Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Easy to purchase and produce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High wear-resistant self-lubricating polyoxymethylene and process for preparing same

The invention relates to organic polymer composite material, in particular to high wear-resistant self-lubricating polyoxymethylene and a process for preparing the same. The high wear-resistant self-lubricating polyoxymethylene comprises the following components by weight percent: 85.5-96 percent of polyoxymethylene, 2-5 percent of silicon lubricant, 1-5 percent of toughening agent, 0.1-1.7 percent of polyoxymethylene absorbing agent, 0.1-0.4 percent of coupling agent, 0.3-2.0 percent of antioxidant and 0.1-2.5 percent of other auxiliary. The high wear-resistant self-lubricating polyoxymethylene has the characteristics of wear resistance and self-lubrication in addition to the original good comprehensive mechanical properties and is convenient to produce and purchase, thereby greatly improving the competitiveness of polyoxymethylene products and being more suitable for producing the workpieces needing to improve the wear resistance and reducing the material cost.

Owner:KECHUANG POLYMER SUZHOU

Electromagnetic shielding nylon 66 material and preparation process thereof

InactiveCN101717577AGood physical and mechanical propertiesWith electromagnetic shielding functionMagnetic/electric field screeningCarbon fibersNylon 66

The invention relates to an organic polymer composite material, in particular to an electromagnetic shielding nylon 66 material and a preparation process thereof. The material comprises the following components in percentage by weight: 49.5-90 percent of nylon 66, 0-45 percent of metal fiber, 0-35 percent of carbon fiber, 0-30 percent of conductive graphite, 2-5 percent of heat stabilizer, 0.2-1.0 percent of coupling agent and 0.3-5.5 percent of other auxiliary agents. The electromagnetic shielding nylon 66 material can replace metal raw materials to produce parts or shells, and has higher physical and mechanical properties of the nylon 66 and the electromagnetic shielding function of the metal materials, thereby being convenient to produce and purchase, greatly reducing relevant cost and comprehensively improving the competitiveness.

Owner:KECHUANG POLYMER SUZHOU

Electromagnetic shielding polyethylene material and preparation process thereof

InactiveCN101701083AEasy to produce and purchaseLow costMagnetic/electric field screeningThermoplasticCorrosion

The invention relates to an organic polymer composite material, in particular to a polyethylene material capable of electromagnetic shielding and a preparation method thereof. The polyethylene material comprises the following components in percentage by weight: 49.5-90 percent of polyethylene, 5-35 percent of carbon fiber, 2-30 percent of conductive graphite, 0.2-1.0 percent of antioxidant, 0.2-2.0 percent of coupling agent and 0.3-5.5 percent of other auxiliary agent. The electromagnetic shielding polyethylene material can replace metal raw materials to produce spare and accessory parts or casings, and combines the favorable performance of thermoplastic plastics which can be processed easily and the electromagnetic shielding function of metal materials, therefore, the production purchasing of the electromagnetic shielding polyethylene material can be realized conveniently, and the relevant cost can be greatly reduced. The electromagnetic shielding polyethylene material also has the advantages of acid-resistant and alkali-resistant corrosion, certain mechanical strength and temperature toleration, thereby comprehensively improving the competitiveness.

Owner:KECHUANG POLYMER SUZHOU

Cold-resistant super-toughened nylon 66 and manufacturing process thereof

The invention relates to an organic polymer composite material, in particular to cold-resistant super-toughened nylon 66 and a manufacturing process thereof. The cold-resistant super-toughened nylon 66 consists of the following components in percentage by weight: 49.5 to 90 percent of nylon 66, 3 to 35 percent of anti-freezing agent, 3 to 35 percent of impact modifier, 0.3 to 1.5 percent of antioxidant, and 0.3 to 5.5 percent of other aids. Through the cold-resistant super-toughened nylon 66 and the manufacturing process thereof, the impact strength of a cantilever notch is about ten times higher than that of common nylon 66 at the low temperature of 40 DEG C below zero; the cold-resistant super-toughened nylon 66 is convenient to produce and purchase; and raw and auxiliary materials and production equipment are all made in China, so that the raw material cost and production cost are greatly reduced, and the comprehensive competitive power of the product is effectively improved.

Owner:KECHUANG POLYMER SUZHOU

Cold-resistant super-toughened nylon 6 and manufacturing process thereof

The invention relates to an organic polymer composite material, in particular to cold-resistant super-toughened nylon 6 and a preparation method thereof. The cold-resistant super-toughened nylon 6 consists of the following components in percentage by weight: 49.5 to 90 percent of nylon 6, 3 to 35 percent of anti-freezing agent, 3 to 35 percent of impact modifier, 0.3 to 1.5 percent of antioxidant, and 0.3 to 5.5 percent of other aids. Through the cold-resistant super-toughened nylon 6 and the manufacturing process thereof, the impact strength of a cantilever notch is about ten times higher than that of common nylon 6 at the low temperature of 40 DEG C below zero; the cold-resistant super-toughened nylon 6 is convenient to produce and purchase; and raw and auxiliary materials and production equipment are all made in China, so that the raw material cost and production cost are greatly reduced, and the comprehensive competitive power of the product is effectively improved.

Owner:KECHUANG POLYMER SUZHOU

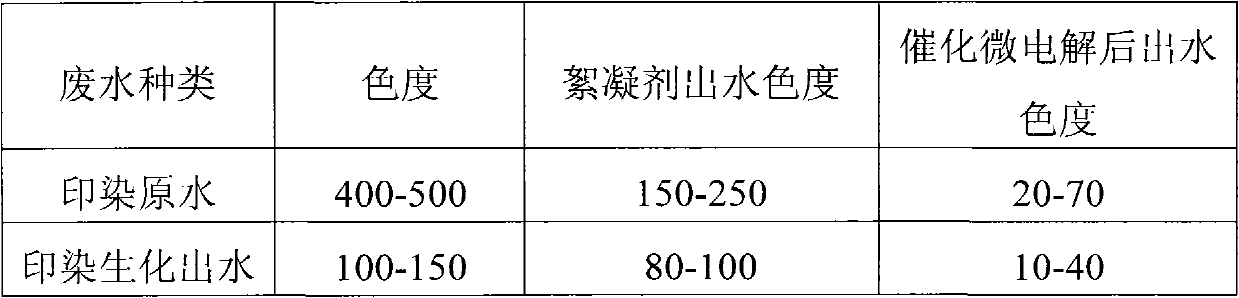

Micro-electrolysis filling material and preparation method thereof

ActiveCN102557201ALarge specific surface areaHigh activityWater/sewage treatmentChemical oxygen demandElectrolysis

The invention discloses a preparation method of a micro-electrolysis filling material. The method comprises the steps of mixing the raw materials including scrap iron, activated carbon and dispersant, calcinating the mixture at the temperature ranging from 1080 DEG C to 1180 DEG C and under oxygen-free conditions; cooling, crushing and screening, wherein the consumed scrap iron accounts for 60 to 70% of the total mass of the raw material, the consumed activated carbon accounts for 20 to 30% of the total mass of the raw material, and the consumed dispersant accounts for 5 to 10% of the total mass of the raw material. The micro-electrolysis filling material has remarkable effects on removing wastewater COD (Chemical Oxygen Demand) and lowering the chromaticness, can improve the biodegradability of wastewater well, avoids inactivation and hardening during treatment process, and is stable and effective during long-term operation, so that the reaction rate is high and only 30 to 60 minutes is required to treat industrial wastewater; the micro-electrolysis filling material is relatively lower in iron content, so that the specific weight is greatly reduced and convenience is provided for load, transportation and use; the application range of the activated carbon is expanded, so that convenience is provided for purchase and production; and a wide variety of dispersants can be used in the method and can be adjusted according to different kinds of wastewater, thereby having a better treatment effect on all kinds of wastewater.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH +1

Special low smoke zero halogen fire resistant polycarbonate/acrylonitrile-butadiene-styrene alloy material for slot extrusion

InactiveCN102061075AImprove mechanical propertiesBeautiful appearanceEnvironmental resistanceLow smoke zero halogen

The invention discloses a special low smoke zero halogen fire resistant polycarbonate / acrylonitrile-butadiene (PCABS) alloy material for slot extrusion. The alloy material comprises the following components by weight percent: 47.5-96% of polycarbonate, 3.0-50.0% of ABS resin, 1-35% of composite halogen-free fire retardant, 0-3.0% of smoke suppressant, 0.1-2.0% of antioxidant, 0.1-2.0% of lubricant and 1.3-5.5% of other additives. The alloy material provided by the invention has the following advantages: the comprehensive mechanical performance is good, the alloy material does not contain halogen, and the product has beautiful appearance and is convenient to produce and purchase; and all the requirements on environmental friendliness can be met and the product competitiveness can be increased comprehensively.

Owner:苏州工业园区科创橡塑有限公司

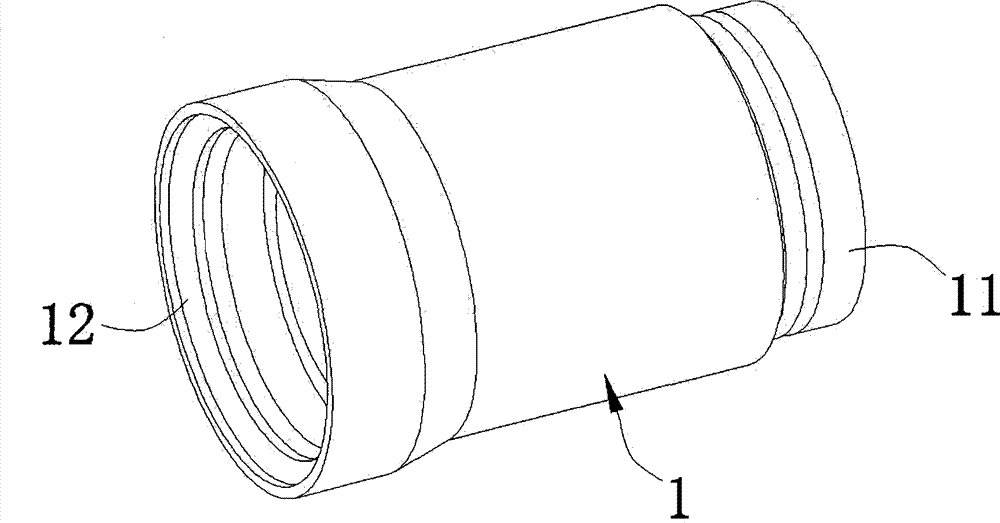

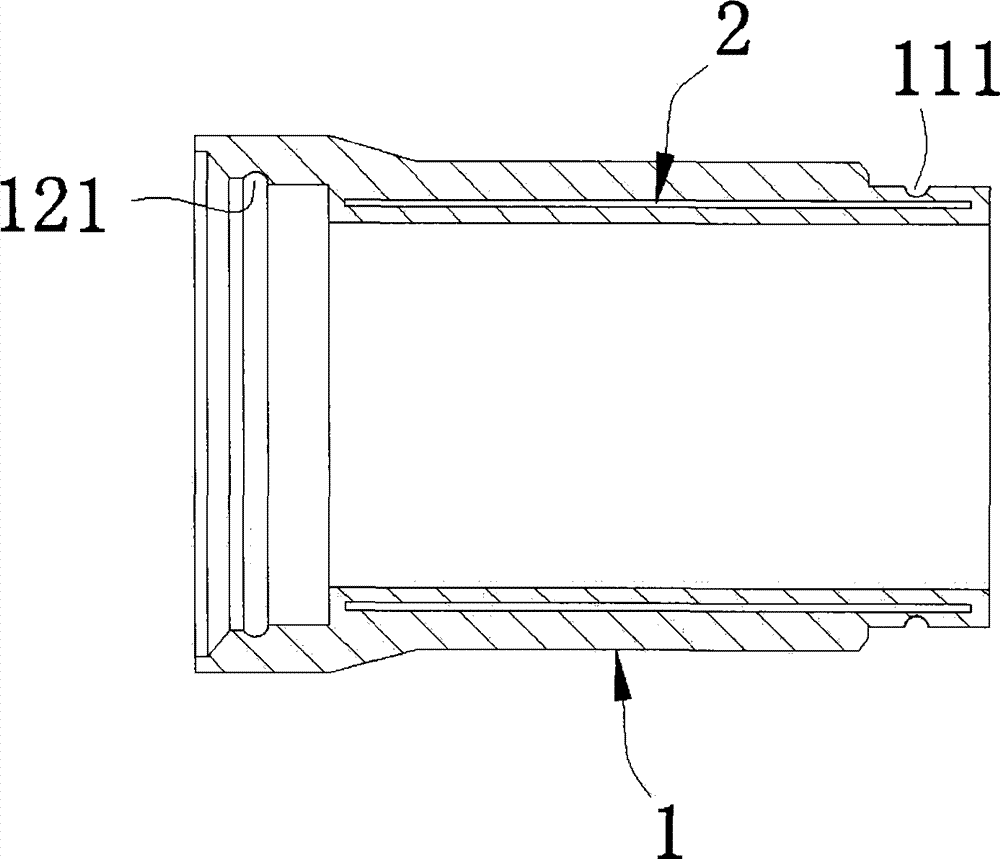

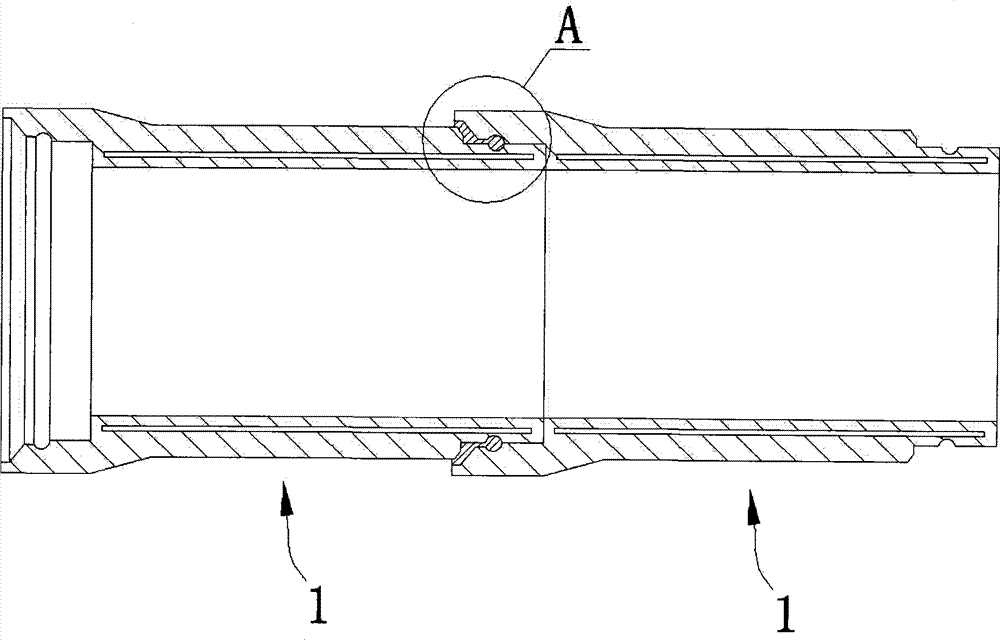

Regenerated concrete dewatering pipe and manufacturing method thereof

ActiveCN104500857AIngenious structural designReasonable formulaSolid waste managementShaping reinforcementsSocial benefitsEconomic benefits

The invention discloses a regenerated concrete dewatering pipe which comprises a tubular body and a reinforcing rod embedded in the tubular body and extending along the axial direction of the same. The outer edge of an opening at one end of the tubular body is provided with an annular notch to form a connection plug while an opening at the other end radially expands to form an insertion connecting cavity, and the tubular body is composed of cement, fly ash, sand and regenerated gravel. The invention further discloses a manufacturing method of the regenerated concrete dewatering pipe. The regenerated concrete dewatering pipe is ingenious in structural design, reasonable in formula, high in integral structure strength, high in pressure bearing capacity and stable and firm in connection; building waste is utilized for regeneration, so that environment is protected; the regenerated concrete dewatering pipe is low in cost and simple and convenient to manufacture, so that competitiveness is improved, and good economic benefit and social benefit are realized. The manufacturing method is simple and easy in process, easy to realize and high in production efficiency, and the problem of regenerating utilization of the building waste can be solved while the regenerated concrete dewatering pipe is manufactured quickly.

Owner:丰永沅(北京)科技有限公司

Neohouttuynin sodium freeze-dried powder-injection, and its prepn. method

InactiveCN1459284AGood effectImprove solubilityOrganic active ingredientsPowder deliverySolubilityFreeze-drying

A freeze-dried powder injection of neohouttuynine sodium for treating pelvic inflammation, annexitis and chronic cervicitis contains neohouttuynine sodium, one or more of cyclodextrin and its derivatives and excipient in a certain proportion. It is prepared through dissolving neohouttuynine sodium and cyclodextrin or its derivative in the water for injection, adding excipient, regulating the pH value, filtering, freezing, and sublimation drying.

Owner:肖广常 +1

Halogen-free high-luster anti-buckling deformation filled high-temperature nylon and production process thereof

The invention relates to an organic polymer composite, in particular to halogen-free high-luster anti-buckling deformation filled high-temperature nylon and a preparation method thereof. The nylon consists of the following components by weight ratio: 49.5-90% of high-temperature nylon; 0-25% of talcpowder; 0-25% of crystal whisker; 0-30% of halogen-free glass beads; 1-5% of flexibilizer; 0.1-0.4% of coupling agent; and 0.1-5.5% of other agents. The halogen-free high-luster anti-buckling deformation filled high-temperature nylon and the production process thereof have no halogen, are environment-friendly, are added with the characteristics of good anti-buckling deformation and high-luster and beautiful appearance on the basis of keeping good synthetic mechanical properties, and have convenient production and purchasing, thus improving the competitive force and being more applicable to producing heat-resisting workpieces such as masks / shells needing to be tightly assembled and having beautiful appearance.

Owner:KECHUANG POLYMER SUZHOU

Technique for making mouldproof antibacterial wood plastic composite

The invention relates to a mouldproof antibacterial wood plastic composite, comprising the following components in percentage by weight: 20-45% of polypropylene, 50-70% of crop straw powder, 0.2-8.0% of compound mouldproof antibacterial agent, 0.2-2.0% of lubricating agent, 3-15% of toughening agent, 1.0-8.0% of coupling agent, 0.0-5.0% of moisture absorbing agent and 0.1-5.5% of other auxiliaries. According to the mouldproof antibacterial wood plastic composite provided by the invention, ratio of the crop straw powder is far higher than 50% under the condition that the comprehensive mechanical performances are well maintained, the mouldproof antibacterial wood plastic composite provided by the invention can be used for producing a product with complex structure and large area by virtue of injection moulding, has natural flavour of timber and high strength, can be coloured as required, is low in cost and simple and convenient to process, meets low-carbon requirement, also has mouldproof and antibacterial functions and is especially preponderant when applied to outdoor, damp and biological contact products.

Owner:KECHUANG POLYMER SUZHOU

High-electric breakdown strength modified polyphenyl ether and preparation process thereof

InactiveCN101701102ALow costImproved electrical breakdown strength modificationAntioxidantPolystyrene

The invention relates to an organic macromolecule composite material, in particular to a high-electric breakdown strength modified polyphenyl ether and a preparation process thereof. The high-electric breakdown strength modified polyphenyl ether comprises the following components in percentage by weight: 30-80 percent of polyphenyl ether powder, 5-40 parts of polystyrene, 0-35 percent of ceramic micropowder, 0-35 percent of kaolin micropowder, 0.3-1.5 percent of antioxidant, 0.1-3.0 percent of toughening agent, 0.1-2.8 percent of coupling agent, 0.1-3.0 percent of high molecular weight silicone oil, 1-5 percent of compatilizer and 0.3-5.5 percent of other auxiliary agents. The high-electric breakdown strength modified polyphenyl ether and the preparation process thereof have well improved high-electric breakdown strength modification on the premise of maintaining the original advantages of the polyphenyl ether, convenient production purchase, domestic raw and auxiliary materials and production equipment and low production cost and raw material cost, thereby greatly improving competitiveness.

Owner:KECHUANG POLYMER SUZHOU

Halogen-free high glowing filament ignition temperature flame-retardant nylon 6 and manufacturing process thereof

InactiveCN101792597AEasy to produce and purchaseReduce raw material cost and production costChemistryAntioxidant

Owner:KECHUANG POLYMER SUZHOU

Halogen-free warp-resistant PBT of excellent electrical properties and preparing technique thereof

InactiveCN101759967AIncreased warpage resistance and high electrical performanceEasy to produce and purchaseHalogenStone mastic asphalt

The present invention relates to an organic polymer composite, particularly to a halogen-free warp-resistant polybutylece terephthalate (PBT) of excellent electrical properties and a preparing technique thereof. The PBT consists of the following constituents in a ratio by weight: 40 to 90% of PBT, 1 to 3% of stone mastic asphalt (SMA), 1 to 35% of micro halogen-free mica sheet, 1 to 30% of halogen-free glass microsphere, 1 to 5% of toughening agent, 0.1 to 0.4% of coupling agent and 0.1 to 5.5% of other auxiliaries. The halogen-free warp-resistant PBT of excellent electrical properties and the preparing technique have the advantages that warp-resistant properties and excellent electrical properties are increased on the basis of excellent comprehensive mechanical properties, and the PBT does not contain halogen. Production and procurement are convenient, and meanwhile, all the other environmental protection requirements are met. Thus, the comprehensive competitive power is improved.

Owner:KECHUANG POLYMER SUZHOU

High-strength wear-resistant engineering plastic

The invention discloses a high-strength wear-resistant engineering plastic. The invention is characterized in that the engineering plastic is prepared from the following raw materials in parts by weight: 10-20 parts of polytetrafluoroethylene, 5-8 parts of toughener, 3-6 parts of high-aluminum aggregate, 4-8 parts of mica, 6-8 parts of silicone oil, 3-6 parts of silicon carbide, 2-5 parts of asbestos, 3-6 parts of plasticizer and 8-14 parts of internal molding lubricant. The engineering plastic has excellent electrical properties and favorable appearance, changes the situation that the user can only select either properties or appearance when designing the product, and satisfies all environmental requirements; the properties are similar to those of imported like materials, but the price is only one-third to one half of that of the imported like materials; and the engineering plastic is convenient to produce and purchase.

Owner:QINGDAO HUIERTONG TRADING

Halogen-free buckling deformation resistant reinforced high-temperature nylon and preparation method thereof

InactiveCN101704997AEasy to produce and purchaseImprove overall competitivenessMetallurgyHigh polymer

The invention relates to an organic high-polymer composite, in particular to halogen-free buckling deformation resistant reinforced high-temperature nylon and a preparation method thereof. The halogen-free buckling deformation resistant reinforced high-temperature nylon comprises the following components by weight percentage: 49.5 to 90 percent of high-temperature nylon, 1 to 35 percent of halogen-free and alkali-free glass fiber, 1 to 30 percent of halogen-free glass beads, 1 to 5 percent of flexibilizer, 0.1 to 0.4 percent of coupling agent, and 0.1 to 5.5 percent of other assistants. The halogen-free buckling deformation resistant reinforced high-temperature nylon and the preparation method thereof are halogen-free and environment-friendly, have the additional characteristic of good resistance to buckling deformation on the basis of maintaining good comprehensive mechanical performances, are more suitable for being used for producing workpieces which need to be assembled tightly, such as mask / shell and product frameworks, and are also convenient for producing and purchasing, thus improving the comprehensive competitiveness of products in all aspects.

Owner:KECHUANG POLYMER SUZHOU

Glass fiber enhanced nylon 6 material for improving transparency

InactiveCN101955656AExpand the range of material selectionHigh transparencyEnvironmental resistanceGlass fiber

The invention relates to a glass fiber enhanced nylon 6 material for improving the transparency, comprising the following components in percentage by weight: 38.5-95 percent of nylon 6, 5-60 percent of alkali-free glass fiber, 0.5-6.0 percent of clarifier, 0.1-3.0 percent of glass fiber treating agent and 1.3-5.5 percent of other assistants. The glass fiber enhanced nylon 6 material for improving the transparency has approximate performance to that of the like materials, is convenient to produce and purchase, improves the transparency and also meets all other environment-friendly requirements, so that the material can also be used in places through which the condition can be seen by the shield of products, which increases the application fields, widens the material selecting range of product designers, solves the problem of design limitation of products and improves the competitiveness of the products.

Owner:KECHUANG POLYMER SUZHOU

Highly-polished ethylene glycol resistant composite reinforced nylon 66 and process for producing same

The invention relates to organic polymer composite material, in particular to highly-polished ethylene glycol resistant composite reinforced nylon 66 and a process for producing the same. The highly-polished ethylene glycol resistant composite reinforced nylon 66 comprises the following components by weight percent: 50-70 percent of nylon 66, 25-35 percent of halogen-free alkali-free glass fiber, 0.1-3.0 percent of heat stabilizer, 0.2-1.5 percent of ethylene glycol resistant treating agent, 0.1-3.0 percent of glass fiber treating agent, 0.1-0.5 percent of nucleating agent, 1.0-2.5 percent of nylon-base high-pigment black masterbatch and 1.3-5.5 percent of other auxiliary agent. The highly-polished ethylene glycol resistant composite reinforced nylon 66 has highly-polished appearance and long-term heat, aging and ethylene glycol resisting characteristics in addition to the excellent mechanical properties, is convenient to produce and purchase, adopts the domestic raw materials, auxiliary materials and additives and meets all the environmental protection requirements, thereby being more competitive.

Owner:KECHUANG POLYMER SUZHOU

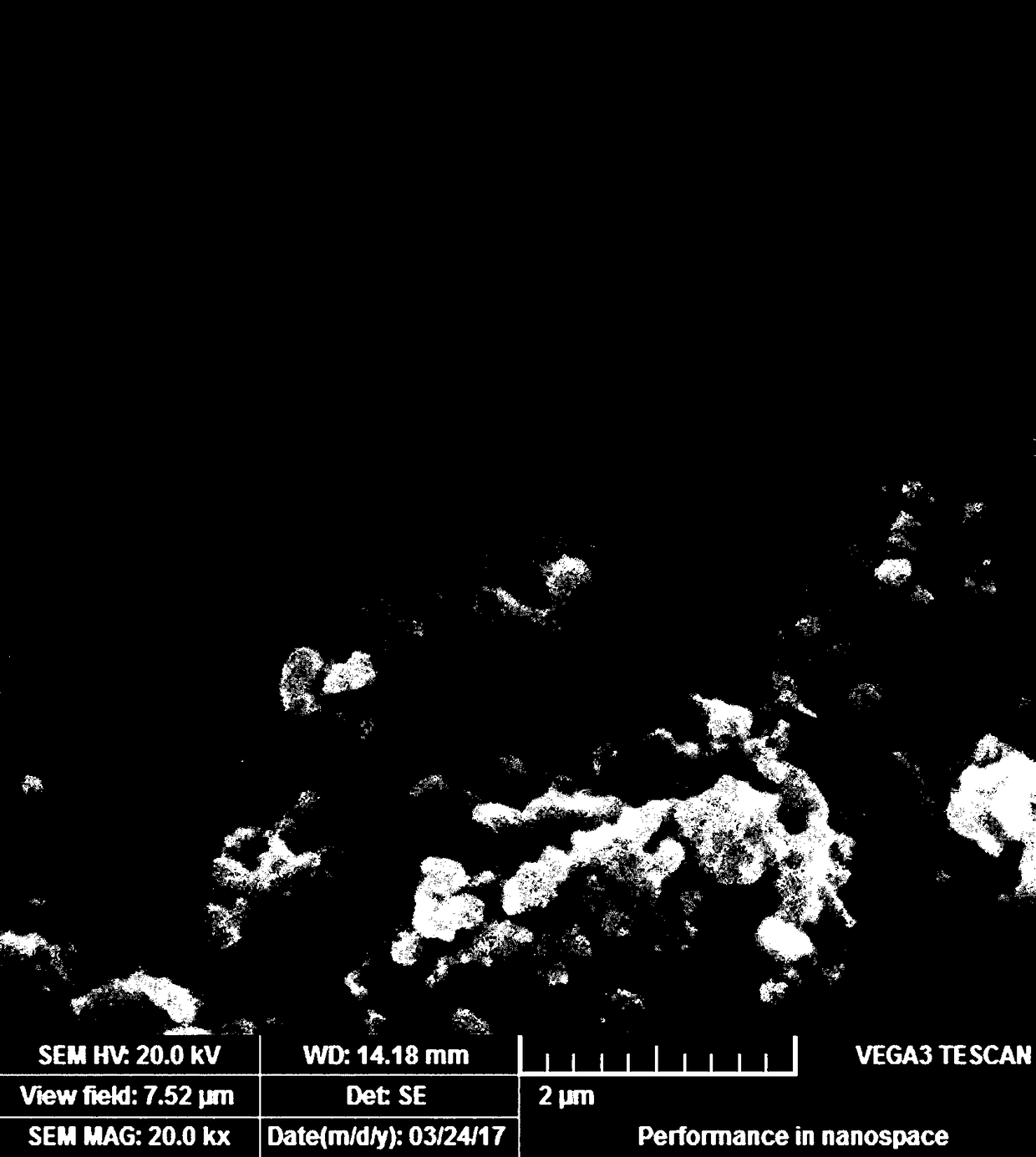

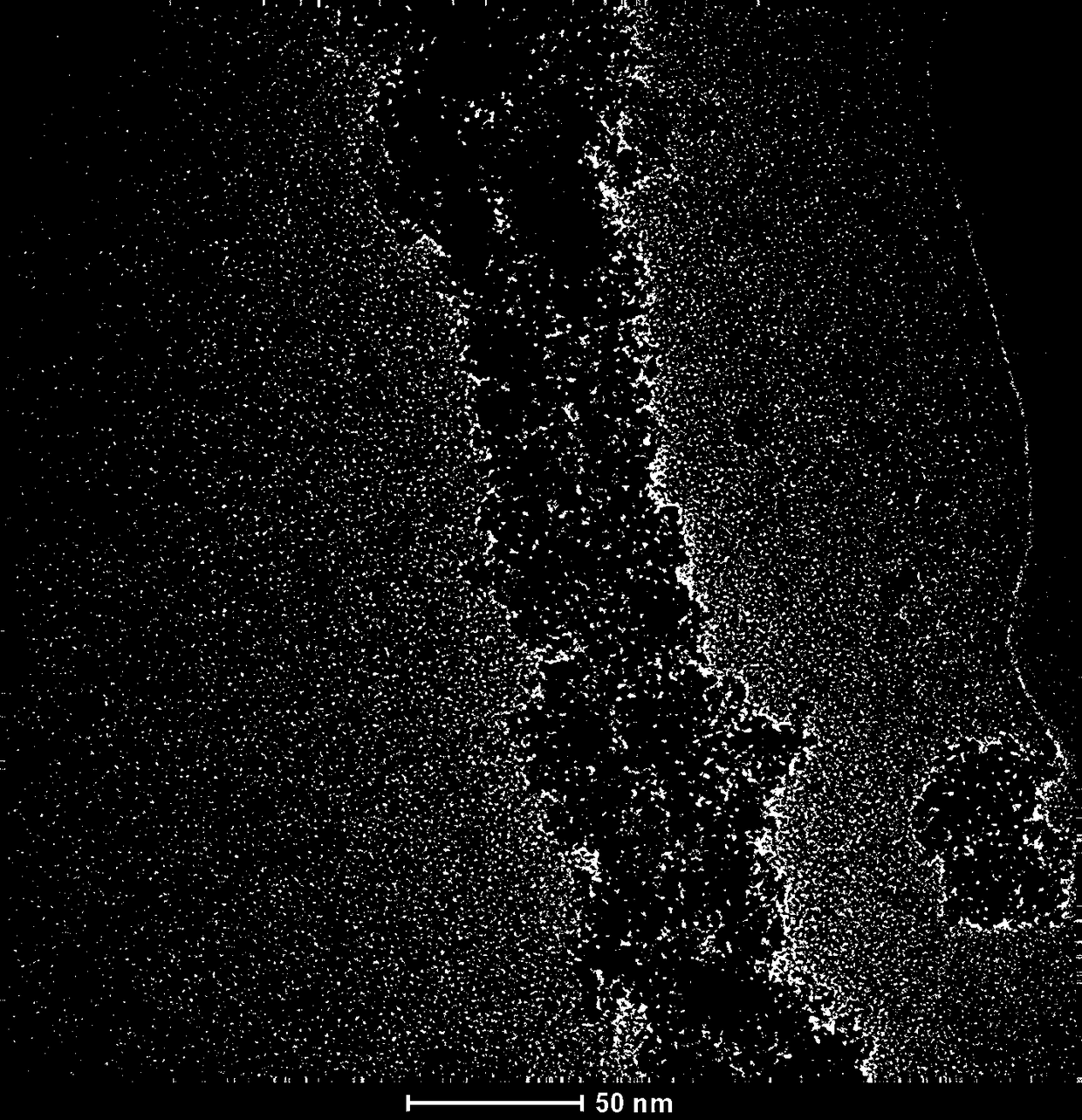

Preparation method of nickel-coated carbon nanotube composite material

ActiveCN108546938AEasy to handleFacilitate depositionTransportation and packagingMetal-working apparatusNitrogen gasBiological activation

The invention relates to a preparation method of a nickel-coated carbon nanotube composite material. The preparation method comprises the following steps: (1) grinding a carbon nanotube, soaking the carbon nanotube with concentrated nitric acid and cleaning the carbon nanotube with hydrofluoric acid to remove impurities; (2) adding a sensitizing solution to sensitize, ultrasonically treating and stirring the mixture for 4-20 min, and filtering the mixture, wherein the sensitizing solution is prepared from SnCl2 and HCl; (3) adding an activating liquid to activate the mixture, ultrasonically treating and stirring the mixture for 7-30 min, and filtering the mixture after activation, wherein the activating liquid is prepared from Pb(NO3)2 and HNO3; and (4) adding a nickeling liquid and a reducer, adjusting the pH to 8.5-9.5, heating the mixture to 65-75 DEG C, stirring the mixture to react for 1-4 h, filtering and washing the mixture to be neutral, and carrying out thermal treatment for 4h at 380 DEG C under nitrogen protection to obtain the nickel-coated carbon nanotube, wherein the nickeling liquid, the reducer and the pH adjustor are prepared by the inventor. The prepared nickel-coated carbon nanotube composite material is good in uniformity and continuity of the coating, high in bonding force, controllable in metal grain size and suitable for being popularized and applied.

Owner:江苏博霖环保科技有限公司

Manufacturing process of heat conduction nylon material

The invention relates to a manufacturing process of a heat conduction nylon material. The heat conduction nylon material is composed of the following components in percentage by weight: 5-70% of nylon, 3-45% of heat conduction fiber, 20-70% of heat conduction powder, 2-5% of lubricant, 0.2-1.0% of coupling agent and 0.3-5.5% of other assistants. According to the invention, the green environment-friendly heat conduction nylon material can be used instead of a metal raw material for the production of spare parts or shells, and simultaneously has higher physical and mechanical properties of the nylon as well as heat conduction and heat radiation functions and heat stability of the metal material; both the production and the procurement are convenient; and the relevant cost is greatly lowered. Thus, the competitive power is greatly improved.

Owner:KECHUANG POLYMER SUZHOU

Special wood and plastic material for railway sleeper

InactiveCN101982506AImprove mechanical propertiesEasy to processBallastwayPlastic materialsPolypropylene

The invention discloses a special wood and plastic material for a railway sleeper, which comprises the following components by weight ratio: 5-30% of polypropylene recycled material, 5-30% of polyethylene recycled material, 51-70% of wood flour, 0.2-2.0% of lubricant, 3-15% of coating agent, 1.0-8.0% of coupling agent, 1.0-5.0% of moisture absorbing agent, 0.5-2.0% of anti-aging agent and 0.1-5.5% of other additives. The special wood and plastic material for the railway sleeper can lead the proportion of crop straw powder to be far higher than 50% on the basis of having excellent comprehensive mechanical properties and good processability, and the use of the material can rapidly produce the railway sleeper by extrusion; furthermore, the product has high strength and can keep all the advantages of the wood sleeper, avoid the decay phenomenon, relatively greatly prolong the service life, simultaneously avoid consuming wood, realizing low cost and simple processing and being in line with environmental protection.

Owner:KECHUANG POLYMER SUZHOU

Special nylon material of bicycle brake lever

InactiveCN101974224AEasy to purchase and produceMeet environmental protection requirementsGlass fiberAlkali free

The invention discloses a special nylon material of a bicycle brake lever, consisting of the following components by weight percentage: 49.5 to 95% of nylon 6, 5 to 50% of alkali-free glass fiber, 0.1 to 3.0% of heat stabilizer, 0.1 to 3.0% of glass fiber finishing agent, 0.1 to 1.0% of antioxygen, 1 to 15% of shock resistant agent and 3.3 to 9.5% of other auxiliaries. The special nylon material of the bicycle brake lever has the similar using effect as the existing high-strength aluminum alloy material, the manufacturing and the purchasing are convenient and the special nylon material meets all the requirements of environmental protection, therefore, the product competitiveness is enhanced comprehensively.

Owner:KECHUANG POLYMER SUZHOU

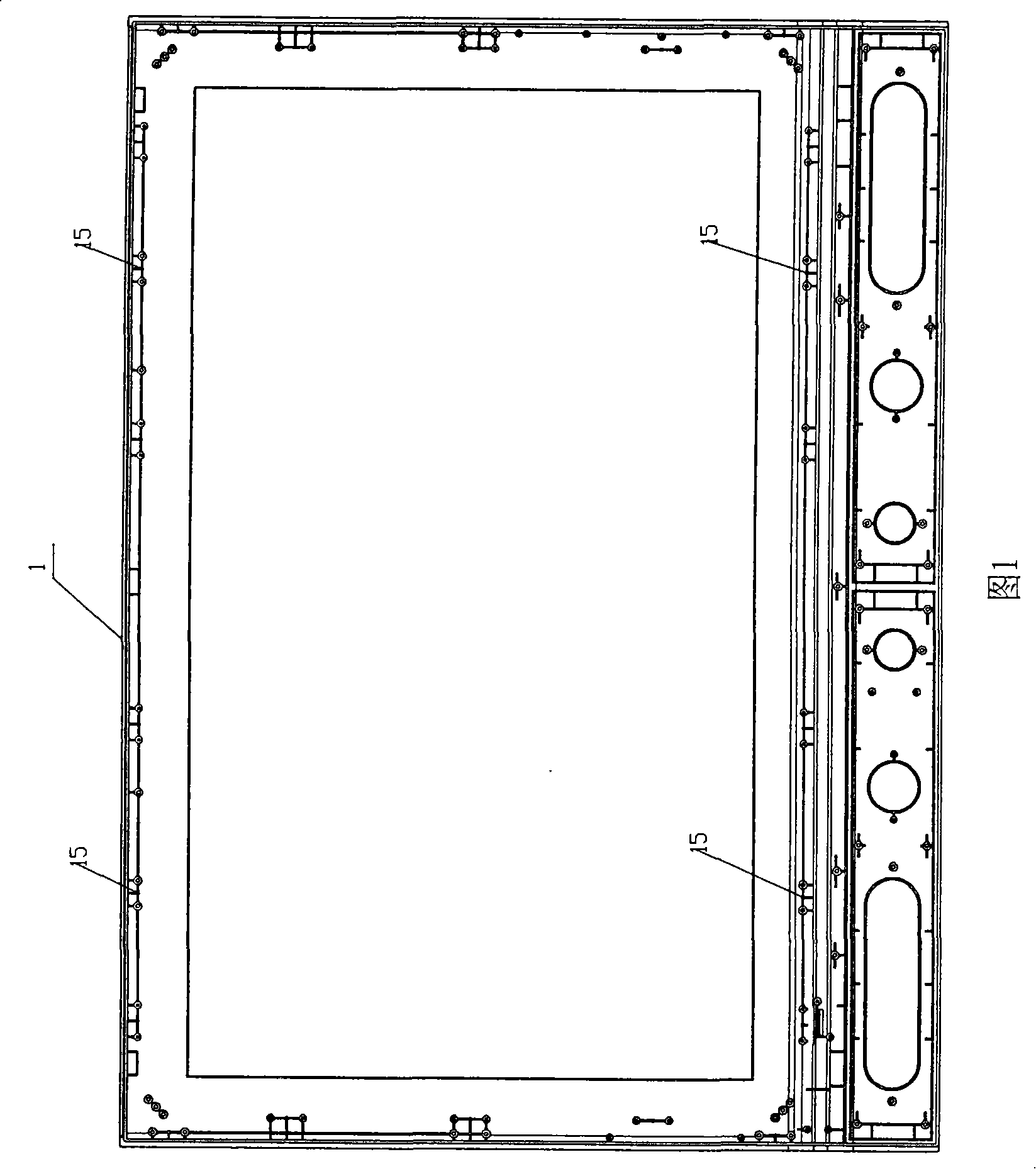

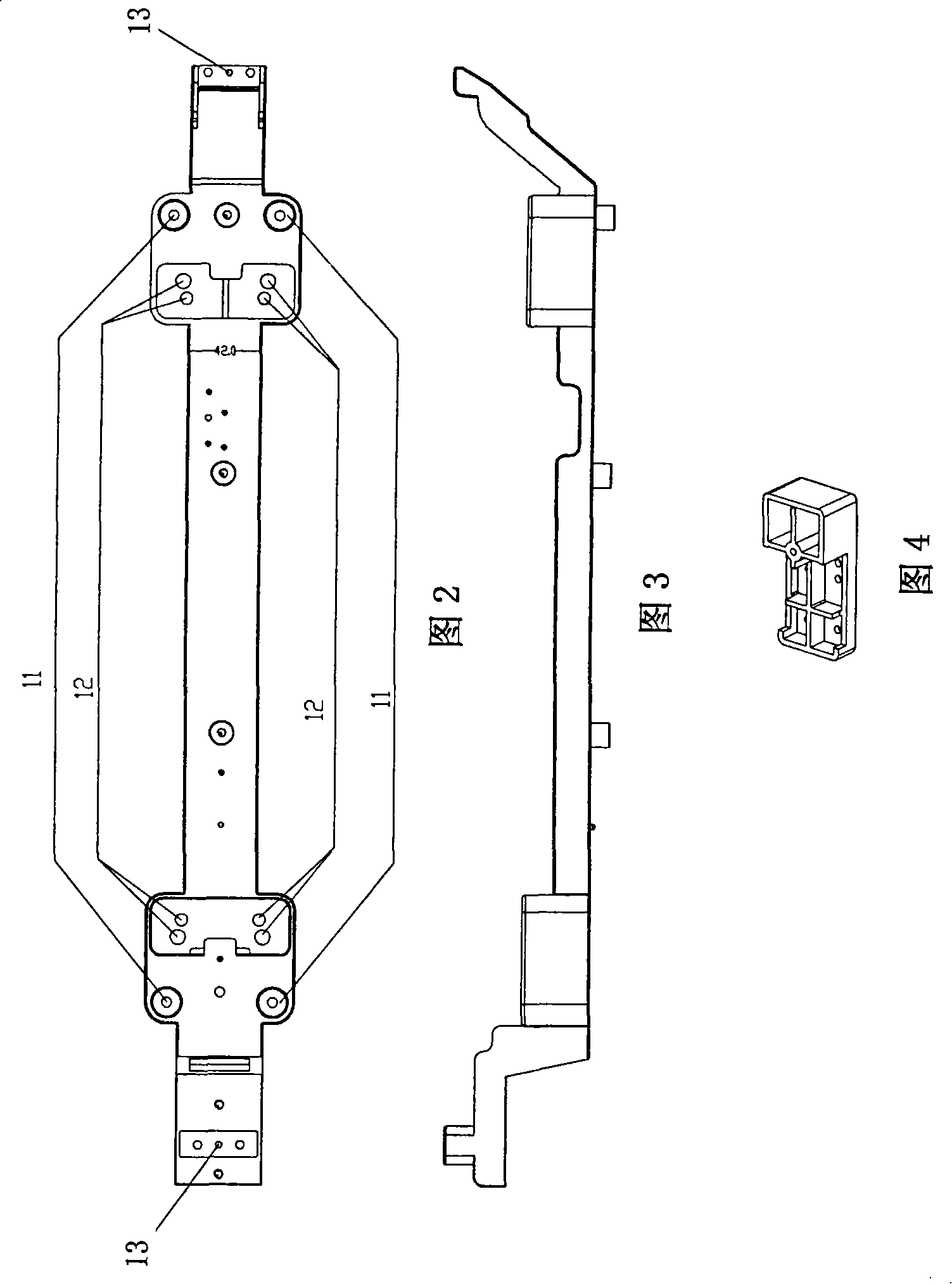

Cabinet for multipurpose flat plate television set

InactiveCN101252660ALow costImprove versatilityTelevision system detailsColor television detailsLiquid-crystal displayEngineering

The invention relates to a casing for a multipurpose flat television. which is characterized in that the flat television comprises a front casing (1) and a back frame (2), wherein a mounting hole (11) used for installing a screen fixing bracket (3) and used during the installation of an LCD screen and a mounting hole (12) for installing a PDP module group are arranged on the back frame (2), positioning holes (13) are arranged at both ends of the back frame (2), and are fixed on the edge of the rear part of the frame casing (1) through corresponding connecting screws. By using he invention, the exchange of the casings of two different brands of televisions can be realized through simple design, the exchange and the installation of the liquid crystal display (LCD) and the PDP can be conveniently realized only through the replacement of a small quantity of components, and thereby the organizational management of the production is greatly facilitated.

Owner:PANDA ELECTRONICS GROUP +1

Halogen-free anti-buckling-deformation reinforced nylon 6 and manufacturing process thereof

InactiveCN102888100AHalogen-free and environmentally friendlyImprove mechanical propertiesGlass fiberAlkali free

The invention relates to an organic high polymer composite material, and more specifically relates to a halogen-free anti-buckling-deformation reinforced nylon 6 and a manufacturing process thereof. The halogen-free anti-buckling-deformation reinforced nylon 6 is composed of the following components in percentage by weight: 45-70% of nylon 6, 1-35% of halogen-free and alkali-free glass fiber, 1-40% of halogen-free glass microsphere, 1-5% of toughener, 0.1-0.4% of coupling agent and 0.1-5.5% of other assistants. According to the invention, the halogen-free anti-buckling-deformation reinforced nylon 6 and the manufacturing process thereof have the characteristics that the reinforced nylon 6 is halogen-free and environment-friendly and a good anti-buckling-deformation property is added on the basis of keeping favorable comprehensive mechanical properties, thereby being more suitable for the production of masks / shells required to be tightly assembled and molded parts such as product frameworks and the like; and both the production and the procurement are convenient. Thus, the comprehensive competitive power of the product is comprehensively improved.

Owner:KECHUANG POLYMER SUZHOU

Special nylon 6 material for fast injection molding of green and environment-friendly thin film

The invention discloses a special nylon 6 material for fast injection molding of a green and environment-friendly thin film, which comprises the following components in percentage by weight: 85.5%-99% of nylon 6 slices, 0.1-0.3% of nucleating agent, 1.0-3.0% of high-speed flowing modifying agent, 1.0-8.0% of plasticizer, 0.3-1.5% of antioxidant, and 0.1-1.5% of other auxiliary agents. The special nylon 6 material has the beneficial effects that the flowability is extremely high, all the advantages of the common nylon 6 are remained simultaneously, the production and the purchase are convenient, and the original auxiliary materials and production equipment are domestic, therefore, the competitiveness is improved to a greater degree.

Owner:KECHUANG POLYMER SUZHOU

Preparation process of self-lubricating wear-resistant injection molding molybdenum disulfide polyformaldehyde

InactiveCN102888076AEasy to purchase and produceReduce manufacturing costPolyoxymethylenePolymer science

The invention relates to an organic polymer composite material, in particular to a preparation process of self-lubricating wear-resistant injection molding molybdenum disulfide polyformaldehyde; and the molybdenum disulfide polyformaldehyde comprises the components by weight percent: 86.5-90% of polyformaldehyde, 1-10% of molybdenum disulfide powder, 1-5% of toughening agent, 0.2-2.0% of antioxidant, 0.1-1.7% of aldehyde absorbing agent, 0.1-0.4% of coupling agent and 0.1-2.5% of other auxiliary agents. The technology adds the characteristic of high wear resistance based on maintaining the good comprehensive mechanical property; the raw materials of the technology are convenient to produce and purchase as well as are low in production cost; and the choking smell is not decomposed when the product is processed by injection molding or extrusion, so that the product competitiveness is comprehensively improved.

Owner:KECHUANG POLYMER SUZHOU

Nylon 6 special for low-noise, self-lubricated wear-resisting injection molding gear and preparation process thereof

The invention relates to an organic polymer composite material, in particular to a nylon 6 special for a low-noise, self-lubricated wear-resisting injection molding gear and a preparation method thereof. The nylon 6 consists of the following components in percentage by weight: 49.5-90 percent of nylon 6, 3-35 percent of cross-linking wear-resisting agent, 3-35 percent of nylon 6 powder, 0.3-1.5 percent of antioxidant, 0.3-3.0 percent of heat stabilizer and 0.3-5.5 percent of other addition agents. By the nylon 6 special for the low-noise, self-lubricated wear-resisting injection molding gear and the preparation method thereof, gears with different sizes can be rapidly produced by adopting an injection molding mode; the gear produced by the material has the characteristic of effectively eliminating noise when being used together with a metal gear, simultaneously has better self-lubricating and wear resisting performances and cannot fall off powder dust caused by wear, thereby providing longer service life.

Owner:KECHUANG POLYMER SUZHOU

High-strength reinforced nylon material

InactiveCN103772969AEasy to purchase and produceMeet environmental protection requirementsNylon materialAlkali free

The invention discloses a high-strength reinforced nylon material, which is composed of the following components according to weight ratio: 49.5-95 percent of nylon 6, 5-50 percent of alkali-free fiberglass, 0.1-3.0 percent of a heat stabilizer, 0.1-3.0 percent of a fiberglass treatment agent, 0.1-1.0 percent of an antioxidant and 3.3-9.5 percent of other auxiliaries. The special high-strength reinforced nylon material for disc brakes of a bicycle, disclosed by the invention, has the use effect almost same with that of the high-strength aluminum alloy material used at present, is convenient to produce and purchase, and besides, meets all requirements on environmental protection, accordingly, the product competitiveness is comprehensively improved.

Owner:KECHUANG POLYMER SUZHOU

Acid and alkali-resistant polyethylene

InactiveCN102344601AWith electromagnetic shielding functionWith acid and alkali corrosion resistanceAntioxidantElectromagnetic shielding

The invention relates to an organic polymer composite material, and specifically, relates to acid and alkali-resistant polyethylene. The acid and alkali-resistant polyethylene comprises: by weight, 50.5 to 89.5% of polyethylene, 5 to 40% of an antioxidant, 2 to 30% of conductive graphite, 0.2 to 1.0% of a thermoplastic resin, 0.2 to 2.0% of a plasticizer, 0.3 to 5.5% of activated carbon, and 0.3 to 5.5% of other auxiliary agents. The acid and alkali-resistant polyethylene can replace a metal raw material to be utilized for production of spare and accessory parts or housings, is convenient for processing, has electromagnetic shielding functions belonging to a metal material, is convenient for purchase, and has acid and alkali corrosion resistance and a certain of mechanical strength and temperature toleration, and thus realizing improvement of competitiveness in all respects.

Owner:SUZHOU IND PARK XINFENGLIN PLASTIC TECH

Special high-intensity reinforced nylon material for brake disc of bicycle

InactiveCN102002232AEasy to produce and purchaseImprove product competitivenessFriction liningHigh intensityAluminium alloy

The invention discloses a special high high-intensity reinforced nylon material for a brake disc of a bicycle, comprising the following components according to weight proportion: 49.5-95% of nylon, 5-50% of alkali-free glass fiber, 0.1-3.0% of thermal stabilizer, 0.1-3.0% of glass fiber treating agent, 0.1-1.0% of antioxygen, 3.3-9.5% of other accessories. The use effect of the special high high-intensity reinforced nylon material for the brake disc of the bicycle in the invention is approximate with that of the current high-intensity aluminum alloy material; the material is convenient for producing and purchasing; simultaneously, the material meets all environmental requirements, thereby comprehensively improving product competitiveness.

Owner:KECHUANG POLYMER SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com