Synthesis method and application of size-controlled low-dimensional strontium titanate crystals

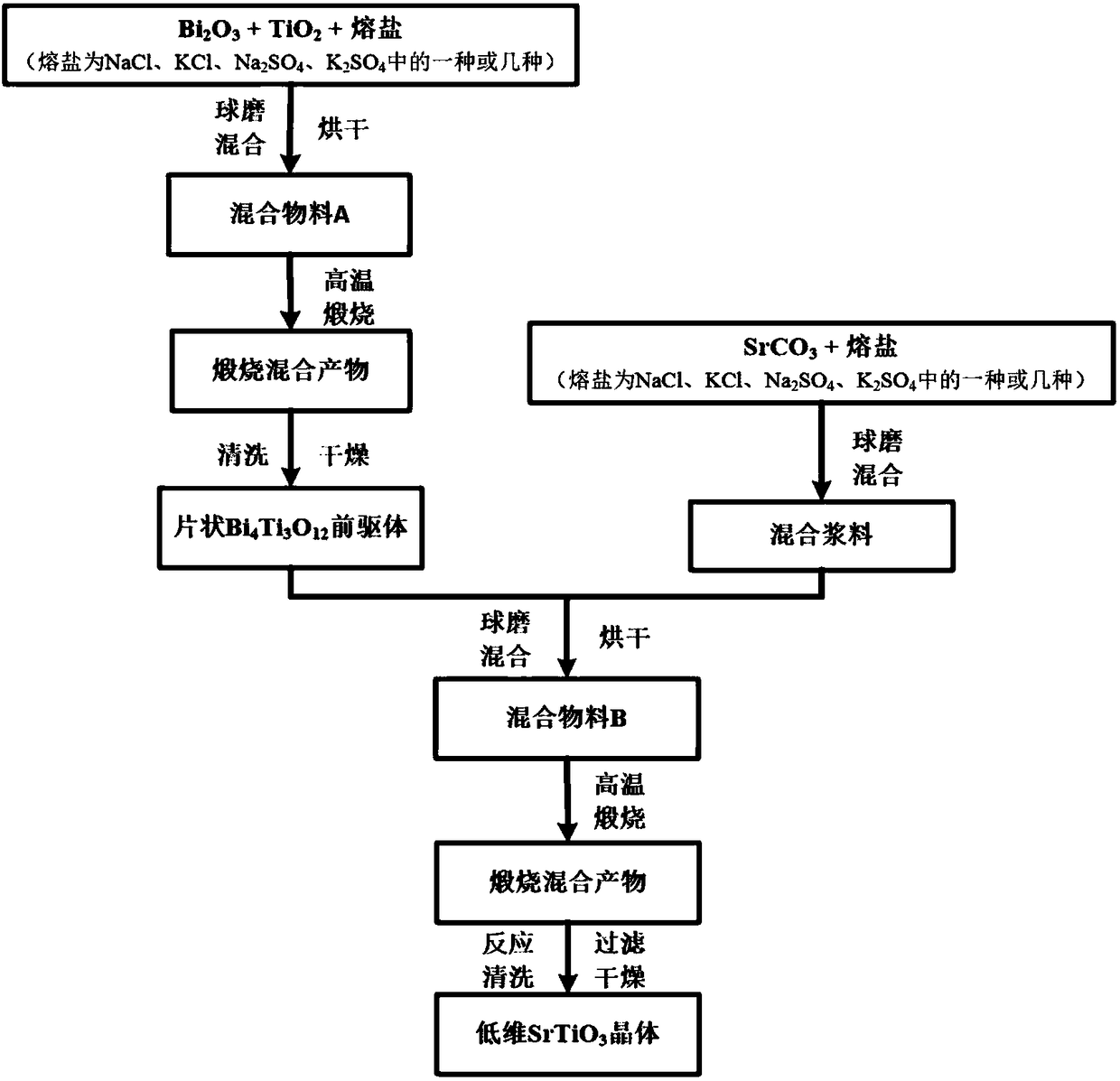

A synthesis method, the technology of strontium titanate, applied in the direction of titanate, titanium compound, alkali metal titanate, etc., can solve the problems of high content of impurity atoms, excessive particle size, narrow controllable range, etc., and achieve the goal of equipment The effect of low requirements, simple preparation process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0042] Specific Embodiment 1: This embodiment is a method for synthesizing a size-controllable low-dimensional strontium titanate crystal, which is completed in the following steps:

[0043] 1. TiO 2 Powder and Bi 2 o 3 Mix the powders, and then add molten salt to obtain mixture Ⅰ; use absolute ethanol as the ball milling medium, use zirconia balls as the balls, mill the mixture Ⅰ at a ball milling speed of 60r / min-240r / min, and bake the mixture after ball milling Dry the slurry to obtain the mixed raw material I;

[0044] TiO as described in step 1 2 Powder and Bi 2 o 3 The molar ratio of powder is 3:(1.3~3);

[0045] TiO as described in step 1 2 The particle size of the powder is ≤100nm;

[0046] The molten salt described in step 1 is Na 2 SO 4 、K2 SO 4 , one of NaCl and KCl or a mixture of several of them;

[0047] TiO as described in step 1 2 Powder and Bi 2 o 3 The mass ratio of the total mass of the powder to the molten salt is 1:(0.5~15);

[0048] 2. Put...

specific Embodiment approach 2

[0070] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ball milling time in step 1 is 4h-72h. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0071] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the heating rate of the high-temperature furnace in step 2 is 0.1° C. / min to 15° C. / min. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com