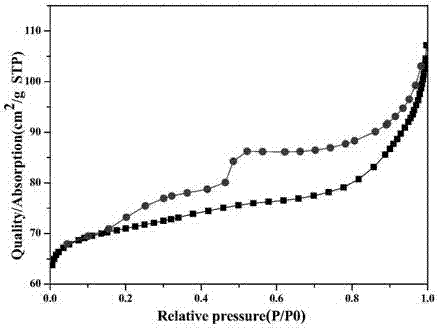

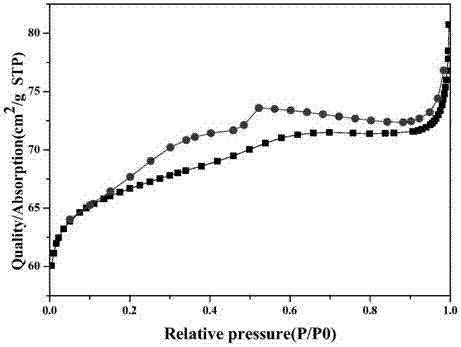

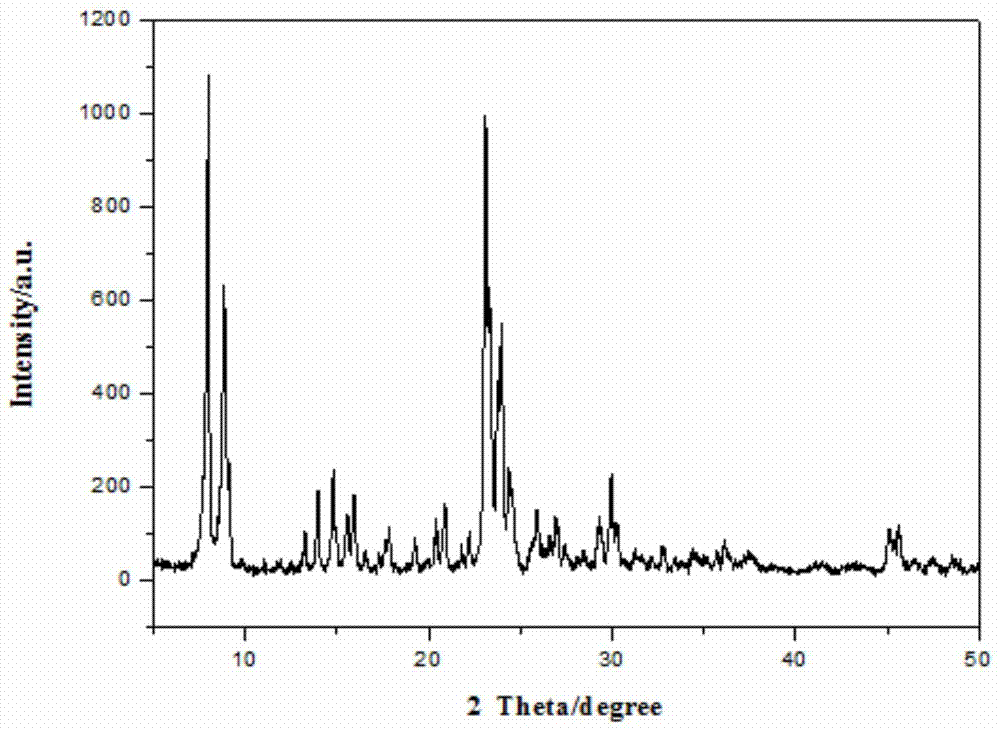

Tin-containing L zeolite and preparation method thereof

ActiveCN101746774AHigh purityHigh crystallinityCrystalline aluminosilicate zeolitesAlkaneMolecular sieve

The invention provides tin-containing L zeolite. The chemical composition of the zeolite is (0.9-1.3)M.(0.01-0.3) SnO2.Al2O3.(5-7) SiO2, wherein M in a formula is K2O or a mixture of K2O and Na2O. The zeolite supporting noble metal is used for alkane aromatization reaction, and has good aromatization activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

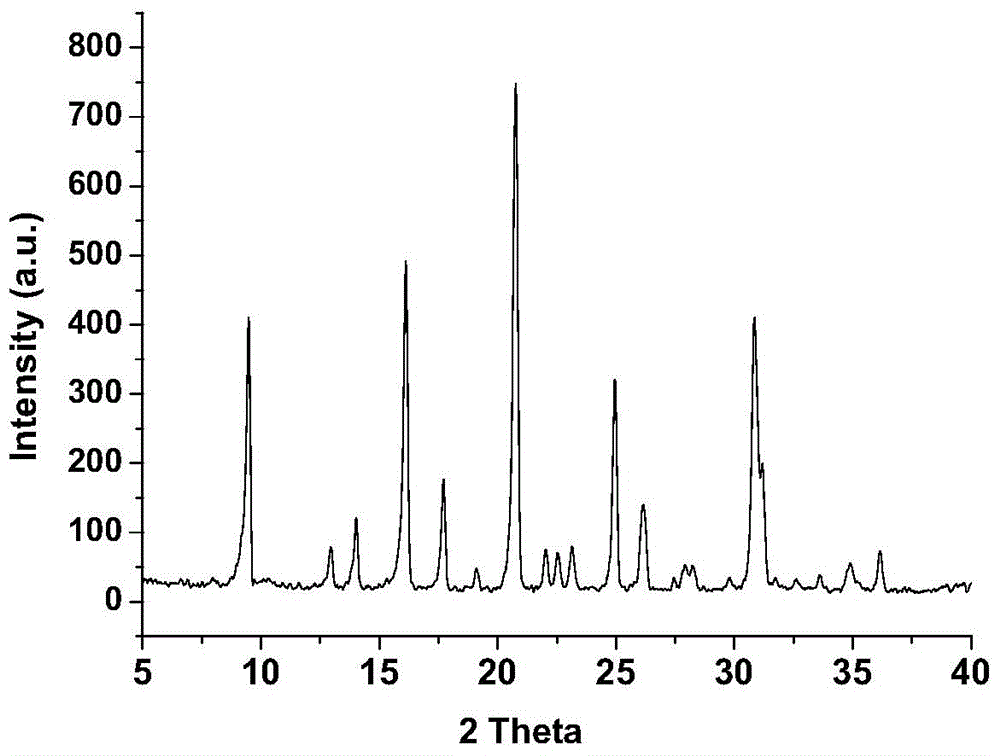

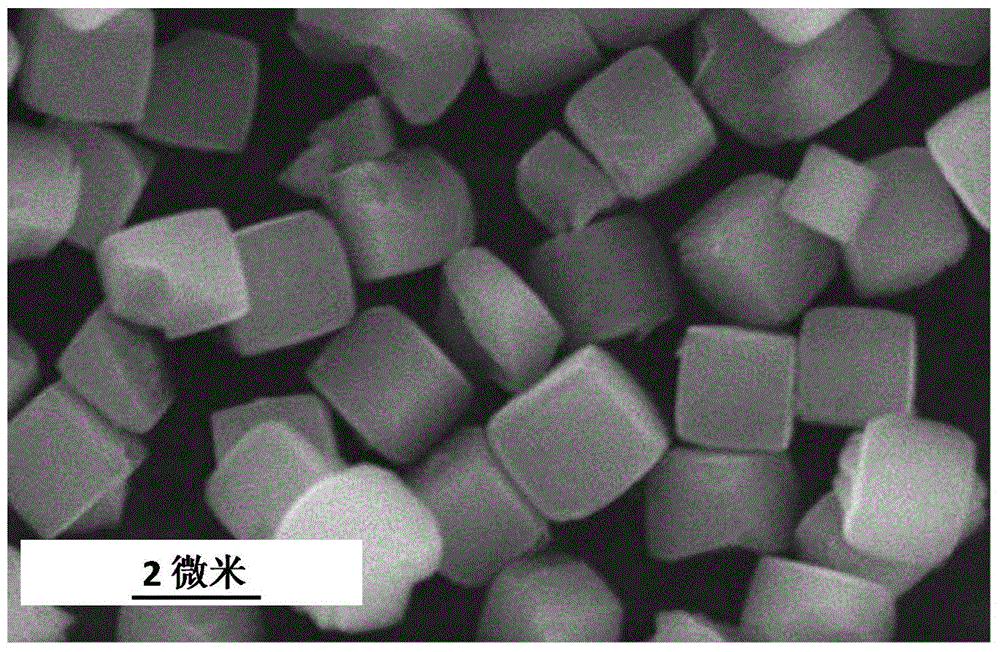

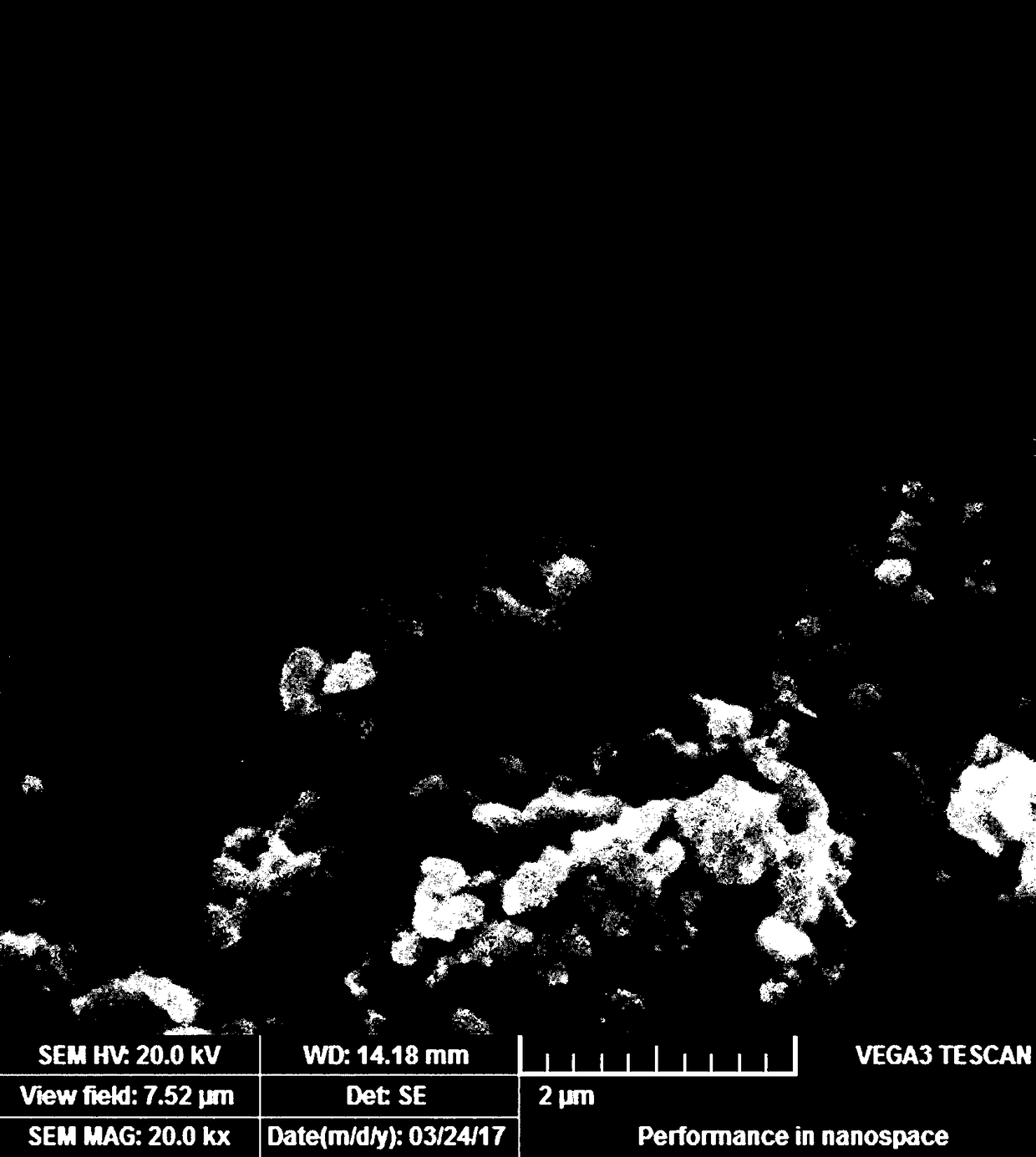

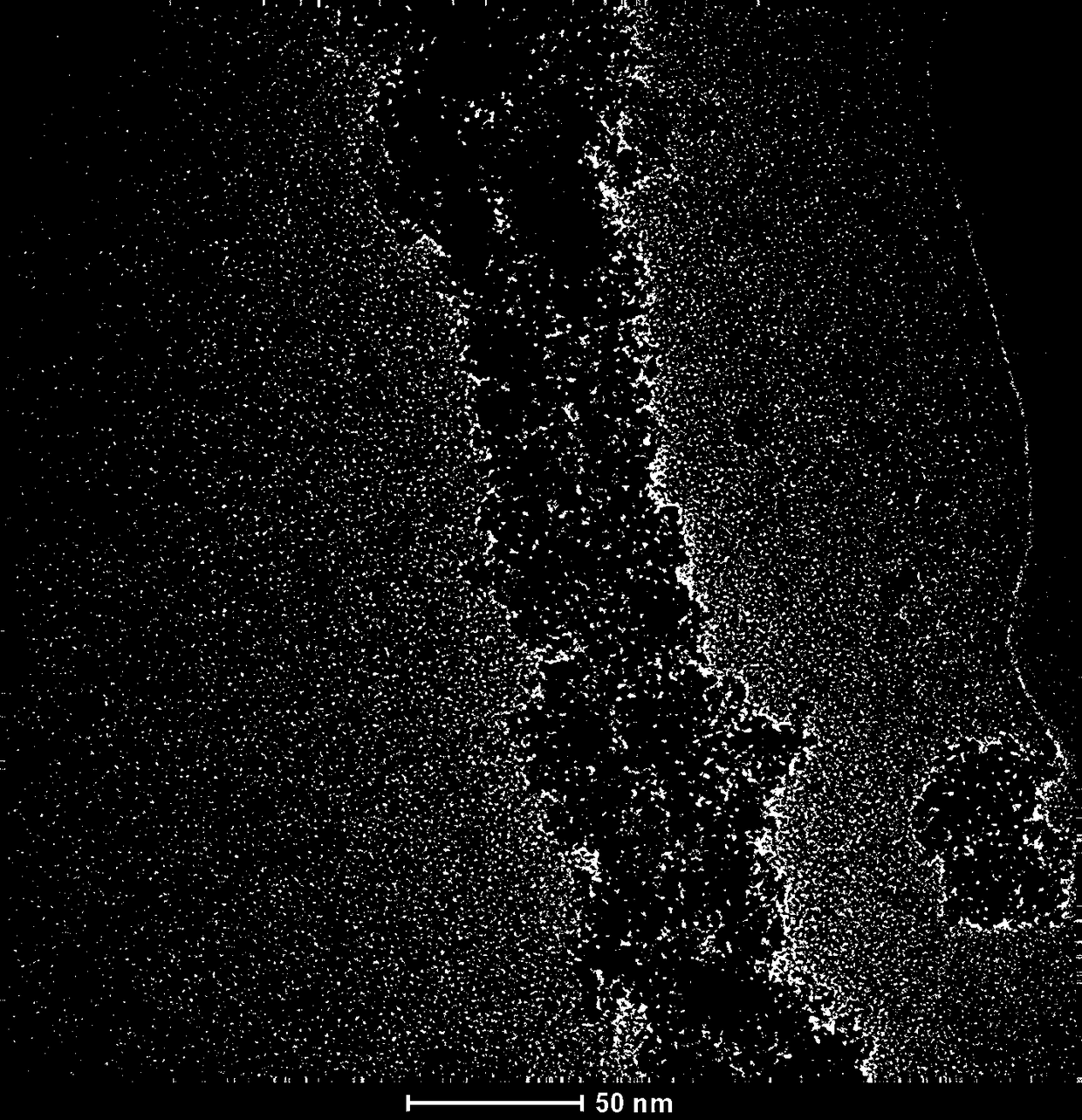

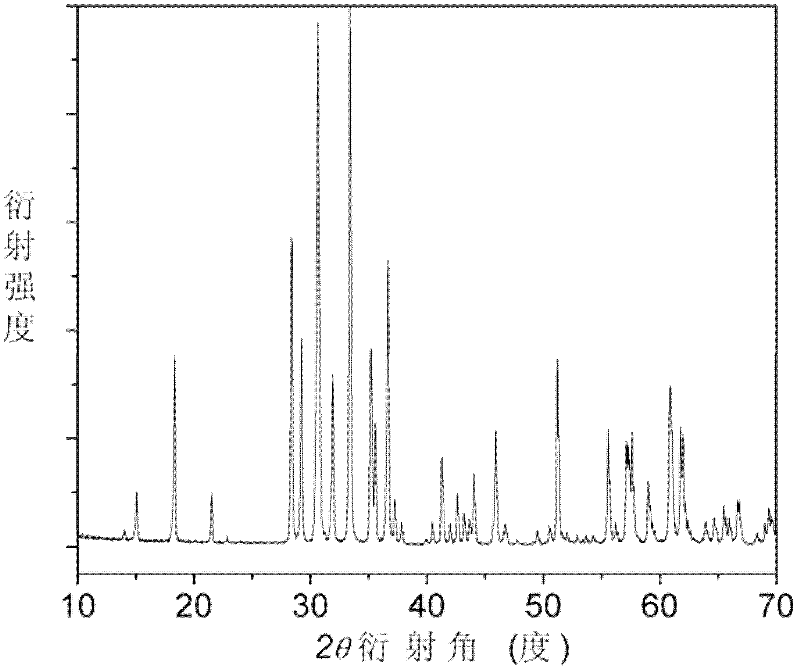

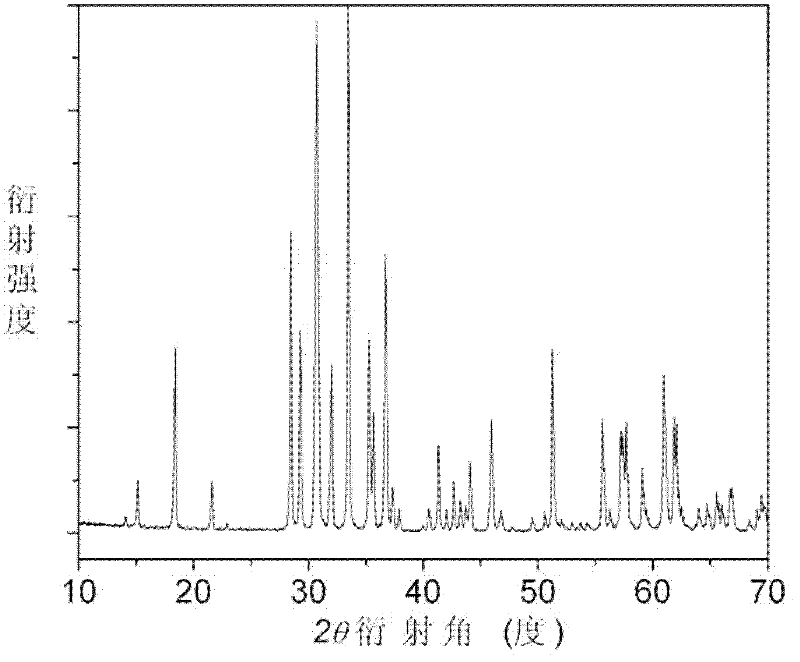

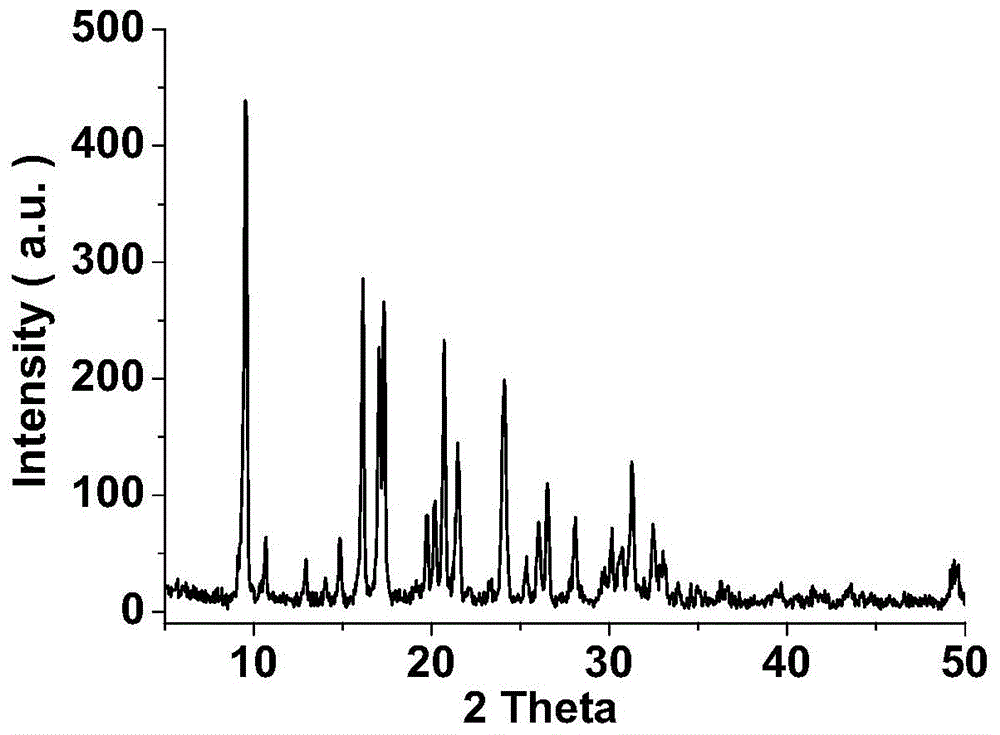

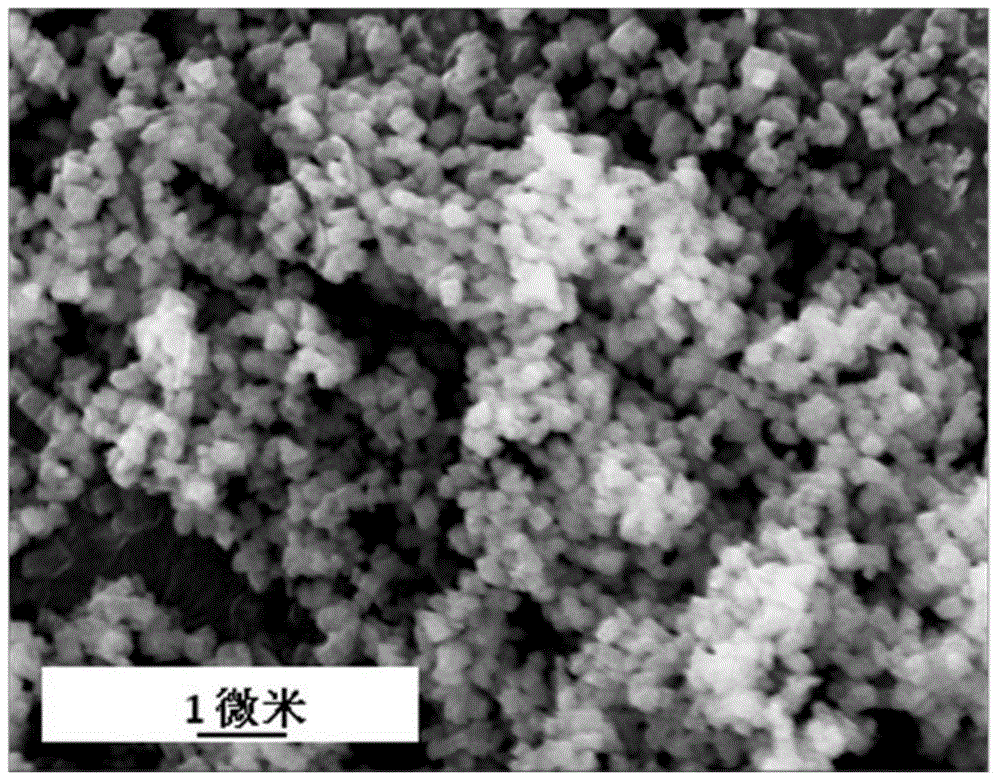

CHA-type silicon-aluminum molecular sieves, and preparation methods and applications thereof

ActiveCN105314648AControllable grain sizeEvenly distributedMolecular sieve catalystsDispersed particle separationMolecular sievePetrochemical

The invention discloses CHA-type silicon-aluminum molecular sieves, an automobile tail gas purification catalyst prepared with the molecular sieve, and preparation methods and applications thereof. The CHA-type silicon-aluminum molecular sieves are a series of molecular sieves with different silicon-to-aluminum ratios. The grain sizes are controllable and are uniformly distributed. The molecular sieves are especially suitable for satisfying the performance demands of automobile tail gas purification catalysts. Also, the automobile tail gas purification catalyst with the CHA-type silicon-aluminum molecular sieve as a carrier has excellent high-temperature hydrothermal stability and high-efficiency denitration catalytic activity. The molecular sieve can be widely applied in the aspects of petrochemical engineering, and chemistry and chemical engineering.

Owner:南京开丽环保材料有限公司

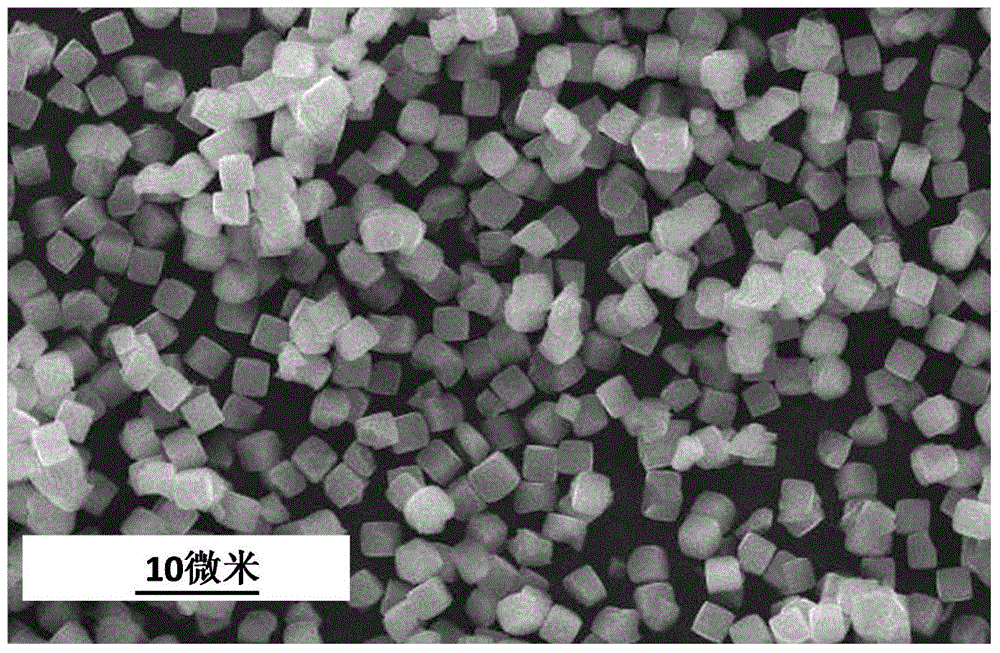

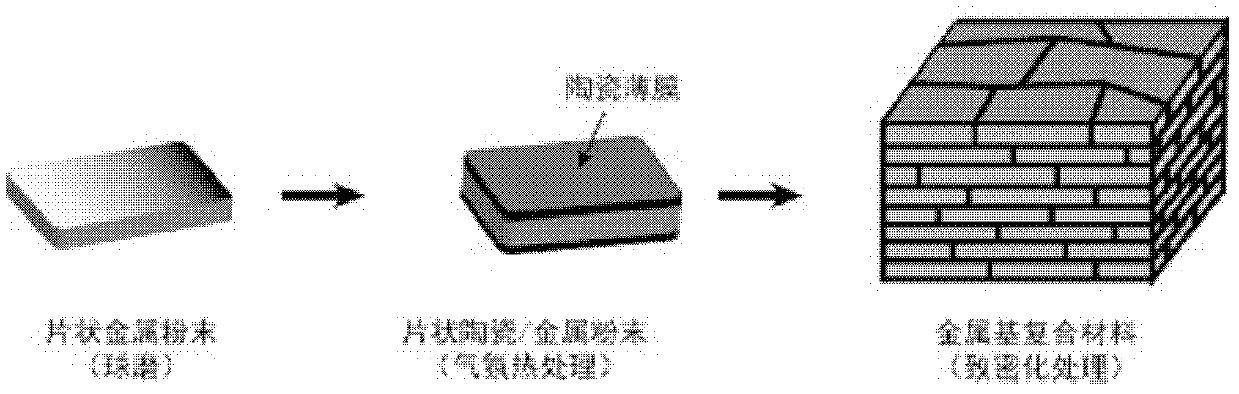

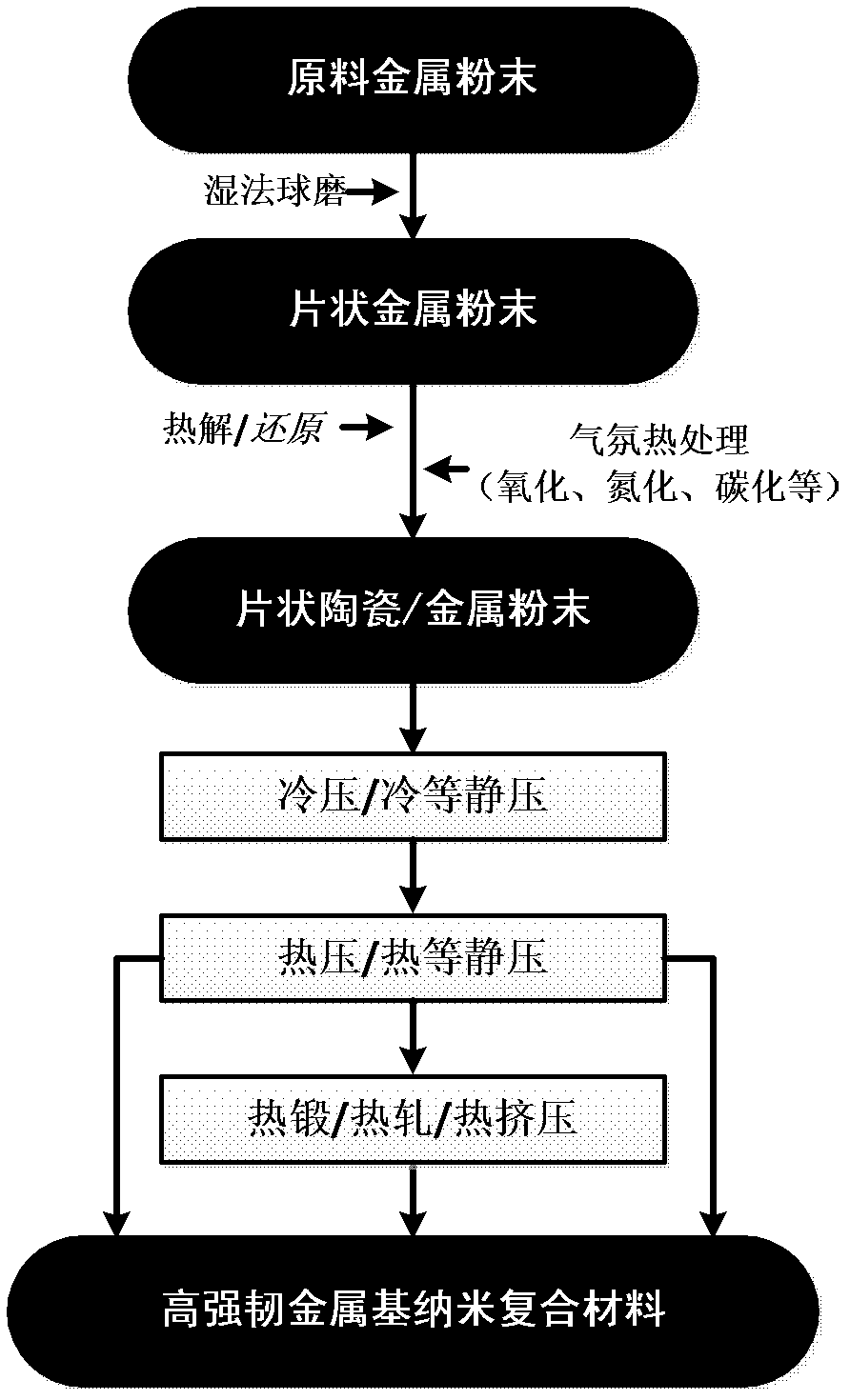

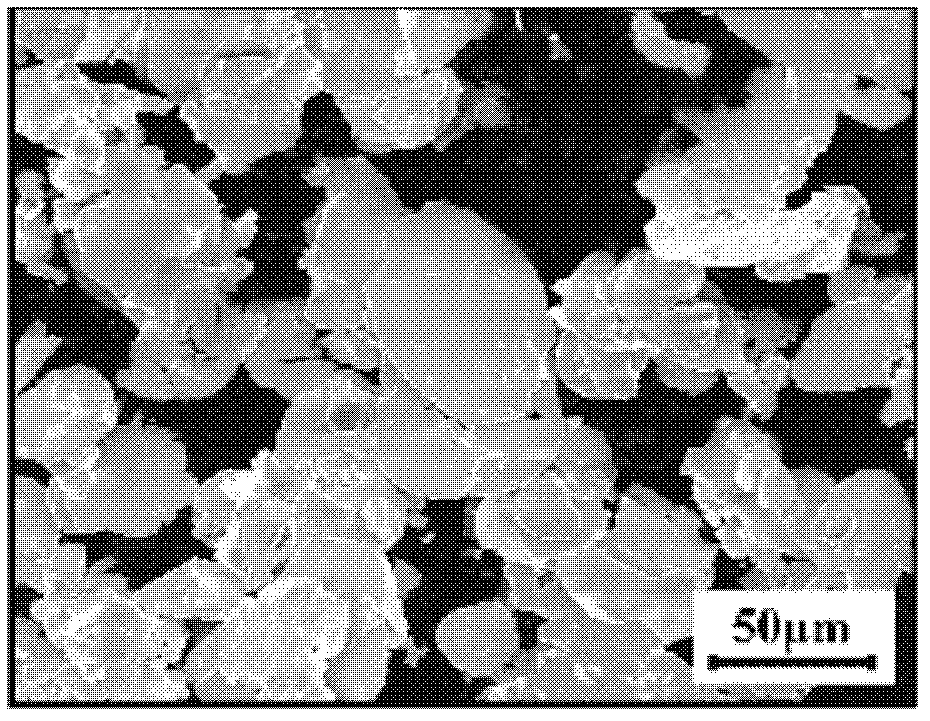

Preparation method of high-toughness metal-based nanometer composite material

The invention provides a preparation method of a high-toughness metal-based nanometer composite material and belongs to the technical field of composite materials. The preparation method provided by the invention comprises the following steps of: firstly, using an atmosphere heat treatment process, generating a layer of a nanometer ceramic thin film on the sheet-shaped metal powder through reaction in-situ; and then carrying out densifying treatment by using a powder metallurgical process, so as to obtain the large compact metal-based composite material. The metal-based composite material prepared by the invention has a metal / ceramic alternative laminated structure, wherein a ceramic layer can be used for effectively restraining the reply of a metal layer and the crystal grain growth, improving the high-position wrong storage capability, keeping a nanometer crystal matrix structure, and causing the rotation and inactivation of fissures, so as to realize mechanical properties matched with the high toughness. The preparation method provided by the invention is simple, convenient and practicable, can be used for realizing the macro-quantized preparation of the large-size composite material, and is good for prompting engineering applications of the metal-based nanometer composite material.

Owner:SHANGHAI JIAO TONG UNIV

Nanometer silicon carbide particle reinforced aluminum matrix composite and preparation method thereof

The invention relates to the technical field of particle reinforced aluminum matrix composites and discloses a nanometer silicon carbide particle reinforced aluminum matrix composite and a preparation method thereof. The composite is prepared by uniformly distributing nanometer silicon carbide particles with the volume percentage of 6-16% into aluminum alloy with the volume percentage of 84-94%. The preparation method comprises the steps of firstly, proportioning, ball milling, premolding and carrying out hot pressing molding to prepare 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite; next, carrying out vacuum concentration on the 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite to evaporate parts of aluminum alloy matrixes; and finally, carrying out solid solution and aging treatment to prepare the nanometer silicon carbide particle reinforced aluminum matrix composite disclosed by the invention. Experiment data proves that the reinforced aluminum matrix composite with high nanometer silicon carbide particle content, prepared by using the preparation method not only has the functional properties of high heat conductivity, electrical conductivity, specific modulus, wear resistance and the like due to the high nanometer silicon carbide particle content, but also has strength as well as plasticity and toughness.

Owner:HENAN UNIV OF SCI & TECH

Medical ultra-fine grain titanium alloy with ultrahigh plasticity, high strength and low modulus and preparation method thereof

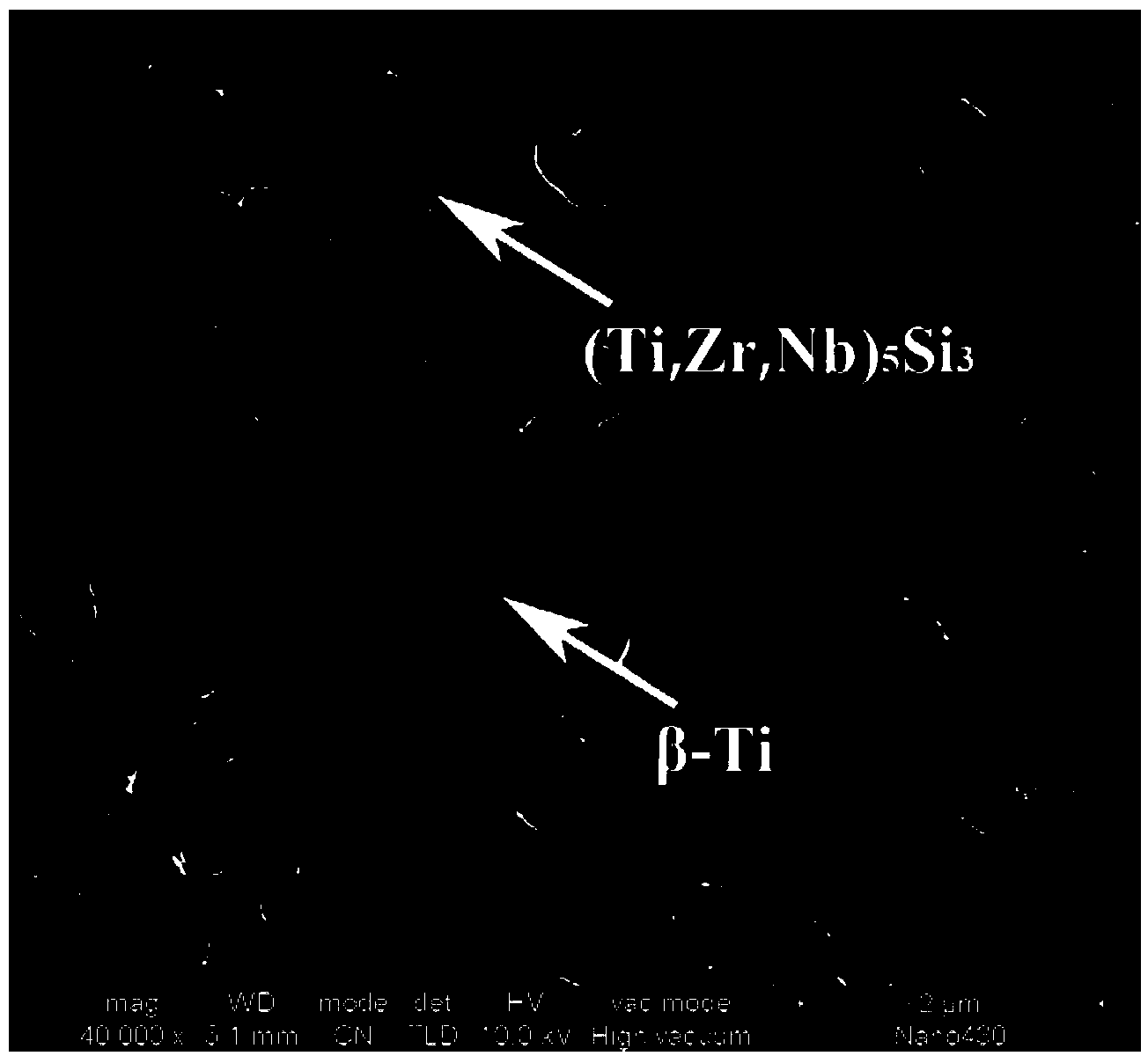

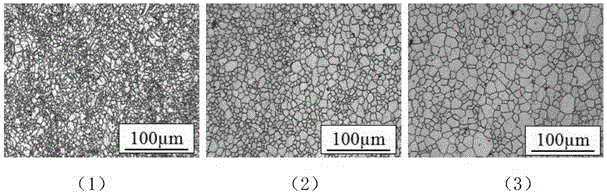

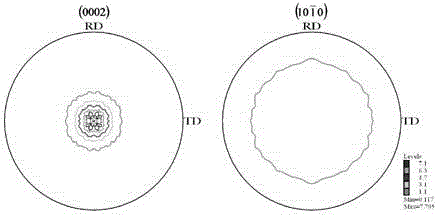

The invention discloses a medical ultra-fine grain titanium alloy with ultrahigh plasticity, high strength and low modulus and a preparation method thereof. The medical ultra-fine grain titanium alloy contains the following specific components in atomic percent: 60-70% of Ti, 16-24% of Nb, 5-14% of Zr, 1-8% of Ta, 0-5% of Si, and inevitable trace impurities. The preparation method of the medical ultra-fine grain titanium alloy is a formation method of the powder metallurgy sintering technology combined with an amorphous crystallization method; specifically, powder mixing and high-energy ball milling are performed until the content of the amorphous phase is maximum, next, the powder metallurgy sintering technology is adopted to solidify the alloy powder, and finally, a spark plasma sintering system or a vacuum hot pressing furnace is adopted for sintering by use of pulse current or radiation heating. The prepared complex-structure medical ultra-fine grain titanium alloy with ultrahigh plasticity, high strength and low modulus is good in biocompatibility, controllable in grain size, excellent in comprehensive mechanical properties and bright popularization and application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Multi-scale and double-state structure titanium alloy based on eutectic transformation, preparation and application

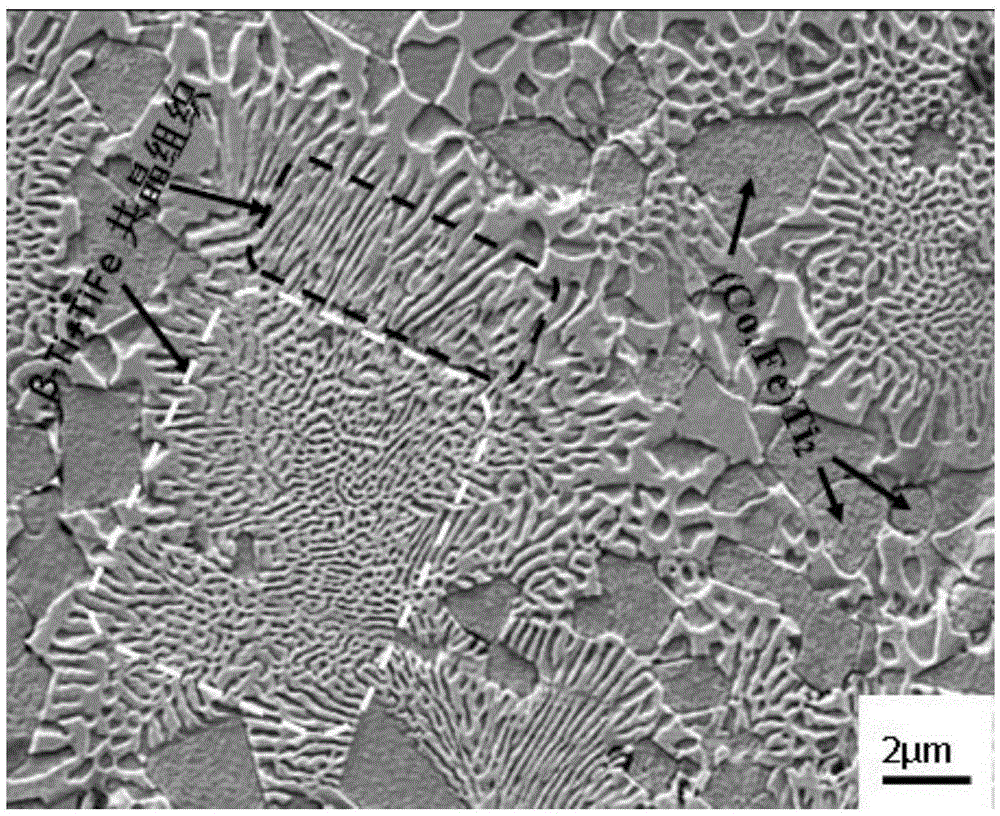

The invention belongs to the technical field of alloy machining and discloses a multi-scale and double-state structure titanium alloy based on eutectic transformation, preparation and application. The alloy is prepared from, by atomic percent, 52.5-62% of Ti, 10.0-14.1% of Nb, 5.5-21.5% of Fe, 8-16.3% of Co and 5.8-6.7% of Al. The microstructure of the multi-scale and double-state structure titanium alloy comprises a lamellar-type eutectic structure base body of nanocrystalline and ultra-fine grains, and an isometric crystal second phase of the micron size. A preparing method includes the three steps of powder mixing, alloy powder preparing through high-energy ball grinding and semi-solid sintering of alloy powder. The sintering temperature is controlled to be between the beginning temperature of eutectic transformation and the melting beginning time, so that the obtained alloy has the nanometer and superfine-scale lamellar-type eutectic structure and an isometric crystal coexisting multi-scale and double-state structure of the micron size, and the performance of the alloy is more superior.

Owner:SOUTH CHINA UNIV OF TECH

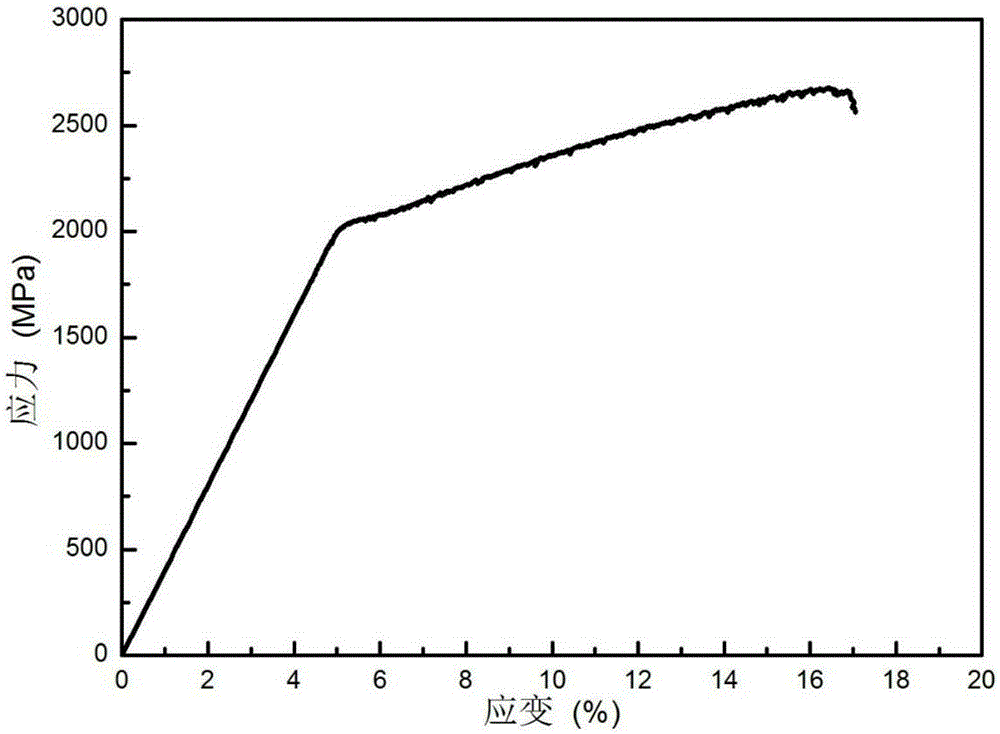

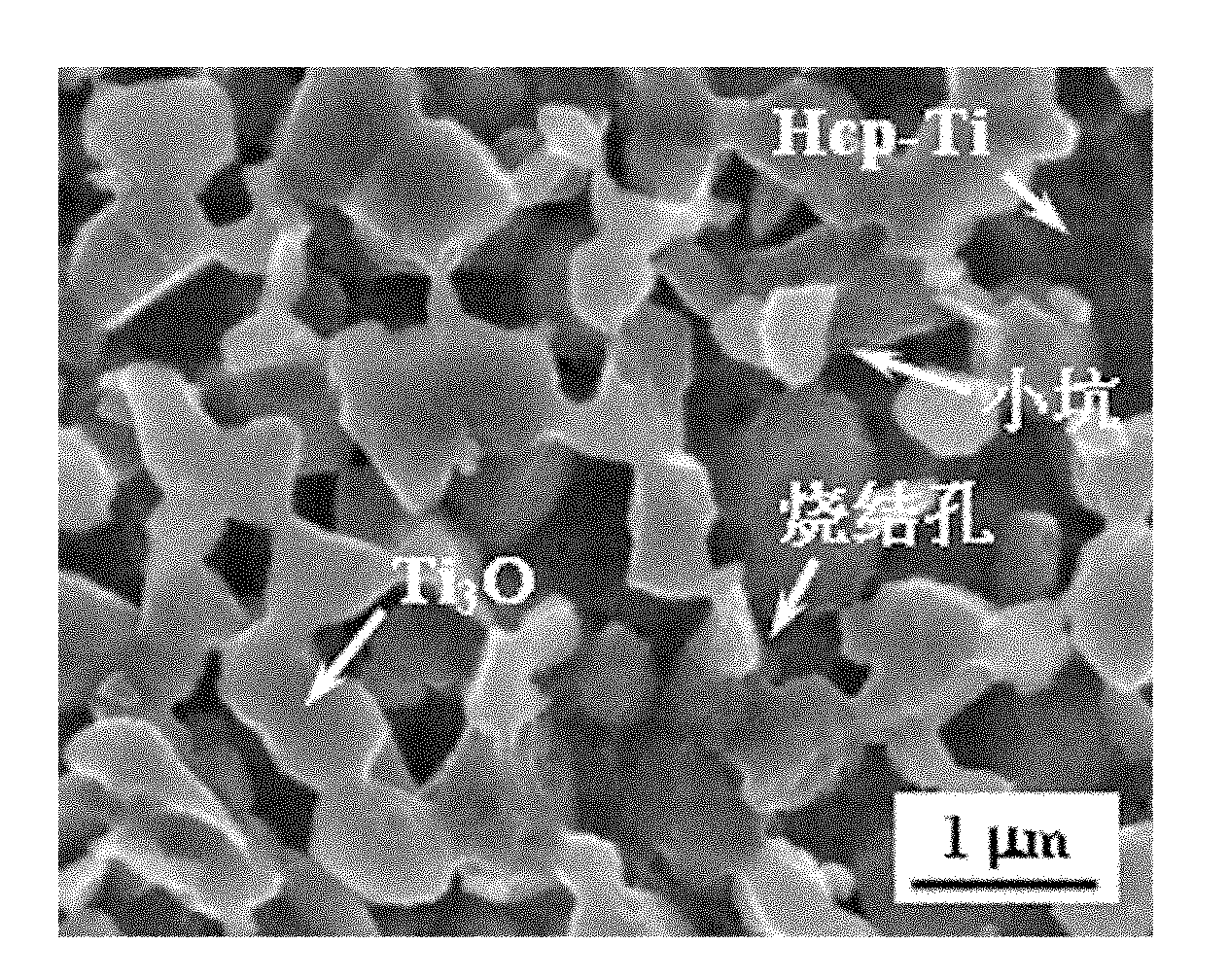

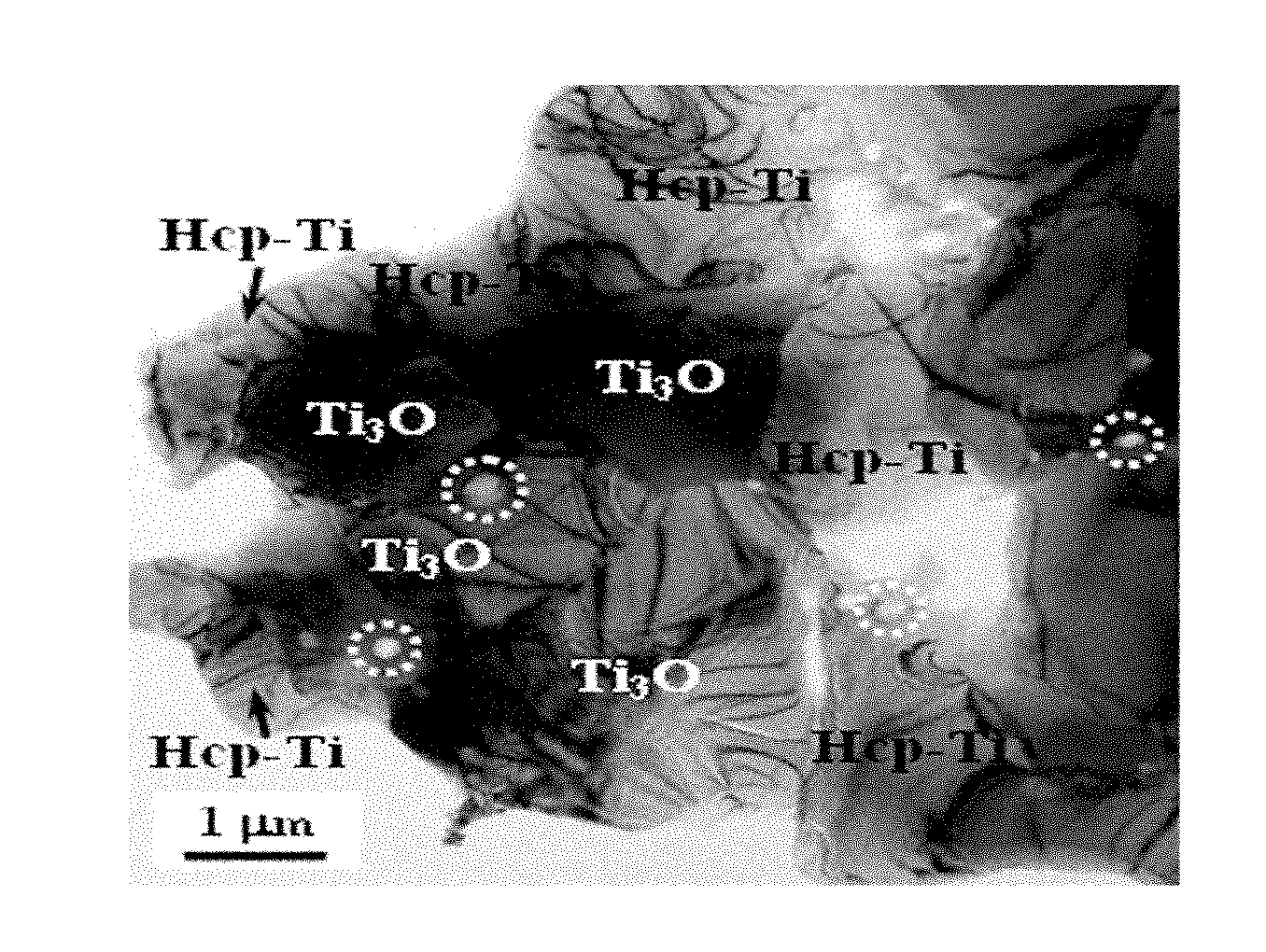

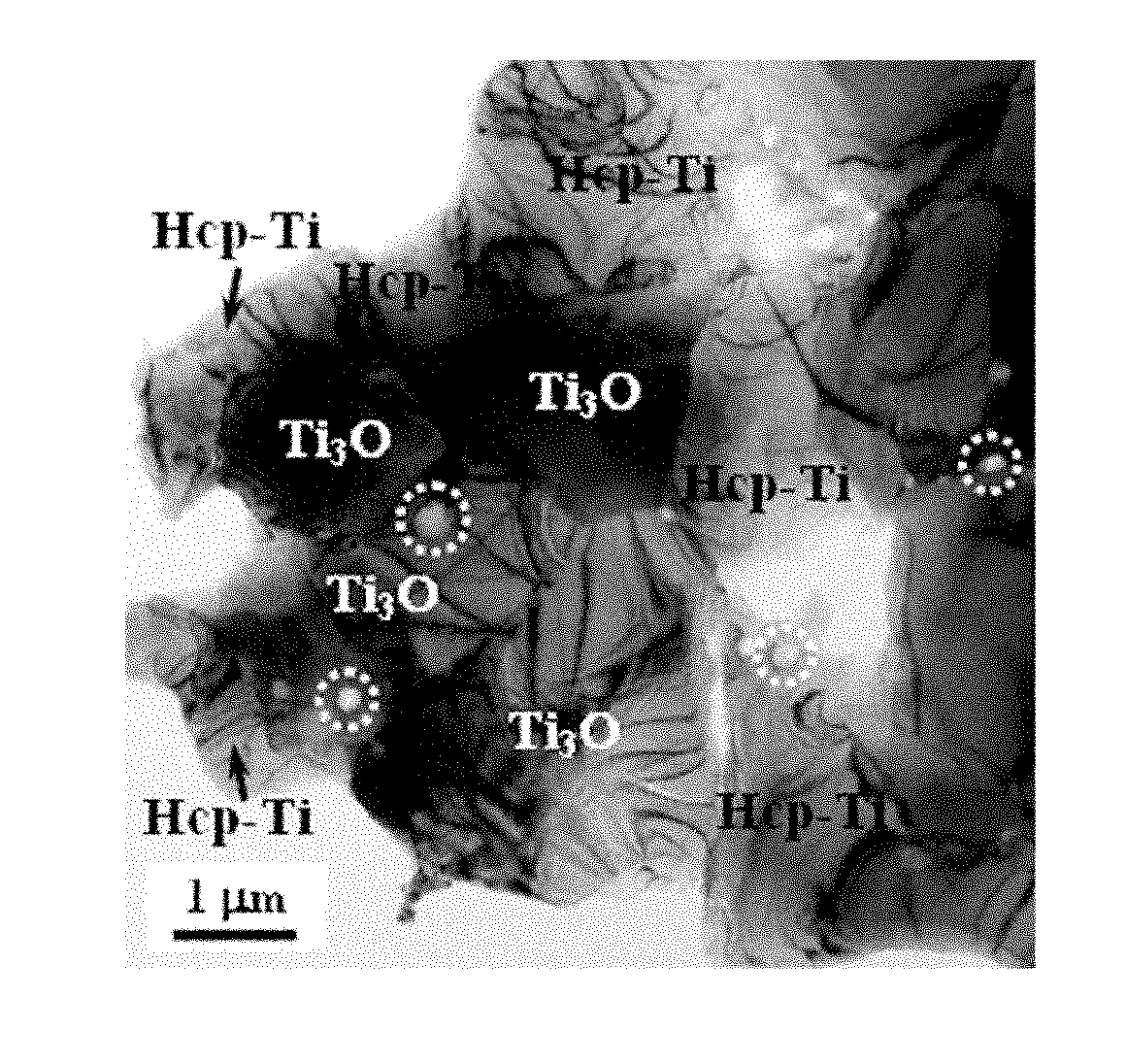

Titanium-based ultrafine grain or fine grain composite material with high compression ratio strength and preparation method thereof

The invention discloses a titanium-based ultrafine grain or fine grain composite material with high compression ratio strength and a preparation method thereof. In a microstructure of the titanium-based ultrafine grain composite material, Hcp Ti3O is taken as a matrix phase and Hcp Ti as an enhanced phase; and in a microstructure of the titanium-based fine grain composite material, Hcp Ti is taken as the matrix phase and Hcp Ti3O as the enhanced phase. The preparation method comprises the following steps of: interruptedly exposing powder in the air until the initial powder becomes amorphous state titanium alloy powder by a high-energy ball; and quickly sintering by adopting pulse current at the sintering temperature Ts being not less than 740K and not more than 1,473K and the sintering pressure of at least 40MPa for 1-10 minutes. The method has simple process and convenient operation; grains have controllable size, high finished rate, raw materials saving and near net shape; and the large-sized titanium-based ultrafine grain or fine grain composite material has excellent comprehensive mechanical property and favorable popularization and application prospect.

Owner:SOUTH CHINA UNIV OF TECH

High-toughness ultrafine-grain composite titanium alloy and application and preparation method thereof

The invention belongs to the technical field of alloy materials, and particularly relates to high-toughness ultrafine-grain composite titanium alloy and application and preparation method thereof. The high-toughness ultrafine-grain composite titanium alloy consists of the following elements in percentage by mass: 55-62% of Ti, 15-24% of Nb, 6-16% of Fe, 2-12% of Co and 2-6% of Al, wherein a microstructure thereof takes a body centered cubic disordered solid solution phase rich in Ti and Nb as a matrix phase and takes a second isometric crystal phase rich in Ti and Co as a reinforcing phase. The preparation method of the high-toughness ultrafine-grain composite titanium alloy comprises the following steps: mixing powder of the elementary substances according to the percentages by mass, performing ball milling at high energy to prepare amorphous alloy powder and sintering to obtain the high-toughness ultrafine-grain composite titanium alloy. The high-toughness ultrafine-grain composite titanium alloy prepared by the preparation method has the advantages of large size and good comprehensive mechanical properties, and can be applied to the field of aerospace materials.

Owner:SOUTH CHINA UNIV OF TECH

Rolling machining method for improving microstructure texture and mechanical property of magnesium alloy sheet strip

InactiveCN105234173AWeaken base textureControllable grain sizeMetal rolling arrangementsCrystalliteGrain boundary

The invention discloses a rolling machining method for improving the microstructure texture and the mechanical property of a magnesium alloy sheet strip. Cooling continuous rolling is carried out on a magnesium alloy cogging panel, wherein the rolling starting temperature ranges from 250 DEG C to 500 DEG C, the number of continuous rolling times is two to eight, and one-time rolling reduction ranges from 2% to 20%; 200 DEG C-450 DEG C intermediate annealing is carried out after continuous rolling, wherein the annealing time ranges from 1 min to 60 min; and then the cooling continuous rolling step is repeatedly executed until the thickness of a magnesium alloy sheet reaches the needed size. According to the rolling machining method, through a cooling continuous rolling technology, base face slippage, taper face slippage and twinborn and grain boundary slippage can be started at the same time in the rolling process of the magnesium alloy sheet strip; meanwhile, the continuous rolling process facilitates grain accumulation coordinated deflection, and the base face texture inclines and is weakened; and the grain size of the magnesium alloy sheet strip is controllable through combination of the annealing process, and the mechanical property of a magnesium alloy is obviously improved.

Owner:GUIZHOU UNIV

Method for preparing ultra-fine crystal grain pure molybdenum block material

A method for preparing ultra-fine crystal grain pure molybdenum block material belongs to the technical field of high-melting-point metal and metal-based heat sink material. The invention is characterized in that firstly the molybdenum powder with granularity which is smaller than 10mum and larger than 1mum is selected for executing the vacuum hot pressing pre-burning of green body. Then the pre-burned green body is placed in a pyrauxite mold and is placed into a press for exerting pressure of 1-10GPa on the sample. Then the 10-25 kW alternating current is exerted on two ends of the sample for sintering. The energized current is 1000A-3000A and lasts for 15 seconds to 3 minutes. After energizing and sintering, pressure is continuously maintained for 30 seconds to 3 minutes; then the sintered body is milled and polished. The relative density is 96-99.9% and the grain size is smaller than or equal to the initial powder size of used raw material. The pre-burning is executed under the following conditions: 20-50MPa of pressure, 10<-2>-10<-3>Pa of vacuum degree, 800-1000 DEG C of temperature and 30min-60min of time. The ultra-fine crystal grain pure molybdenum block material prepared by the invention has better mechanical performance and thermal-shock resistance and is suitable for electronic packaging materials, hot sink materials, electrical contact materials and fire-resistant plasma scouring components, such as divertor materials in nuclear fusion devices.

Owner:UNIV OF SCI & TECH BEIJING

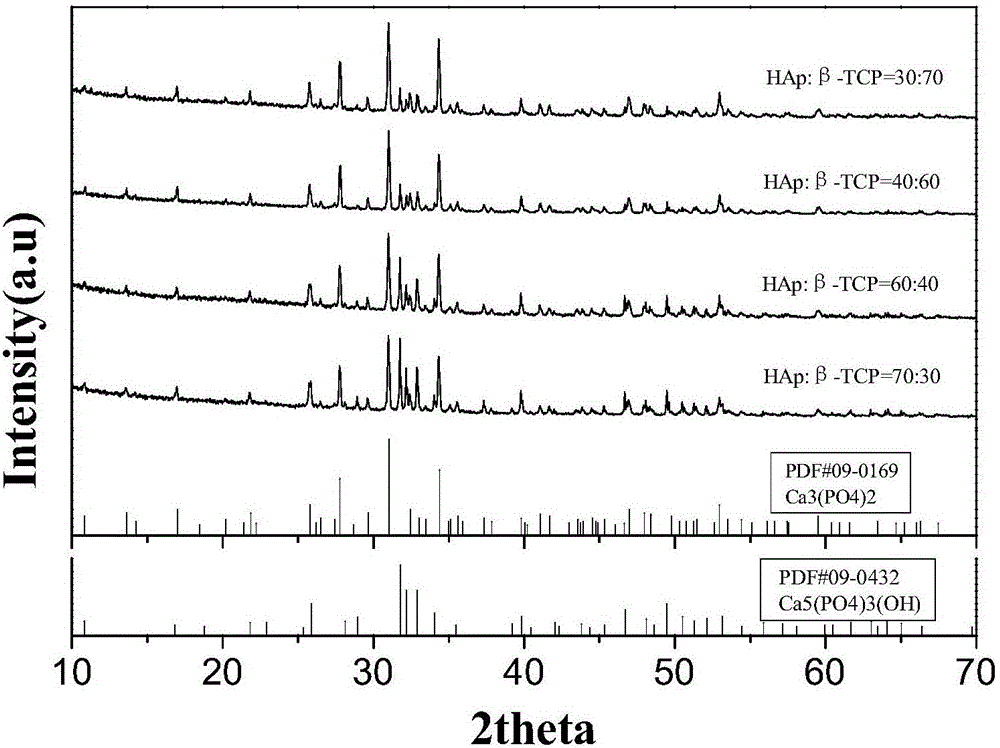

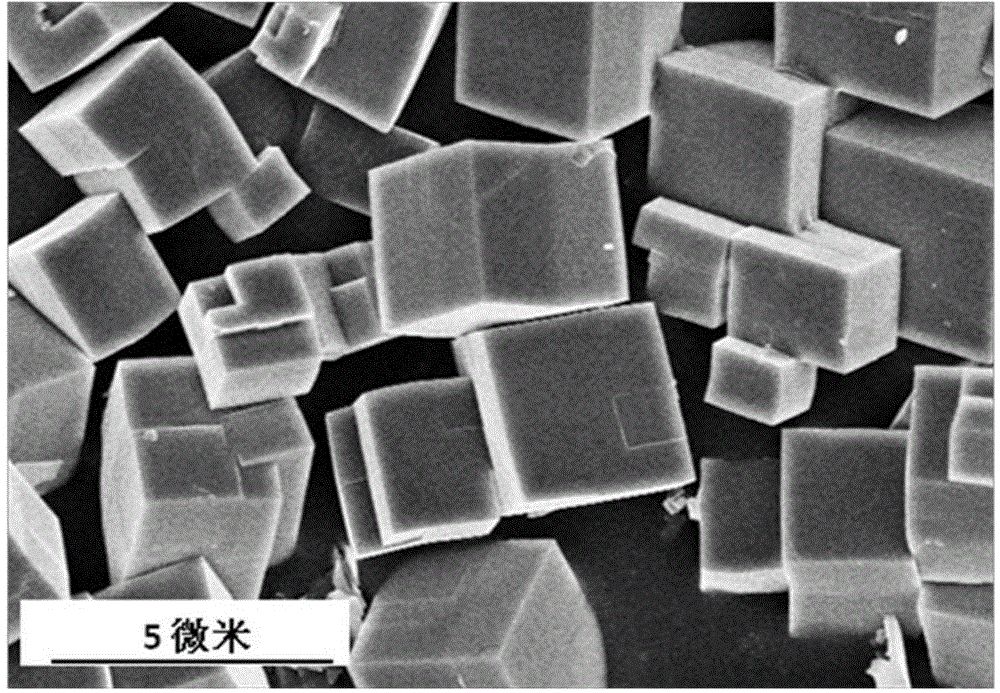

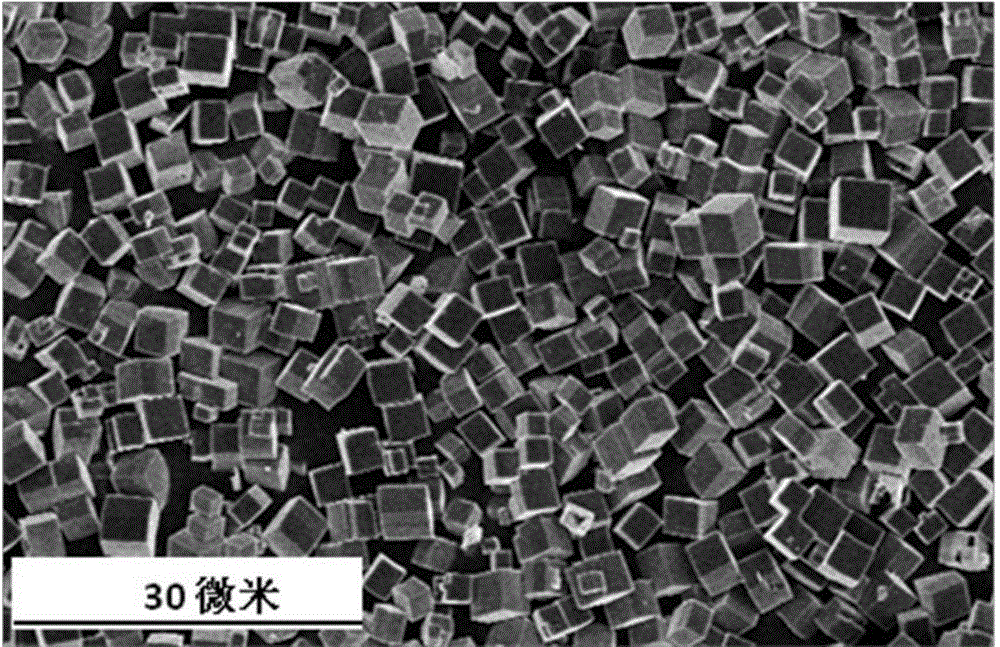

Biphase calcium phosphate (BCP) composite powder synthesized by high-temperature solid phase reaction and preparation method thereof

The invention discloses biphase calcium phosphate (BCP) composite powder synthesized by a high-temperature solid phase reaction. BCP powder is biphase composite powder prepared from hydroxyapatite (HA) and beta-tricalcium phosphate (beta-TCP), in which the molar ratio Ca / P of calcium to phosphorus is 1.5 to 1.67, wherein the value ranges of the relative mass percent of HA and beta-TCP two phases are each 1 to 99 percent; the sizes of crystalline grains of the HA and beta-TCP two phases are 20nm to 300 microns; the crystallinity is 50 to 100 percent. The invention also discloses a preparation method of the BCP composite powder synthesized by the high-temperature solid phase reaction. The BCP composite powder is prepared through the high-temperature solid phase reaction of a calcium-containing solid compound and a calcium-phosphorus solid containing compound. The BCP composite powder has the advantages that a reaction period is short; the costs of raw materials are low; the equipment investment is low; no waste gas and waste water are discharged; further, the proportion of the HA and beta-TCP two phase in the BCP powder is easily regulated and controlled at the same time; the two phases are distributed uniformly; the sizes of the crystal grains and the crystallinity are controllable; finally; the production requirement that the compression strength of BCP biphase composite ceramic is improved or a degradation speed is regulated and controlled is met.

Owner:SUZHOU DINGAN ELECTRONICS TECH

Reforming protective agent and preparation method thereof

ActiveCN104593044AEvenly dispersedIncrease the number of active centersMolecular sieve catalystsRefining with metal oxidesManganese oxideBULK ACTIVE INGREDIENT

The invention provides a reforming protective agent. Acidified pseudoboehmite and an acidified molecular sieve are taken as a common carrier under the synergistic effect, uniform dispersion of active ingredients such as manganese oxide and ferric oxide is promoted, the pore channel structure of the carrier can be optimized, the pore size, pore volume and specific surface area are increased, more vacant orbits and active centers are formed in the space structure of the carrier, the components further comprise catalyst wastes, and the mechanical strength of the carrier can be improved. Meanwhile, the vacant orbits and active centers in the structures of the acidified pseudoboehmite and an acidified molecular sieve can be coordinated with the catalyst wastes and active ingredients in the manganese oxide, the active center sites of the catalyst are improved, and the reaction is promoted. Therefore, according to the reforming protective agent disclosed by the invention, the mechanical strength is improved, and the protective agent has the advantages that the desulfurization reaction activity is high, the desulfurization efficiency is high, the service life of the catalyst is long, and side reactions can be effectively avoided.

Owner:SHENYANG SANJUKAITE CATALYST

CHA-type silicon-aluminum-phosphorous molecular sieves, and preparation methods and applications thereof

ActiveCN105312083AControllable grain sizeEvenly distributedMolecular sieve catalystsDispersed particle separationMolecular sievePetrochemical

The invention discloses CHA-type silicon-aluminum-phosphorous molecular sieves, an automobile tail gas purification catalyst prepared with the molecular sieve, and preparation methods and applications thereof. The CHA-type silicon-aluminum-phosphorous molecular sieves are a series of molecular sieves with different oxide contents. The grain sizes are controllable and are uniformly distributed. The molecular sieves are especially suitable for satisfying the performance demands of automobile tail gas purification catalysts. Also, the automobile tail gas purification catalyst with the CHA-type silicon-aluminum-phosphorous molecular sieve as a carrier has excellent high-temperature and low-temperature hydrothermal stability and high-efficiency denitration catalytic activity. The molecular sieve can be widely applied in the aspects of petrochemical engineering, and chemistry and chemical engineering.

Owner:南京开丽环保材料有限公司

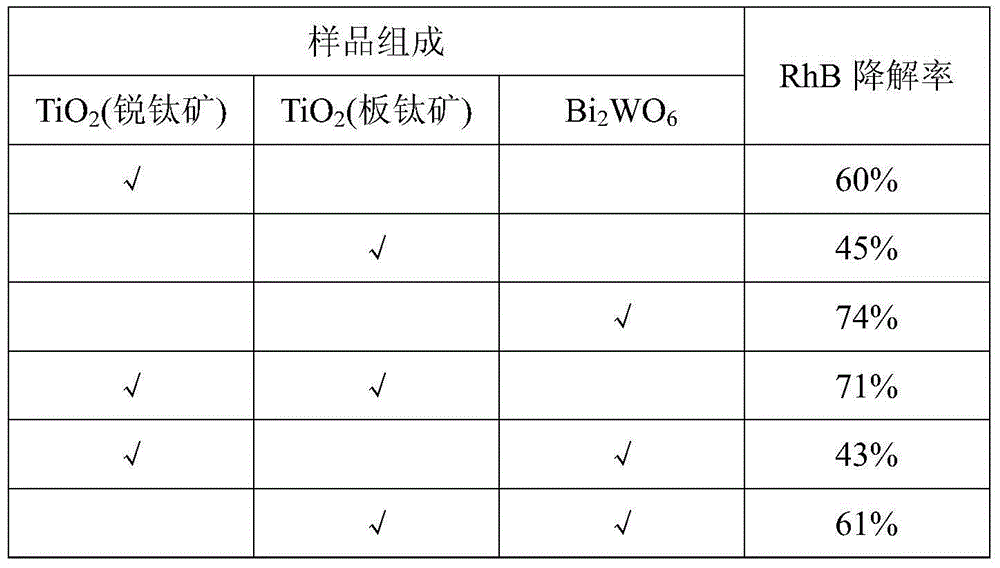

Visible light-sensitive semiconductor composite photocatalytic material and preparation method thereof

InactiveCN103331155ABroaden the photoresponse rangeHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionSolvent

The invention discloses a visible light-sensitive semiconductor composite photocatalytic material. The visible light-sensitive semiconductor composite photocatalytic material is characterized in that the visible light-sensitive semiconductor composite photocatalytic material is a TiO2 / Bi2WO6 composite crystal material having a multistage heterojunction structure and is prepared from 1-30 parts by mole of TiO2 nanocrystals, 1 part by mole of a tungsten salt and 1.8 to 2.2 parts by mole of a bismuth salt. The invention also discloses a preparation method of the visible light-sensitive semiconductor composite photocatalytic material. The TiO2 / Bi2WO6 composite crystal material has the multistage heterojunction structure so that photon-generated carrier separation is promoted. Through optimization of composition and a ratio of a reaction solvent, a particle size of a Bi2WO6 phase in the composite system is controlled so that a nanoscale TiO2 / Bi2WO6 composite photocatalyst is obtained. The visible light-sensitive semiconductor composite photocatalytic material has good photocatalysis effects in visible-light photocatalysis of RhB.

Owner:东莞上海大学纳米技术研究院 +1

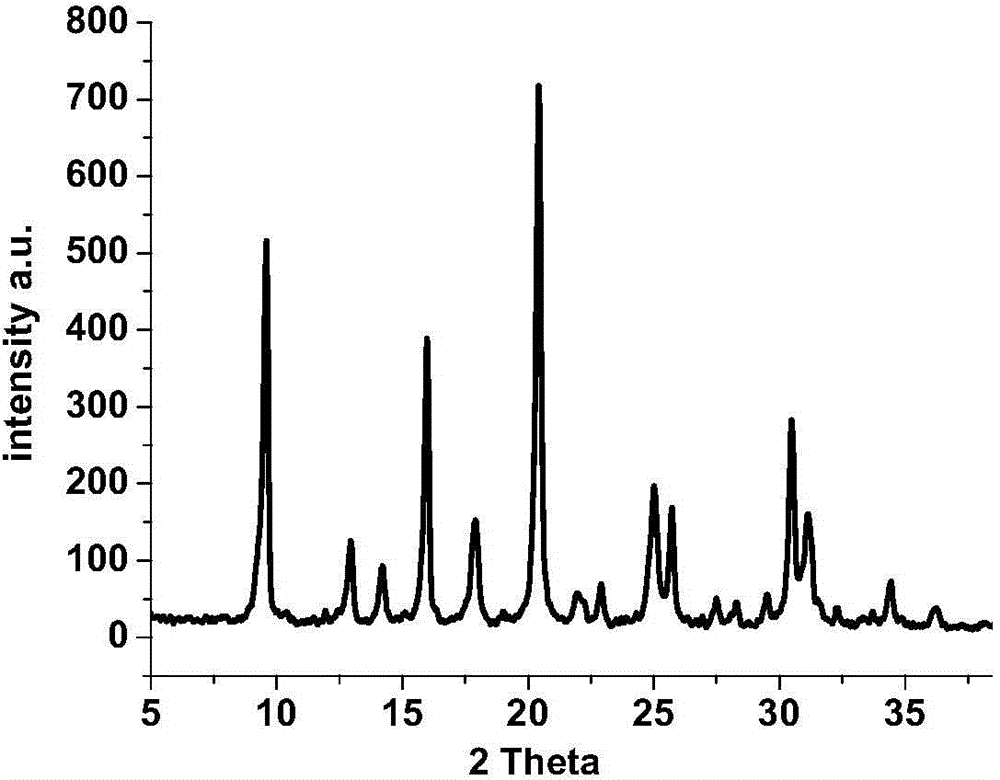

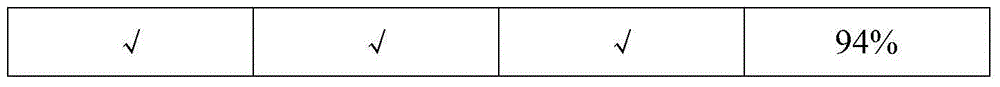

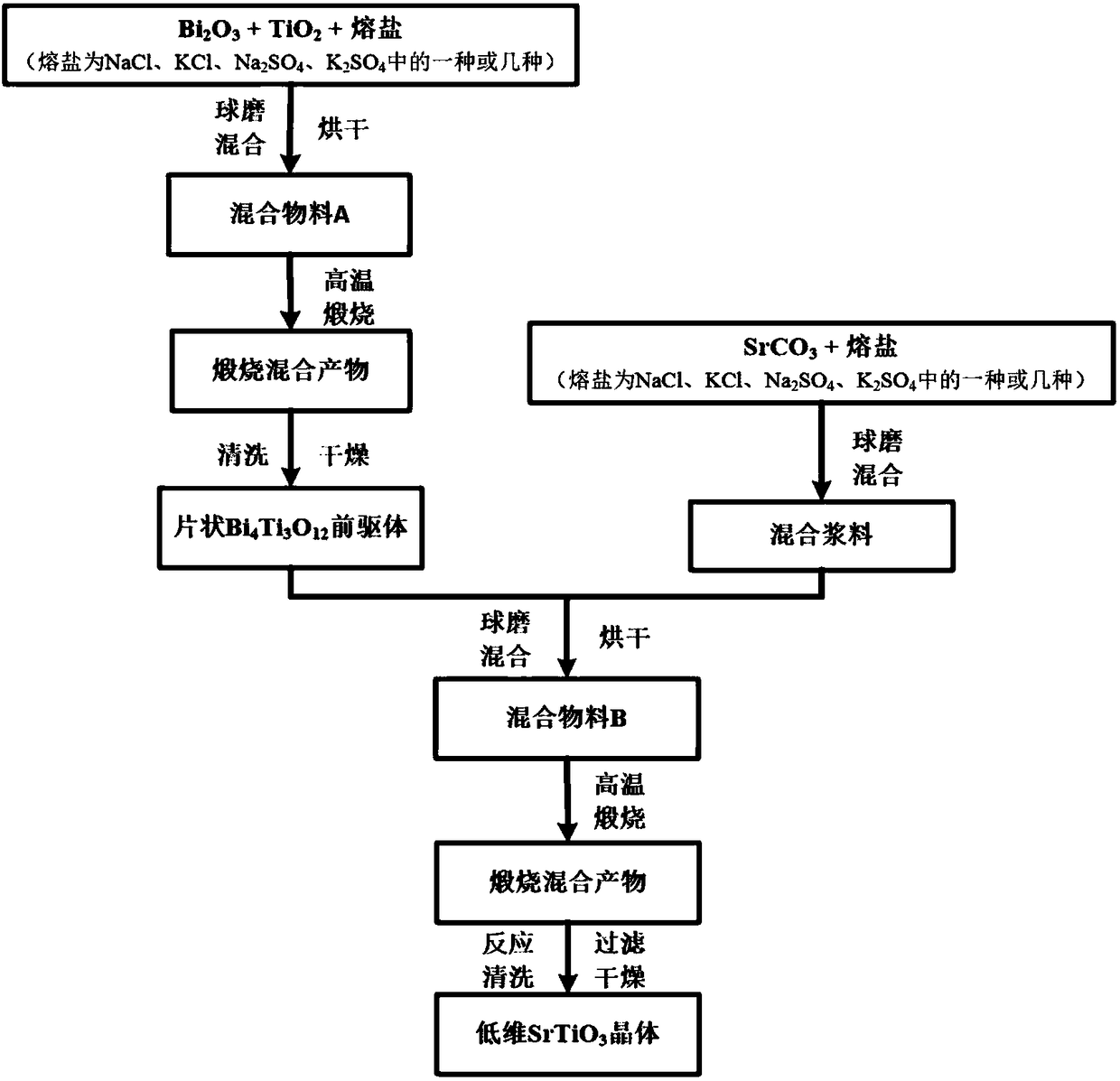

Synthesis method and application of size-controlled low-dimensional strontium titanate crystals

ActiveCN108147452AGood size controlSimple processAlkali titanatesNanotechnologyStrontium titanateSynthesis methods

The invention discloses a synthesis method and an application of size-controlled low-dimensional strontium titanate crystals, relates to a synthesis method and an application of strontium titanate crystals, and aims to solve the problems that plate SrTiO3 crystals prepared by an existing preparation process are excessive in particle size, narrow in controllable range and provided with polycrystalline aggregates, and narrow range, poor stability, low orientation degree and deteriorated performance in applications of the crystals are caused by impurity atoms in the crystals. The method includesthe steps: firstly, preparing precursor mixing raw materials; secondly, calcining the raw materials to prepare a precursor; thirdly, cleaning and dispersing the precursor to obtain a size-controlled plate Bi4Ti3O12 precursor with uniform particle size; fourthly, performing product mixing raw materials; fifthly, calcining the raw materials to prepare a product; sixthly, cleaning the product. The crystals are used for the field of preparation of photocatalysis, nano-devices, organic filler and energy storage, high-performance multifunctional electronic texture ceramics, thin films and mono-crystals. According to the method, the size-controlled low-dimensional strontium titanate crystals can be acquired.

Owner:HARBIN INST OF TECH

Method for extracting refined phenazine from RT base wastes

The invention provides a method for extracting refined phenazine from RT base wastes, belonging to the technical field of phenazine refining. The method provided by the invention has the advantages that high-purity phenazine crystals can be obtained, used solvents are all recovered and repeatedly-used solvents, and no waste liquid pollution exists. The adopted technical scheme is as follows: the refined phenazine is obtained in a manner that the RT base wastes are subjected to extraction twice, recrystallization twice, drying, solvent recovery and melting crystallization. According to the phenazine produced by the method, the purity can be stabilized over 99.8%, is much higher than the requirements of a pharmaceutical grade and can fully meet the market demand. The method is widely applied to the field of extracting the refined phenazine from the RT base wastes.

Owner:张国柱

Preparation method of nickel-coated carbon nanotube composite material

ActiveCN108546938AEasy to handleFacilitate depositionTransportation and packagingMetal-working apparatusNitrogen gasBiological activation

The invention relates to a preparation method of a nickel-coated carbon nanotube composite material. The preparation method comprises the following steps: (1) grinding a carbon nanotube, soaking the carbon nanotube with concentrated nitric acid and cleaning the carbon nanotube with hydrofluoric acid to remove impurities; (2) adding a sensitizing solution to sensitize, ultrasonically treating and stirring the mixture for 4-20 min, and filtering the mixture, wherein the sensitizing solution is prepared from SnCl2 and HCl; (3) adding an activating liquid to activate the mixture, ultrasonically treating and stirring the mixture for 7-30 min, and filtering the mixture after activation, wherein the activating liquid is prepared from Pb(NO3)2 and HNO3; and (4) adding a nickeling liquid and a reducer, adjusting the pH to 8.5-9.5, heating the mixture to 65-75 DEG C, stirring the mixture to react for 1-4 h, filtering and washing the mixture to be neutral, and carrying out thermal treatment for 4h at 380 DEG C under nitrogen protection to obtain the nickel-coated carbon nanotube, wherein the nickeling liquid, the reducer and the pH adjustor are prepared by the inventor. The prepared nickel-coated carbon nanotube composite material is good in uniformity and continuity of the coating, high in bonding force, controllable in metal grain size and suitable for being popularized and applied.

Owner:江苏博霖环保科技有限公司

In-Ga-O base oxide thermoelectric ceramic material and preparation method thereof

InactiveCN102351515ASolve the disadvantages of low thermoelectric performanceImprove electrical transmission performanceCrystalliteCrystal

The invention discloses an In-Ga-O base oxide thermoelectric ceramic material and a preparation method thereof. The preparation method comprises steps of: (1) sintering a mixture of Ga2O3 and In2O3 to obtain a precursor powder, wherein a molar ratio of Ga2O3 to In2O3 equals to a molar ratio of Ga to In in Ga1-xIn1+x (0.05<=x<=0.95); (2) carrying out discharge plasma sintering on the precursor powder and annealing to obtain the In-Ga-O base oxide thermoelectric ceramic material. Compared with an ordinary solid sintering, the method provided by the invention has advantages of short reaction time, low sintering temperature, controllable material crystal grain size and capability of synthesizing series of ceramic samples of different sizes.

Owner:TSINGHUA UNIV

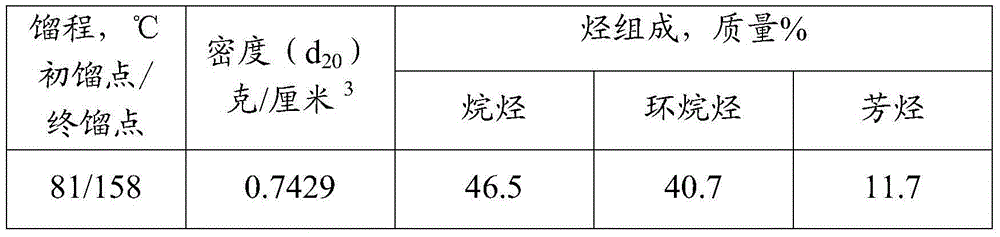

Hydrogen type germanium-silicon molecular sieve with ZSM-5 structure and preparation method thereof

ActiveCN104556108ARefine the grain sizeControllable grain sizeCrystalline aluminosilicate zeolitesCatalytic reformingPlatinum

The invention provides a hydrogen type germanium-silicon molecular sieve with a ZSM-5 structure. The non-aqueous chemical structural expression is GeO2.xSiO2, wherein x ranges from 10 to 400, and the grain size of the germanium-silicon molecular sieve is 1 to 4 microns. The molecular sieve is relatively large in grain size; a catalyst prepared after loading platinum is applied to catalytic reforming of naphtha, and the paraxylene selectivity is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

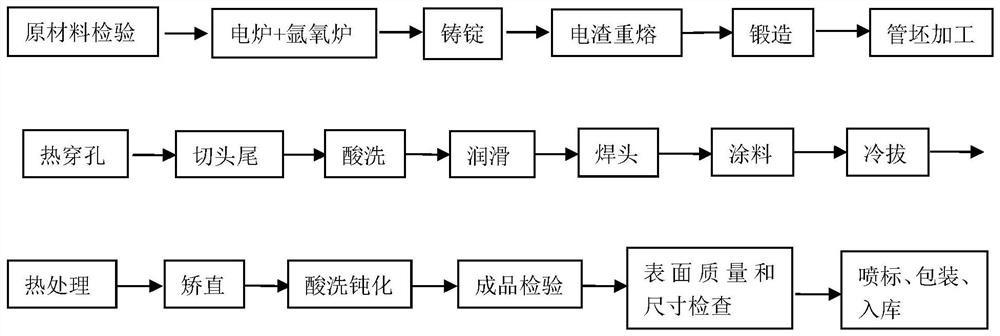

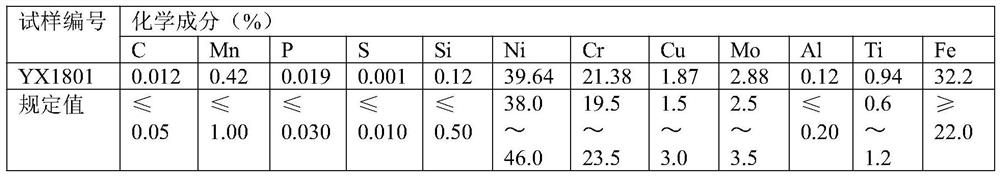

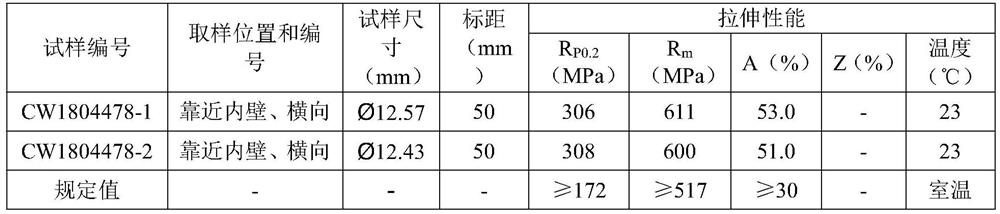

Production method of phi 762 * 48 mm large-diameter nickel-based alloy seamless tube for oil refining device

The invention discloses a production method of a phi 762*48 mm large-diameter nickel-based alloy seamless tube for an oil refining device. The method comprises the steps of electric furnace smelting,argon oxygen furnace refining, ingot casting, electroslag remelting, forging, tube blank machining, perforating, cold drawing and heat treatment. Technological parameters are optimized. The obtained phi 762 * 48 mm large-diameter nickel-based alloy seamless tube is pure in material, uniform in components, controllable in grain size and good in corrosion resistance, and the inspection result meetsthe technical requirement of the ASTM B423 standard. The product quality can be effectively guaranteed, the yield is high, batch production is facilitated, imported goods can be replaced by the phi 762 * 48 mm large-diameter nickel-based alloy seamless tube, and the use requirement of domestic large oil refining devices for large-diameter thick-wall nickel-based alloy seamless tubes is met.

Owner:ZHONGXING ENERGY EQUIP

Method for preparing grain size-controllable solid phase synthetic molecular sieve

ActiveCN107010640ASmall grain sizeImprove catalytic selectivityPentasil aluminosilicate zeoliteSolid phasesCrystallite

The invention belongs to the field of material chemistry, and relates to a method for preparing a grain size-controllable solid phase synthetic molecular sieve. The invention provides the grain size-controllable solid phase synthetic molecular sieve; the preparation method of the molecular sieve concretely comprises the following steps: adding a solid silicon source, an aluminum source, a template agent and an alkali source, crushing the added materials together with a seed crystal, mixing and taking the obtained mixture as a reaction raw material; carrying out a crystallization reaction, roasting the product of the crystallization reaction and removing the template agent so as to obtain the grain size-controllable solid phase synthetic molecular sieve. The method for preparing the grain size-controllable solid phase synthetic molecular sieve can be used for obtaining the ZSM-5 molecular sieve, which is high in relative crystallinity and has a grain size controllable within a certain range, by controlling the adding amount of the ZSM-5 seed crystal, thus improving the catalytic selectivity of the ZSM-5 molecular sieve; furthermore, by adopting solid-phase synthesis, the method can reduce the discharge of waste water, thus realizing a green molecular sieve synthesis route.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method for producing ultra-thick tungsten plate through tungsten rod upsetting

The invention discloses a method for producing an ultra-thick tungsten plate through tungsten rod upsetting. The method for producing the ultra-thick tungsten plate through tungsten rod upsetting comprises the following steps that (1) tungsten powder with the Fisher particle size being 3.0-3.5 microns is selected, and the tungsten powder is pressed into tungsten rods with a cold isostatic pressingmethod; (2) in a sintering device in a hydrogen atmosphere, heating and sintering are conducted on the tungsten rods, and tungsten rod blanks are obtained after natural cooling, wherein the highest temperature of heating and sintering is 2300-2350 DEG C, and the temperature keeping time is 6-12 h; (3) in a hydrogen molybdenum wire furnace in a hydrogen atmosphere, the tungsten rod blanks are heated, wherein the heating temperature is 1550-1580 DEG C, and the heating time is 1.5-2.5 h; (4) upsetting forging is conducted on the tungsten rod blanks on a 750 kg air hammer, and a thick tungsten plate is obtained; (5) the forged thick tungsten plate undergoes stress relief annealing in the hydrogen molybdenum wire furnace; (6) the outline of the tungsten plate is cut through wire-electrode cutting, and the ultra-thick polished tungsten plate is obtained after grinding with a surface grinding machine.

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

A kind of nano silicon carbide particle reinforced aluminum matrix composite material and preparation method thereof

The invention relates to the technical field of particle-reinforced aluminum-based composite materials, and discloses a nano-silicon carbide particle-reinforced aluminum-based composite material and a preparation method thereof. The composite material is composed of nano-silicon carbide particles with a volume fraction of 6-16% uniformly distributed in an aluminum alloy with a volume fraction of 84-94%. The preparation method is firstly through batching, ball milling, preforming and hot pressing Prepare 1-5% nano-silicon carbide particle-reinforced aluminum-based composite material, then vacuum concentrate and evaporate part of the aluminum alloy matrix, and finally undergo solid solution and aging treatment to obtain the reinforced aluminum-based composite material with nano-silicon carbide particle content of the present invention. Material. Experimental data proves that the reinforced aluminum matrix composite material with high nano-silicon carbide particle content prepared by the present invention not only has high thermal conductivity, electrical conductivity, specific modulus, wear resistance and other functional properties due to the high content of nano-silicon carbide particles, but also takes into account the strength and plastic toughness.

Owner:HENAN UNIV OF SCI & TECH

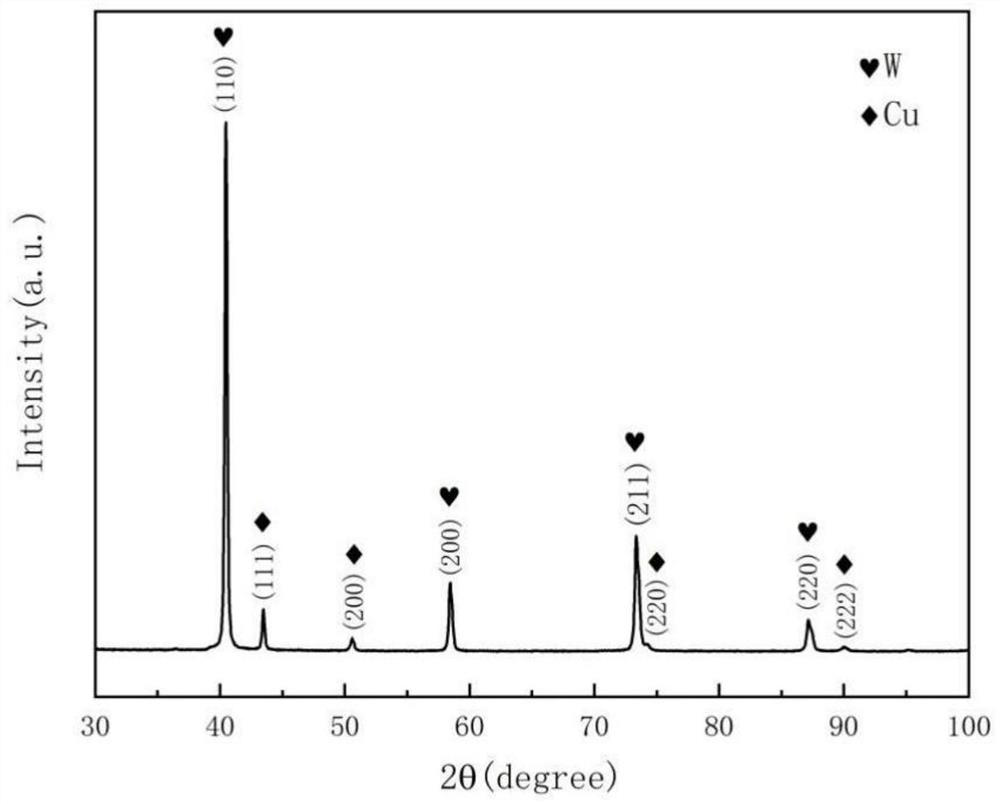

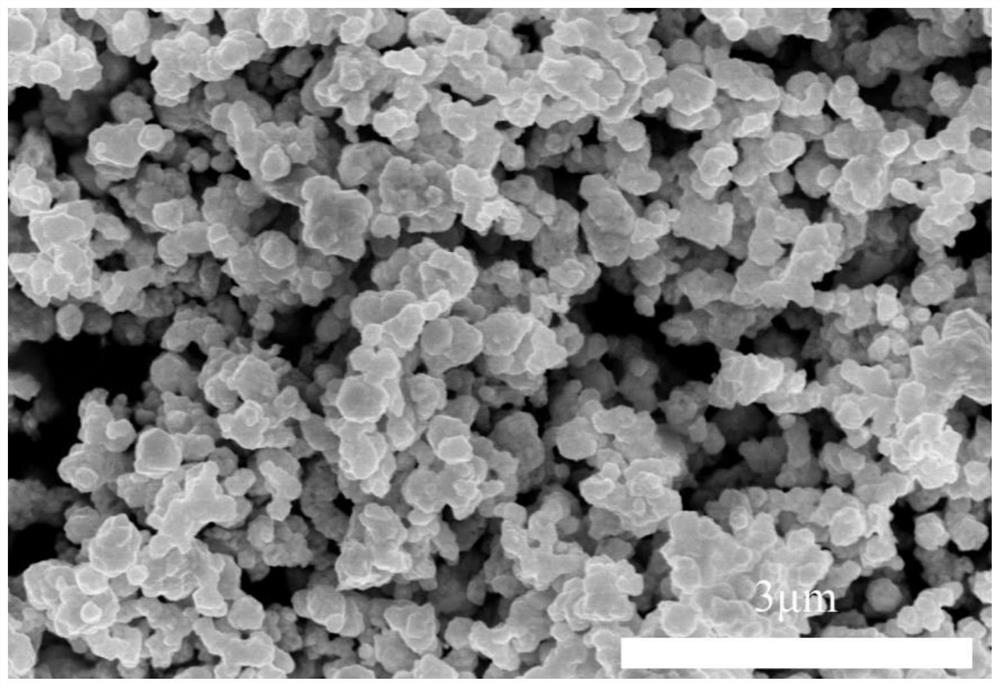

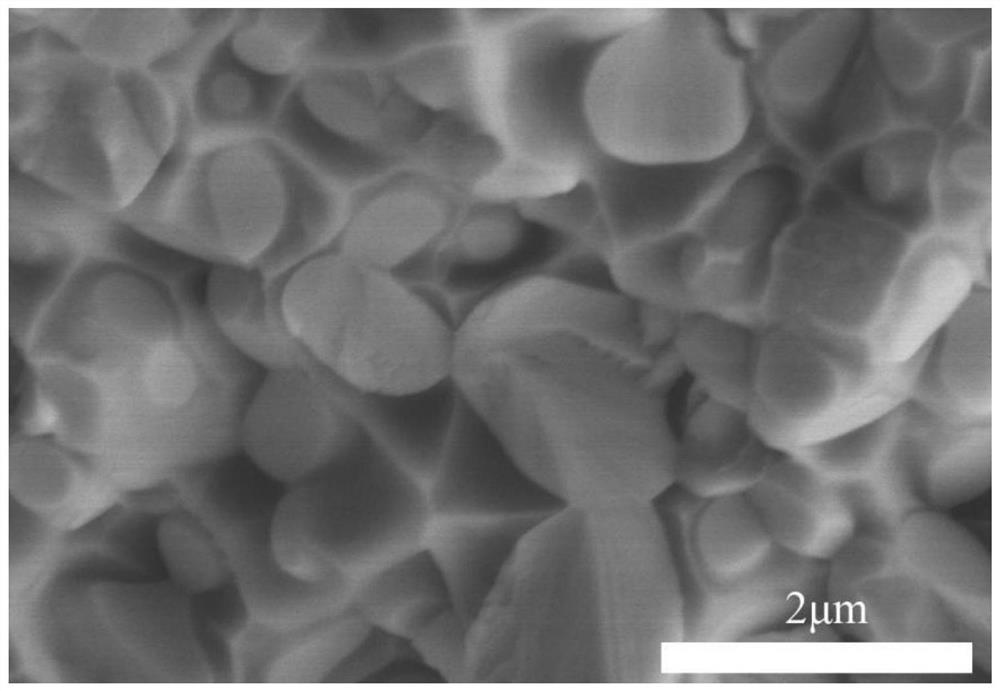

W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient and preparation method thereof

PendingCN113909484AHigh sintering activityImprove density and physical propertiesSemiconductor/solid-state device detailsSolid-state devicesThermal conductivityThermal transmittance

The invention discloses W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient. The thermal conductivity is 200-235W / (m.K), and the thermal expansion coefficient is (5.6-9.3) * 10<-6> / K. The invention further discloses a preparation method of the W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient. The preparation method comprises the following steps of: preparing a W-Cu precursor by adopting a wet chemical method; carrying out pyrolysis reduction on the W-Cu precursor in a hydrogen environment; and carrying out compression molding on the reduced W-Cu composite powder, then heating to 1100-1300 DEG C in a hydrogen atmosphere, carrying out heat preservation for 100-140 minutes, and cooling to obtain the W-Cu composite powder. According to the preparation method, the W-Cu composite precursor is prepared by adopting the wet chemical method, the W-Cu composite powder with high sintering activity is obtained through different reduction process combinations, and then the W-Cu composite powder with high density, high thermal conductivity, low thermal expansion coefficient and uniform tissue distribution is prepared through subsequent liquid phase sintering.

Owner:安徽亿恒新材料科技有限公司

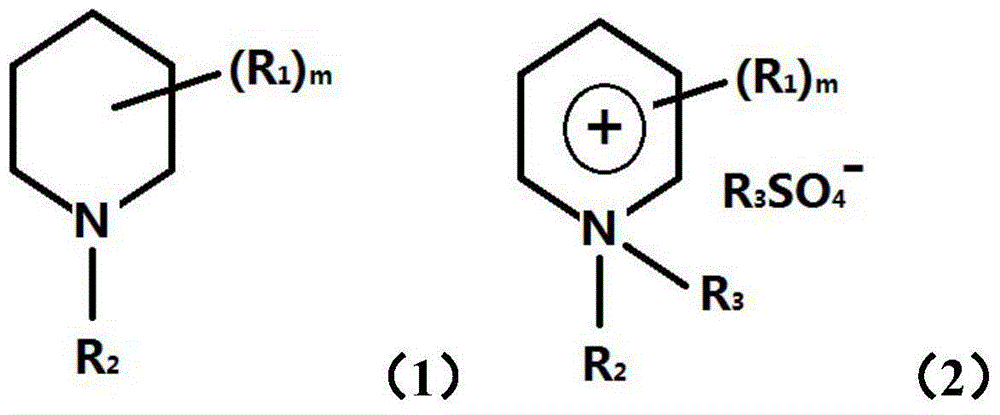

Template agent and preparation method therefor and application thereof

ActiveCN105315195AControllable grain sizeEvenly distributedCatalyst carriersMolecular sieve catalystsExhaust gasMolecular sieve

The invention discloses a template agent used in the preparation of a carrier for a catalyst for automobile exhaust gas purification and a preparation method therefor and application thereof. The template agent is particularly suitable for preparing novel AEI type silicon-aluminum molecular sieves. In addition, the template agent can be effectively prepared by the method disclosed by the invention, and the total yield of reaction reaches up to 80%; and the method is simple, is low in cost and is applicable to industrial production.

Owner:南京开丽环保材料有限公司

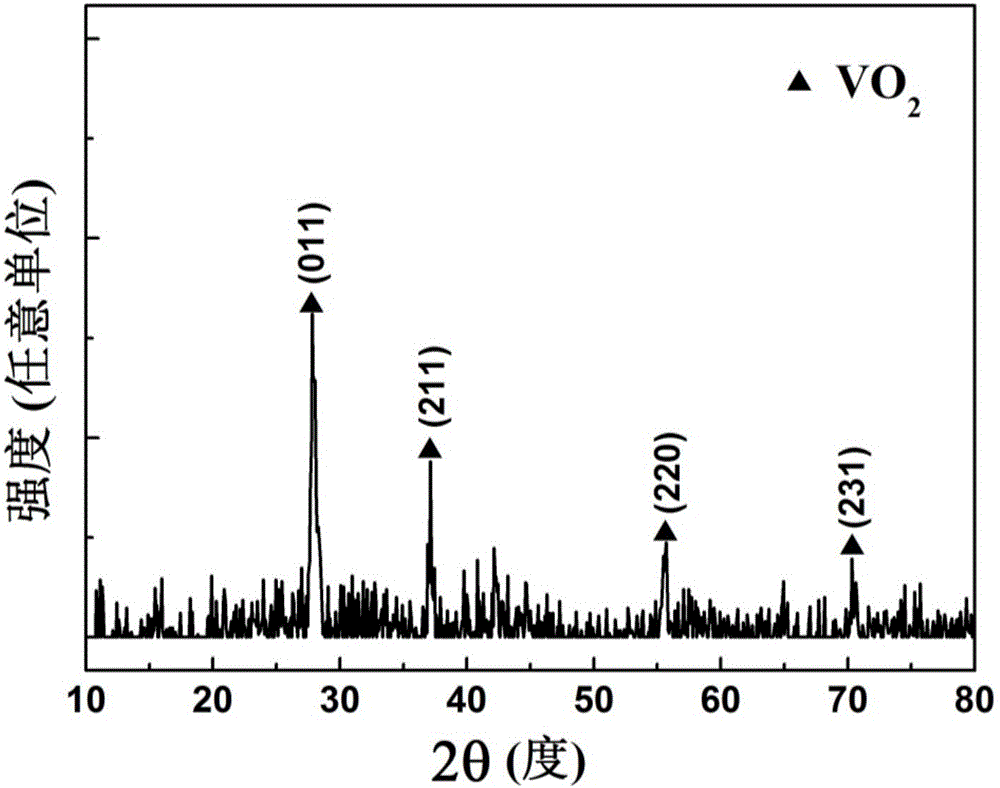

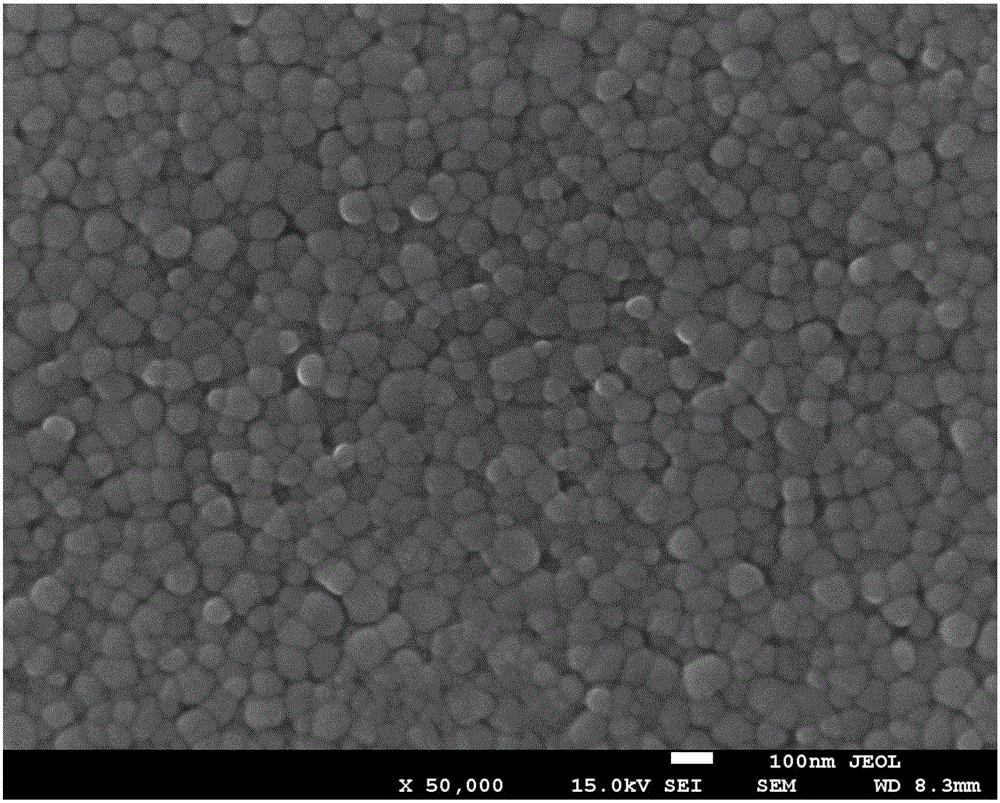

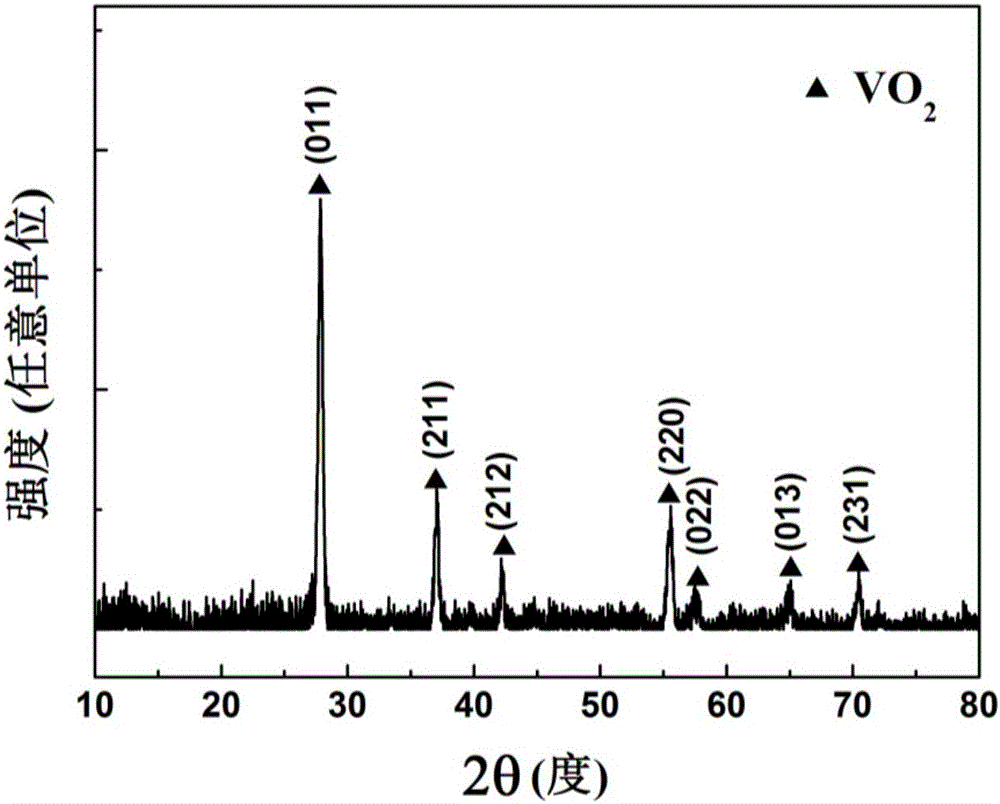

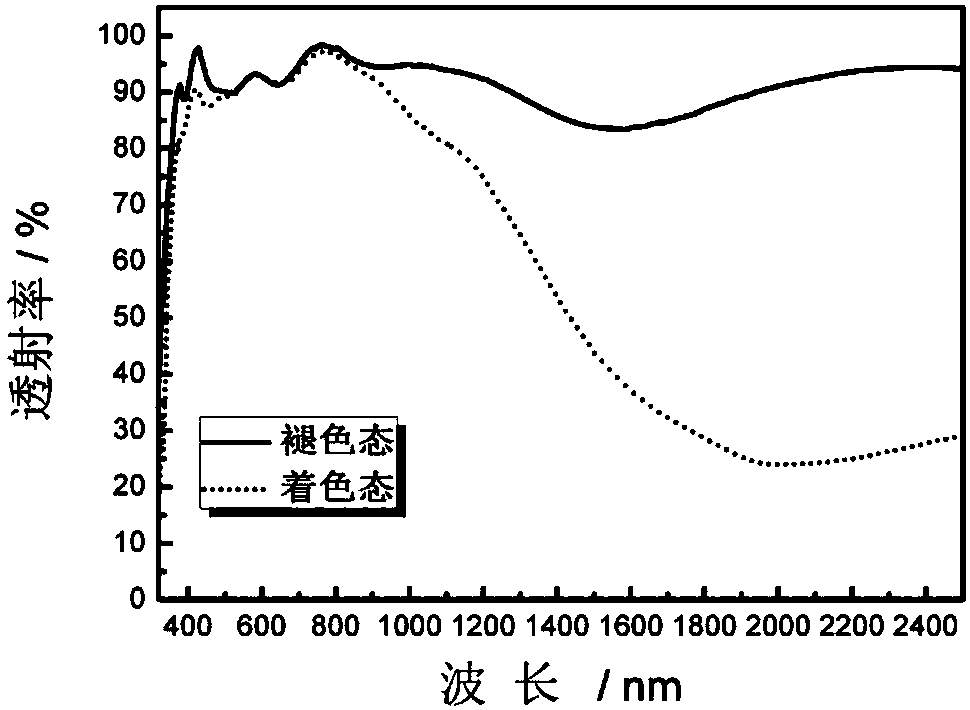

Preparation method for vanadium dioxide nano-particle film

ActiveCN106048532AGet rid of dependenceEasy and quick to makeVacuum evaporation coatingSputtering coatingVanadium dioxideTube furnace

The invention relates to the field of intelligent film material, in particular to a preparation method for a vanadium dioxide nano-particle film. According to the preparation method, a metal vanadium film is prepared through the magnetron sputtering method, then is placed into an open tube furnace with nitrogen gas for undergoing high temperature annealing treatment and is fast taken out and cooled after heat preservation for a certain period of time. According to the preparation method, complex vacuum heat treatment equipment is not needed, and the required vanadium dioxide film can be obtained through the simple oxidation reaction. The process and the technology are simple and controllable, grains of the prepared film are uniform in size and small, and the phase transition property is obvious. A new technology low in cost, short in cycle and capable of being applied industrially is provided for the vanadium dioxide film material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preparing antimony-doped tin oxide electrochromic film

The invention discloses a method for preparing an antimony-doped tin oxide electrochromic film. The method particularly comprises the following steps: step 1, preparing a spray liquid: firstly, addingantimony butter into acetylacetone, then, adding tin chloride pentahydrate, adding acetic anhydride after the obtained mixed solution is cooled to the room temperature, performing stirring for 30 minat the room temperature, finally, adding absolute ethyl alcohol, and performing stirring for 20 min at the room temperature to obtain an ATO spray liquid; step 2, preparing an ATO film: at first, placing a soda-lime glass substrate into a heating furnace, heating the soda-lime glass substrate up to 350-450 DEG C, driving the soda-lime glass substrate to translate into a spray room by means of a transmission device, using an ultrasonic spray gun to spray the ATO spray liquid, prepared in step 1, onto the soda-lime glass substrate by taking nitrogen as a carrier gas, performing cooling with strong wind after ending of spraying, and unloading coated glass to finally obtain the antimony-doped tin oxide electrochromic film. The method is simple in process and does not need a special vacuum environment or a reaction room.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com