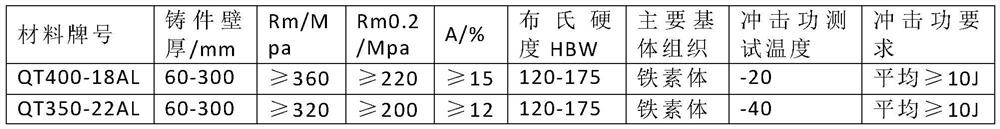

Low-temperature high-toughness nodular cast iron for large thick-wall wind power casting and preparation method of low-temperature high-toughness nodular cast iron

A technology of ductile iron and thick-walled castings, which is applied in the field of metallurgy, can solve the problems of unfavorable casting cost control, etc., and achieve the effects of reducing cross-section sensitivity, pure material, and stable metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

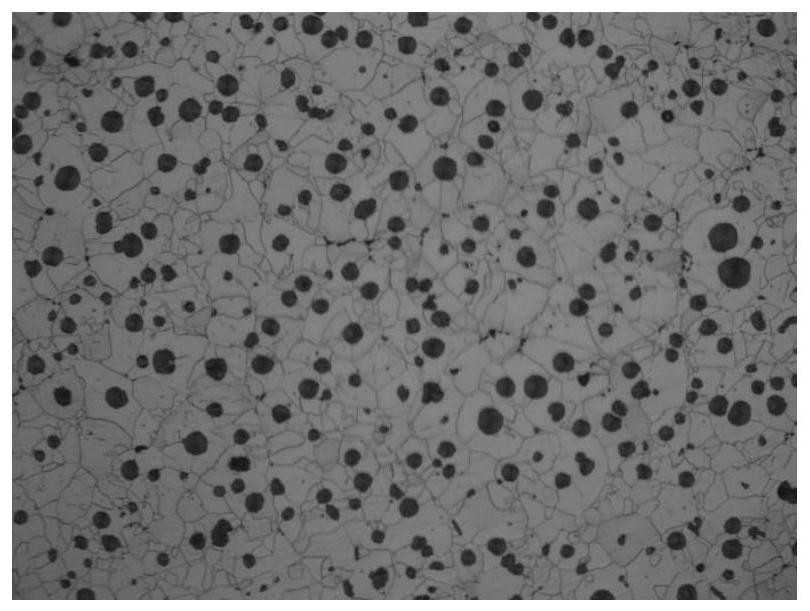

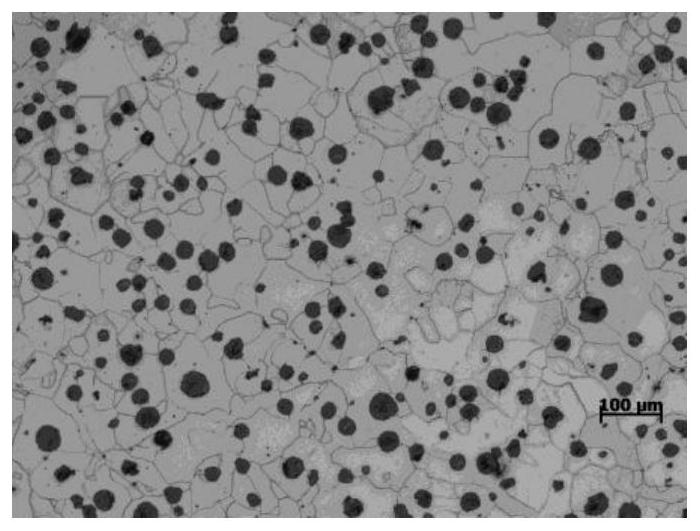

Image

Examples

Embodiment 1

[0052] The preparation process of the low-temperature high-toughness ductile iron for large thick-walled wind power castings in this embodiment is as follows:

[0053] (1) Raw materials are configured according to the following weight percentages: 80% pig iron, 20% scrap steel, 8% coke, 3% limestone, and 0.9% ferrosilicon. Add pig iron, scrap steel, coke, limestone, and ferrosilicon to the cupola at one time for smelting It is molten iron, and the tapping temperature is controlled at 1500°C.

[0054] Among them, the components of pig iron include: C4.60%, Si0.40%, Mn0.1%, P0.013%, S0.020%, As0.0003%, Pb0.0002%, Sn0.0003 %, Sb0.0004%, Zn0.0002%, Cr0.0041%, Ni0.0030%, Cu0.0030%, V0.010%, Ti0.012%, Mo0.0008%, B≤0.0007% (meet pig iron Components by weight percentage C≥4.00%, Si0.30-0.60%, Mn≤0.1%, P≤0.020%, S≤0.025%, As≤0.0008%, Pb≤0.0005%, Sn≤0.0005%, Sb≤ 0.0006%, Zn≤0.0003%, Cr≤0.0050%, Ni≤0.0060%, Cu≤0.0050%, V≤0.010%, Ti≤0.015%, Mo≤0.0010%, B≤0.0010%),

[0055] Scrap steel ...

Embodiment 2

[0075] In this embodiment, the preparation process of low-temperature high-toughness ductile iron for large thick-walled wind power castings is as follows:

[0076] (1) Raw materials are configured according to the following weight percentages: 85% pig iron, 15% scrap steel, 9% coke, 2.5% limestone, and 1.2% ferrosilicon. Add pig iron, scrap steel, coke, limestone, and ferrosilicon to the cupola at one time for smelting It is molten iron, and the tapping temperature is controlled at 1500°C.

[0077] Among them, the components of pig iron include: C4.60%, Si0.40%, Mn0.1%, P0.013%, S0.020%, As0.0003%, Pb0.0002%, Sn0.0003 %, Sb0.0004%, Zn0.0002%, Cr0.0041%, Ni0.0030%, Cu0.0030%, V0.010%, Ti0.012%, Mo0.0008%, B≤0.0007% (meet pig iron Components by weight percentage C≥4.00%, Si0.30-0.60%, Mn≤0.1%, P≤0.020%, S≤0.025%, As≤0.0008%, Pb≤0.0005%, Sn≤0.0005%, Sb≤ 0.0006%, Zn≤0.0003%, Cr≤0.0050%, Ni≤0.0060%, Cu≤0.0050%, V≤0.010%, Ti≤0.015%, Mo≤0.0010%, B≤0.0010%),

[0078] Scrap steel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com