Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Increase the number of active centers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

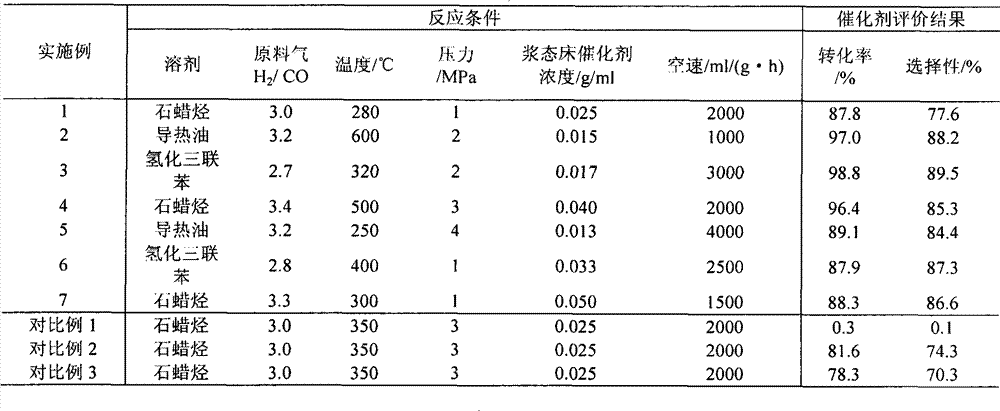

Loaded type nickel-based catalyst used for slurry bed methanation, and preparation method and application thereof

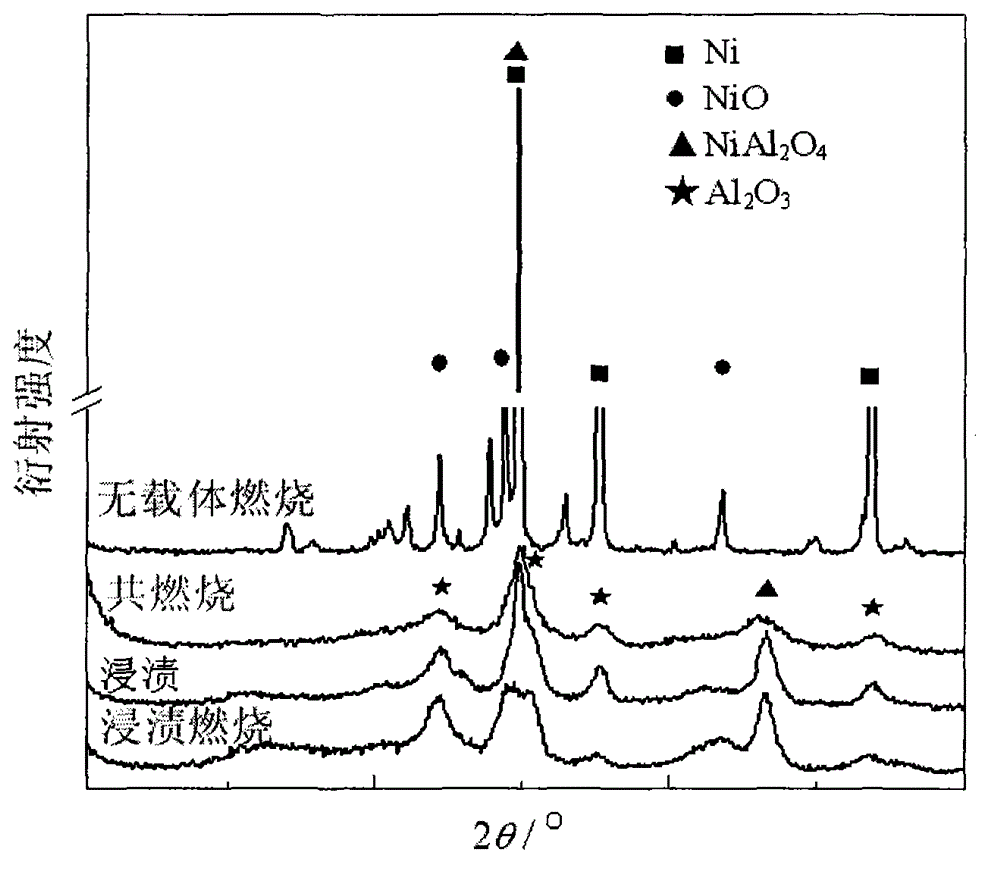

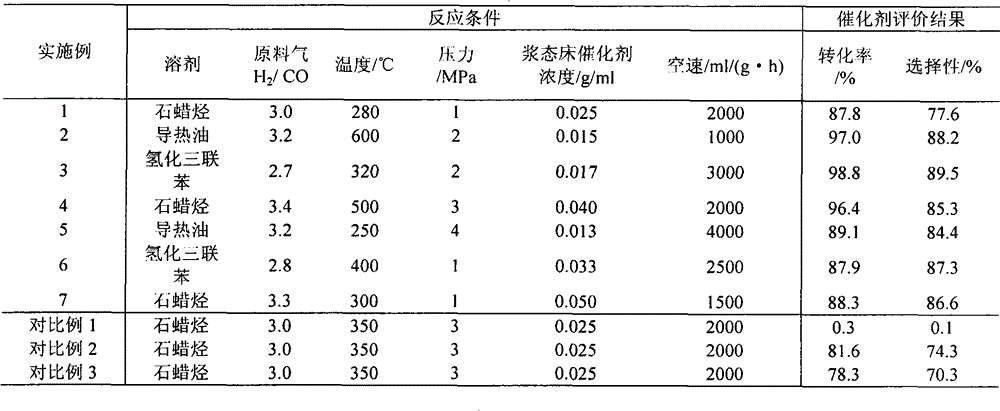

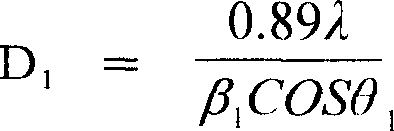

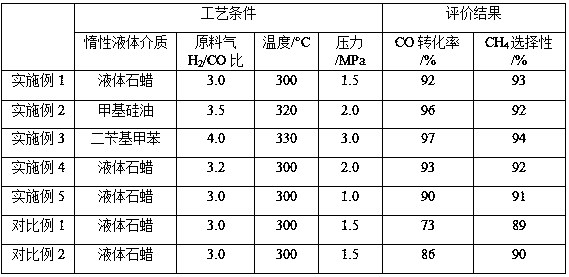

InactiveCN102872874AGood dispersionIncrease the number of active centersGaseous fuelsCatalyst activation/preparationWater bathsNitrate

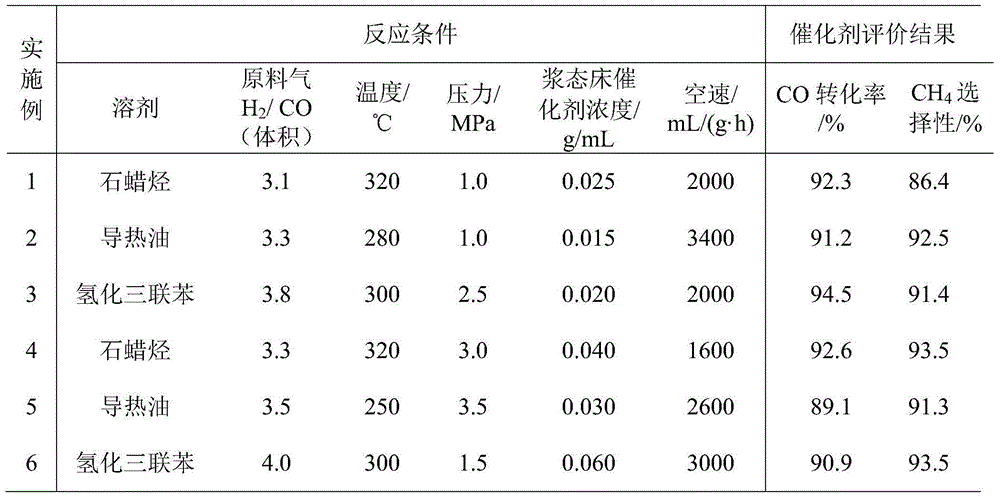

The invention relates to a loaded type nickel-based catalyst used for slurry bed methanation, and a preparation method and an application thereof. The loaded type nickel-based catalyst is composed of, by weight, 10-40 wt% of NiO, 56-90 wt% of a carrier and 0-4 wt% of an auxiliary agent. The loaded type nickel-based catalyst is prepared by the steps of preparing a soluble salt solution of 0.5-1.3 g / mL nicdel nitrate and the auxiliary agent; adding a catalyst carrier and a soluble organic fuel to the salt solution in sequence; impregnating for 6-24 h while stirring; heating the solution for concentration in a water bath with a temperature of 60-90 DEG C after finishing the impregnation, or heating for igniting the solution at a temperature of 300-700 DEG C directly; collecting the combustion residue powder, grinding the powder and granulating, and reducing for 2-6 h with a reducing gas on a fixed bed at a temperature of 500-700 DEG C. The loaded type nickel-based catalyst has a slurry bed methanation process, and has the advantages of good and stable catalytic performance, and can be used for large-scale industrialization.

Owner:TAIYUAN UNIV OF TECH +1

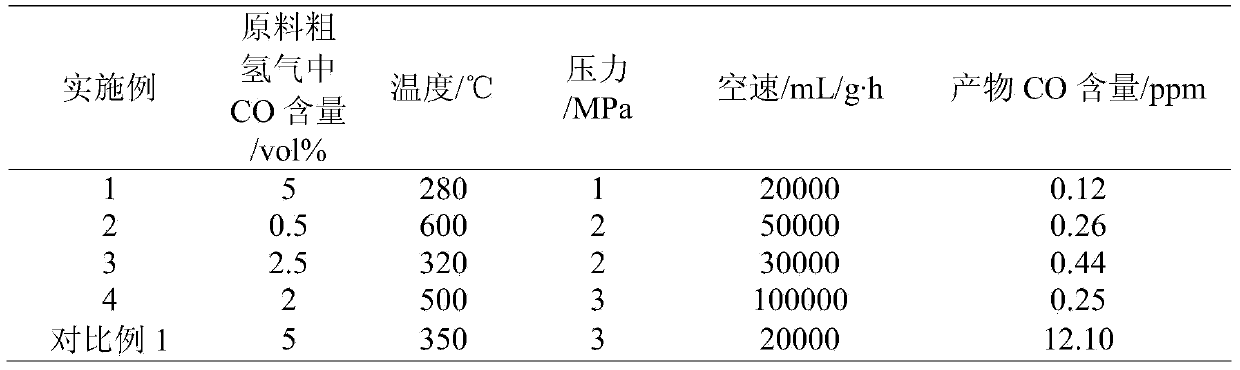

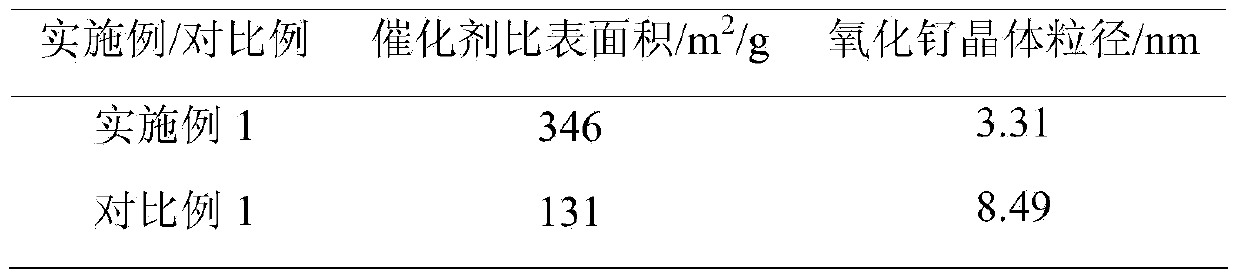

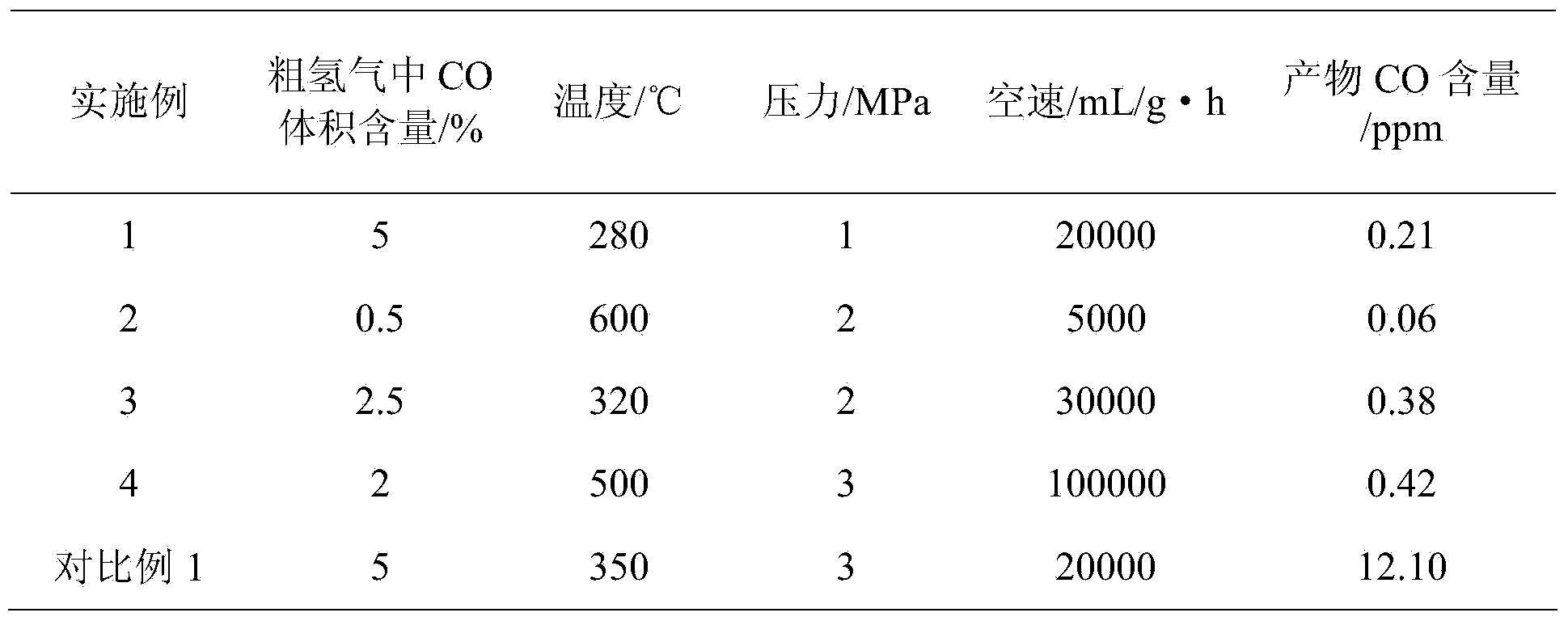

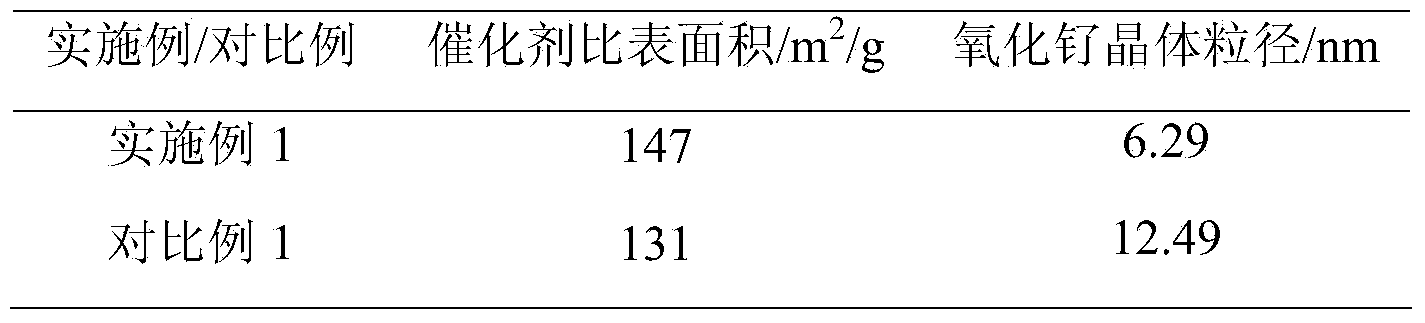

Precious metal methanation catalyst prepared by using solution combustion method and preparation method and applications thereof

InactiveCN103801290AImprove catalytic performanceLarge specific surface areaHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationSolution combustion

The invention discloses a precious metal methanation catalyst prepared by using a solution combustion method, which comprises the following components in percentage by weight: 1-10% of precious metal oxides and 90-99% of a carrier. The precious metal methanation catalyst disclosed by the invention has the advantages that the catalyst is applicable to a trace CO methanation process, and stable in catalytic performance.

Owner:TAIYUAN UNIV OF TECH +1

Method for cracking biomass pyrolytic tar catalytically using nickel-carrying carbon nano tube

InactiveCN102634355AGood thermal stability and mechanical strengthPrevent carbon deposition and deactivationBiofuelsSpecial form destructive distillationTarBiomass

The invention belongs to the field of biomass energy utilization and particularly relates to a method for cracking biomass pyrolytic tar catalytically using a nickel-carrying carbon nano tube. The method includes: obtaining nickel-based catalyst based on a carbon nano tube carrier by utilizing the carbon nano tube as a carrier and elementary-substance nickel as active component, and allowing for high-efficiency catalytic cracking of the biomass pyrolytic tar using the nickel-based catalyst, wherein the elementary-substance is in mass percentage of 0.5-30% in the composite catalyst. Specific surface area of the catalyst is enlarged greatly by utilizing the carbon nano tube as the carrier, order pore passage structure suitable for cracking reaction of macromolecule organic matters in tar is provided, and combustible gas with tar content smaller than or equal to 1% can be obtained after catalytic cracking of the biomass pyrolytic tar.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Supported precious metal methanation catalyst, and preparation method and application thereof

InactiveCN103816895AHigh methanation activityGood dispersionHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationFixed bed

The invention provides a supported precious metal methanation catalyst, comprising, by weight, 0.5 to 10% of a precious metal oxide and 90 to 99.5% of a carrier. The catalyst has the advantages of applicability to fixed-bed microscale CO methanation and stable catalytic performance.

Owner:SEDIN ENG +1

Sulfur transfer catalyst and its preparation method

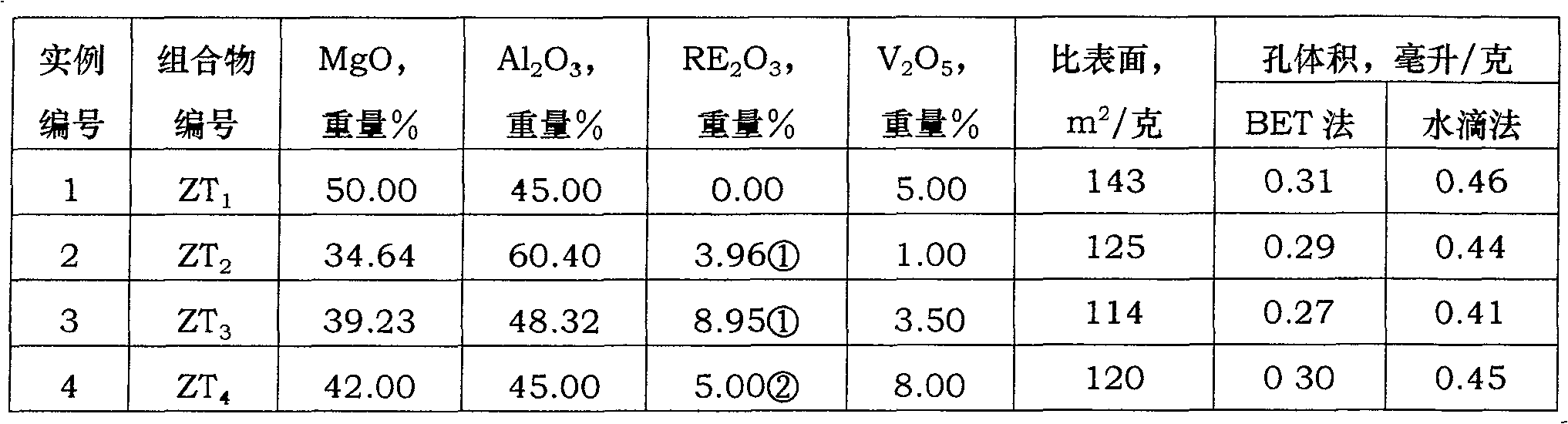

ActiveCN100425339CEvenly dispersedNot easy to gatherCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalCerium

Sulfur transfer catalyst comprises spinel compound contained with alkaline-earth metal and aluminum, or contained rare earth metal except cerium, or without vanadium; and oxide with adding metal component of cerium oxide and zinc oxide; based on catalyst, the weight share is spinel compound 50-90%, cerium oxide and zinc oxide 10-50%; the average particle diameter of cerium oxide and zinc oxide is less separately 130A and 300A with XRD method. It can decrease the reproduced SOx with high active in FCC and sulfur content in gas outcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reforming protective agent and preparation method thereof

ActiveCN104593044AEvenly dispersedIncrease the number of active centersMolecular sieve catalystsRefining with metal oxidesManganese oxideBULK ACTIVE INGREDIENT

The invention provides a reforming protective agent. Acidified pseudoboehmite and an acidified molecular sieve are taken as a common carrier under the synergistic effect, uniform dispersion of active ingredients such as manganese oxide and ferric oxide is promoted, the pore channel structure of the carrier can be optimized, the pore size, pore volume and specific surface area are increased, more vacant orbits and active centers are formed in the space structure of the carrier, the components further comprise catalyst wastes, and the mechanical strength of the carrier can be improved. Meanwhile, the vacant orbits and active centers in the structures of the acidified pseudoboehmite and an acidified molecular sieve can be coordinated with the catalyst wastes and active ingredients in the manganese oxide, the active center sites of the catalyst are improved, and the reaction is promoted. Therefore, according to the reforming protective agent disclosed by the invention, the mechanical strength is improved, and the protective agent has the advantages that the desulfurization reaction activity is high, the desulfurization efficiency is high, the service life of the catalyst is long, and side reactions can be effectively avoided.

Owner:SHENYANG SANJUKAITE CATALYST

In-situ level nano selenium carbon based mercury removal adsorbent material and preparation method and application thereof

InactiveCN110170302ASolve the defect of easy reunionMild reducing conditionsGas treatmentOther chemical processesDispersityNon-ferrous extractive metallurgy

The invention discloses an in-situ level nano selenium carbon based mercury removal adsorbent material and a preparation method and application thereof. Sulfur dioxide gas is introduced into a selenium-loaded carbon based adsorbent material to prepare the in-situ level nano selenium carbon based mercury removal adsorbent material through a gas phase in-situ reduction method. The preparation methodis simple, the preparation cost is low, and the prepared in-situ level nano selenium carbon based mercury removal adsorbent material has the advantages of being high in selenium crystal adhesion force, not easy to fall off, and good in dispersity. There are many mercury adsorption active sites and active centers, the mercury adsorption capacity is high, the material has long service life, and therequirements of the mercury related industry, natural-gas mercury removal, a non-ferrous metal smelting plant, a coal-fired power plant and the like for complex mercury-containing flue gas exhaust processing are met.

Owner:贵州重力科技环保股份有限公司

Sulfur transfer catalyst and its preparation method

ActiveCN1721061AEvenly dispersedNot easy to gatherCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalCerium

Sulfur transfer catalyst comprises spinel compound contained with alkaline-earth metal and aluminum, or contained rare earth metal except cerium, or without vanadium; and oxide with adding metal component of cerium oxide and zinc oxide; based on catalyst, the weight share is spinel compound 50-90%, cerium oxide and zinc oxide 10-50%; the average particle diameter of cerium oxide and zinc oxide is less separately 130A and 300A with XRD method. It can decrease the reproduced SOx with high active in FCC and sulfur content in gas outcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of in-situ-grade nano-selenium non-carbon-based demercuration adsorption material, material and application

InactiveCN110170301ASolve the defect of easy reunionMild reducing conditionsGas treatmentOther chemical processesDispersityGas phase

The invention discloses a preparation method of an in-situ-grade nano-selenium non-carbon-based demercuration adsorption material, the material and application. According to the preparation method, sulfur dioxide gas is introduced into a non-carbon-based adsorption material loading selenium, and by utilizing an in-situ gas-phase reduction mode, the in-situ-grade nano-selenium non-carbon-based demercuration adsorption material is prepared. The preparation method is simple, reduction conditions are mild, the preparation cost is low, and the prepared in-situ-grade nano-selenium non-carbon-based demercuration adsorption material has the advantages that selenium crystals are high in adhesive force, cannot easily shed and are good in dispersity; there are many active sites and active centers foradsorbing mercury, the adsorption reaction activity to the mercury is improved, the mercury adsorption capacity is high, the service life is long, and the requirements of natural gas demercuration and treatment of complex mercury-containing flue gas and tail gas of non-ferrous metal smelting plants and coal-fired power plants in industries related to the mercury can be met.

Owner:贵州重力科技环保股份有限公司

Anti-carbon synthesis gas methanation catalyst, preparation method and application thereof

InactiveCN104353463AReduce wearGood dispersionGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsSyngasMethanation

An anti-carbon synthesis gas methanation catalyst takes 55-85 percent by weight of gama-Al2O3 as a carrier, 10-40 percent by weight of Ni as an active component, and 1-7 percent by weight of one of Mo, Co, La and Ce as an additive.. The anti-carbon synthesis gas methanation catalyst disclosed by the invention has the advantages of high catalytic activity, high heat stability, strong anti-carbon capability and long catalyst service life.

Owner:SEDIN ENG +1

Preparation method of roasting-free pre-vulcanized hydrogenation catalyst

InactiveCN107349934AImprove hydrogenation activityGood dispersionHeterogenous catalyst chemical elementsCatalyst activation/preparationDispersityVulcanization

The invention discloses a preparation method of a roasting-free pre-vulcanized hydrogenation catalyst. The method comprises the steps that the environment-friendly dipping technology is adopted for preparing the hydrogenation catalyst, after the dipped catalyst is treated under the temperature of 180-250 DEG C, an organic solvent, elemental sulfur and auxiliaries are added to be mixed to be uniform, and thermal treatment is performed to obtain the roasting-free pre-vulcanized hydrogenation catalyst. The method solves the problems that a conventional catalyst is low in activity, poor in dispersity, long in vulcanization on-stream time and high in operation cost, and meanwhile overcomes the defects that the vulcanized catalyst preparation process is complex and concentrated heat release is easy. The pre-vulcanized hydrogenation catalyst prepared through the method is high in strength, good in activity and short in preparation process flow and has the good application value.

Owner:湖北润驰环保科技有限公司

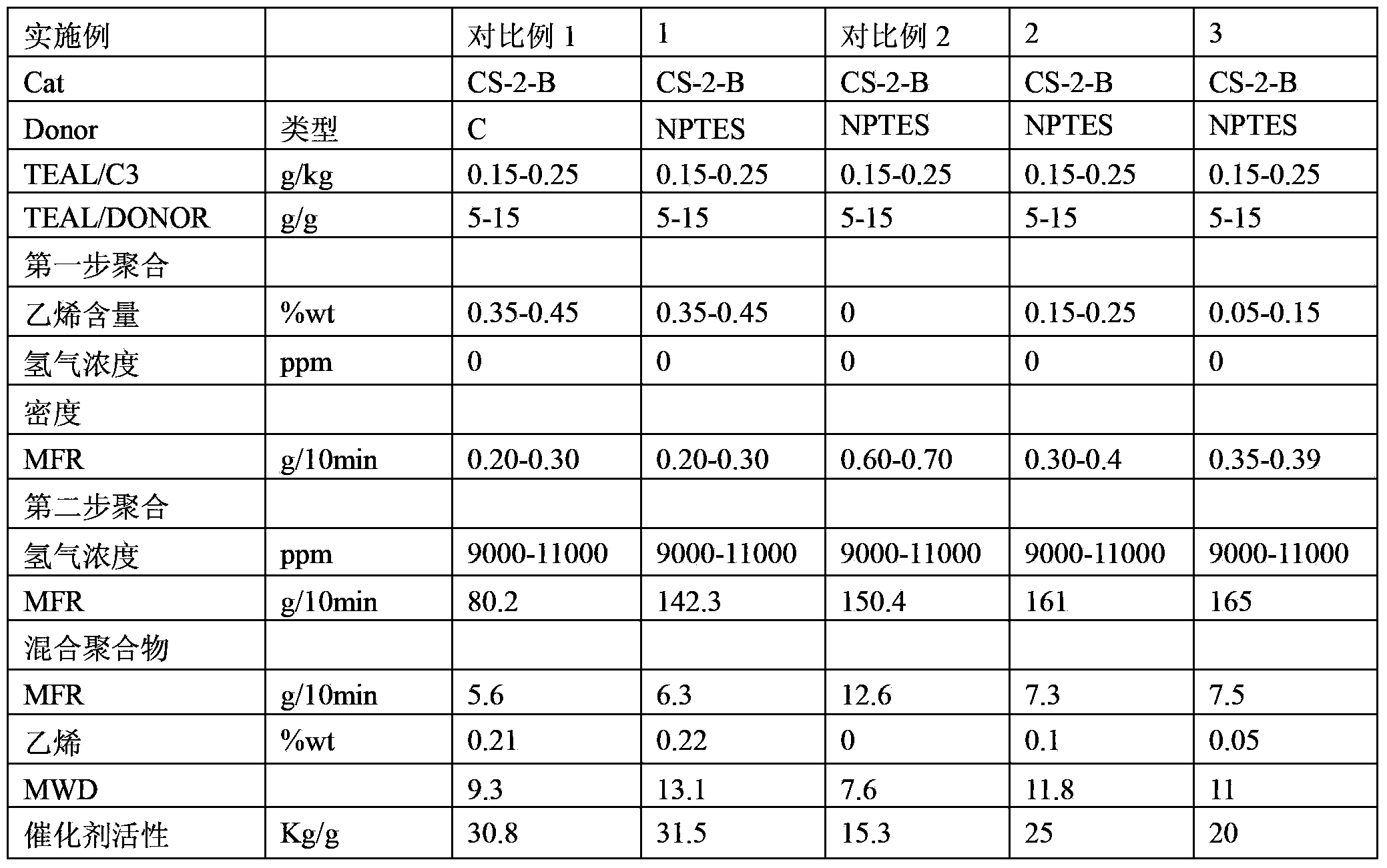

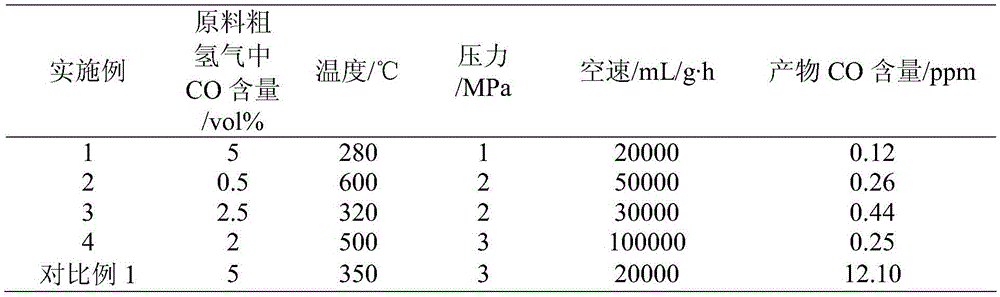

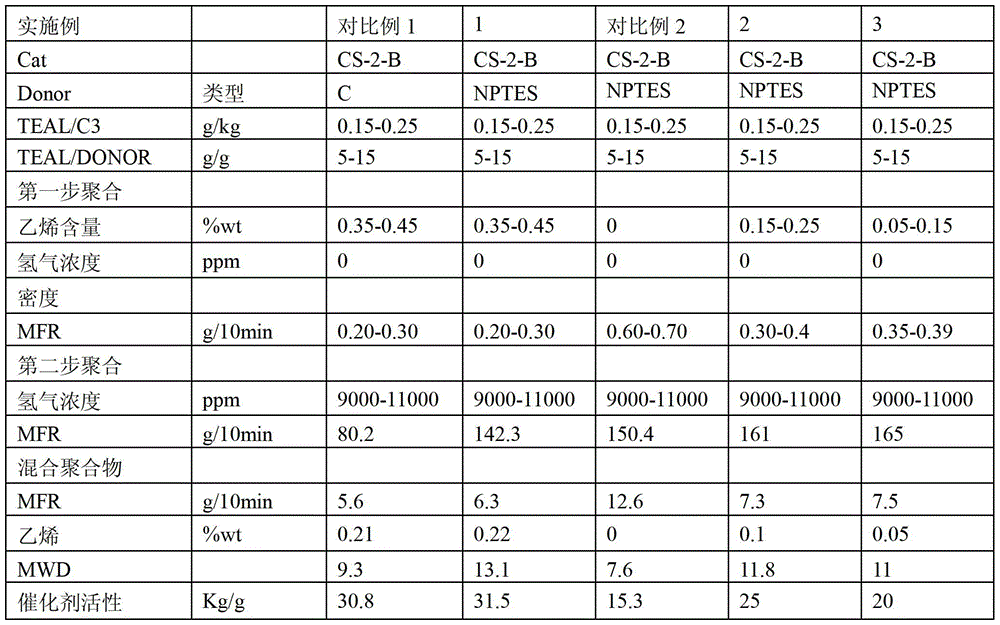

Preparation method of propylene copolymer with low ethylene content and wide molecular weight distribution

The invention provides a preparation method of a propylene copolymer with ethylene content lower than 0.5% (wt) and wide molecular weight distribution. The method comprises a catalyst system and a two-step polymerization process. The catalyst system comprises a Ziegler-Natta catalyst with organosilane with extremely high hydrogen sensitivity. With the catalyst system, extremely high molecular weight can be produced in first step polymerization, and extremely low molecular weight can be produced in the second step. Polymerization products obtained in the two steps are mechanically mixed, wherein melt flow rate ratio (2.16kg, 230 DEG C) of the fist step and the second step is higher than 400, such that the propylene copolymer with wide molecular weight distribution can be obtained.

Owner:PETROCHINA CO LTD

Nickel-based tar reforming catalyst based on mesoporous zirconia carrier and preparation method thereof

InactiveCN102380387APrevent carbon deposition and deactivationGood tar catalytic conversion performanceCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveNickel oxides

The invention belongs to the field of utilization of catalyst and biomass energy and particularly relates to a nickel-based tar reforming catalyst based on a mesoporous zirconia carrier and a preparation method thereof. The nickel-based tar reforming catalyst based on a mesoporous zirconia carrier utilizes mesoporous zirconia molecular sieves as carriers and utilizes nickel oxide as an active component, and is a composite catalyst which comprises 70%-99.5% by mass of mesoporous zirconia molecular sieves and 0.5%-30% by mass of nickel oxide. Since the mesoporous zirconia molecular sieves are used as the carriers, the specific surface area of the catalyst is expanded greatly, and an order channel structure suitable for cracking reaction of macromolecular organic matter in tar is provided. By means of interaction between the mesoporous zirconia molecular sieves and the nickel oxide, reactivity of the catalyst is improved, and the catalytic reforming rate to tar can be over 99%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

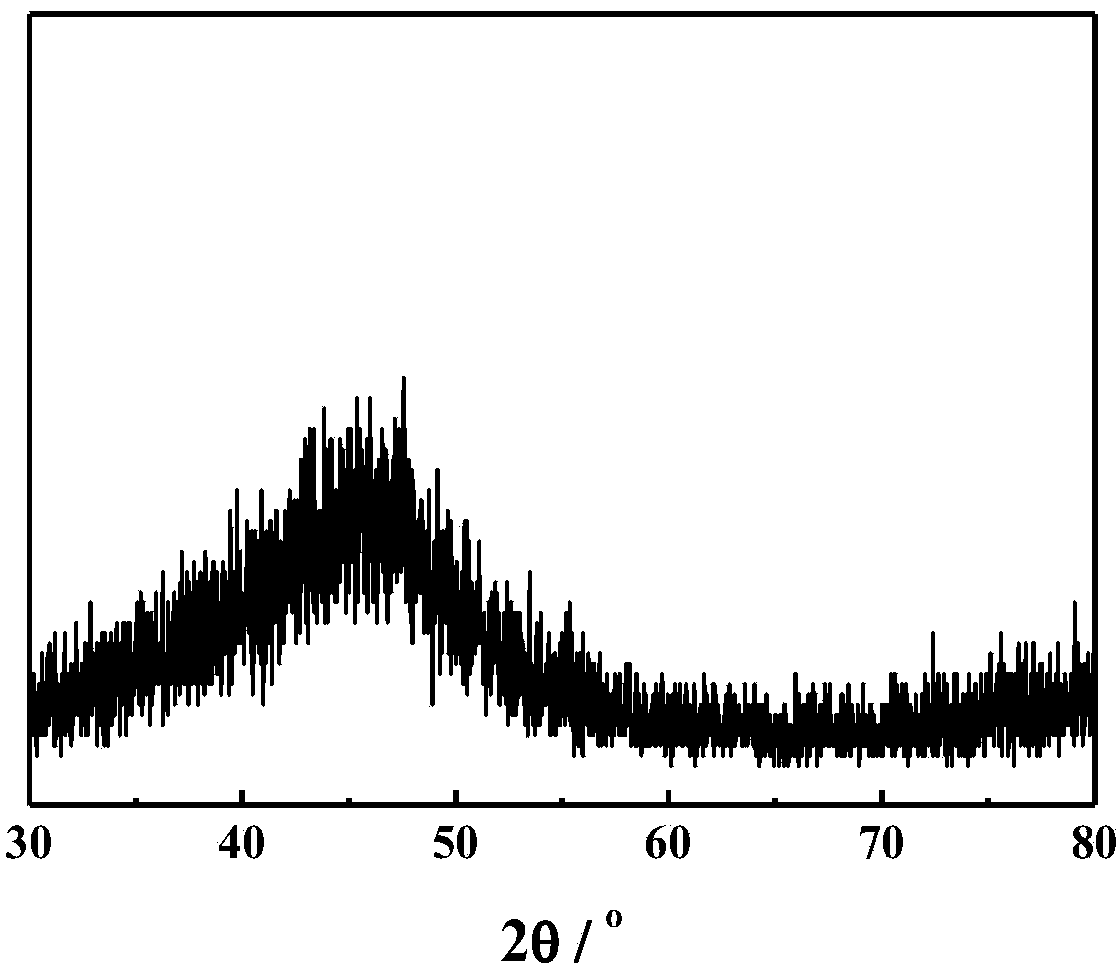

Nickel-cobalt-boron amorphous alloy nanosphere catalyst with hollow structure, preparation method and application of catalyst

InactiveCN103877979ALow costIncrease the number of active centersMaterial nanotechnologyOrganic compound preparationPotassium borohydridePotassium

The invention discloses a nickel-cobalt-boron amorphous alloy nanosphere catalyst with a hollow structure, a preparation method and application of the catalyst. The method comprises the following steps: respectively adding an aqueous solution of nickel inorganic salt and cobalt inorganic salt into an aqueous solution of a cationic surface active agent, and stirring to be uniform, wherein a mole ratio of the surfactant, nickel ions and cobalt ions is 2:1:1; adding potassium chloride solid into the solution to form a saturated solution, stirring for 10 minutes; dropwise adding a potassium borohydride aqueous solution at temperature of 273K, wherein a mole ratio of the potassium borohydride, the nickel ions and the cobalt ions is 10:1:1; continuing to for 30 minutes after the dropping is ended; centrifuging to obtain a black solid, repetitively scrubbing the black solid by using deionized water to be neutral. The prepared catalyst is large in specific surface area and high in catalytic activity; due to the application of the prepared catalyst in preparation of 2-ethylhexanol in an octenal solution through hydrogenation and preparation of corresponding alcohols by hydrogenating relevant aldehydes, the prepared alcohol products are high in purity, and the catalyst is high in stability.

Owner:SHANGHAI NORMAL UNIVERSITY

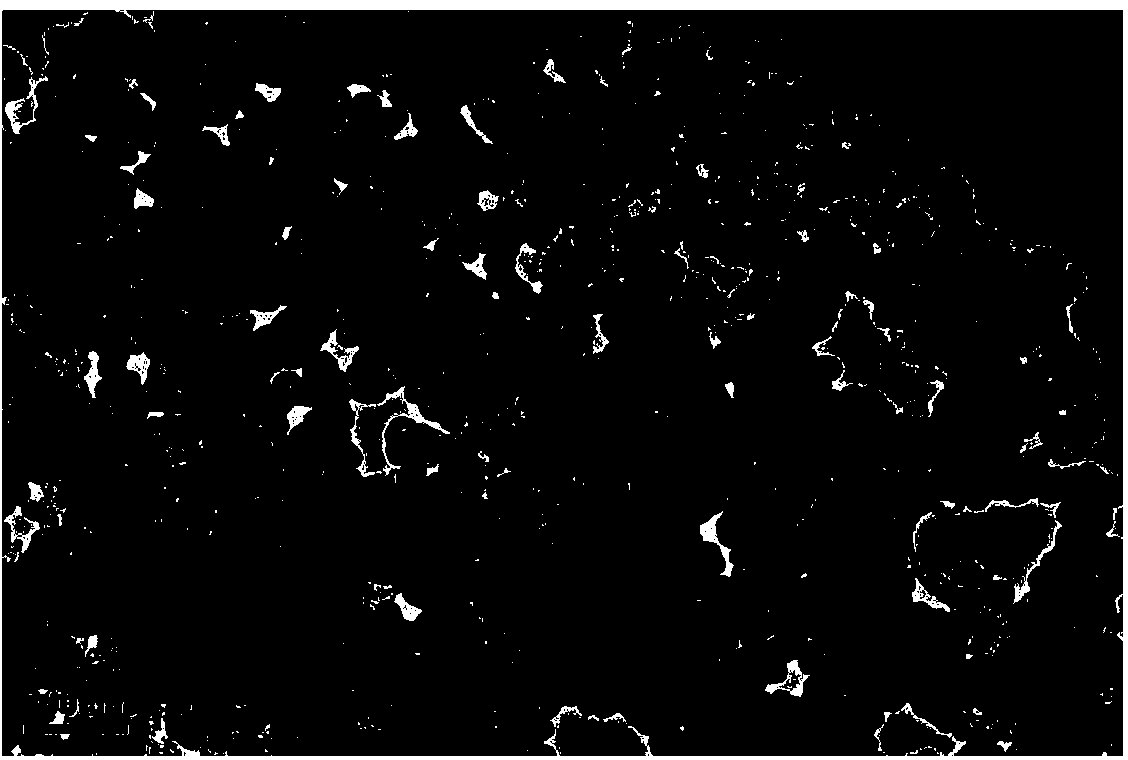

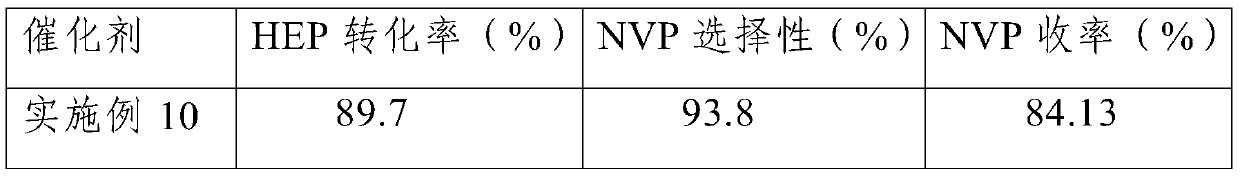

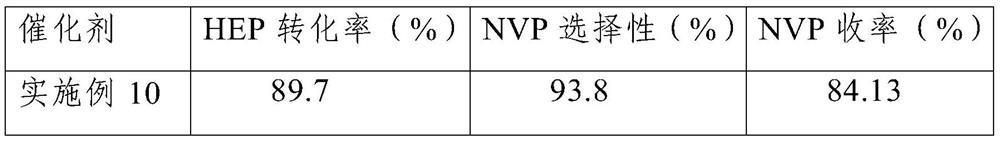

Preparation method of catalyst carrier as well as application of catalyst carrier

ActiveCN110327989AHigh mechanical strengthFacilitate loss of activityCatalyst carriersOrganic chemistryAdhesiveUltimate tensile strength

The invention discloses a preparation method of a catalyst carrier. The method comprises the steps of mixing white carbon black, an adhesive, a surfactant and / or silicon carbide uniformly, performingextrusion molding, and drying and roasting to obtain the catalyst carrier. The invention also discloses application of the catalyst carrier. An N-hydroxyethyl pyrrolidone dehydration synthesized N-vinyl pyrrolidone catalyst is prepared by loading a catalyst precursor on the carrier catalyst by a dipping method. The surfactant and / or the silicon carbide is introduced into the preparation raw materials of the catalyst carrier, so that uniform dispersion of the white carbon black is promoted, hydroxyl agglomeration is avoided, the activity loss of the catalyst is reduced and the mechanical strength of the carrier is improved. The catalyst carrier is applied to preparation of the N-hydroxyethyl pyrrolidone dehydration synthesized N-vinyl pyrrolidone catalyst, the active center number of the catalyst is increased and the activity of the catalyst after formation is reduced.

Owner:THE NORTHWEST RES INST OF CHEM IND

Preparation method of catalyst with high CO purification performance and catalyst thereof

PendingCN114797851AImprove anti-aging propertiesIncrease the number of active centersGas treatmentHeterogenous catalyst chemical elementsPtru catalystMetallurgy

The invention discloses a preparation method of a catalyst with high CO purification performance and the catalyst. The catalyst is used for being coated on the surface of a carrier to prepare an engine tail gas purification catalyst and is prepared by loading noble metal on a carrier material; the noble metal is Ru and one or more of Pt, Pd and Rh, the Ru content is 1g / ft < 3 >-30g / ft < 3 >, and the rest is 5g / ft < 3 >-40g / ft < 3 >; according to the catalyst, a loading material of Ru is adjusted, oxygen deficiency of a Ce-containing material is utilized, the synergistic effect of Ru and the material is increased, migration and sintering of Ru particles under the high-temperature condition are inhibited, and the anti-aging performance of Ru is improved; meanwhile, the roasting temperature of Ru powder is changed, a Ru precursor is firstly converted into Ru oxide, and strong interaction is generated between the Ru oxide and the carrier, so that Ru is in the optimal active valence state, the number of active centers of the whole catalyst coating is increased, and the CO performance and durability of the catalyst are improved; according to the invention, Ru with relatively low price is adopted to replace a part of Pt, Pd and Rh, so that the cost of the catalyst is reduced, and the cost performance of the catalyst is improved.

Owner:SINOCAT ENVIRONMENTAL TECH

Method for cracking hydrocarbon oil containing surphur

ActiveCN1743419AIncreased number of active centersHigh SOx emissionsCatalytic crackingAluminiumCerium oxide

A cracking method for alkymer containing S includes contacting the alkymer containing S with a catalyst mixture with a cracking catalyst and a sulfurtransfer catalyst to recover the cracked products, among which, the sulfurtransfer catalyst contains spinel composition with alkali earth, Al and additional metal oxide and the spinel contains alkal: earth, Al, rare earth metal and or not except Ce, said additional metal component oxide is CeO and ZnO, the content of the spinel is 50-90weight%, the content of CeO AND ZnO is 10-50weight% with a catalyst as the primary standard. The mean particle diameter of CeO is less than 130A measured by XRD method and that of ZnO is less than 300A.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for cracking hydrocarbon oil containing surphur

ActiveCN1323132CIncrease the number of active centersEmission reductionCatalytic crackingMischmetalAlkaline earth metal

A cracking method for alkymer containing S includes contacting the alkymer containing S with a catalyst mixture with a cracking catalyst and a sulfurtransfer catalyst to recover the cracked products, among which, the sulfurtransfer catalyst contains spinel composition with alkali earth, Al and additional metal oxide and the spinel contains alkal: earth, Al, rare earth metal and or not except Ce, said additional metal component oxide is CeO and ZnO, the content of the spinel is 50-90weight%, the content of CeO AND ZnO is 10-50weight% with a catalyst as the primary standard. The mean particle diameter of CeO is less than 130A measured by XRD method and that of ZnO is less than 300A.

Owner:CHINA PETROLEUM & CHEM CORP +1

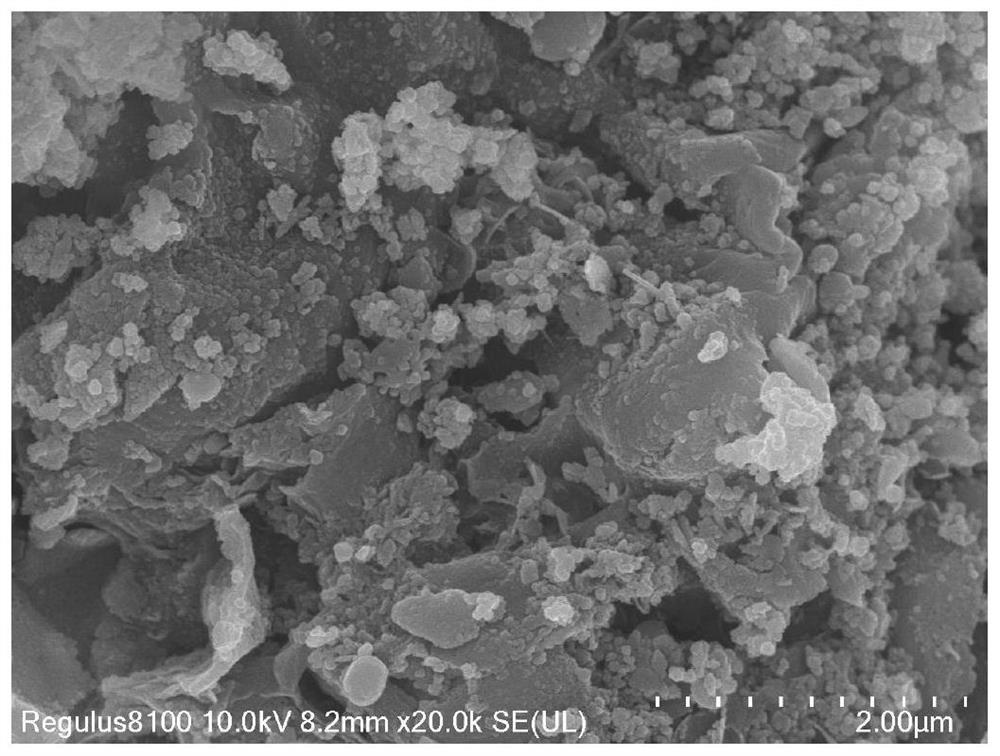

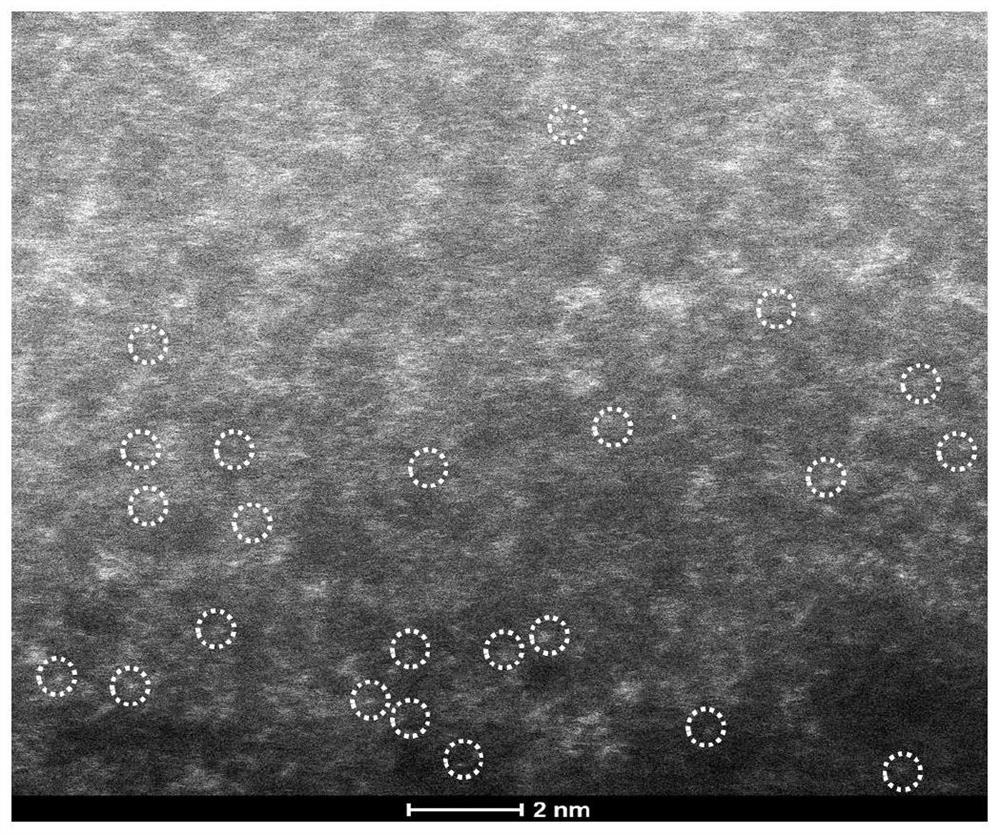

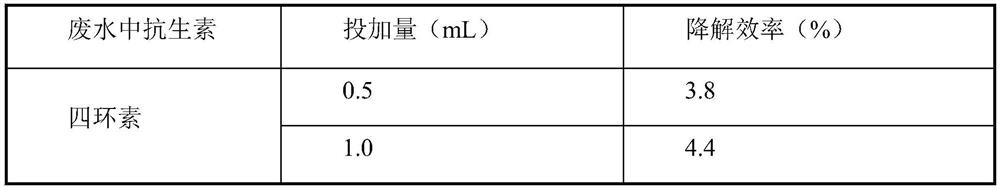

Nitrogen-doped magnetic graphene oxide confinement iron-cobalt bimetallic monatomic composite material as well as preparation method and application of nitrogen-doped magnetic graphene oxide confinement iron-cobalt bimetallic monatomic composite material

PendingCN114682289ASimple preparation processFacilitates the formation of single atomsWater treatment compoundsWater contaminantsGraphite oxidePyrolysis

The invention relates to a nitrogen-doped magnetic graphene oxide confinement iron-cobalt bimetal monatomic composite material, a preparation method and application of the nitrogen-doped magnetic graphene oxide confinement iron-cobalt bimetal monatomic composite material. Graphene oxide serves as a base material of the composite material, firstly, the graphene oxide is magnetized through a coprecipitation method, and then the nitrogen-doped magnetic graphene oxide confinement iron-cobalt bimetal monatomic composite material is obtained; and then forming nitrogen vacancy defect anchored iron-cobalt bimetallic monoatoms on the magnetic graphene oxide in one step through a fused salt assisted high-temperature pyrolysis method. In the preparation process of the composite material, anchoring sites of monatomic iron and cobalt on graphene oxide are greatly increased by introducing nitrogen-containing groups, metal atom agglomeration can be reduced by applying molten salt to assist high-temperature pyrolysis, and a salt phase is easy to wash and recycle, environment-friendly and non-toxic. According to the prepared catalyst, loading of monatomic iron and cobalt on graphene oxide is greatly increased, and the obtained material is high in stability, can be easily separated from a solution, can be recycled, reduces the preparation cost and is economical and efficient. The product has a good degradation effect on tetracycline in wastewater.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

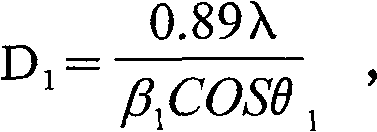

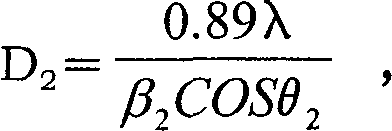

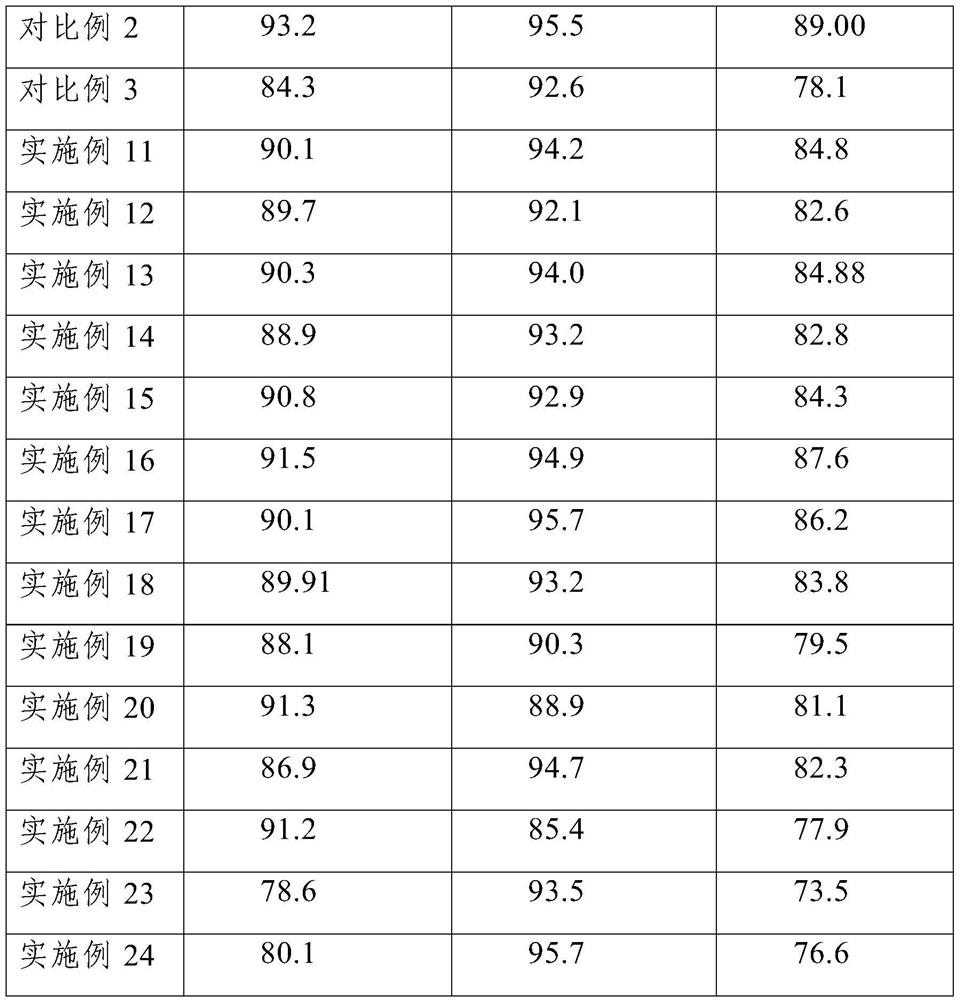

A kind of preparation method and application of nanometer nickel-based CO methanation catalyst

ActiveCN107029726BGood dispersionSmall particle sizeHydrocarbon from carbon oxidesCatalyst activation/preparationAir atmosphereNickel salt

Owner:TAIYUAN UNIV OF TECH

A kind of preparation method and application of catalyst carrier

ActiveCN110327989BHigh mechanical strengthFacilitate loss of activityCatalyst carriersOrganic chemistryCarbide siliconPtru catalyst

The invention discloses a method for preparing a catalyst carrier. In the method, white carbon black, a binder, a surfactant and / or silicon carbide are uniformly mixed, extruded, and then dried and calcined to obtain a catalyst carrier; the invention Also disclosed is an application of a catalyst carrier, wherein the catalyst precursor is loaded onto the catalyst carrier by an impregnation method to prepare a catalyst for dehydration of N-hydroxyethylpyrrolidone to synthesize N-vinylpyrrolidone. The present invention introduces surfactant and / or silicon carbide into the preparation raw material of the catalyst carrier, which promotes the uniform dispersion of white carbon black, avoids the agglomeration of hydroxyl groups, reduces the activity loss of the catalyst, and improves the mechanical strength of the carrier at the same time; The catalyst carrier is applied to the preparation of N-hydroxyethylpyrrolidone dehydration synthesis N-vinylpyrrolidone catalyst, which increases the number of active centers of the catalyst and reduces the activity decline of the catalyst after molding.

Owner:THE NORTHWEST RES INST OF CHEM IND

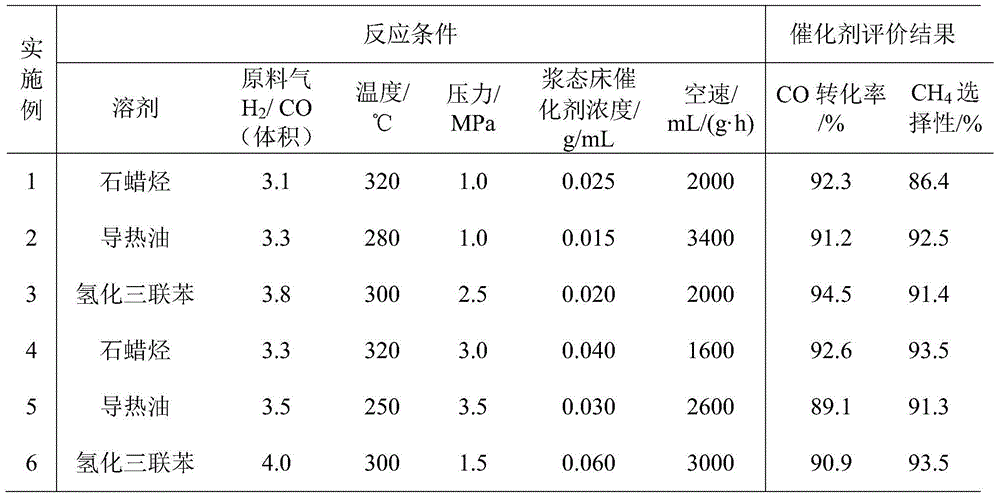

Loaded type nickel-based catalyst used for slurry bed methanation, and preparation method and application thereof

InactiveCN102872874BGood dispersionIncrease the number of active centersGaseous fuelsCatalyst activation/preparationPtru catalystMetallurgy

The invention relates to a loaded type nickel-based catalyst used for slurry bed methanation, and a preparation method and an application thereof. The loaded type nickel-based catalyst is composed of, by weight, 10-40 wt% of NiO, 56-90 wt% of a carrier and 0-4 wt% of an auxiliary agent. The loaded type nickel-based catalyst is prepared by the steps of preparing a soluble salt solution of 0.5-1.3 g / mL nicdel nitrate and the auxiliary agent; adding a catalyst carrier and a soluble organic fuel to the salt solution in sequence; impregnating for 6-24 h while stirring; heating the solution for concentration in a water bath with a temperature of 60-90 DEG C after finishing the impregnation, or heating for igniting the solution at a temperature of 300-700 DEG C directly; collecting the combustion residue powder, grinding the powder and granulating, and reducing for 2-6 h with a reducing gas on a fixed bed at a temperature of 500-700 DEG C. The loaded type nickel-based catalyst has a slurry bed methanation process, and has the advantages of good and stable catalytic performance, and can be used for large-scale industrialization.

Owner:TAIYUAN UNIV OF TECH +1

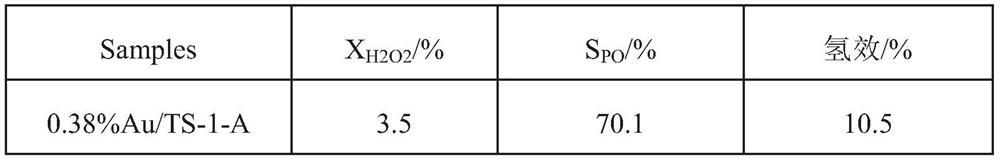

High-activity propylene gas-phase epoxidation catalyst and preparation method thereof

InactiveCN112871204ALarge specific surface areaIncrease contentOrganic chemistryMolecular sieve catalystsPtru catalystHigh activity

The invention discloses a high-activity propylene gas-phase epoxidation catalyst and a preparation method thereof. In the preparation process of the catalyst, a defect site auxiliary agent and an S auxiliary agent are added, a large number of defect sites which are rich in titanium and suitable for Au loading are obtained, amorphous species on the catalyst are stabilized by S, the high-activity propylene gas-phase epoxidation catalyst is obtained, and the conversion rate of propylene, the selectivity of PO and the hydrogen efficiency are greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for cracking biomass pyrolytic tar catalytically using nickel-carrying carbon nano tube

InactiveCN102634355BHigh reactivityPrevent carbon deposition and deactivationBiofuelsSpecial form destructive distillationActive componentCarbon nanotube

The invention belongs to the field of biomass energy utilization and particularly relates to a method for cracking biomass pyrolytic tar catalytically using a nickel-carrying carbon nano tube. The method includes: obtaining nickel-based catalyst based on a carbon nano tube carrier by utilizing the carbon nano tube as a carrier and elementary-substance nickel as active component, and allowing for high-efficiency catalytic cracking of the biomass pyrolytic tar using the nickel-based catalyst, wherein the elementary-substance is in mass percentage of 0.5-30% in the composite catalyst. Specific surface area of the catalyst is enlarged greatly by utilizing the carbon nano tube as the carrier, order pore passage structure suitable for cracking reaction of macromolecule organic matters in tar is provided, and combustible gas with tar content smaller than or equal to 1% can be obtained after catalytic cracking of the biomass pyrolytic tar.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

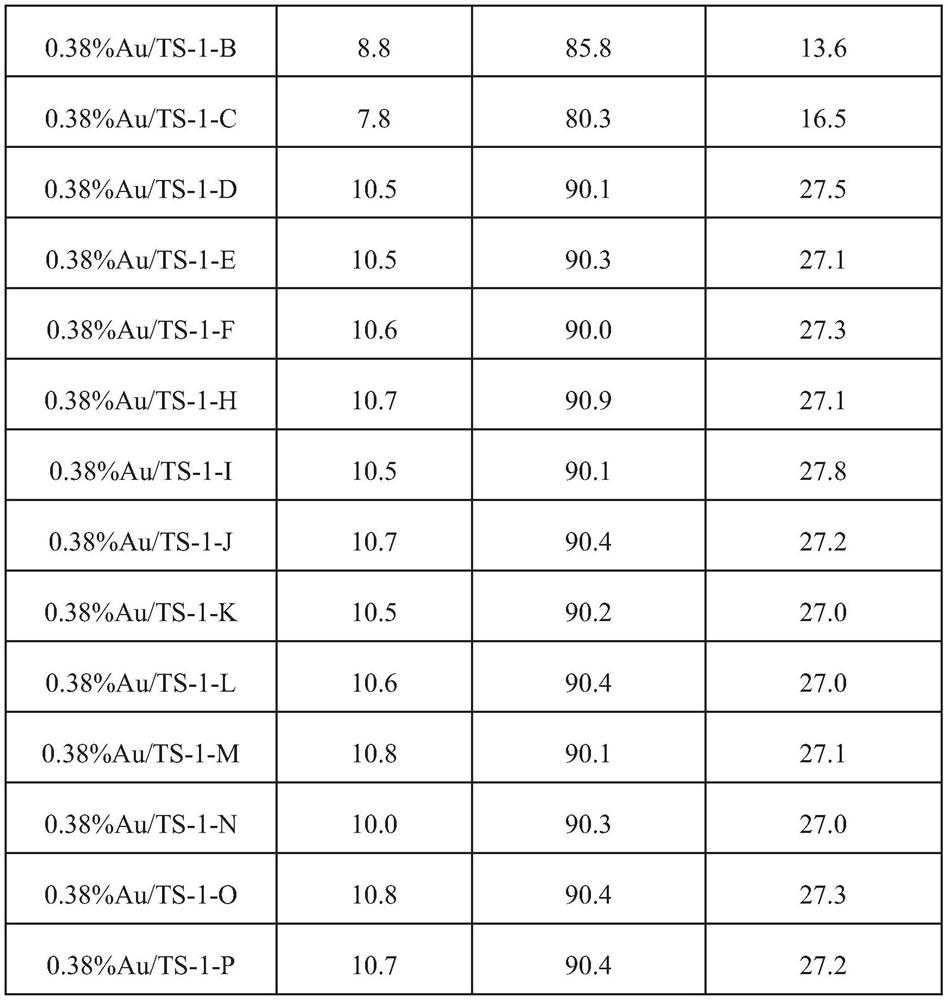

A kind of preparation method of supporting type palladium-alumina catalyst

ActiveCN106902815BLow impurity contentAperture size controllableCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereHexamethylenetetramine

Owner:福建省福大百阳化工科技有限公司

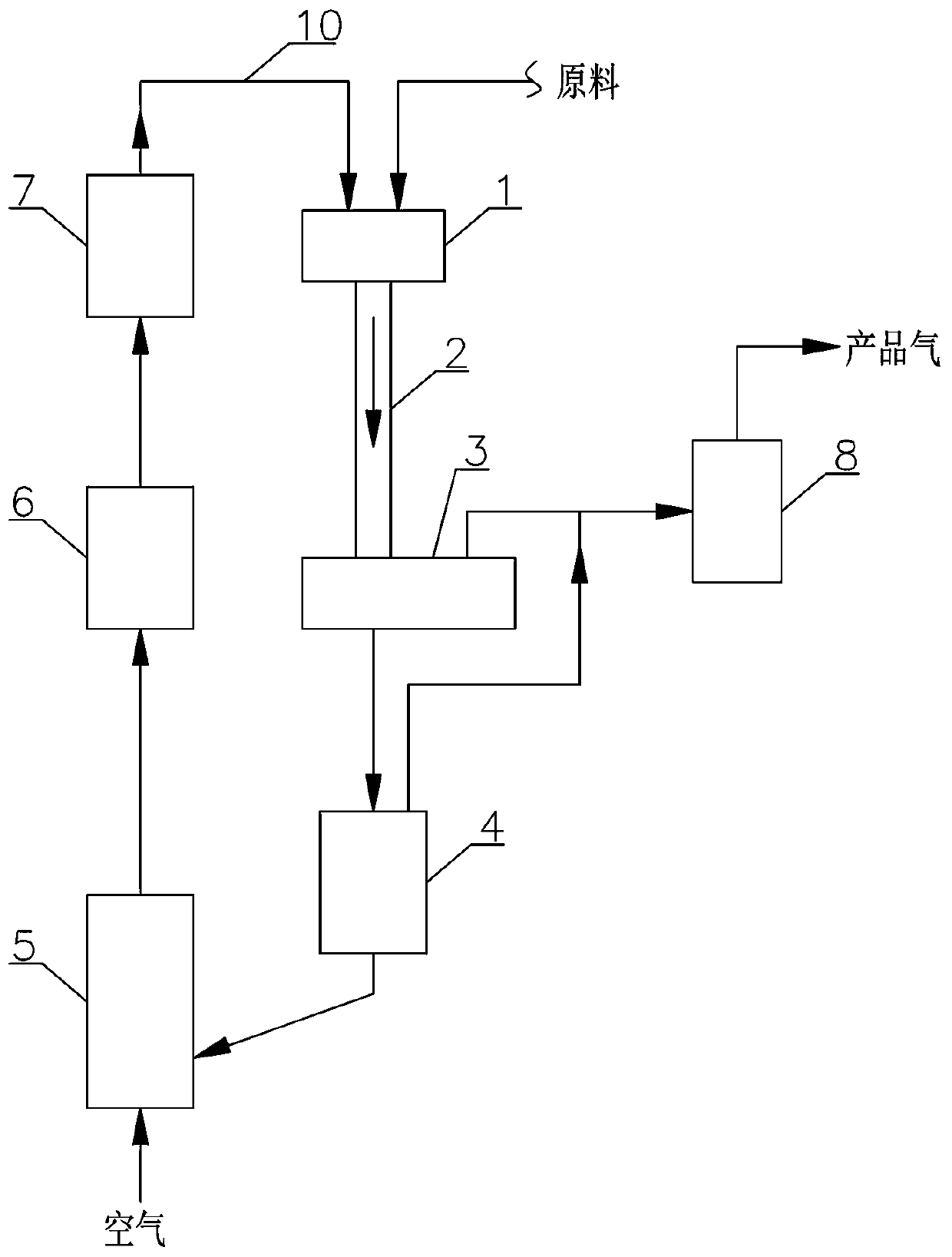

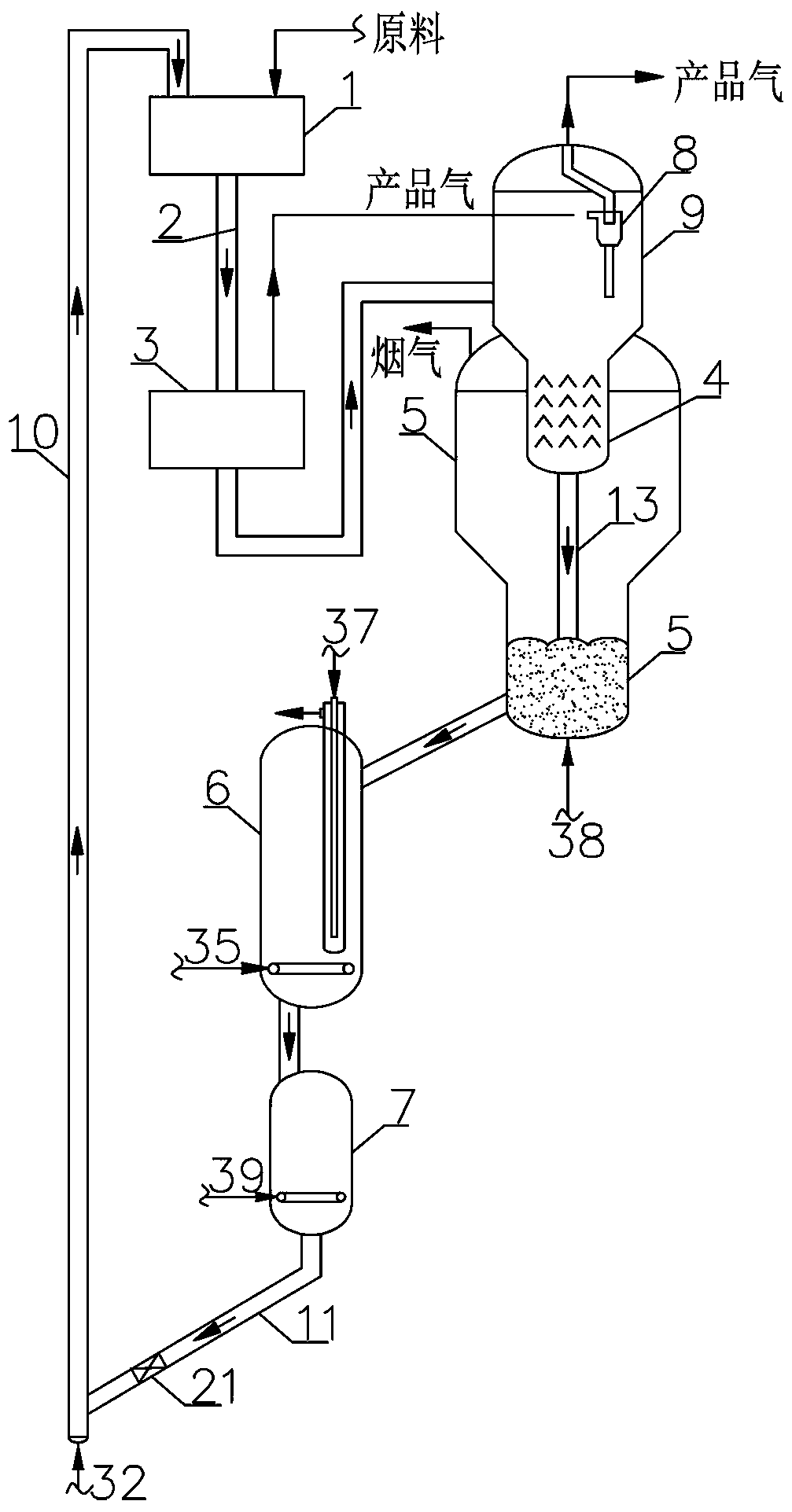

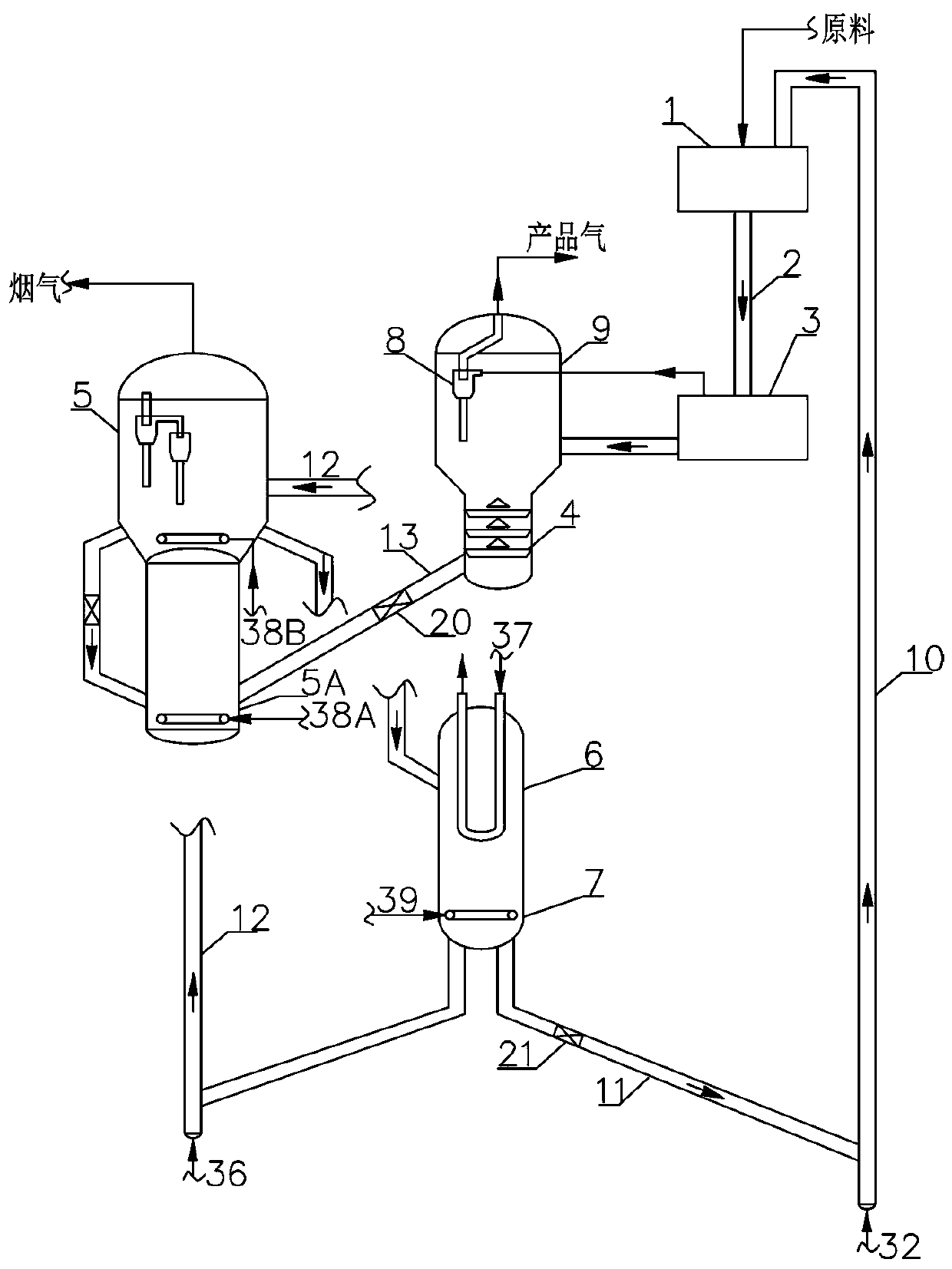

Downer reactor light hydrocarbon catalytic converting method and device

PendingCN109609175AImprove temperature distributionReduce yieldCatalytic crackingContact timeReaction temperature

The invention provides a downer reactor light hydrocarbon catalytic converting method and device. The method specifically includes the following steps of firstly, making a preheated or non-preheated light hydrocarbon raw material and a low-temperature regenerant from a regenerant cooler enter the inlet end of a downer reactor and flow downwards along the reactor for catalytic cracking and other reactions, and making a mixture of reaction oil gas and a catalyst go downwards to the tail end of the reactor to be rapidly separated so that the catalyst and the oil gas can be rapidly separated, wherein the main operation conditions include the reaction temperature of 520-680 DEG C, the reaction pressure of 0.11-0.4 MPa, the contact time of 0.05-2 seconds and the agent-to-oil ratio of 6-50; secondly, making a separated to-be-generated agent enter a regenerator to be burned and regenerated after the to-be-generated agent is subjected to steam stripping through a to-be-generated agent stripper,wherein the regeneration temperature is controlled to be 630-730 DEG C; thirdly, making a regenerant from the regenerator enter the regenerant cooler to be cooled into 200-720 DEG C, and making the regenerant recycled in the downer reactor.

Owner:李群柱

A kind of synthesis gas methanation catalyst anti-carbon deposition and its preparation method and application

InactiveCN104353463BReduce wearGood dispersionGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsSyngasMethanation

An anti-carbon synthesis gas methanation catalyst takes 55-85 percent by weight of gama-Al2O3 as a carrier, 10-40 percent by weight of Ni as an active component, and 1-7 percent by weight of one of Mo, Co, La and Ce as an additive.. The anti-carbon synthesis gas methanation catalyst disclosed by the invention has the advantages of high catalytic activity, high heat stability, strong anti-carbon capability and long catalyst service life.

Owner:SEDIN ENG +1

Precious metal methanation catalyst prepared by solution combustion method, preparation method and application

InactiveCN103801290BImprove catalytic performanceLarge specific surface areaHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationSolution combustion

The invention discloses a precious metal methanation catalyst prepared by using a solution combustion method, which comprises the following components in percentage by weight: 1-10% of precious metal oxides and 90-99% of a carrier. The precious metal methanation catalyst disclosed by the invention has the advantages that the catalyst is applicable to a trace CO methanation process, and stable in catalytic performance.

Owner:TAIYUAN UNIV OF TECH +1

Nickel-based tar reforming catalyst based on mesoporous zirconia carrier and preparation method thereof

InactiveCN102380387BHighly ordered mesoporous channel structurePrevent carbon deposition and deactivationCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveCatalytic reforming

The invention belongs to the field of utilization of catalyst and biomass energy and particularly relates to a nickel-based tar reforming catalyst based on a mesoporous zirconia carrier and a preparation method thereof. The nickel-based tar reforming catalyst based on a mesoporous zirconia carrier utilizes mesoporous zirconia molecular sieves as carriers and utilizes nickel oxide as an active component, and is a composite catalyst which comprises 70%-99.5% by mass of mesoporous zirconia molecular sieves and 0.5%-30% by mass of nickel oxide. Since the mesoporous zirconia molecular sieves are used as the carriers, the specific surface area of the catalyst is expanded greatly, and an order channel structure suitable for cracking reaction of macromolecular organic matter in tar is provided. By means of interaction between the mesoporous zirconia molecular sieves and the nickel oxide, reactivity of the catalyst is improved, and the catalytic reforming rate to tar can be over 99%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A kind of preparation method of propylene copolymer with low ethylene content and broad molecular weight distribution

The invention provides a preparation method of a propylene copolymer with ethylene content lower than 0.5% (wt) and wide molecular weight distribution. The method comprises a catalyst system and a two-step polymerization process. The catalyst system comprises a Ziegler-Natta catalyst with organosilane with extremely high hydrogen sensitivity. With the catalyst system, extremely high molecular weight can be produced in first step polymerization, and extremely low molecular weight can be produced in the second step. Polymerization products obtained in the two steps are mechanically mixed, wherein melt flow rate ratio (2.16kg, 230 DEG C) of the fist step and the second step is higher than 400, such that the propylene copolymer with wide molecular weight distribution can be obtained.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com