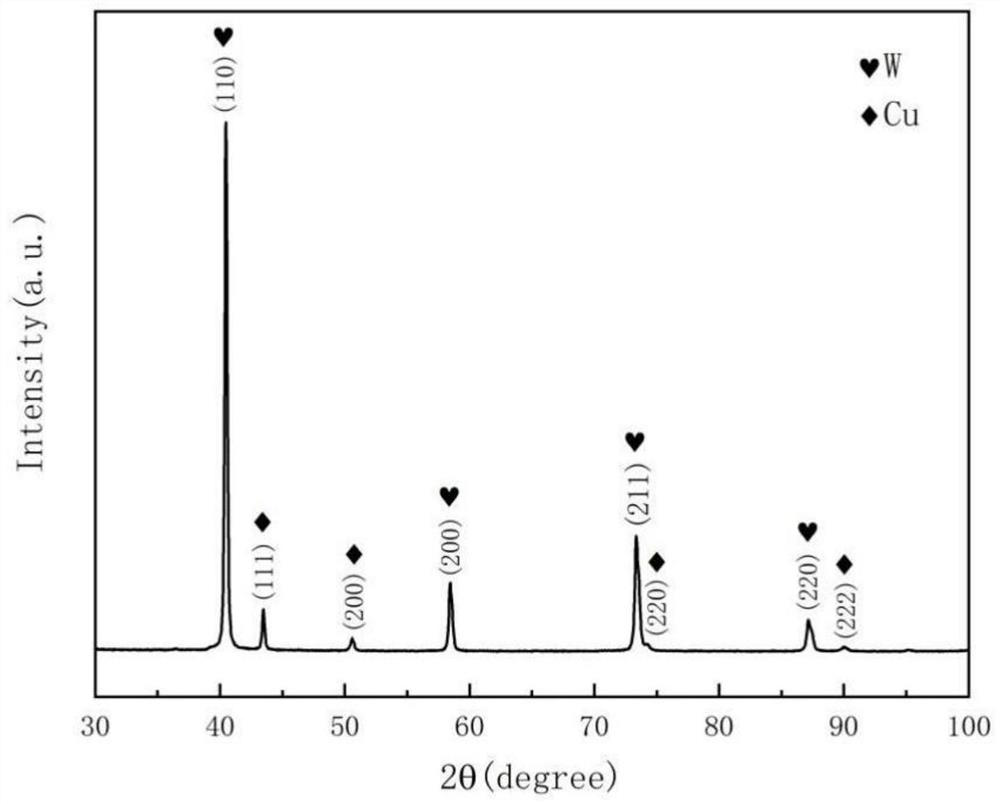

W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient and preparation method thereof

A low thermal expansion coefficient, composite powder technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problem of W and Cu immiscible wettability, unfavorable material physical properties, and difficult mass production To achieve the effect of improving density and physical properties, less agglomeration, and reducing thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

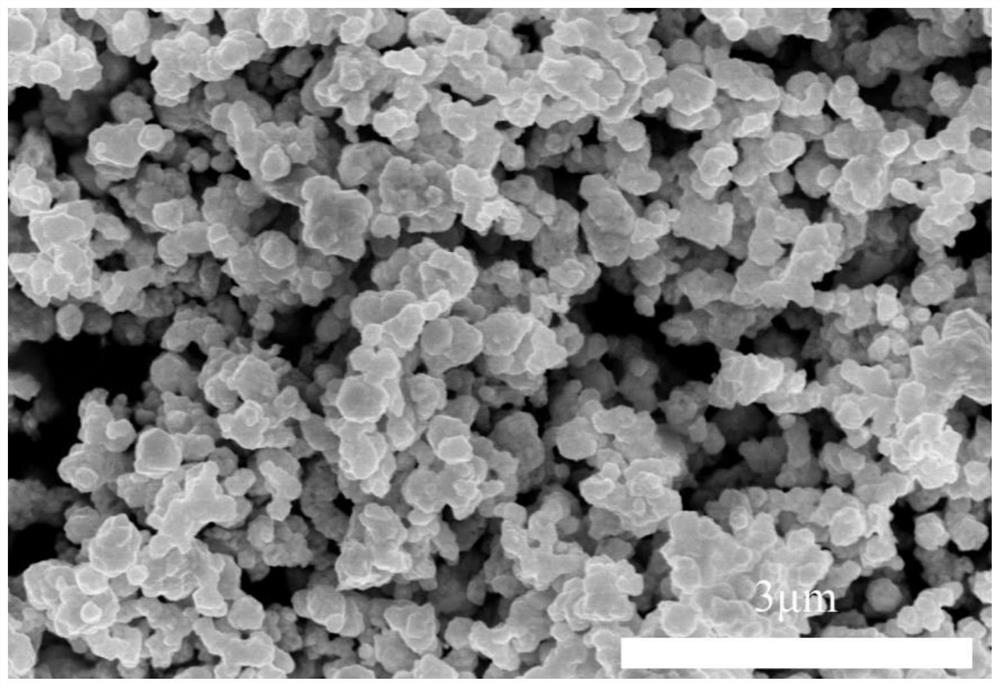

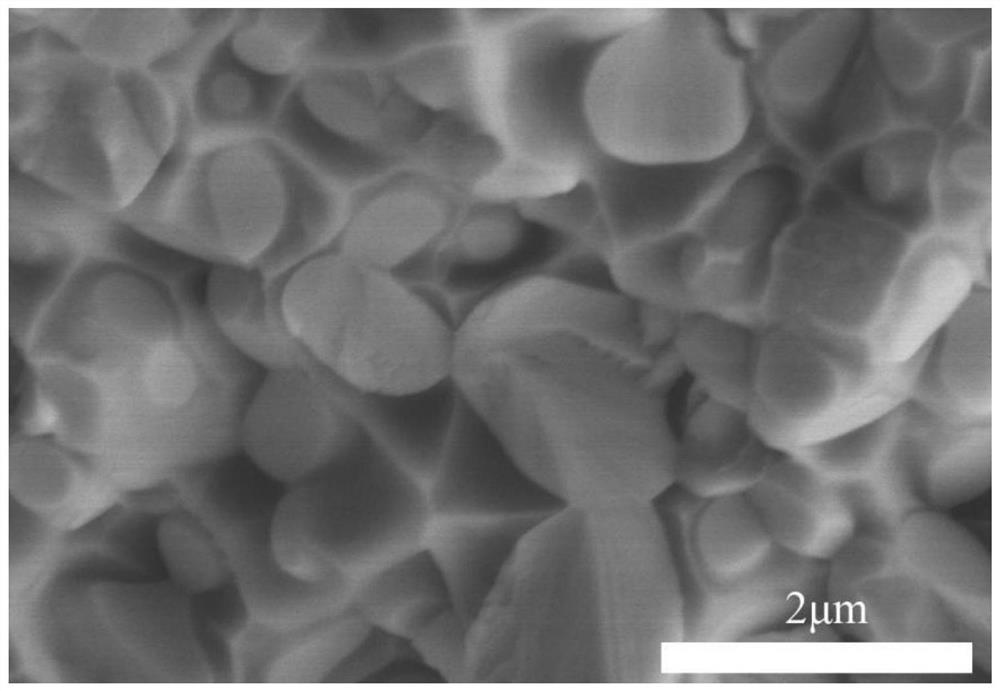

Embodiment 1

[0027] The preparation method of high thermal conductivity, low thermal expansion coefficient W-Cu composite powder is as follows:

[0028] Step 1: Precursor Preparation

[0029] Ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%) and copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, Aladdin, purity ≥ 99.5%) are dissolved in deionized water, heated and stirred to obtain a mixed solution, and after the mixed solution is transparent, add oxalic acid (C 2 h 2 o 4 2H 2 O, analytically pure), the precipitate obtained after the mixed solution was stirred and evaporated to dryness is the W-Cu precursor.

[0030] Among them, the addition amount of copper nitrate and oxalic acid is 70.41% and 39% of the mass of ammonium metatungstate respectively.

[0031] Step 2: Hydrogen reduction

[0032] Fully grind the massive precursor obtained in step 1 in a mortar to obtain fine powder, put the burning boat containing the fine powder into a hydrogen (hydrogen purity ≥ 99.999%) reduction furnace f...

Embodiment 2

[0040] The chemical preparation method of W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient is as follows:

[0041] Step 1: Precursor preparation

[0042] Ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%) and copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, Aladdin, purity ≥ 99.5%) are dissolved in deionized water, heated and stirred to obtain a mixed solution, and after the mixed solution is transparent, add oxalic acid (C 2 h 2 o 4 2H 2 O, analytically pure), the precipitate obtained after the mixed solution was stirred and evaporated to dryness is the W-Cu precursor.

[0043] Wherein, the addition amount of copper nitrate and oxalic acid is respectively 31.29% and 38% of the mass of ammonium metatungstate.

[0044] Step 2: Hydrogen reduction

[0045] Fully grind the massive precursor obtained in step 1 in a mortar to obtain fine powder, put the burning boat containing the fine powder into a hydrogen (hydrogen purity ≥ 99.999%) reduc...

Embodiment 3

[0050] The preparation method of high thermal conductivity, low thermal expansion coefficient W-Cu composite powder is as follows:

[0051] Step 1: Precursor preparation

[0052] Ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%) and copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, Aladdin, purity ≥ 99.5%) are dissolved in deionized water, heated and stirred to obtain a mixed solution, and after the mixed solution is transparent, add oxalic acid (C 2 h 2 o 4 2H 2 O, analytically pure), the precipitate obtained after the mixed solution was stirred and evaporated to dryness is the W-Cu precursor.

[0053] Wherein, the addition amounts of copper nitrate and oxalic acid are respectively 120.70% and 40% of the mass of ammonium metatungstate.

[0054] Step 2: Hydrogen reduction

[0055] Fully grind the massive precursor obtained in step 1 in a mortar to obtain fine powder, put the burning boat containing the fine powder into a hydrogen (hydrogen purity ≥ 99.999%) reduction furnace f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com