Method for preparing grain size-controllable solid phase synthetic molecular sieve

A technology of solid-phase synthesis and grain size, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of adverse effects of molecular sieves in practical application and difficult control of grain size, etc. Achieve good economic and social benefits, reduce waste water discharge, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

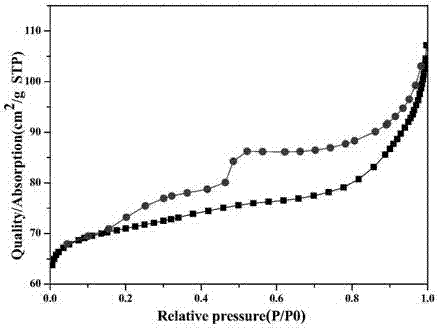

[0045] Take by weighing 13.15g sodium silicate nonahydrate, 3.47g fumed silica gel, 0.25g sodium metaaluminate, 2.40g tetrapropylammonium bromide (TPABr), 4.2g ammonium chloride (SiO 2 :Al 2 o 3 : organic templating agent: NH 4 + The added molar ratio is 1:0.015:0.09:0.79) mixed as reaction raw materials, added to a mechanical pulverizer for pulverization, so that the solid reactants are uniformly mixed. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven for crystallization at 180°C for 48h. The obtained product was calcined at 550° C. for 6 h to obtain the final product.

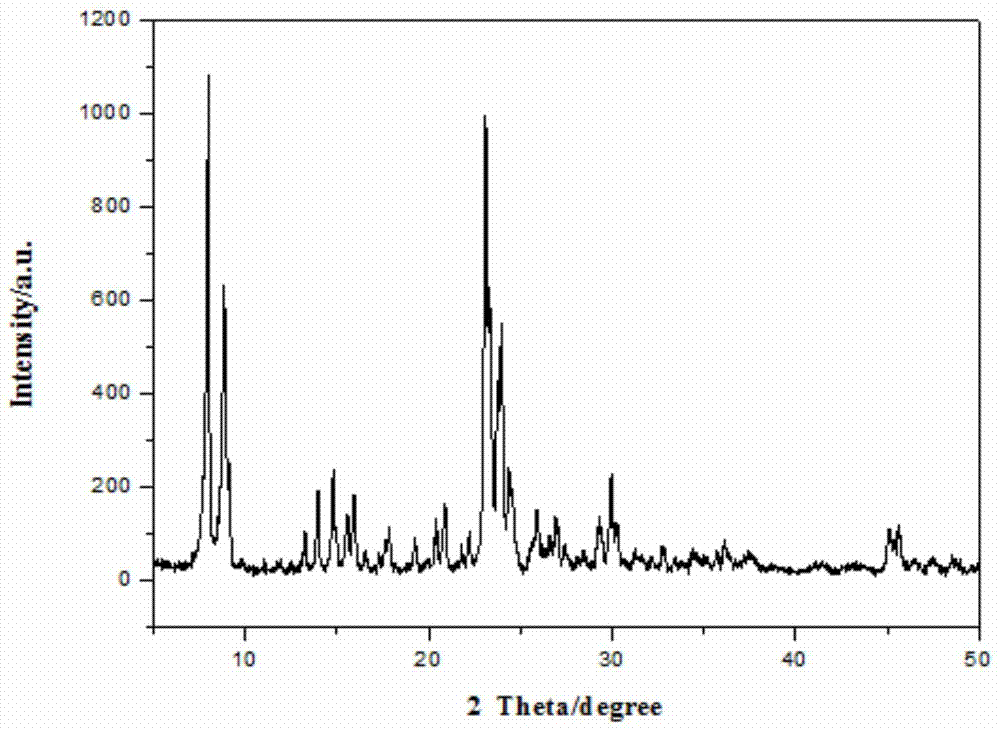

[0046] attached figure 1 According to the XRD characterization results of the above product, it can be seen that the product has a typical MFI structure and has a good crystallinity.

[0047] attached figure 2 It is the SEM scanning electron microscope photo of the above product, it can be seen that the particle of the prod...

Embodiment 2

[0050] Weigh 13.15g sodium silicate nonahydrate, 3.47g fumed silica gel, 0.25g sodium metaaluminate, 2.40g tetrapropylammonium bromide (TPABr), 4.2g ammonium chloride, 0.25gZSM-5 molecular sieve seed crystal mix as reaction Raw materials are added to a mechanical pulverizer for pulverization, so that the solid reactants are evenly mixed. Among them, SiO 2 :Al 2 o 3 : organic templating agent: NH 4 + The added molar ratio is 1:0.015:0.09:0.79; the mass percentage of ZSM-5 molecular sieve seed crystals in the reaction raw materials is 1%. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven for crystallization at 180°C for 48h. The obtained product was calcined at 550° C. for 6 h to obtain the final product.

[0051] attached Figure 5 According to the XRD characterization results of the above product, it can be seen that the product has a typical MFI structure and has a good crystallinity.

[005...

Embodiment 3

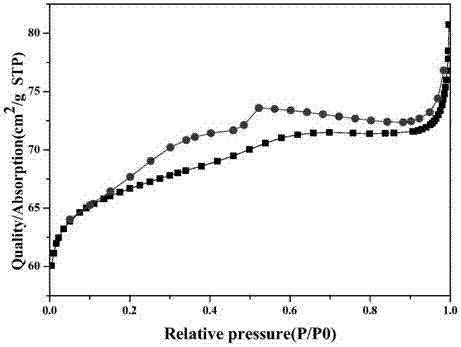

[0056] Weigh 13.15g sodium silicate nonahydrate, 3.47g fumed silica gel, 0.25g sodium metaaluminate, 2.40g tetrapropylammonium bromide (TPABr), 4.2g ammonium chloride, 0.50g ZSM-5 molecular sieve seed crystals and mix as reaction Raw materials are added to a mechanical pulverizer for pulverization, so that the solid reactants are evenly mixed. Among them, SiO 2 :Al 2 o 3 : organic templating agent: NH 4 + The added molar ratio is 1:0.015:0.09:0.79; the mass percentage of ZSM-5 molecular sieve seed crystals in the reaction raw materials is 2%. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven for crystallization at 180°C for 48h. The obtained product was calcined at 550° C. for 6 h to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com