Carboxyl nanocellulose and preparation method and application thereof

A technology of nanocellulose and microcrystalline cellulose, which is applied in the field of preparation of carboxy nanocellulose, can solve the problems of enhancing infectivity of bacteria, secondary infection of sick patients, long use time, etc., and achieves improved mechanical properties, low cost, The effect of good dispersion and interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Example 1 A preparation method of carboxyl nanocellulose / carboxyl nitrile rubber composite material B1

[0034]This embodiment provides a preparation method of carboxyl nanocellulose / carboxyl nitrile rubber composite material B1:

[0035]1) Weigh 2 kg of microcrystalline cellulose dissolved in 4 kg of deionized water, continue to add 1.4 kg of 30% by mass hydrogen peroxide solution and 1.5 g of anhydrous copper sulfate, set the reaction temperature in the circulating shaker to After 72 hours of constant temperature reaction at 35°C, the reaction solution was placed in a centrifuge for three centrifugation treatments, and the upper layer solution was the suspension A1 of carboxyl nanocellulose;

[0036]2) Weigh 1kg of carboxyl nanocellulose suspension A1, add it to 50kg of carboxyl nitrile rubber emulsion with a solid content of 40% and a carboxyl group content of 20%, and mechanically stir (1000r / min) for 50 minutes, then place it on the plate. Bake in a blast oven at a temperature of ...

Embodiment 2~6

[0038]Example 2~6 Preparation method of carboxyl nanocellulose / carboxyl nitrile rubber composite material B2~B6

[0039]Examples 2 to 6 respectively provide a preparation method of carboxyl nanocellulose / carboxyl nitrile rubber composite materials B2 to B6. The preparation method is basically the same as that of Example 1. The difference lies only in some relevant process parameters. For specific process parameters, see Table 1.

[0040]Table 1: List of preparation process parameters of carboxyl nanocellulose / carboxyl nitrile rubber composite materials B2~B6

[0041]

[0042]

[0043]Other process parameters and operations are the same as in Example 1.

Embodiment 7

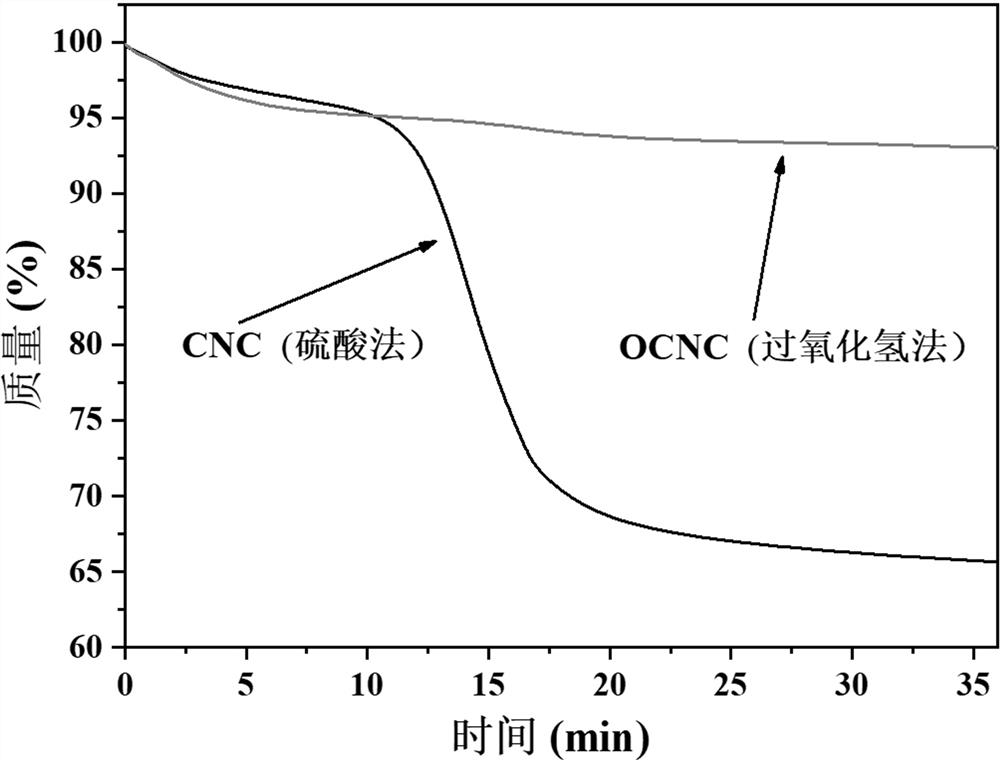

[0044]Example 7 Comparison of thermal properties between carboxyl nanocellulose and traditional commercial nanocellulose

[0045]1) Weigh 2 kg of microcrystalline cellulose dissolved in 4 kg of deionized water, continue to add 2 kg of 14% sodium hypochlorite solution to react for 72 hours, then add HCl to stop the reaction, then use ultrasonic treatment to disperse the sample, centrifuge Obtain the milky white colloid once, place the colloid in a dialysis bag for desalination for several days, and then freeze-dry for 24 hours to obtain the traditional commercial nanocellulose;

[0046]2) Select the carboxyl nanocellulose prepared in Example 1 and the traditional commercial nanocellulose for thermal performance test, the test results are as followsfigure 1 Shown. Fromfigure 1 It can be seen that, at the same temperature, commercial cellulose degrades faster, while oxidized nanocellulose can still maintain a small change in mass fraction, thus exhibiting stronger thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com