Nickel-cobalt-boron amorphous alloy nanosphere catalyst with hollow structure, preparation method and application of catalyst

An amorphous alloy, nickel-cobalt-boron technology, applied in the preparation of amorphous alloy catalysts, the preparation of nickel-cobalt-boron amorphous alloy nanospheres, the catalyst in the liquid phase hydrogenation of octenal to produce 2-ethylhexyl The application field in alcohol can solve the problems of increased cost of precious metal palladium, high production energy consumption, complicated process, etc., and achieve the effect of increasing rate and selectivity, improving catalytic activity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 100mL 0.01mol / L Bu in the beaker 4 PBr aqueous solution, and then add 5mL 0.1mol / L NiCl 2 And CoCl 2 Aqueous solution, stir well. KCl solid was added to the solution until it was supersaturated, and stirring was continued for 10 minutes. Under 273K and vigorous stirring, add 10mL 0.5mol / L KBH dropwise to the above solution 4 After the addition of the aqueous solution, continue to stir for 30 minutes. A black solid was obtained by centrifugation, which was repeatedly washed with deionized water until it became neutral, which was recorded as NiCoB(H)-P.

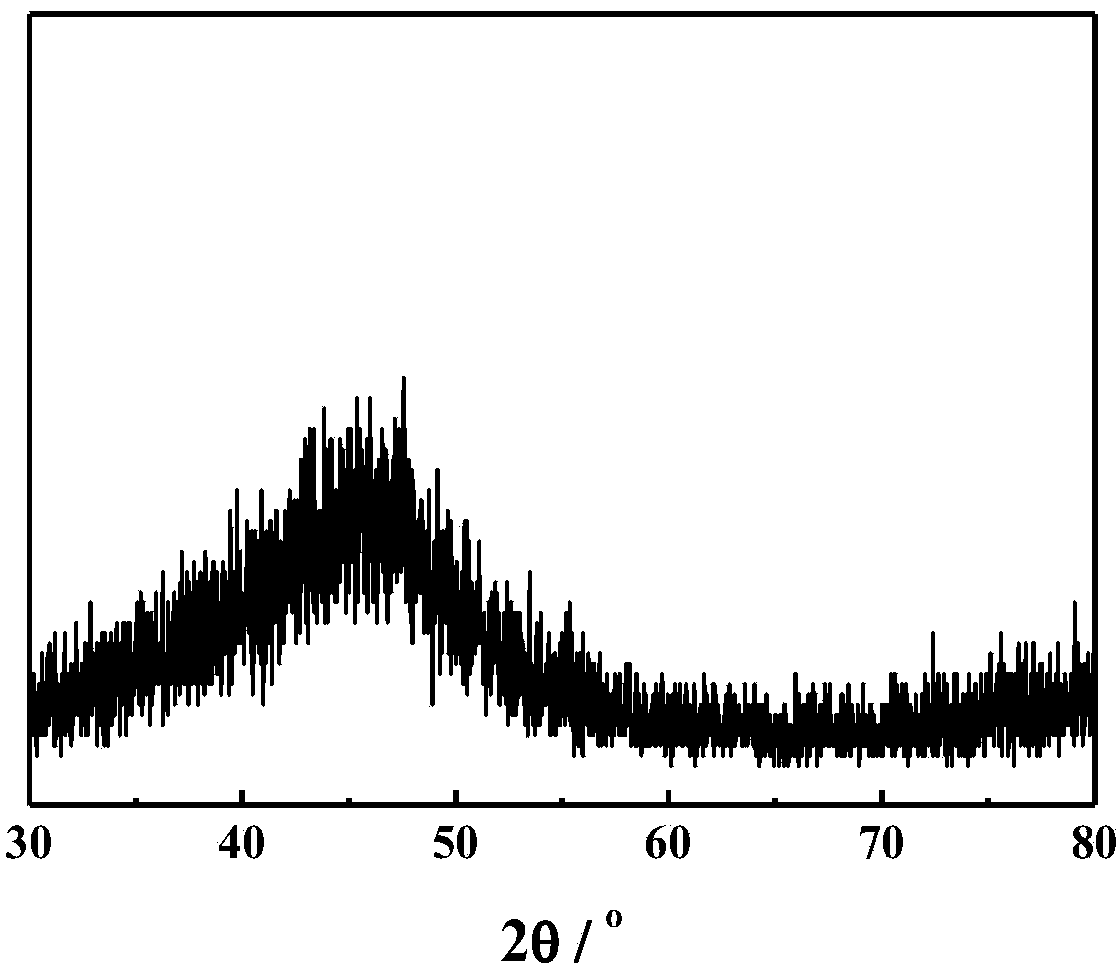

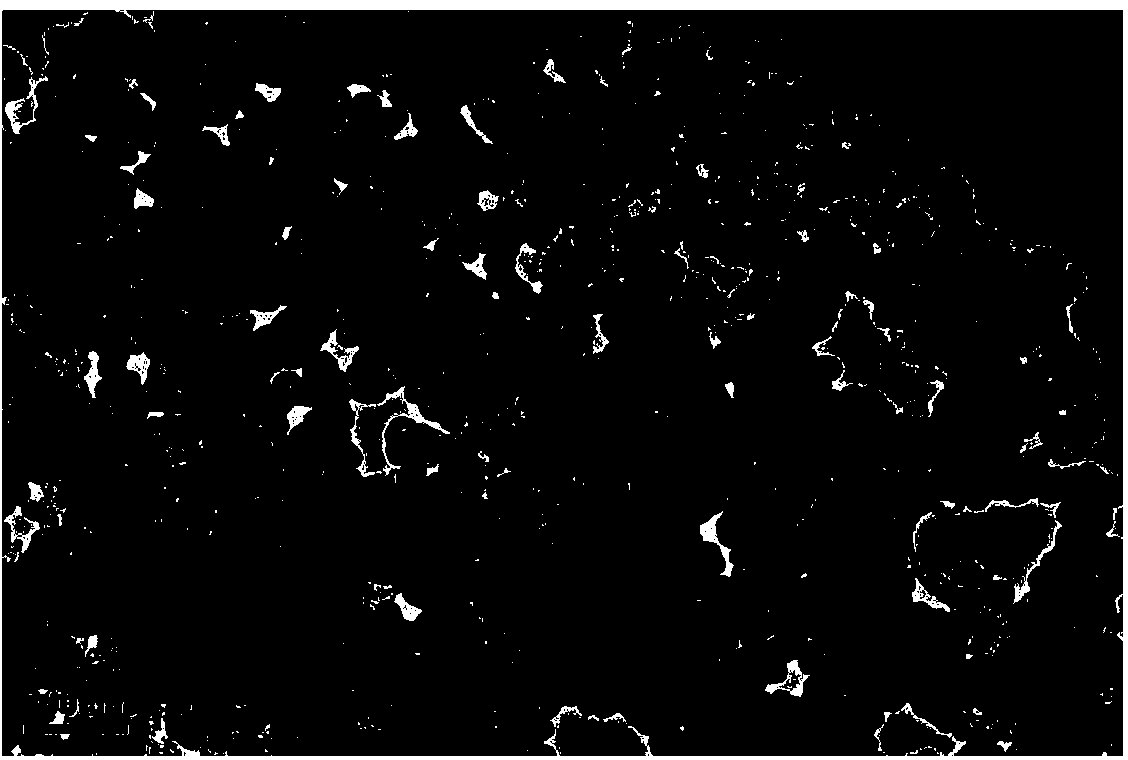

[0025] figure 1 In the XRD spectrum of the sample prepared in this example, it can be seen that there is a broadened dispersion peak near the 45° position, indicating that the sample has an amorphous alloy structure. figure 2 The TEM picture of the sample prepared in this example shows that the obtained sample has a hollow nanosphere morphology with a diameter of about 40 nm.

Embodiment 2

[0027] Add 100mL 0.01mol / L Bu in the beaker 4 NBr aqueous solution, and then add 5mL 0.1mol / L NiCl respectively 2 And CoCl 2 Aqueous solution, stir well. KCl solid was added to the solution until it was supersaturated, and stirring was continued for 10 minutes. Under 273K and vigorous stirring, add 10mL0.5mol / L KBH dropwise to the above solution 4 After the addition of the aqueous solution, continue to stir for 30 minutes. A black solid was obtained by centrifugation, which was repeatedly washed with deionized water until it became neutral, which was recorded as NiCoB(H)-N.

Embodiment 3

[0029] Add 50mL 0.01mol / L Bu into the beaker 4 PBr and Bu 4 NBr aqueous solution, and then add 5mL 0.1mol / L NiCl respectively 2 And CoCl 2 Aqueous solution, stir well. KCl solid was added to the solution until it was supersaturated, and stirring was continued for 10 minutes. Under 273K and vigorous stirring, add 10mL0.5mol / L KBH dropwise to the above solution 4 After the addition of the aqueous solution, continue stirring for 30 minutes. A black solid was obtained by centrifugation, which was repeatedly washed with deionized water until it became neutral, which was recorded as NiCoB(H)-P,N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com