Preparation method, adsorbent and application of three-dimensional chitosan-metal ring complex

A technology for chitosan and complexes, which is applied in the field of preparation of three-dimensional chitosan-metal cyclic complexes, can solve the problems of difficulty in molding and large intermolecular forces, and achieves simple operation, widened application fields and pure materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

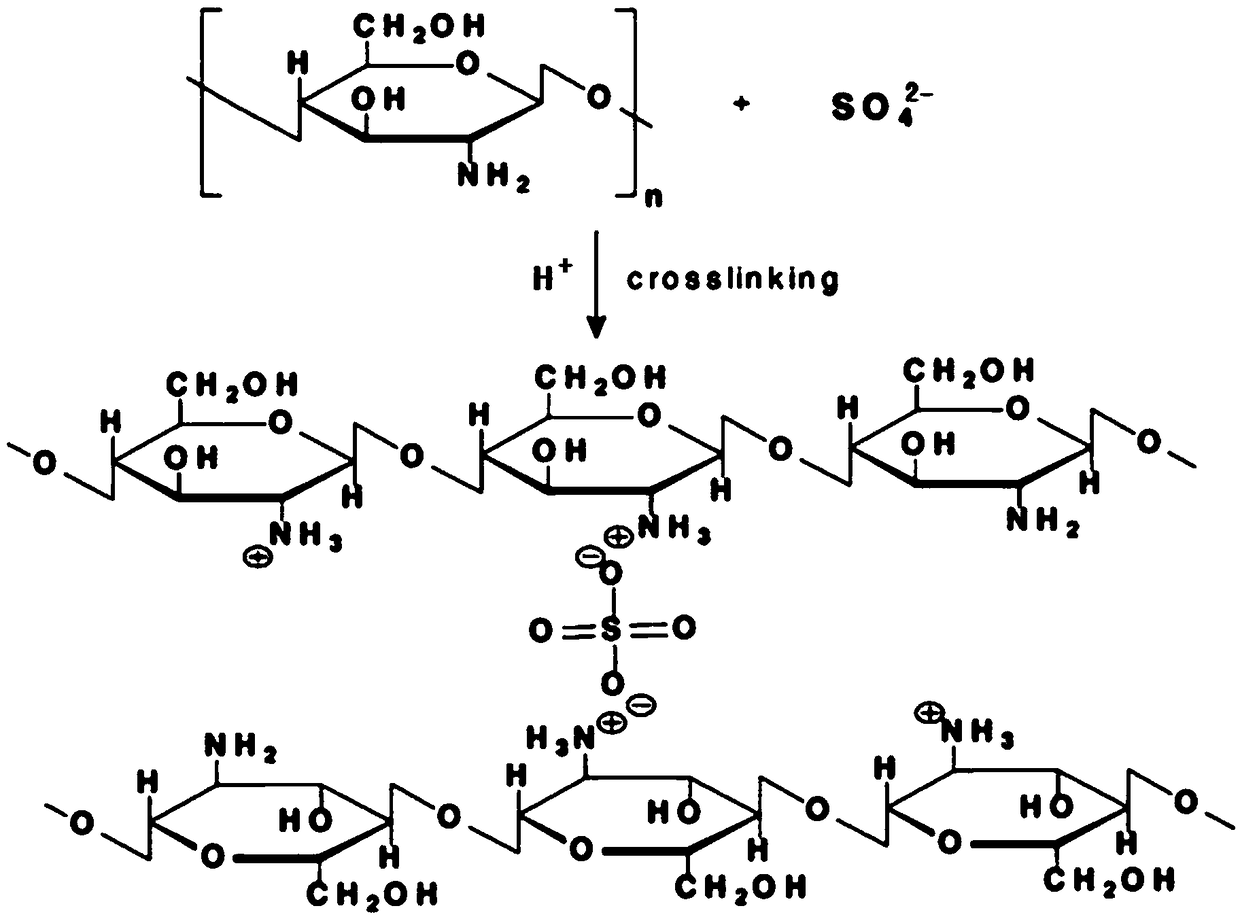

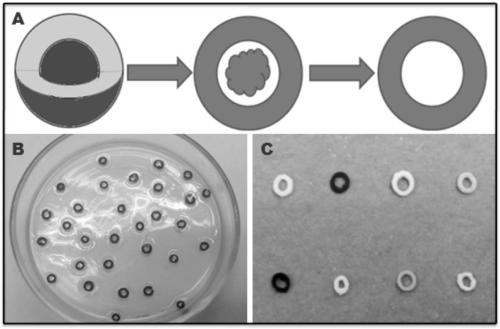

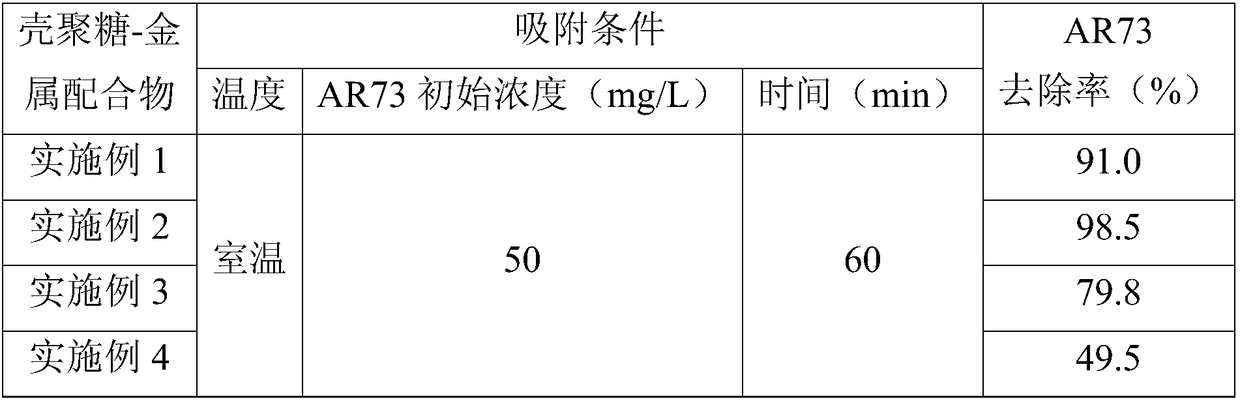

[0036] Prepare 25 mL of glacial acetic acid solution with a volume fraction of 2%, slowly add 0.75 g of chitosan (molecular weight is 1 million, deacetylation degree is 91%), and continue stirring for 2 hours to fully dissolve chitosan, then slowly add 0.7102 g Na 2 SO 4And continue to stir, cross-linking reaction 4h. After fully reacting, use a 100mm inner diameter needle and a 1mL volume syringe to remove the chitosan sol dropwise and drop it into a petri dish containing 25% ammonia solution. and anhydrous ethanol were washed 3 times respectively, and dried in an oven at 50° C. for 2 hours to obtain a chitosan-metal ring complex with a compact structure.

Embodiment 2

[0038] Prepare 25 mL of glacial acetic acid solution with a volume fraction of 2%, slowly add 0.75 g of chitosan (molecular weight is 1 million, deacetylation degree is 91%), and continue stirring for 2 hours to fully dissolve chitosan, then slowly add 0.6665 g Fe 2 (SO 4 ) 3 And continue to stir, cross-linking reaction 4h. After fully reacting, use a 100mm inner diameter needle and a 1mL syringe to remove the chitosan sol drop by drop into a petri dish containing 28% ammonia solution. After the initial formation of the ring complex, pour off the ammonia solution and use water and anhydrous ethanol were washed 3 times respectively, and dried in an oven at 50° C. for 2 hours to obtain a chitosan-metal ring complex with a compact structure.

Embodiment 3

[0040] Prepare 25 mL of glacial acetic acid solution with a volume fraction of 2%, slowly add 0.75 g of chitosan (molecular weight is 1 million, deacetylation degree is 91%), and continue stirring for 2 hours to fully dissolve chitosan, then slowly add 1.3142 g NiSO 4 ·6H 2 O and continue to stir, cross-linking reaction 4h. After fully reacting, use a needle with an inner diameter of 100mm and a syringe with a capacity of 1mL to remove the chitosan sol drop by drop into a petri dish containing 27% ammonia solution. and anhydrous ethanol were washed 3 times respectively, and dried in an oven at 50° C. for 2 hours to obtain a chitosan-metal ring complex with a compact structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com