Medical ultra-fine grain titanium alloy with ultrahigh plasticity, high strength and low modulus and preparation method thereof

An ultra-fine grain, titanium alloy technology, used in medical science, prosthesis, etc., to achieve the effect of controllable grain size, simple processing process, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

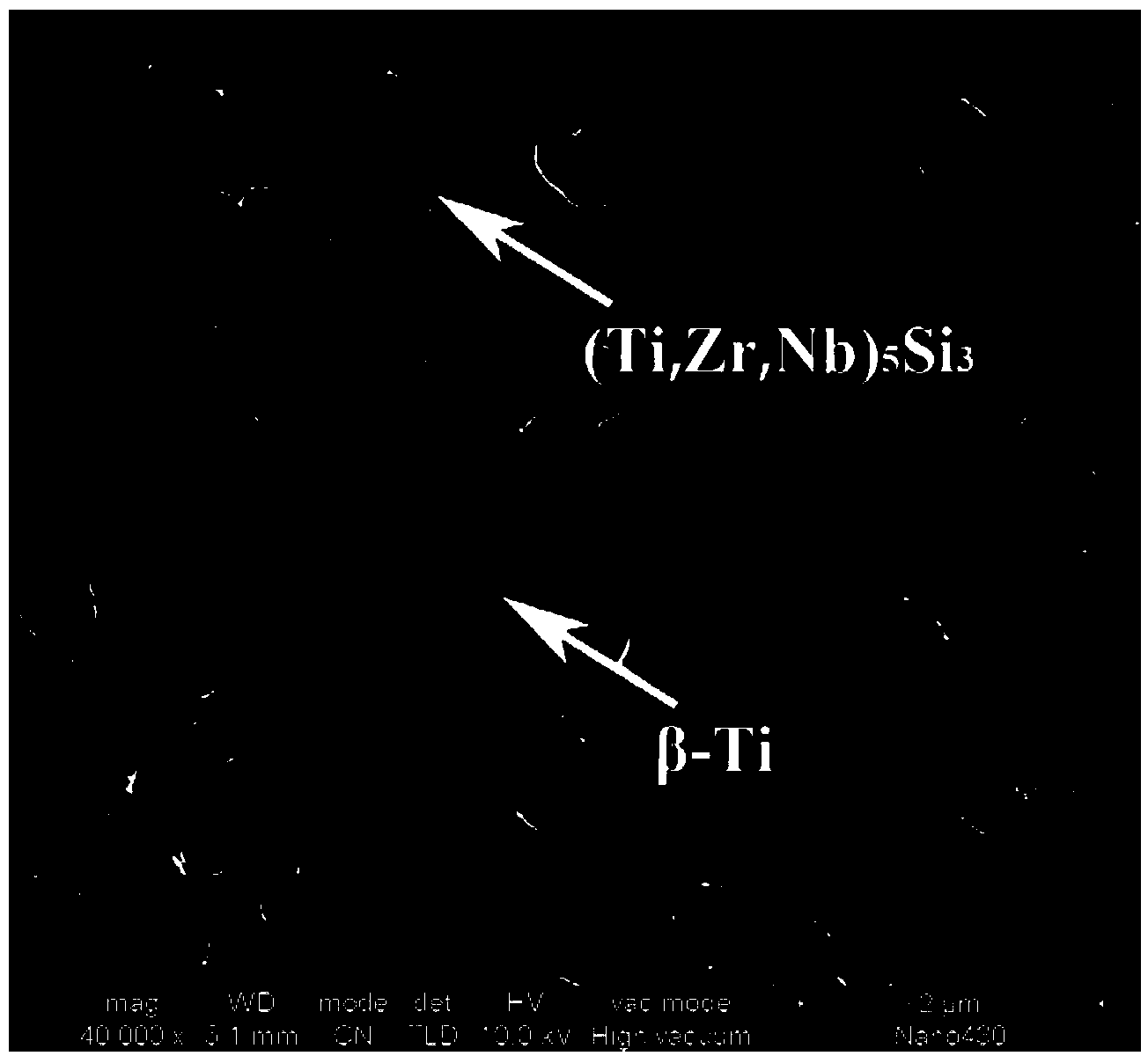

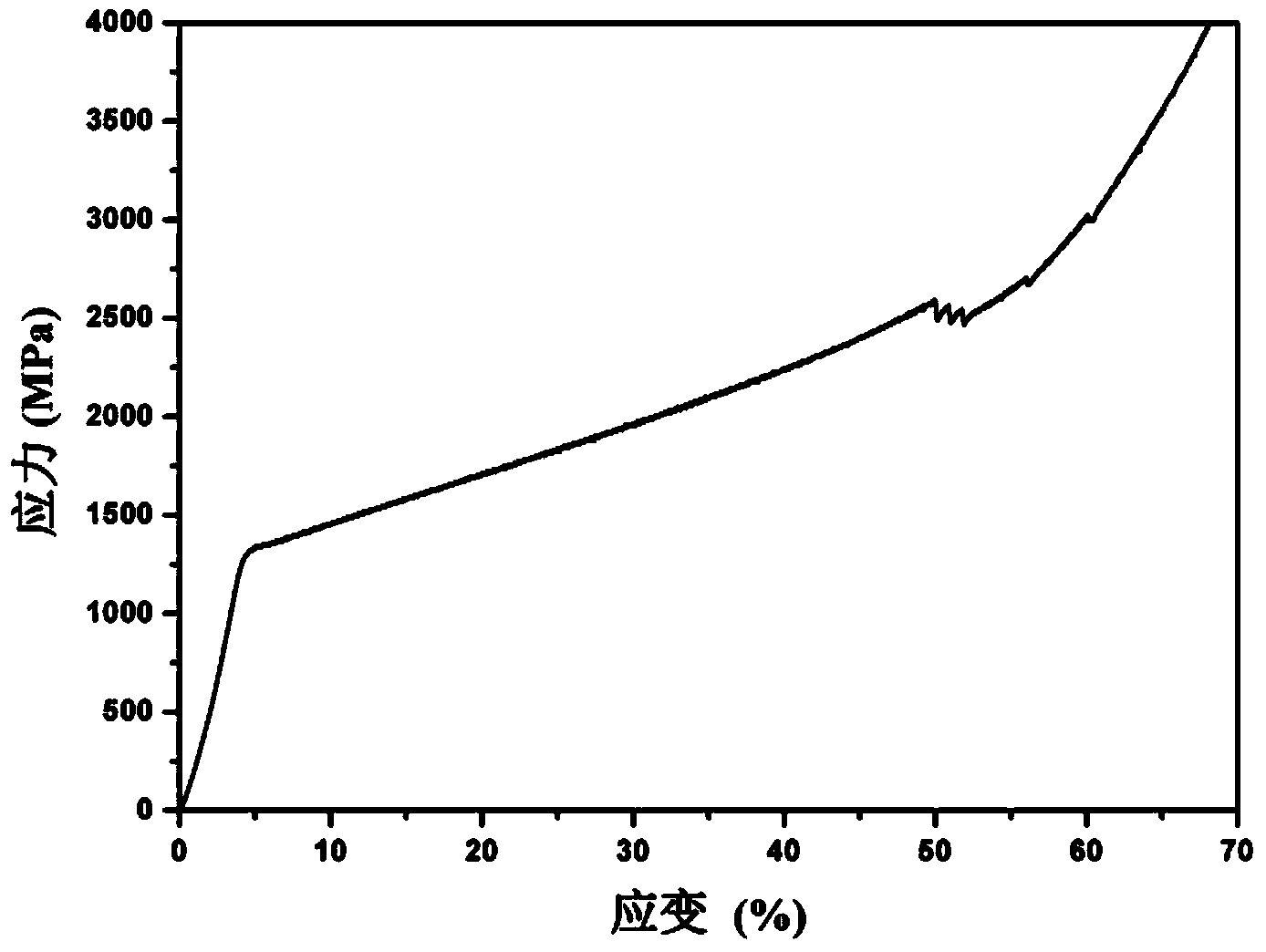

[0040] Prepare ultra-high plasticity, high-strength and low-mode medical ultra-fine-grained titanium alloys according to the following steps:

[0041] Step 1: Mix the powder

[0042] First, according to the following elements and element atomic percentage ingredients: Ti: 68at.%, Nb: 23at.%, Zr: 5at.%, Ta: 2at.%, Si: 2at.%, and unavoidable trace impurities; all components The components are all elemental powders, the average particle size is about 48 μm, and the purity of the particle powder is above 99.5wt.%. The elemental powders were then mixed for 4 hours in a V-0.002 mixer.

[0043] Step 2: Preparation of amorphous alloy powder by high energy ball milling

[0044] The well-mixed elemental powders were placed in a QM-2SP20 planetary ball mill for high-energy ball milling. The ball milling tank and balls were made of stainless steel. The diameters of the balls were 15, 10, and 6 mm, respectively, and the weight ratio was 1:3:1. The high-energy ball milling process parame...

Embodiment 2

[0055] Prepare ultra-high plasticity, high-strength and low-mode medical ultra-fine-grained titanium alloys according to the following steps:

[0056] Step 1: Mix the powder

[0057] First, according to the following elements and element atomic percentage ingredients: Ti:65at.%, Nb:24at.%, Zr:5at.%, Ta:1at.%, Si:5at.%, and unavoidable trace impurities; all components The components are all elemental powders, the average particle size is about 48 μm, and the purity of the particle powder is above 99.5wt.%. The elemental powders were then mixed for 4 hours in a V-0.002 mixer.

[0058] Step 2: Preparation of amorphous alloy powder by high energy ball milling

[0059] The well-mixed elemental powders were placed in a QM-2SP20 planetary ball mill for high-energy ball milling. The ball milling tank and balls were made of stainless steel. The diameters of the balls were 15, 10, and 6 mm, respectively, and the weight ratio was 1:3:1. The high-energy ball milling process parameters ...

Embodiment 3

[0070] Prepare ultra-high plasticity, high-strength and low-mode medical ultra-fine-grained titanium alloys according to the following steps:

[0071] Step 1: Mix the powder

[0072] First, according to the following elements and element atomic percentage ingredients: Ti: 70at.%, Nb: 24at.%, Zr: 5at.%, Ta: 1at.%, Si: 0at.%, and unavoidable trace impurities; all components All are elemental powders, the average particle size is about 48 μm, and the purity of the particle powder is above 99.5wt.%. The elemental powders were then mixed for 4 hours in a V-0.002 mixer.

[0073] Step 2: Preparation of amorphous alloy powder by high energy ball milling

[0074] The well-mixed elemental powders were placed in a QM-2SP20 planetary ball mill for high-energy ball milling. The ball milling tank and balls were made of stainless steel. The diameters of the balls were 15, 10, and 6 mm, respectively, and the weight ratio was 1:3:1. The high-energy ball milling process parameters are as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com