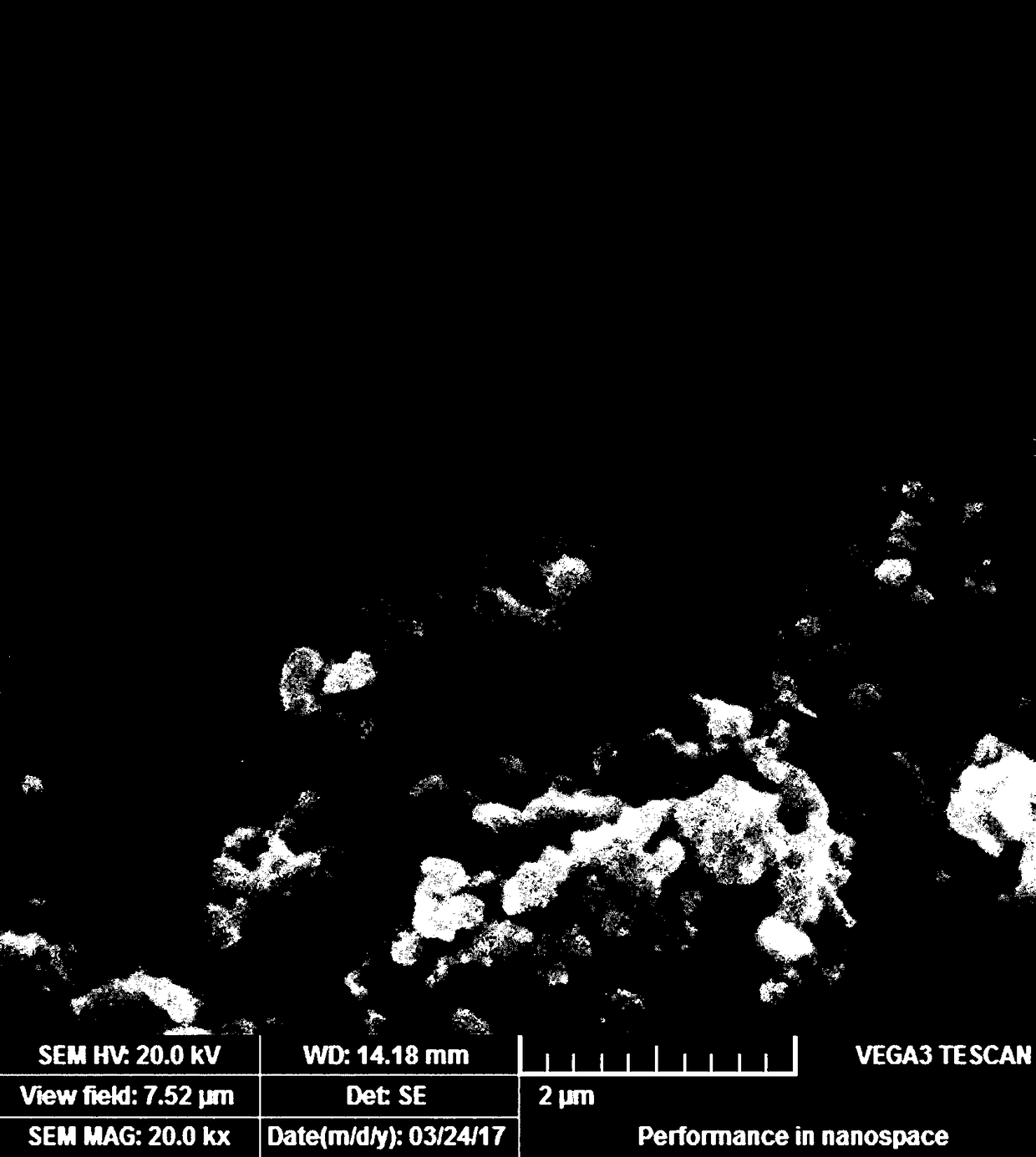

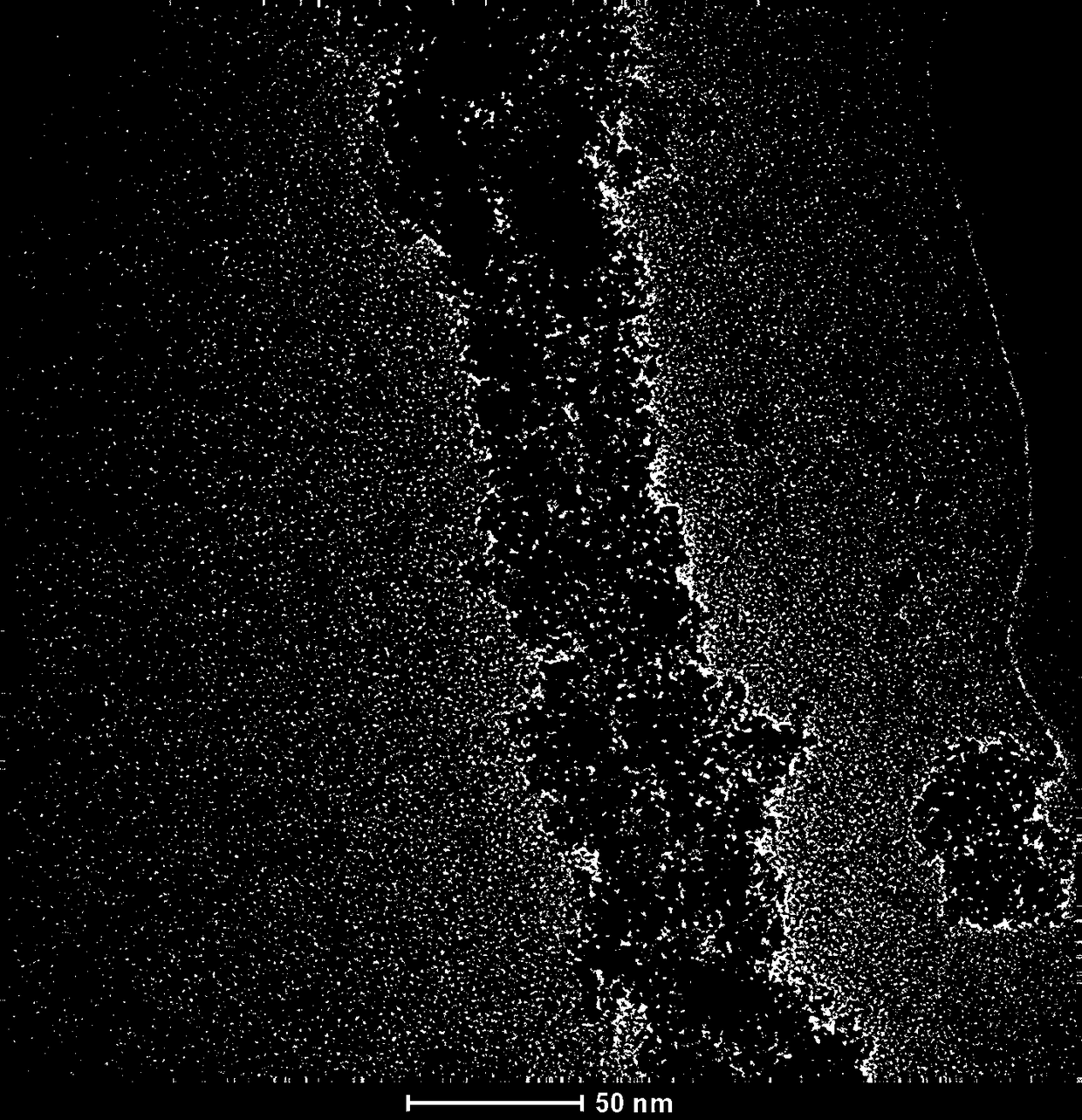

Preparation method of nickel-coated carbon nanotube composite material

A technology of carbon nanotubes and composite materials, applied in metal material coating process, transportation and packaging, liquid chemical plating, etc., can solve the problems of difficult control of coating uniformity and thickness, high preparation cost, etc., so as to facilitate the organization of procurement and production , low porosity, good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of nickel-coated carbon nanotube composite material, consisting of the following steps in turn:

[0027] (1) Weigh an appropriate amount of carbon nanotubes and place them in an agate mortar grinder for 1 hour, transfer them to a glass container, add concentrated nitric acid solution with a mass fraction of 69% to immerse the carbon nanotubes, and stir at room temperature for 24 hours. After filtration, rinse with distilled water until neutral, then transfer the carbon nanotubes into a plastic container, add hydrofluoric acid solution with a mass fraction of 40%, stir at room temperature for 6 hours, filter, rinse with distilled water until neutral, and store at 70°C drying;

[0028] (2) Add a sensitizing solution 70 times the mass of carbon nanotubes to the carbon nanotubes treated in step (1) for sensitization treatment. During the sensitization process, first turn on the ultrasonic oscillator for 5 minutes, and then turn on the magnetic stirrer f...

Embodiment 2

[0035] A kind of preparation method of nickel-coated carbon nanotube composite material of the present invention, consists of following steps successively:

[0036] (1) Weigh an appropriate amount of carbon nanotubes and place them in an agate mortar grinder for 1.5 hours, transfer them to a glass container, add concentrated nitric acid solution with a mass fraction of 69% to immerse the carbon nanotubes, and stir at room temperature for 20 hours. After filtration, rinse with distilled water until neutral, then transfer the carbon nanotubes into a plastic container, add hydrofluoric acid solution with a mass fraction of 30%, stir at room temperature for 12 hours, filter, rinse with distilled water until neutral, and store at 65°C drying;

[0037] (2) Add a sensitizing solution 100 times the mass of carbon nanotubes to the carbon nanotubes treated in step (1) for sensitization treatment. During the sensitization process, first turn on the ultrasonic oscillator for 8 minutes, an...

Embodiment 3

[0043] A kind of preparation method of nickel-coated carbon nanotube composite material of the present invention, consists of following steps successively:

[0044] (1) Weigh an appropriate amount of carbon nanotubes and place them in an agate mortar grinder for 0.5 hours, transfer them to a glass container, add concentrated nitric acid solution with a mass fraction of 69% to immerse the carbon nanotubes, and stir at room temperature for 12 hours. After filtration, rinse with distilled water until neutral, then transfer the carbon nanotubes into a plastic container, add hydrofluoric acid solution with a mass fraction of 35%, stir at room temperature for 10 hours, filter, rinse with distilled water until neutral, and store at 75°C drying;

[0045] (2) Add a sensitizing solution 40 times the mass of carbon nanotubes to the carbon nanotubes treated in step (1) for sensitization treatment. During the sensitization process, first turn on the ultrasonic oscillator for 10 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com