Preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids

A reaction aid, zirconium boride technology, applied in the field of non-oxide composite ceramics to achieve uniform microstructure, low price and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

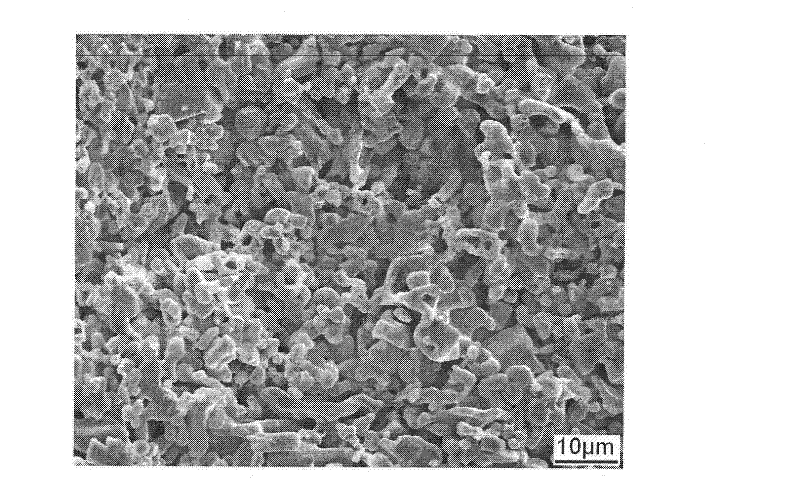

[0028] ZrB 2 (5~20μm, >90%) powder as raw material, Zr powder (5~15μm, 98%) and B 4 C powder (≤2μm, 99%) is a sintering aid, and the design reaction aids Zr and B 4 The amount of C added is 10wt%, and 4.16g zirconium powder and 0.84g B 4 C powder was added into a plastic tank, and ethanol was added to ultrasonically disperse for 15 minutes, and Si 3 N 4 After mixing the balls as the medium for 12 hours, add 45g of ZrB 2 , mixed for 12h, then removed ethanol with a rotary evaporator, dried and sieved to obtain ZrB containing reactive sintering aids 2 Powder. Put the uniformly mixed powder in a graphite mold coated with BN on the inner wall surface, and carry out reaction sintering in vacuum. The heating rate during sintering is 10-20°C / min. After the temperature rises to 1450°C, keep it at 1450°C for 30 minutes. After the heat preservation is over, apply a pressure of 20-30 MPa, then raise the temperature to a sintering temperature of 2000°C, and hold heat and pressure fo...

Embodiment 2

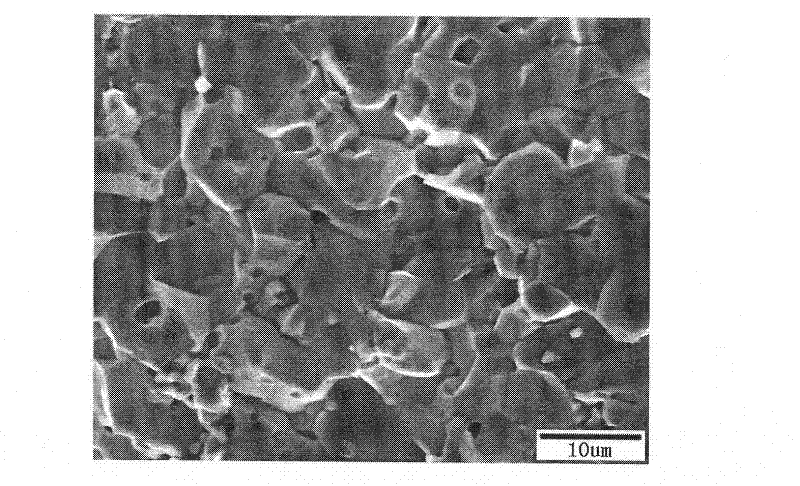

[0030] Design ZrB 2 Medium Zr and B 4 The amount of C added is 20wt%, among them, ZrB 2 Powder 40g, Zr powder 8.32g, B 4 C powder 1.68g. Ceramics were prepared according to the method of Example 1, the sintering temperature was 1900° C., and the heat preservation and pressure holding were carried out for 1 hour. The relative density of the material reaches 98.5%. After the mechanical performance test, the hardness of the material is 17GPa, and the toughness: 5.5MPa m 1 / 2 , Bending strength: 650MPa.

Embodiment 3

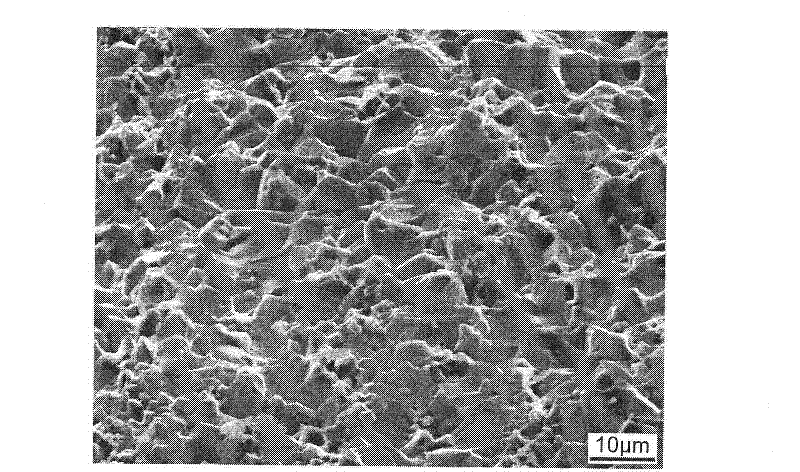

[0032] ZrB 2 Powder (5-20μm, >90%) is used as raw material, Zr powder (5-15μm, 98%) and C powder (≤2μm, 99%) are used as sintering aids, ZrB powder is designed 2 The addition amount of Zr and C is 10wt%. Add 4.42g of Zr powder and 0.58g of C powder into a plastic tank, add ethanol and ultrasonically disperse for 15min, then mix Si on a roll mixer 3 N 4 After mixing the ball for 12 hours, add 45g ZrB 2 , mixed for 12h, then removed ethanol with a rotary evaporator, dried and sieved to obtain ZrB containing reactive sintering aids 2Powder. Ceramics were prepared according to the method of Example 1, the sintering temperature was 2000° C., and the heat preservation and pressure holding were carried out for 1 hour. The relative density of the material reaches 98%. After the mechanical performance test, the hardness of the material is 18GPa, and the toughness is 5.0MPa m 1 / 2 , Bending strength: 630MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com