Production method of phi 762 * 48 mm large-diameter nickel-based alloy seamless tube for oil refining device

A technology of nickel-based alloys and oil refining equipment, which is applied in the field of iron and steel metallurgy, can solve the problems of inability to produce large-diameter thick-walled nickel-based seamless steel pipes, and achieve the effects of batch production, stable product performance, and optimized process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

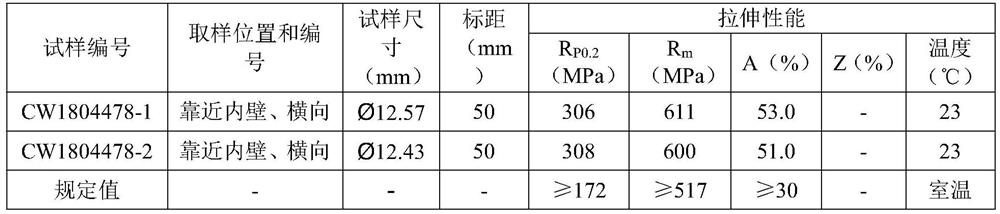

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

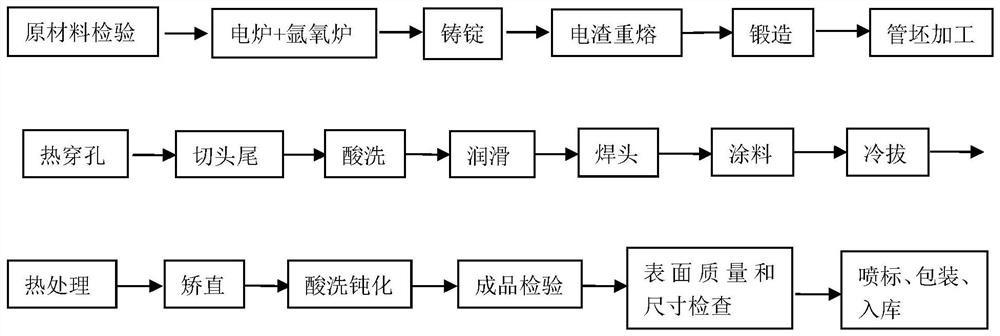

[0021] The target product of this example is a steel grade UNS NO8825, and the finished product specification is φ762×48mm large-diameter nickel-based alloy seamless pipe, which is used in the 20 million-ton oil refining unit of Hengli Petrochemical. 762mm is the diameter and 48mm is the wall thickness. The production method comprises the following steps:

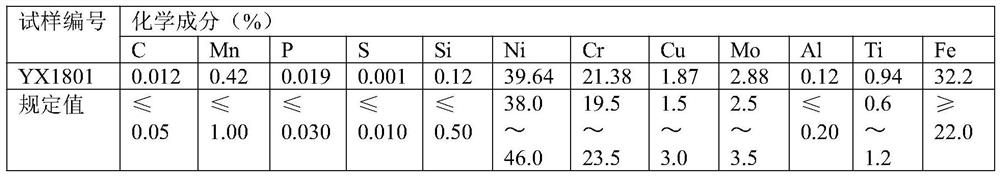

[0022] 1) Smelting: electric furnace smelting, strict control of steelmaking raw materials, using electrolytic nickel, high-carbon ferrochrome, micro-carbon ferrochrome, molybdenum, pure copper, low P raw steel, 1550 ~ 1620 ℃ out of the furnace to tundish; argon oxygen furnace Refining, all raw and auxiliary materials are baked a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com