Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Reduce waste water discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic surface local electroplating method

InactiveCN102978672AReduce waste water dischargeSolve the singularity problemPre treatmentAfter treatment

The invention discloses a plastic surface local electroplating method which is used for locally electroplating accessories in the industries such as bathroom, electronics, automobiles, household appliances. The method comprises the following steps: putting a plastic base material to physical vapour deposition vacuum equipment to be vacuumized, carrying out plasma cleaning and activation on the plastic base material when vacuum degree reaches 10-2Pa, depositing a metal conducting layer in vacuum on the surface of the plastic base material which is activated, performing precise laser etching to remove local conducting layer from the plastic base material which is electroplated with the metal conducting layer, obtaining a required pattern, and performing electroplating or electroplating after-treatment to the plastic base material which is etched by laser. By the method, a high pollution plastic electroplating pre-treatment process is replaced by the physical vapour deposition for depositing the metal conducting layer, so that the wastewater discharge and environment pollution are largely reduced; and in addition, partial electroplated conducting film layer is removed through the laser etching, the plastic in the area is not conductive, and the purpose of selective metallization is reached.

Owner:XIAMEN RUNNER IND CORP

Technological method for rare earth fractional extraction and separation through adopting double feed inlets

InactiveCN103421965ALess consumption of chemical reagentsReduce waste water dischargeProcess efficiency improvementRare-earth elementYttrium

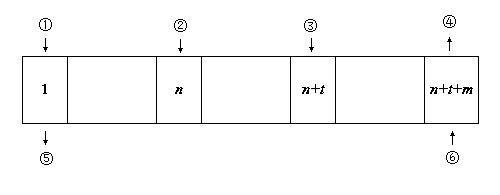

The invention discloses a technological method for rare earth fractional extraction and separation through adopting double feed inlets, which can be used for processing a misch metal liquid formed by two kinds of liquids with the same or similar rare earth elements and a certain difference in contents of rare earth elements, and particularly is realized through two technological schemes, namely, the bastnaesite and ionic adsorption type yttrium riched europium rare earth ore Nd / Sm grouped separation as well as high-yttrium misch metal and ionic adsorption type low-yttrium misch metal Y / non-Y separation. According to the method, a reagent with phosphorous or carboxylic acids is an extraction agent, kerosene or sulfonated kerosene is an organic solvent, and hydrochloric acid is a detergent; a double feed-inlet fractional extraction system includes an extraction section, a middle section and a washing section, and an organic phase enters the fractional extraction system from the first stage; the first kind of rare earth liquid enters the fractional extraction system from the joint of the extraction section and the middle section; the second kind of rear earth liquid enters the fractional extraction system from the joint of the middle section and the washing section; cleaning solution enters the fractional extraction system from the last stage. The technological method provided by the invention has the advantages of low consumption of chemical reagent, high product purity, low waste water quantity, low cost and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

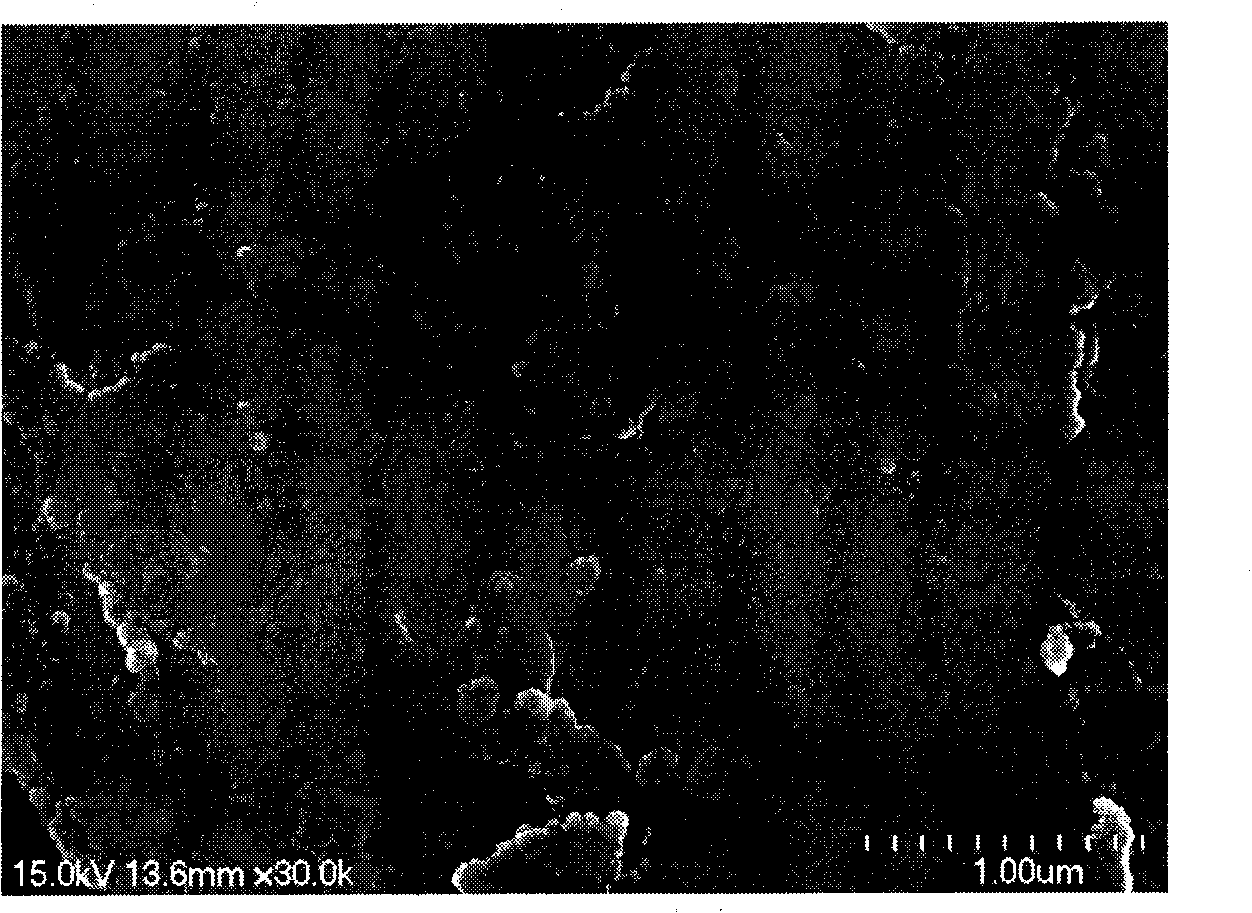

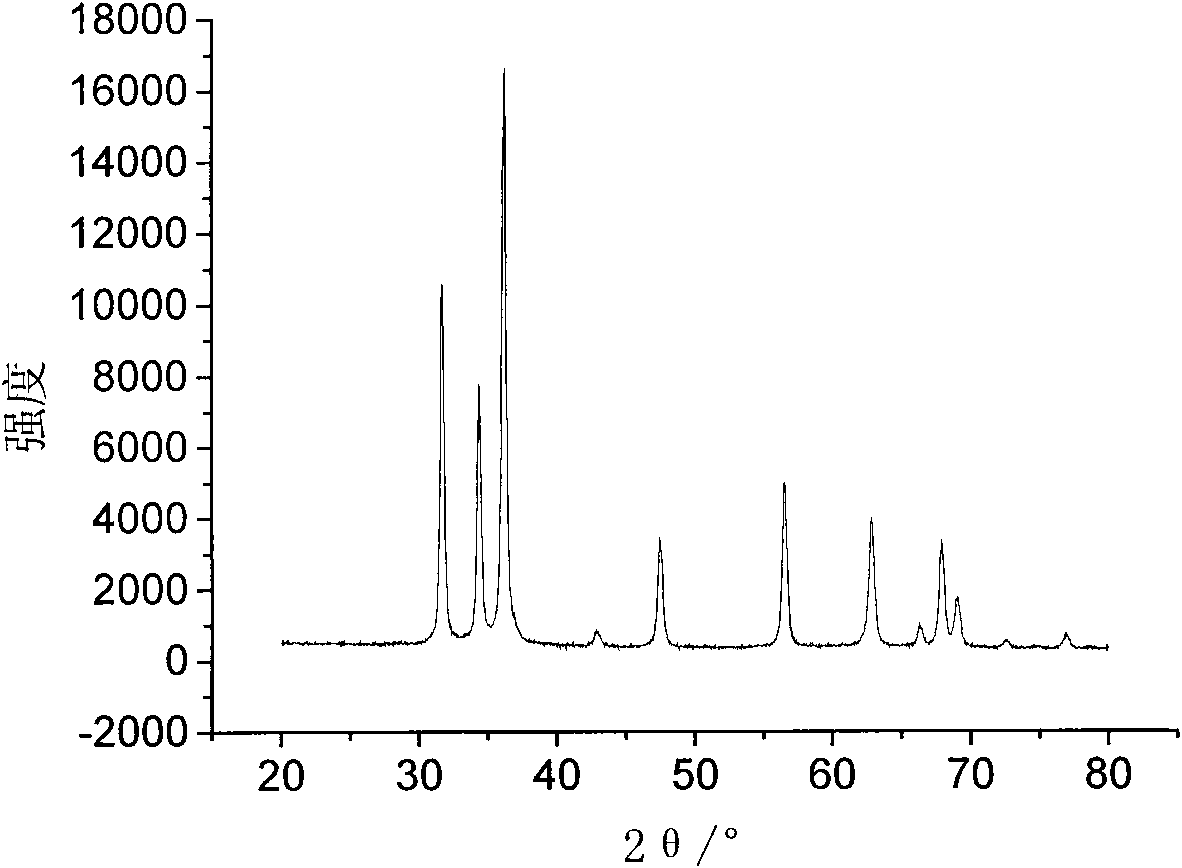

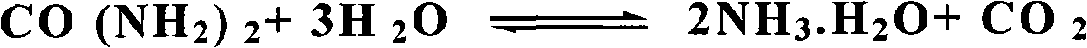

Method for preparing functional textile of nano materials

The invention discloses a method for preparing a functional textile of nano materials. The method takes soluble inorganic metal salt as substrate and leads the configurational ions to be in-situ deposited in the micropore of the textile by selecting a precipitator and a complexing agent and controlling the process condition, thus synthesizing the nano materials directly on the textile and finally endowing the textile with various nano functions such as ultraviolet radiation resistance, anti-bacteria, odor elimination, anti-static property, electromagnetic wave resistance, infrared heat conservation, flame retarding and coloring. The method effectively overcomes the agglomeration problem during the preparation and application of the nano materials and solves the problem that the nano materials and the textile have bad adhesion simultaneously. The technology has great function ion selection range, can synthesize the nano materials of different sorts and different appearance, and has the advantages of short process flow, low equipment requirement, light sewage burden, and endows the textile with various functions; furthermore, part processing technology also has the coloring function, extremely obvious economic benefits and industrial generalization values.

Owner:JIANGSU NADN SCI TECH CO LTD

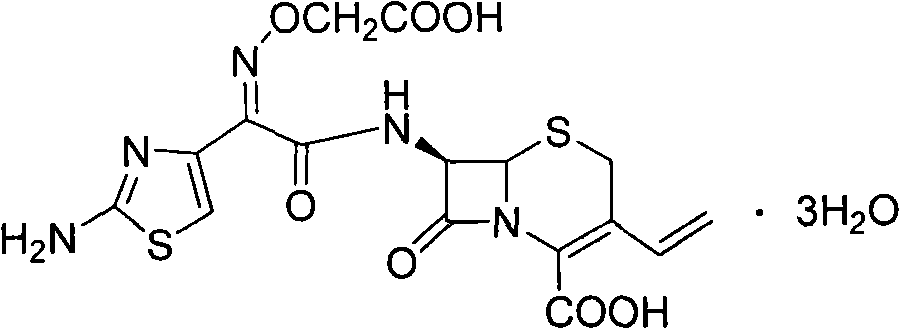

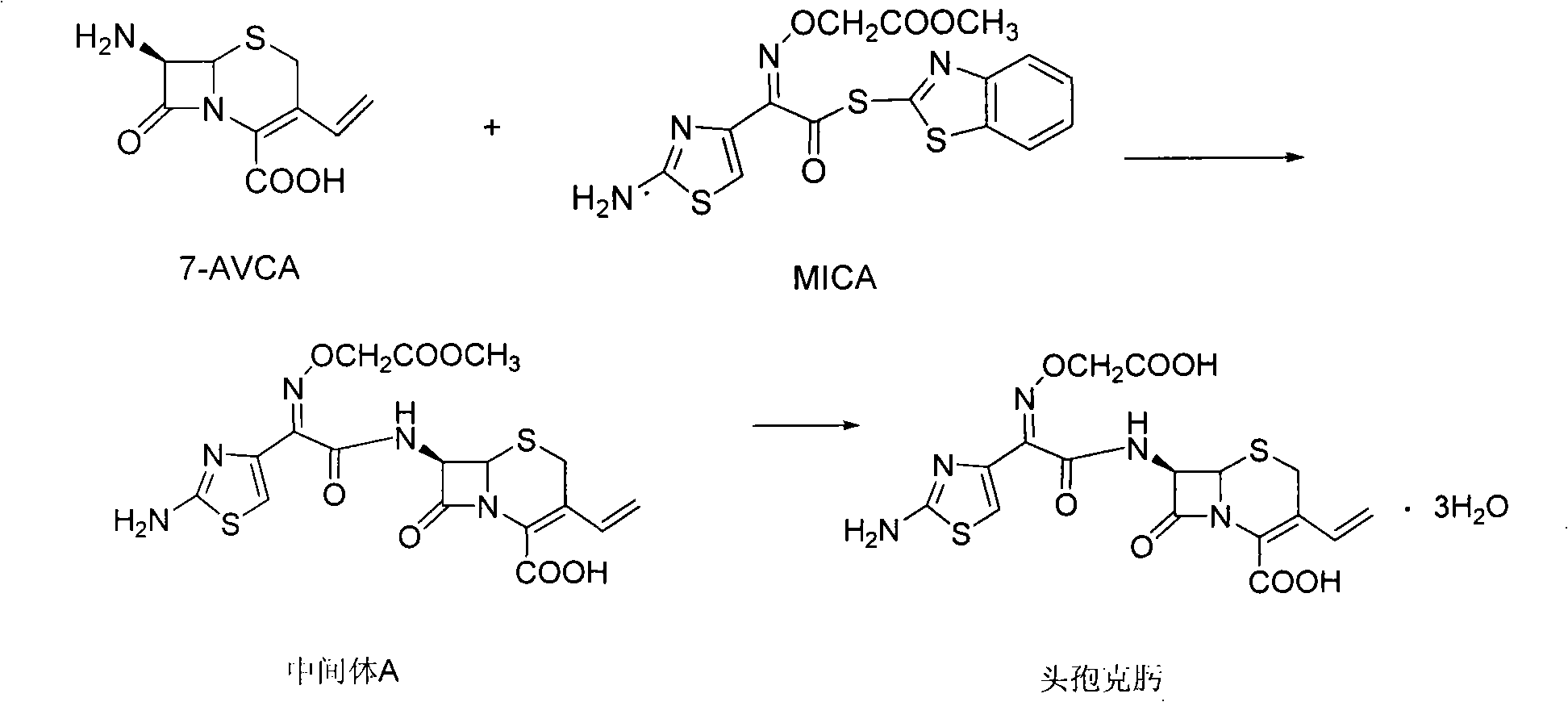

Synthetic method of antibiotic cefixime

InactiveCN101337969ASolve the recycling problemReduce waste water dischargeAntibacterial agentsOrganic chemistryTetrahydrofuranAcetone

The invention relates to a synthesis method of cefixime that is bacteriophage. 7-azyl-3-vinyl cephalosporanic acid (7-AVCA) is used as starting material to react with MICA active ester first, and an intermediate MECEF of cefixime is obtained through separation; the intermediate MECEF is directly hydrolyzed to generate a cefixime product without separation; the condensation and the hydrolyzation in a synthesis route of the cefixime product is combined into one. The synthesis method has the advantages that the technologcial conditions are simple, the operation is convenient, the product yield is high, the product quality is stable, and the method is suitable for the large-scale industrialized production; two-step reactions are combined into one, an intermediate A is not needed to be separated, the operation is simplified, and the production period is shortened; the yield can reach 200 to 212 percent; the purity quotient is more than 99 percent; the curative effect of the product is increased. Expensive tetrahydrofuran which is used in the reaction is replaced by low-cost acetone, the problem that tetrahydrofuran is mixed with the other reaction solvent and cannot be recycled and reused is solved, the wastewater discharge is reduced, the manufacture cost is lowered, and the competitive ability of the product is increased.

Owner:国药集团致君(苏州)制药有限公司

Copper drawing and electroplating method for plastic substrate

ActiveCN102517618AReduce waste water dischargeEmission reductionVacuum evaporation coatingSputtering coatingPlasma treatmentCopper

The invention relates to a copper drawing and electroplating method for a plastic substrate, and relates to a plastic surface wire drawing treatment method. According to the method, a plastic substrate is pretreated; the pretreated plastic substrate is subjected to physical vapor deposition metallization, and is sequentially subjected to physical vapor deposition plasma modification, metal bottom layer plating, metal transition layer plating and metal conductive layer plating; direct copper electroplating is performed; a drawing treatment is performed on the surface of the copper electroplating layer; a dry cleaning treatment is performed on the surface of the plastic substrate; nickel electroplating is performed; the resulting material is hung in a PVD furnace to carry out a plasma treatment, and then is subjected to a PVD film plating treatment, or an organic coating spray plating treatment is performed, or a chromium electroplating treatment is performed, or chromium electroplating is performed and finally a PVD film plating treatment is performed. With the present invention, the surface metallization of the plastic material can be achieved; the copper electroplating layer drawing is adopted to replace the nickel electroplating layer drawing so as to reduce the production cost, simplify the electroplating process, substantially reduce the discharge amount of the wastewater, and reduce the pollution to the environment and the human; and the method meets surface drawing function requirements of a plurality of the plastic substrates.

Owner:XIAMEN RUNNER IND CORP

Method for preparing cyclohexenyl cyclohexanone with high conversion rate

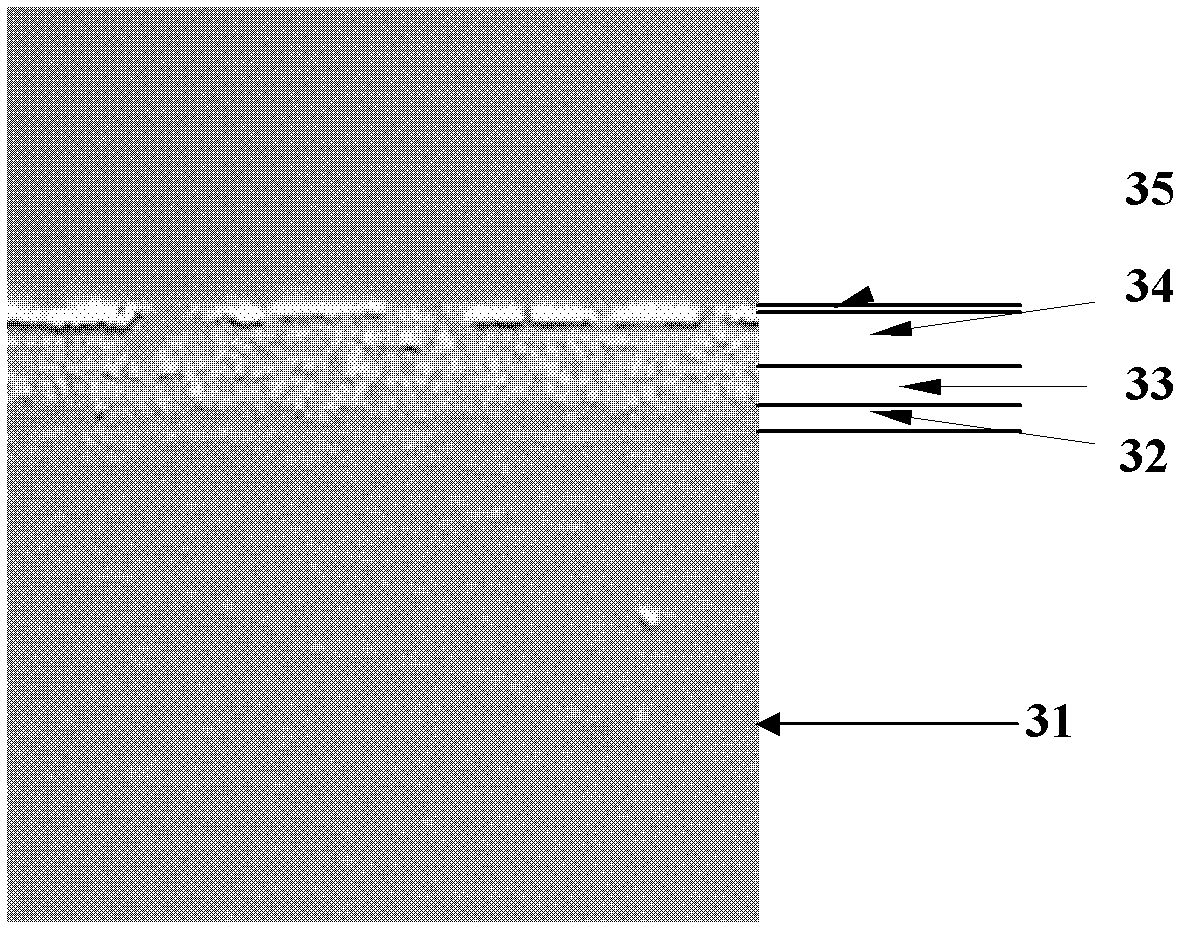

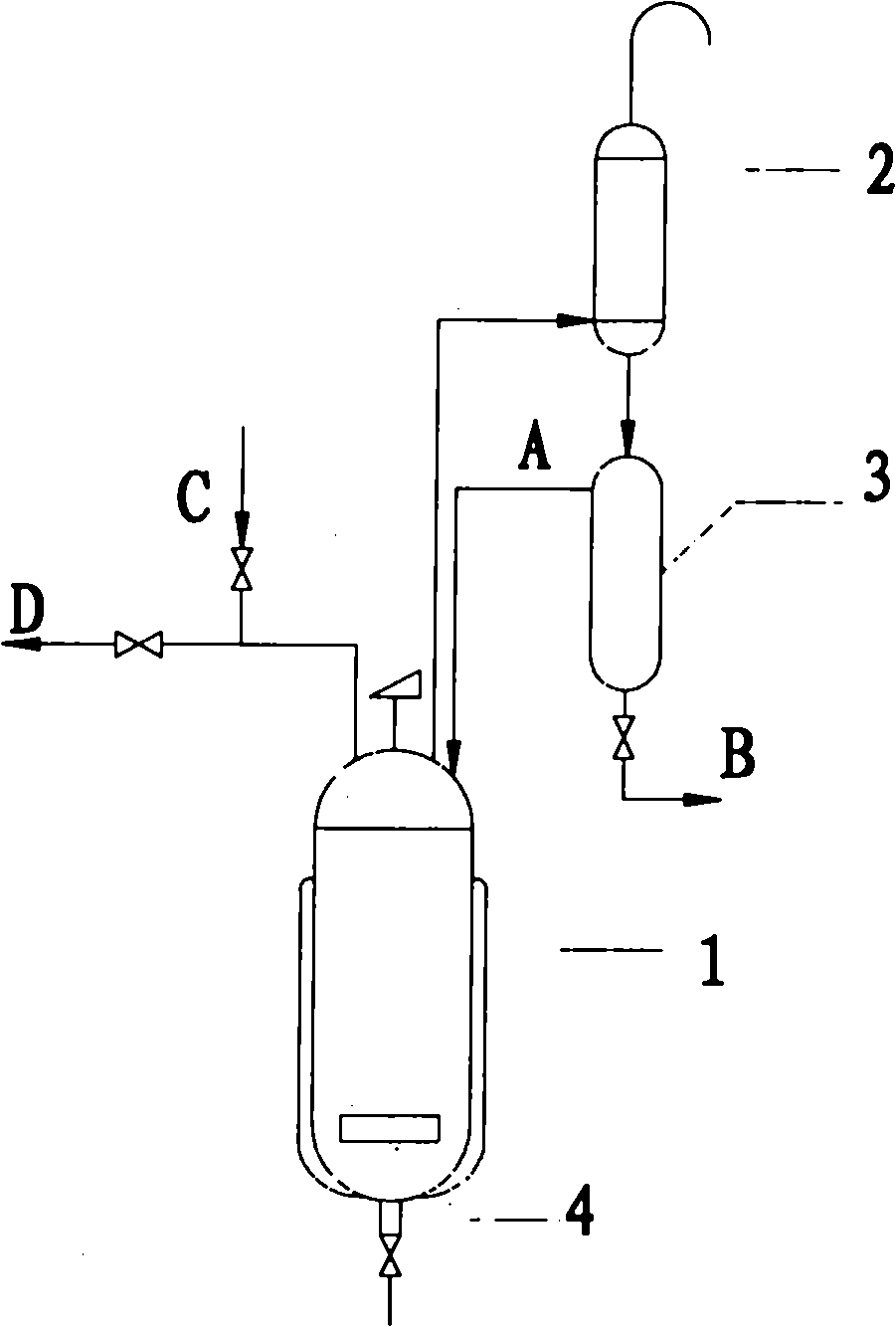

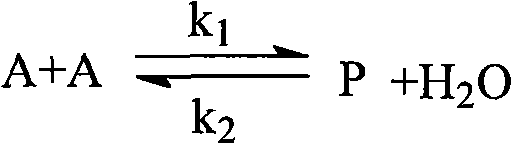

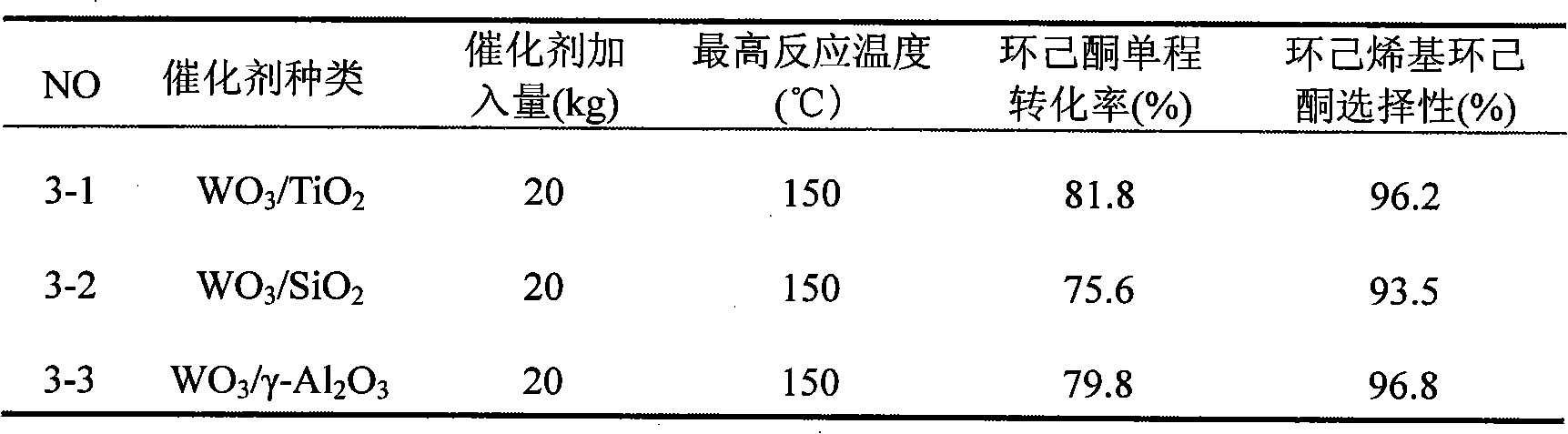

InactiveCN102311326AImprove conversion rateReduce waste water dischargeOrganic compound preparationCarbonyl compound preparationCyclohexanoneOxide

The invention relates to a method for preparing cyclohexenyl cyclohexanone which is the intermediate of o-phenyl phenol, particularly to a method for preparing the cyclohexenyl cyclohexanone with high conversion rate and high selectivity by taking cyclohexanone as raw material and taking solid oxide as catalyst.

Owner:SHANDONG XINGANG CHEM

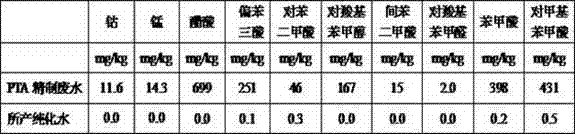

Method for resource comprehensive utilization of PTA refining waste water

ActiveCN103693772AReduce consumptionReduce waste water dischargeWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentChemistrySaline water

The invention discloses technology for resource comprehensive utilization of PTA refining waste water. PTA refining waste water is subjected to cation exchange and 3-stage selective adsorption in order to obtain purified water; when the cation exchanger and the 3-stage selective adsorber are saturated, desorption is carried out; cobalt and manganese are recovered from desorption liquid of the cation exchanger, and p-toluic acid, terephthalic acid and benzoic acid are recovered from desorption liquid of the first-stage selective adsorber. The purified water obtained by the technology has a yield of 75-85%, has quality approaching desalted water, and can be returned to refining units to substitute desalted water for use; the cobalt recovery rate is 90%, the manganese recovery rate is 75%, the p-toluic acid recovery rate is 85%, the terephthalic acid recovery rate is 90%, the benzoic acid recovery rate is 70%, and all of the above are returned to oxidation units for use. Therefore, the technology of the invention not only reduces the discharge of refining waste water by about 80%, but also greatly reduces the using amount of desalted water, recovers precious metals and useful organic matter, reduces the discharge of COD flow by more than 65%, and realizes waste water resource recycle, and harvest of both economic benefits and environmental protection benefits.

Owner:浙江化安安全技术研究院有限公司

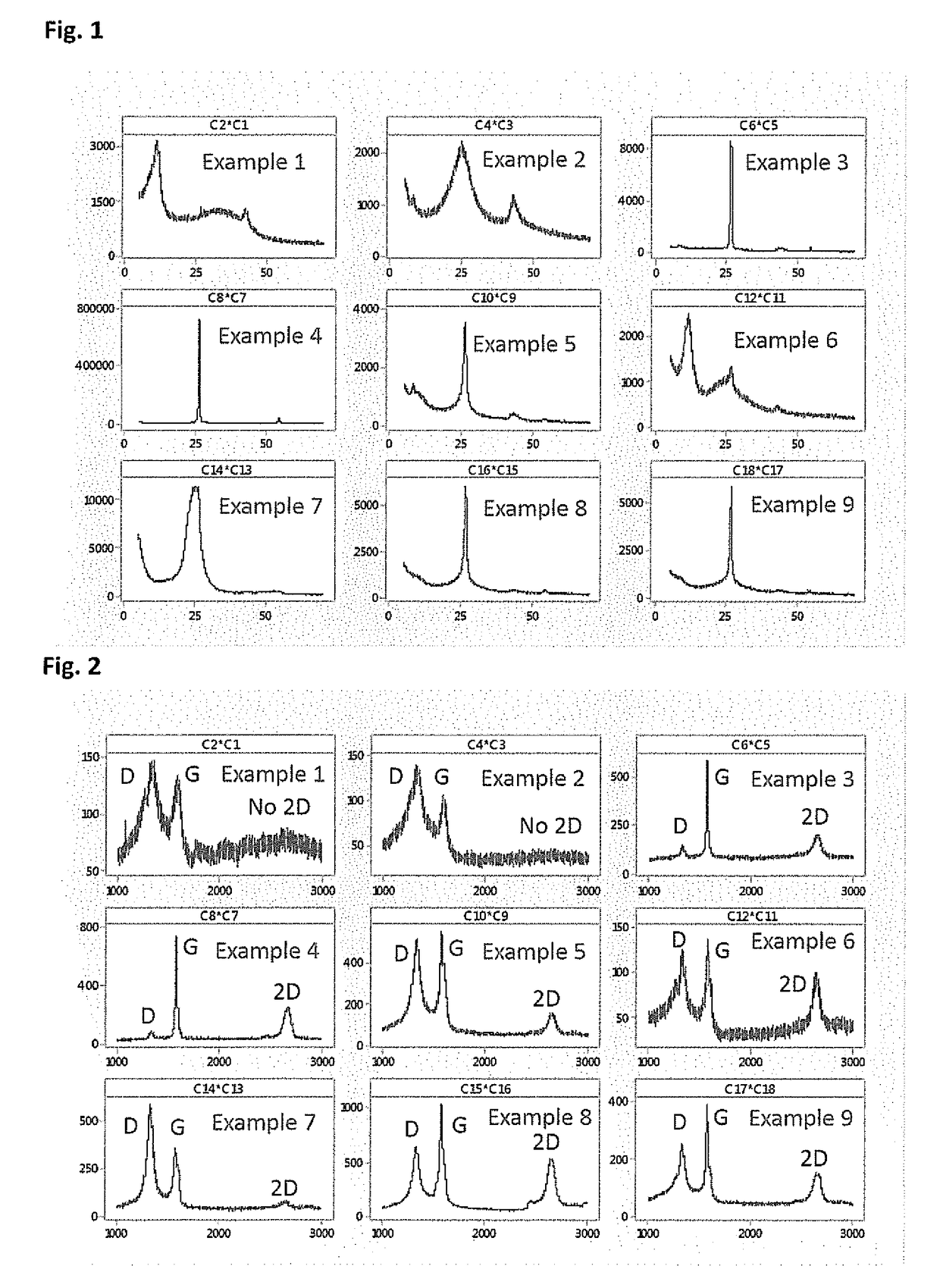

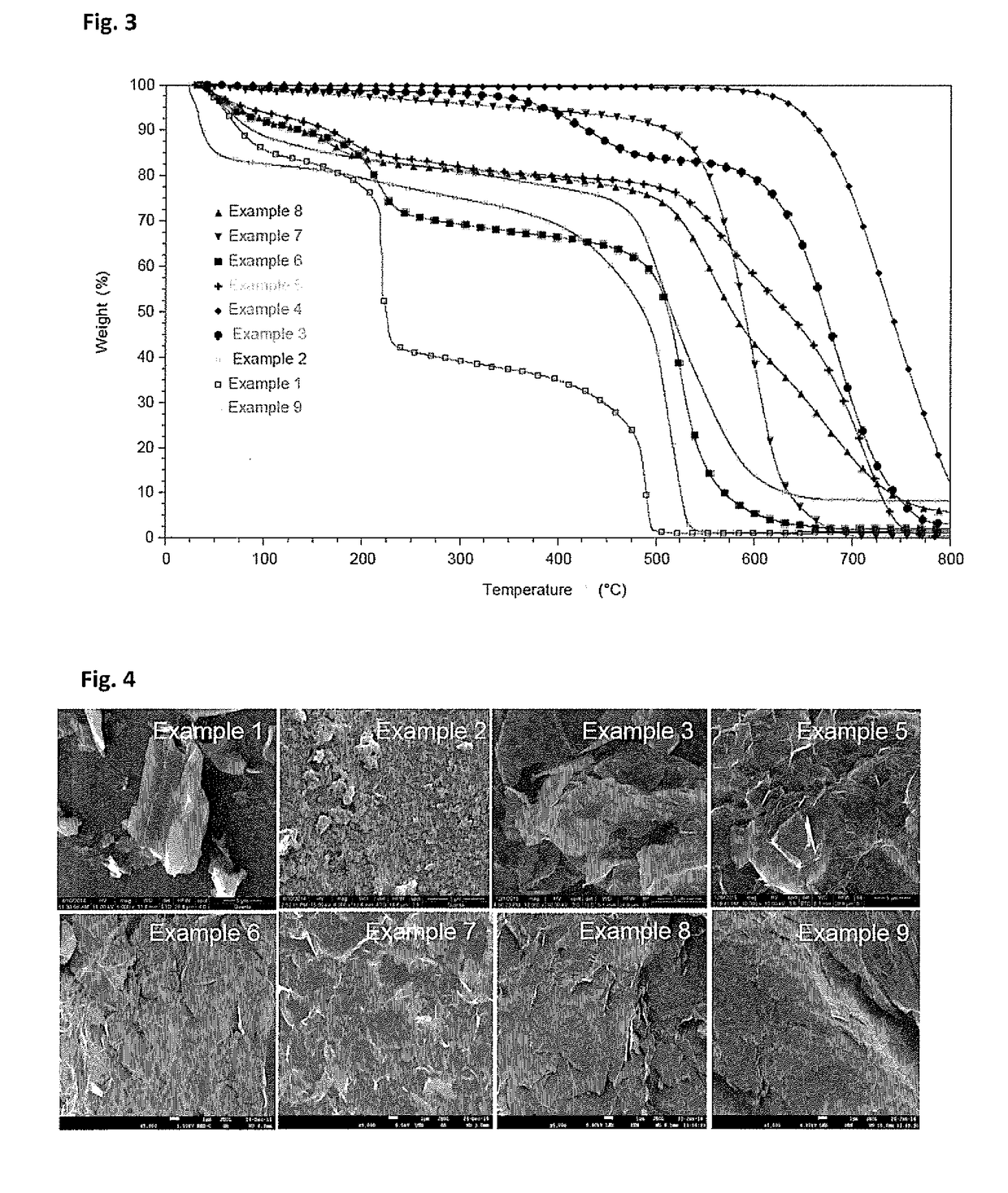

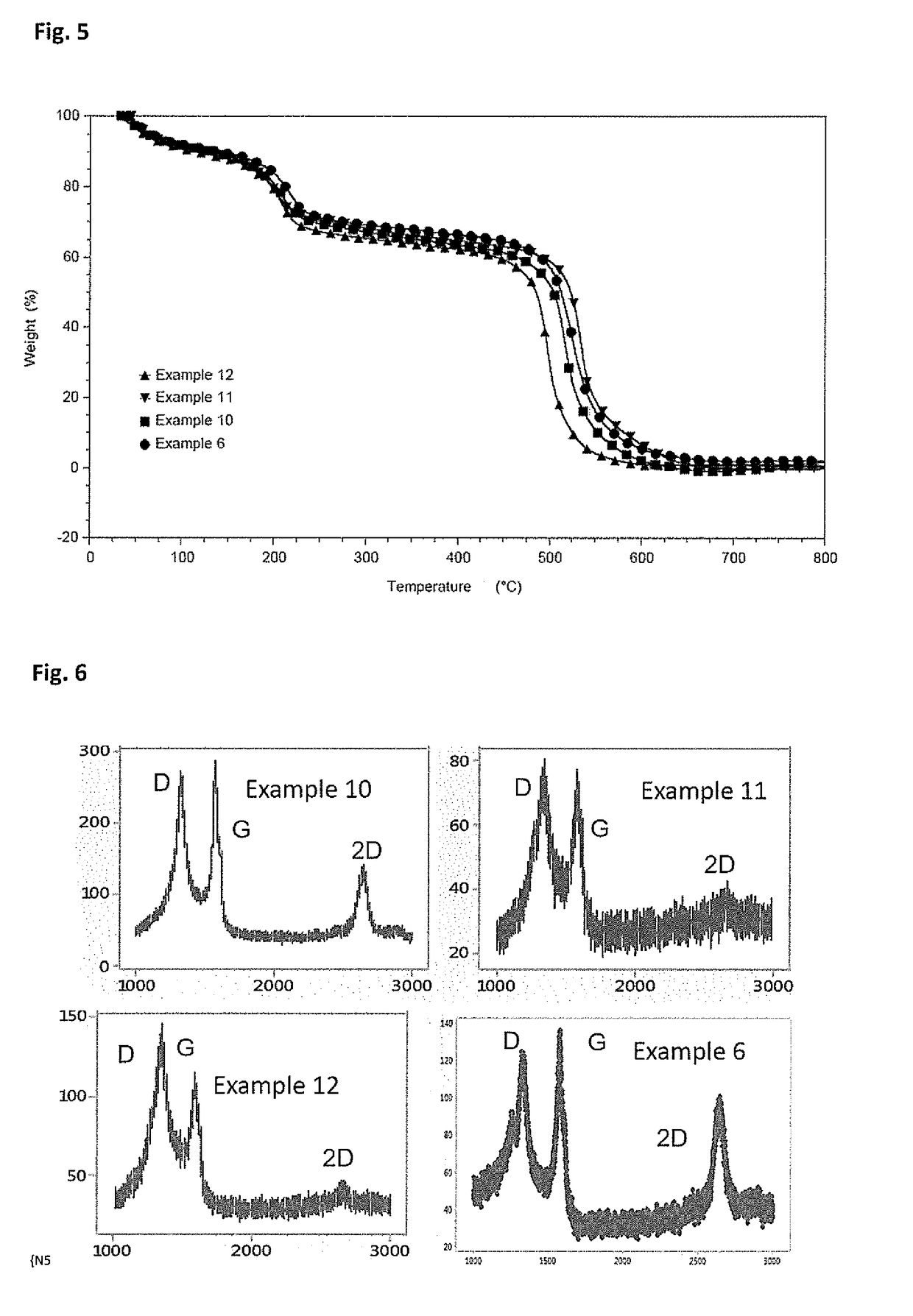

Production of Graphene

PendingUS20180072573A1High volume manufacturing capabilityLow costCellsGrapheneHigh volume manufacturingMetallurgy

A method of synthesizing high quality graphene for producing graphene particles and flakes is presented. The engineered qualities of the graphene include size, aspect ratio, edge definition, surface functionalization and controlling the number of layers. Fewer defects are found in the end graphene product in comparison to previous methods. The inventive method of producing graphene is less aggressive, lower cost and more environmentally friendly than previous methods. This method is applicable to both laboratory scale and high volume manufacturing for producing high quality graphene flakes.

Owner:FRY S METALS INC

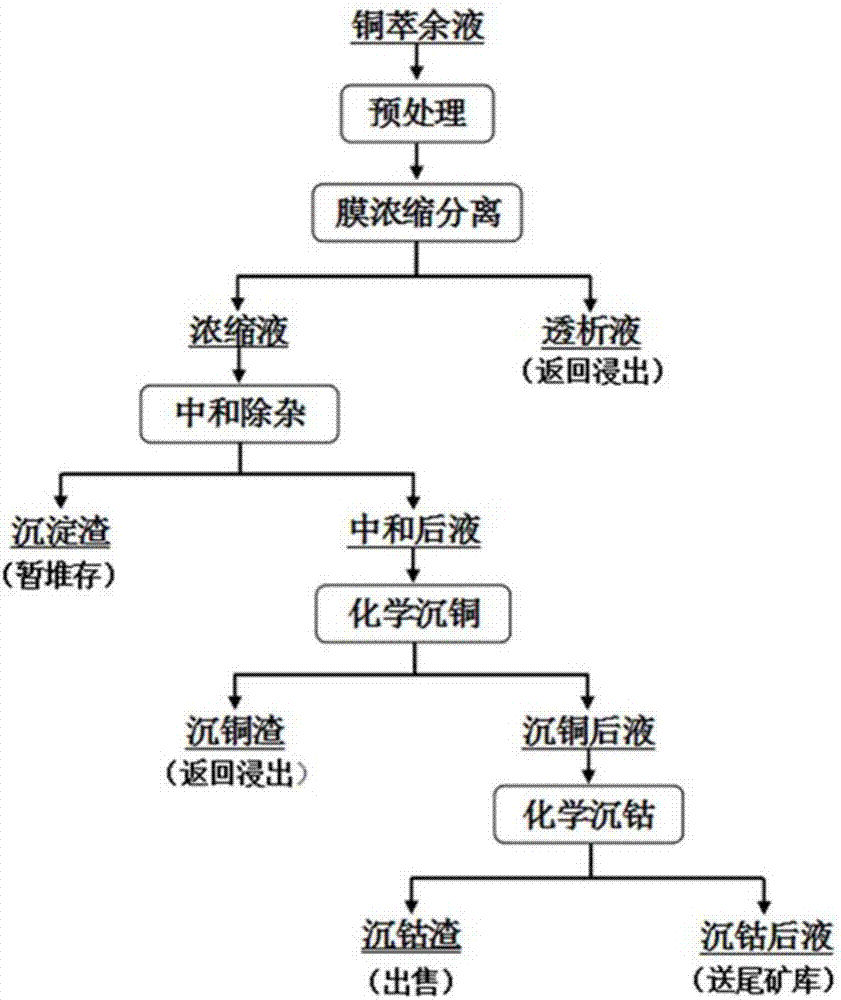

Method for recovering copper and cobalt in copper raffinate by adopting nanofiltration membrane concentration separation-neutralization and sedimentation

ActiveCN107460315AGood effectReduce waste water dischargeProcess efficiency improvementChemistryNanofiltration

The invention belongs to the technical field of wet metallurgy, particularly relates to a method for comprehensively recovering useful resources from a copper raffinate, and especially relates to a method for recovering copper, cobalt and sulfuric acid in the low-cobalt copper raffinate by adopting a nanofiltration membrane concentration separation-neutralization and sedimentation technology. Concretely, the nanofiltration membrane concentration separation technology is adopted for preventing copper, cobalt, iron, calcium, aluminum, arsenic and magnesium in the copper raffinate from entering a concentrated solution, the concentrated solution is treated by chemical precipitation so as to recover valuable metal cobalt and copper, and meanwhile, iron, aluminum, arsenic, calcium and magnesium impurities in the raffinate are open-circuit removed; and a dialysate (a sulfuric acid solution) returns to a leaching system of a copper hydrometallurgy process, so that the aims of recycling the useful resources in the raffinate, purifying and removing impurities are achieved, and meanwhile, the quality requirements of leaching and electrodeposition processes on the solution during copper hydrometallurgy production are met.

Owner:中国有色集团刚果矿业有限公司 +3

Comprehensive cyclic production method of D-glucosamine hydrochloride

ActiveCN108822163AImprove product qualityReduce waste water dischargeSugar derivativesAccessory food factorsMother liquorFermentation broth

The invention discloses a comprehensive cyclic production method of D-glucosamine hydrochloride. At first, N-acetyl-D-glucosamine in fermentation broth is extracted; then, N-acetyl-D-glucosamine crystals are hydrolyzed by hydrochloric acid, a crude product of D-glucosamine hydrochloride is produced; and finally the crude product is refined. During the extraction process, generated bacterial suspension is dried to produce a feed additive or feed proteins; and generated various mother liquors and trapped fluid are cycled and reused. The production method overcomes the shortages that in the priorart, the resources are not comprehensively utilized and wasted, and the environment is polluted; comprehensively and cyclically utilizes the resources, is accord with the green and environment-friendly idea, purifies the environment, promotes the ecological balance, reduces the production cost, and increases the social and economic benefits.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

Treatment method of phosphorus-containing wastewater

InactiveCN105967417AImprove economic efficiencyReduce waste water dischargeWater contaminantsTreatment involving filtrationChemistryActivated carbon

A method for treating phosphorus-containing wastewater, characterized in that the high-concentration phosphorus-containing wastewater is first decolorized by waste activated carbon, filtered and then transported to a neutralization reaction pot, and 230-270kg of 50% potassium hydroxide is added per ton of phosphorus-containing wastewater The proportion of the solution is passed into the potassium hydroxide solution, stirred for 5-6 hours, and then the material is transported to the concentration tower, and the temperature is raised to 130-150°C. The water is evaporated under normal pressure and condensed and collected, and then used to clean the ground. The material in the concentration tower is separated from solid and liquid, and the separated potassium dihydrogen phosphate is transferred to the drying room for drying to obtain the finished product of potassium dihydrogen phosphate. In this production and recycling process, the waste water is turned into potassium dihydrogen phosphate and clean water is reused for ground cleaning, and the production process does not increase the amount of waste water produced. The invention turns waste into wealth, not only reduces pollution, but also recycles and utilizes effective components in waste water, has advanced technology, simple process, low operating cost and less discharge.

Owner:ZHEJIANG EUCHEM CHEM

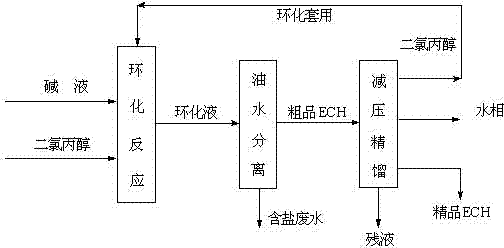

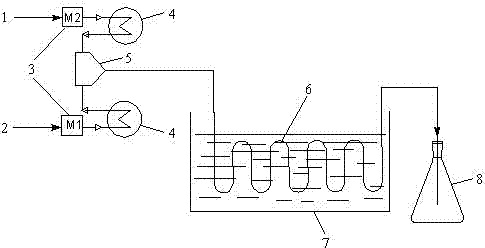

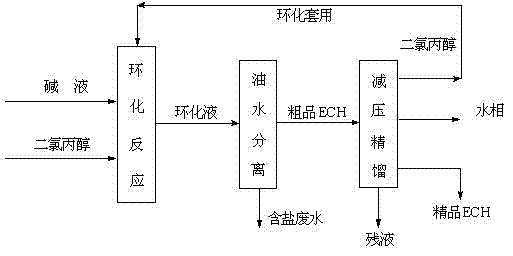

Method for preparing epoxy chloropropane by micro-channel reactor

InactiveCN102372684AReduce energy consumptionReduce waste water dischargeOrganic chemistryChemistryMICRO MIXER

The invention discloses a method for preparing epoxy chloropropane by a micro-channel reactor, which belongs to the technical field of chemical products. Dichloropropanol and alkali liquor are mixed through a micro-mixer and are then fed into the micro-channel reactor for carrying out cyclization reaction. Products obtained through reaction carry out oil-water separation after being neutralized by acid solution, then, oil phases are rectified at the ordinary pressure, and final products of epoxy chloropropane are obtained. The inner diameter of a micro channel is 0.2 to 1.0mm, the length is 5 to 15m, the reaction is carried out at the ordinary pressure and at the temperature being 30 to 90 DEG C, the retention time is 15 to 60s, the alkali liquor is NaOH or Ca(OH)2 solution, the mole ratio of NaOH to dichloropropanol is 1 to 1.5, the mole ratio of Ca(OH)2 to the dichloropropanol is 0.5 to 1, the acid solution is H2SO4 or HCl solution, and the yield of the epoxy chloropropane is about 97 percent. The method has the advantages that the energy consumption is low, the wastewater discharge quantity is small, the selectivity is high, the production cost is low, the process magnification is simple and convenient, and the like.

Owner:CHANGZHOU UNIV

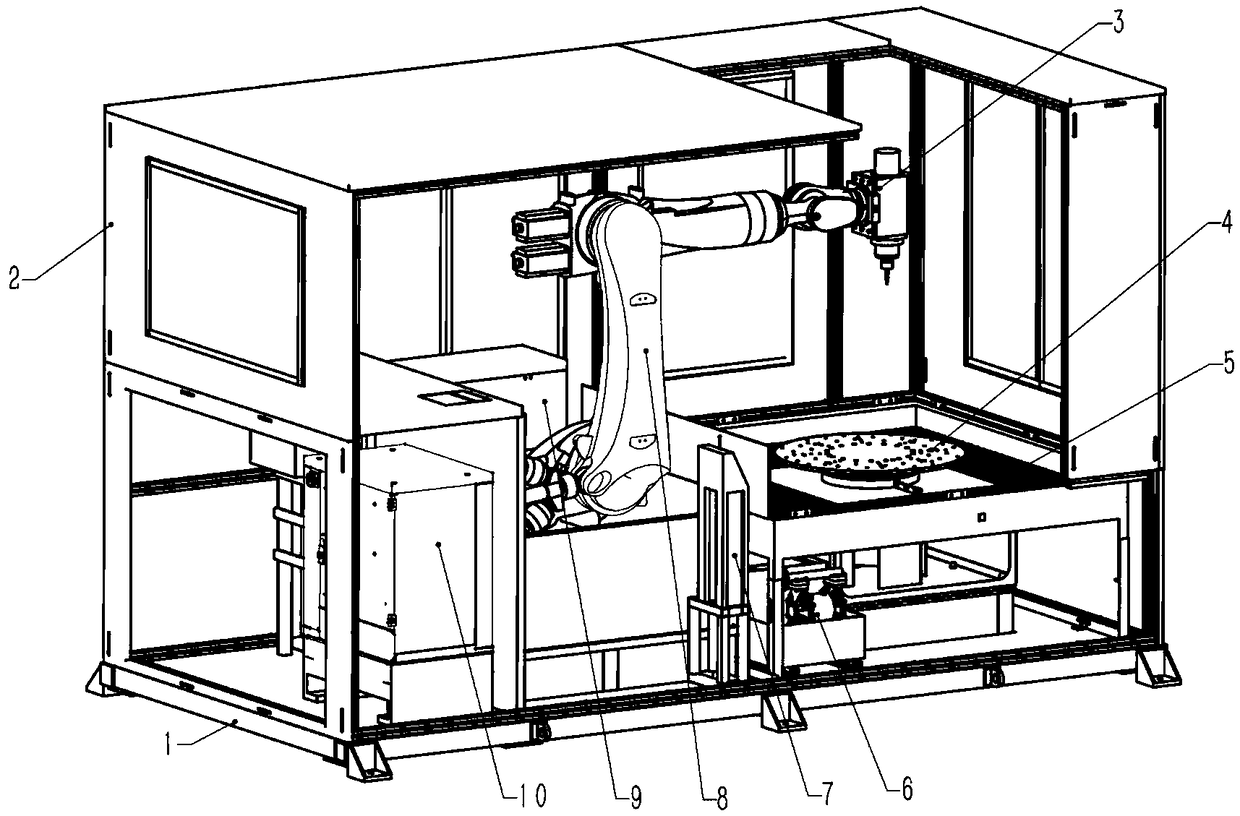

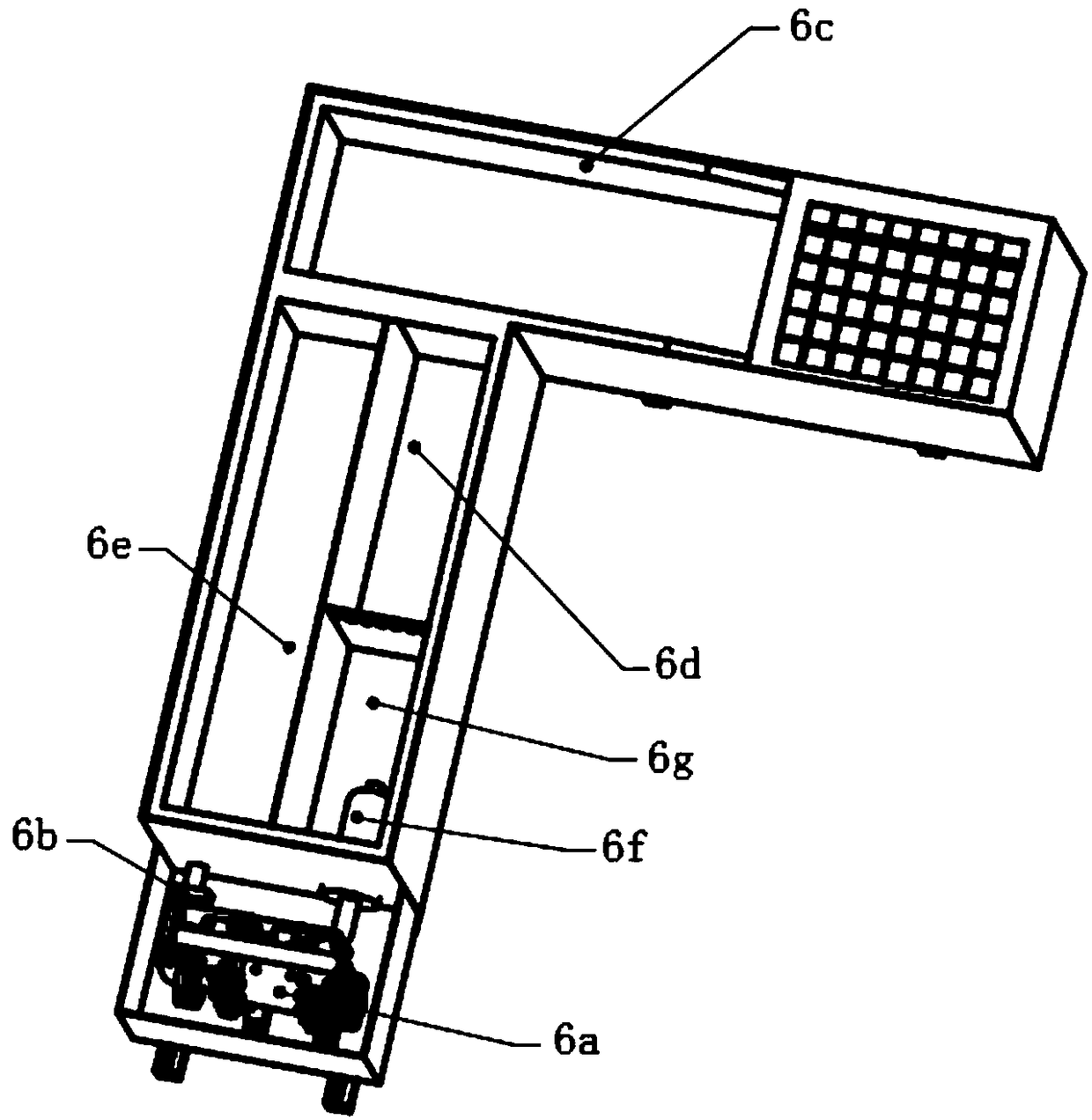

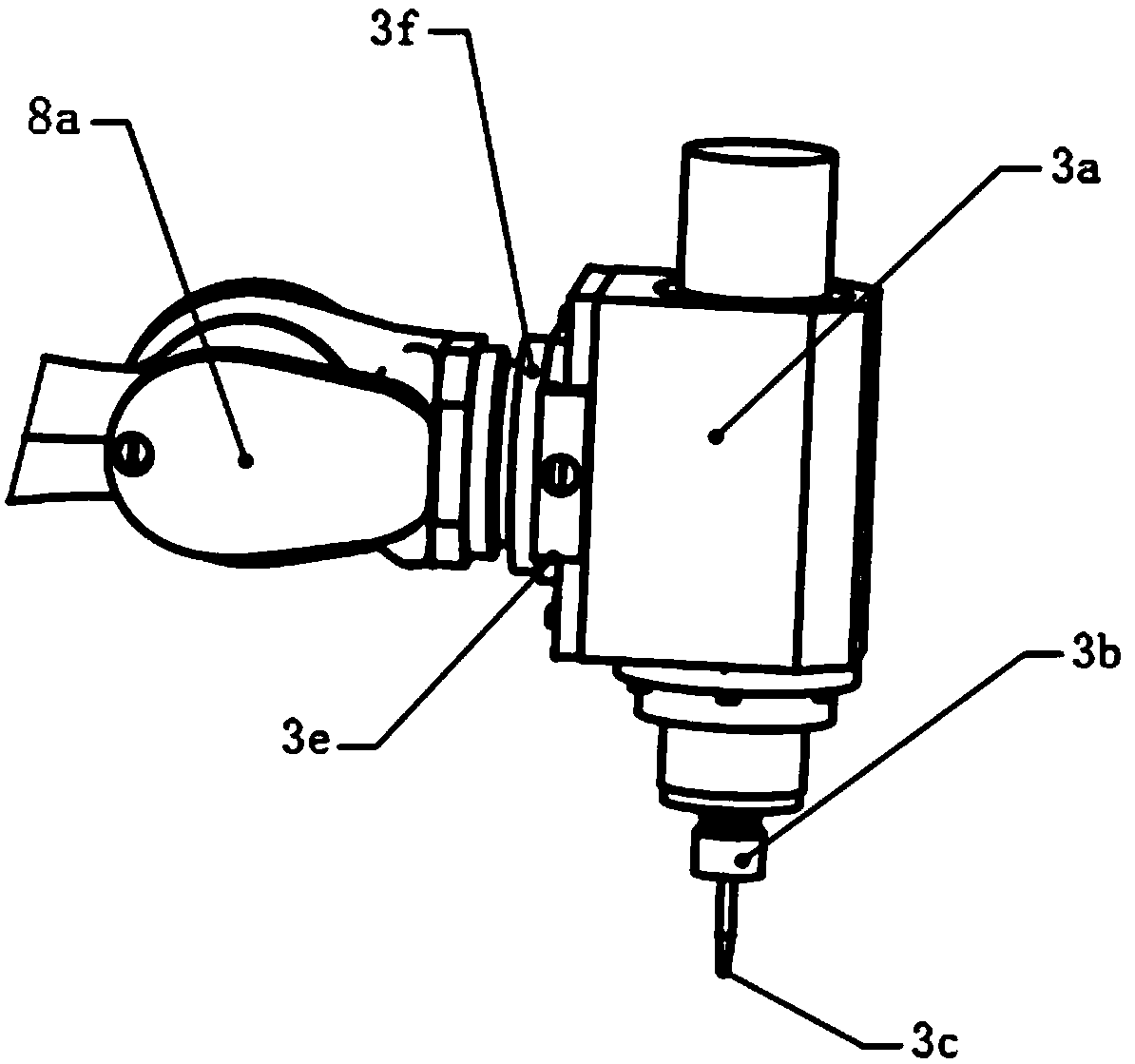

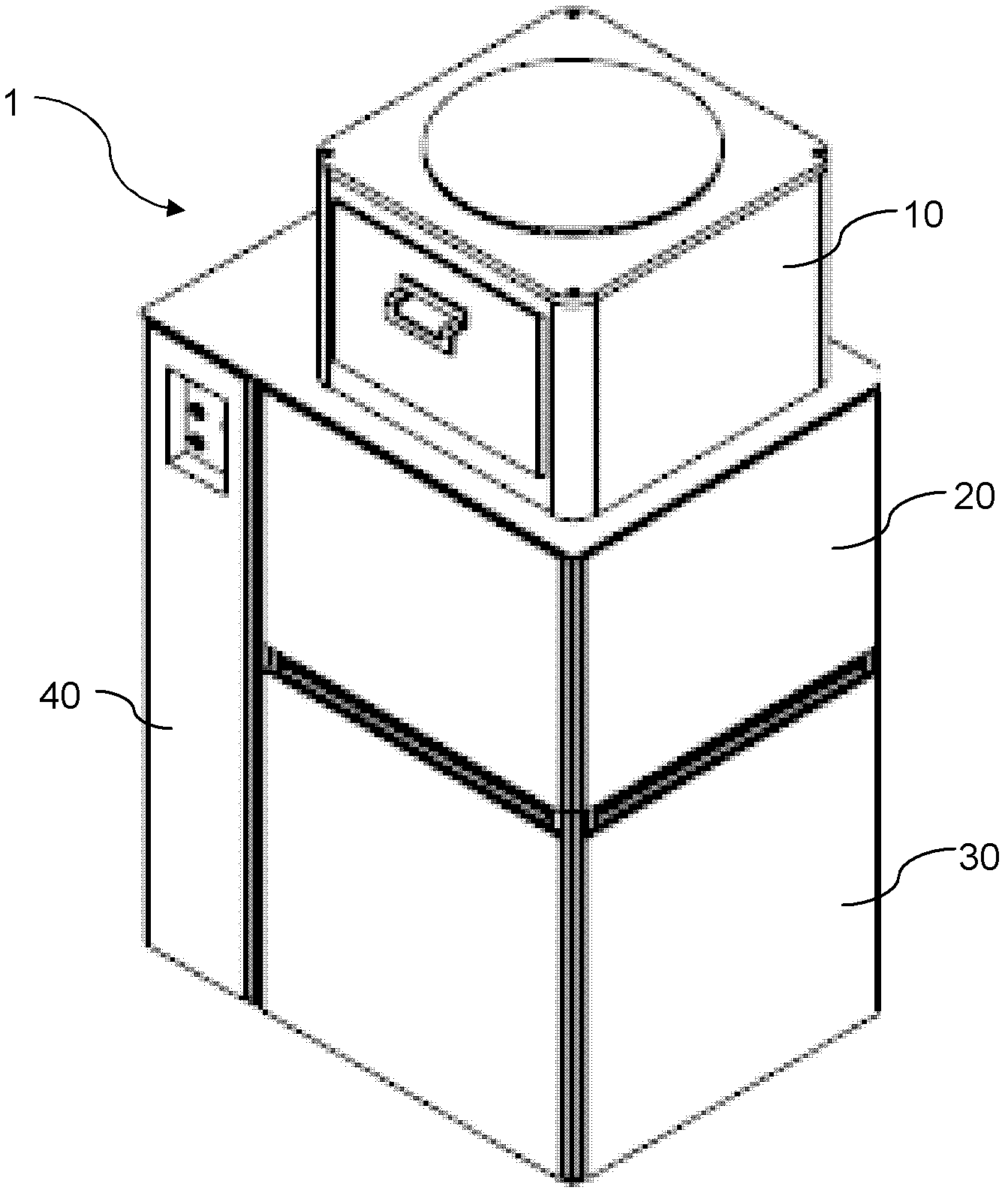

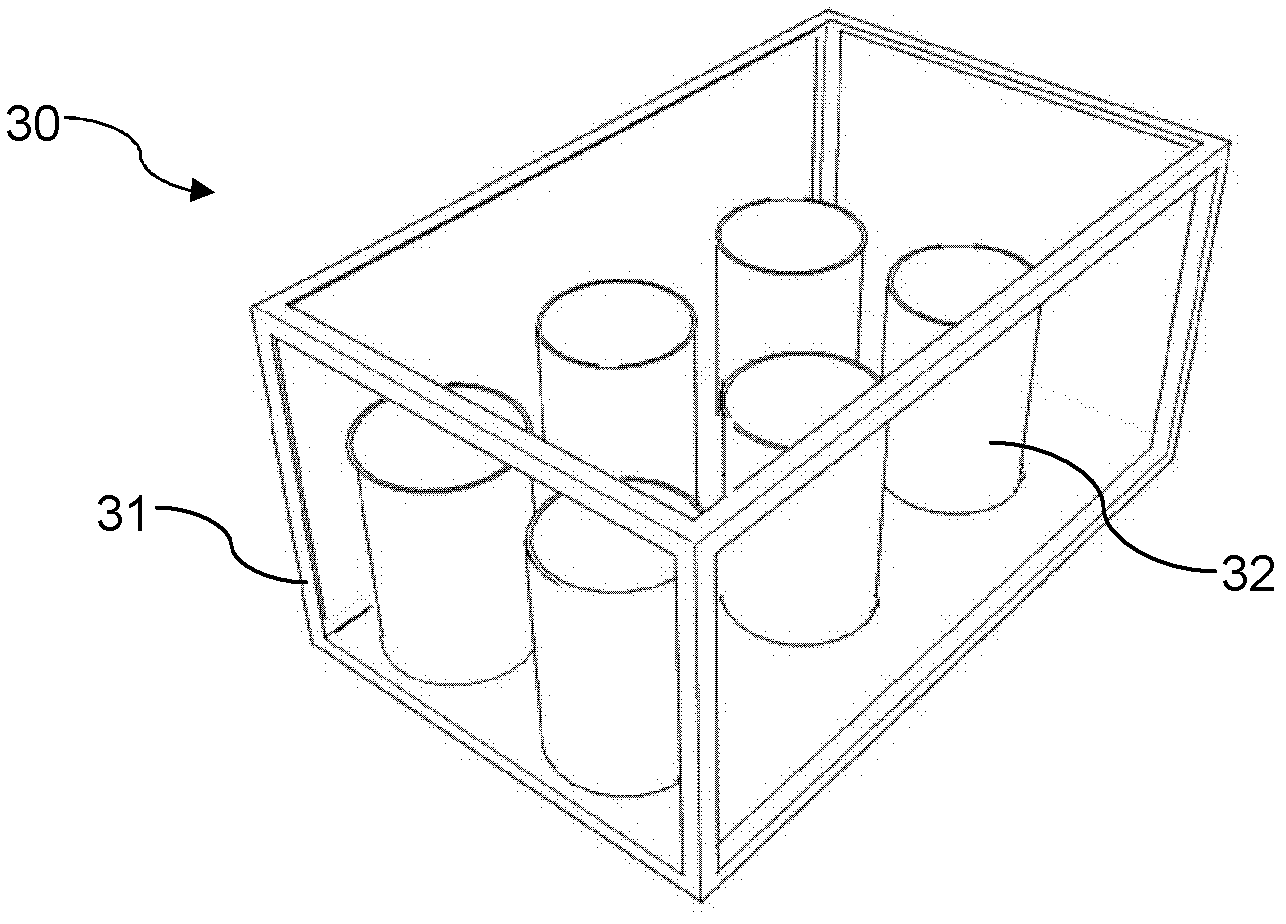

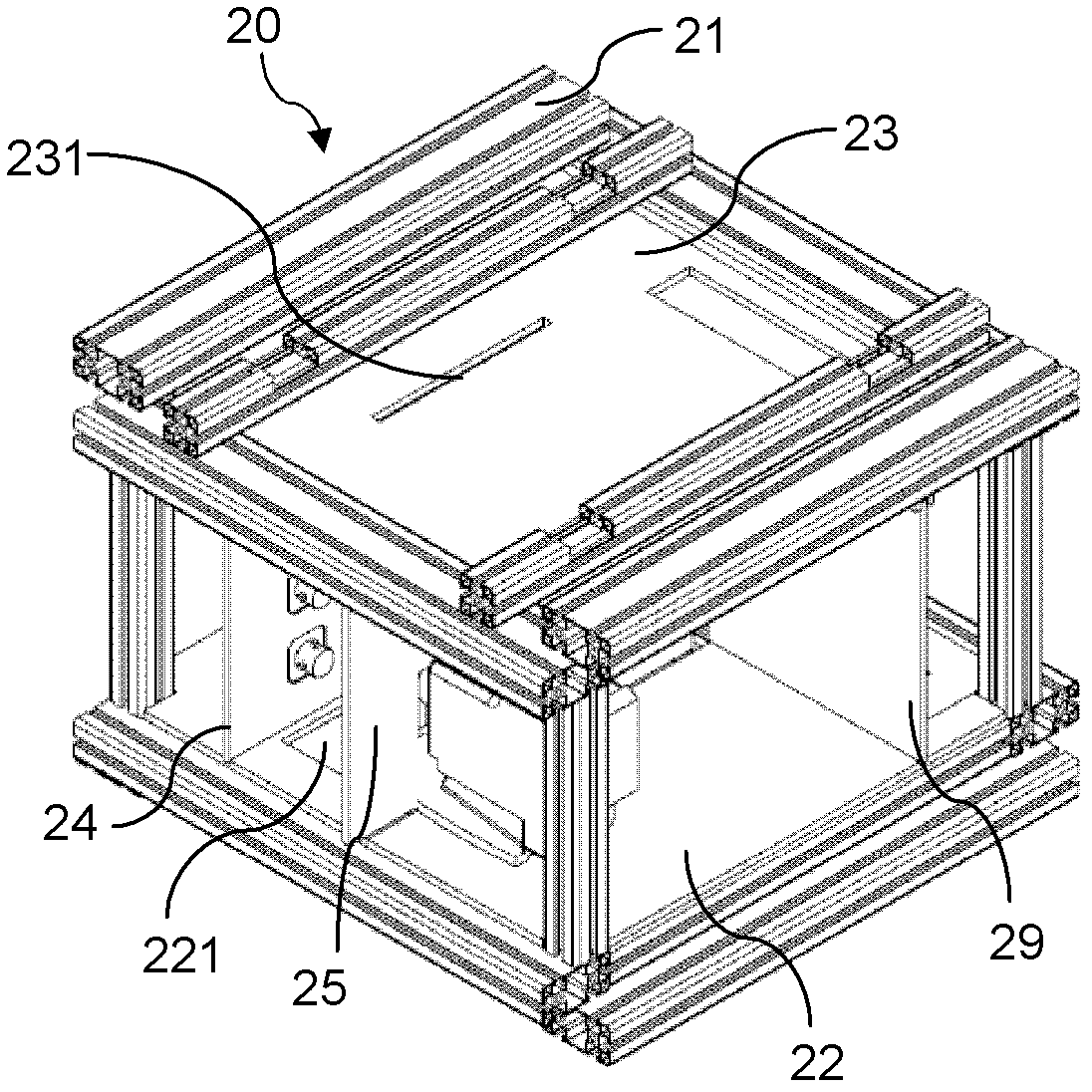

Carving robot system

PendingCN108942967AReduce waste water dischargeProtect environmentWorking accessoriesManipulatorFilter systemCarving

The invention provides a carving robot system, and belongs to the technical field of robots. The carving robot system comprises a robot base, a robot, a rotary platform and a controller used for controlling actions of the robot are arranged on the robot base, the robot comprises a mechanical arm, and a multifunctional carving head is arranged at the tail end of the mechanical arm; and a water collecting tank is arranged on the robot base, the rotary platform is located above the water collecting tank, and the carving robot system further comprises a filtering system, wherein the filtering system communicates with the water collecting tank. According to the carving robot system, waste water and waste residues can be well collected and treated through the water collecting tank and the filtering system correspondingly, the waste water discharge is reduced, the environment is protected, cutter replacement can be automatically achieved on the multifunctional carving head, and the product quality and the carving efficiency are improved.

Owner:云浮中科石材创新科技有限公司 +1

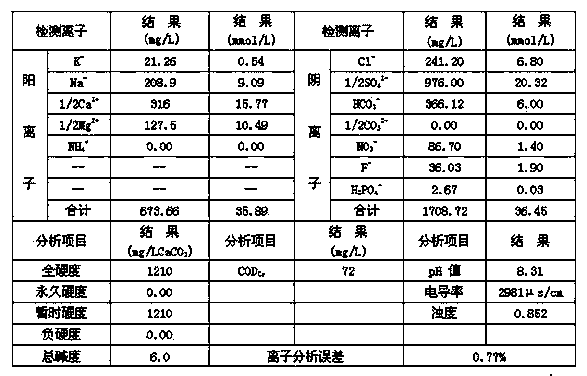

Treatment method for recycling power plant circulating water sewage

InactiveCN104030483AHigh recovery rateReduce waste water dischargeGeneral water supply conservationWater/sewage treatment by ion-exchangeDesalinationCationic exchange

The invention discloses a treatment method for recycling power plant circulating water sewage, which comprises the following steps: sending circulating water sewage into a multimedia filter, and filtering; sequentially passing the effluent water through a primary sodium cation exchanger and a secondary sodium cation exchanger; replenishing part of the effluent water of the secondary sodium cation exchanger into a cooling tower as circulating water; sending the rest of treated effluent water into primary reverse osmosis to be treated; replenishing part of the primary reverse osmosis effluent water into the cooling tower as circulating water; sending the rest of the primary reverse osmosis effluent water into secondary reverse osmosis; and sending the effluent water of the secondary reverse osmosis into a deep desalting system to be treated, and using the treated effluent water as power plant boiler replenishing water. By using the two stages of sodium cation exchangers instead of the lime treatment system, the method prevents sludge and other refractory substances from generation. The reverse osmosis effluent water obtained by the treatment method has high quality, can be directly used as power plant heating network replenishing water, chemical make-up water treatment system water source and circulating water replenishing water.

Owner:STATE GRID CORP OF CHINA +2

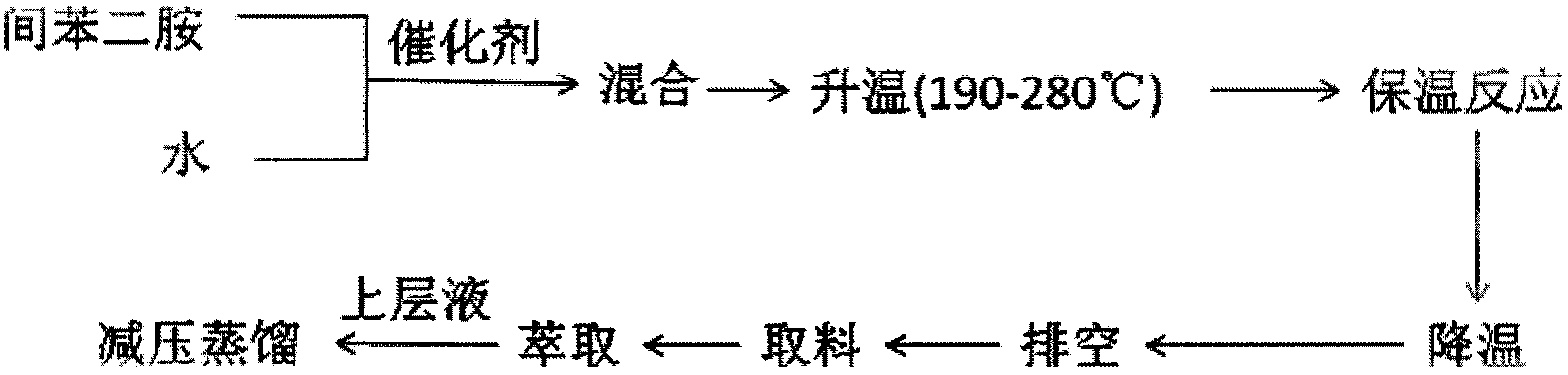

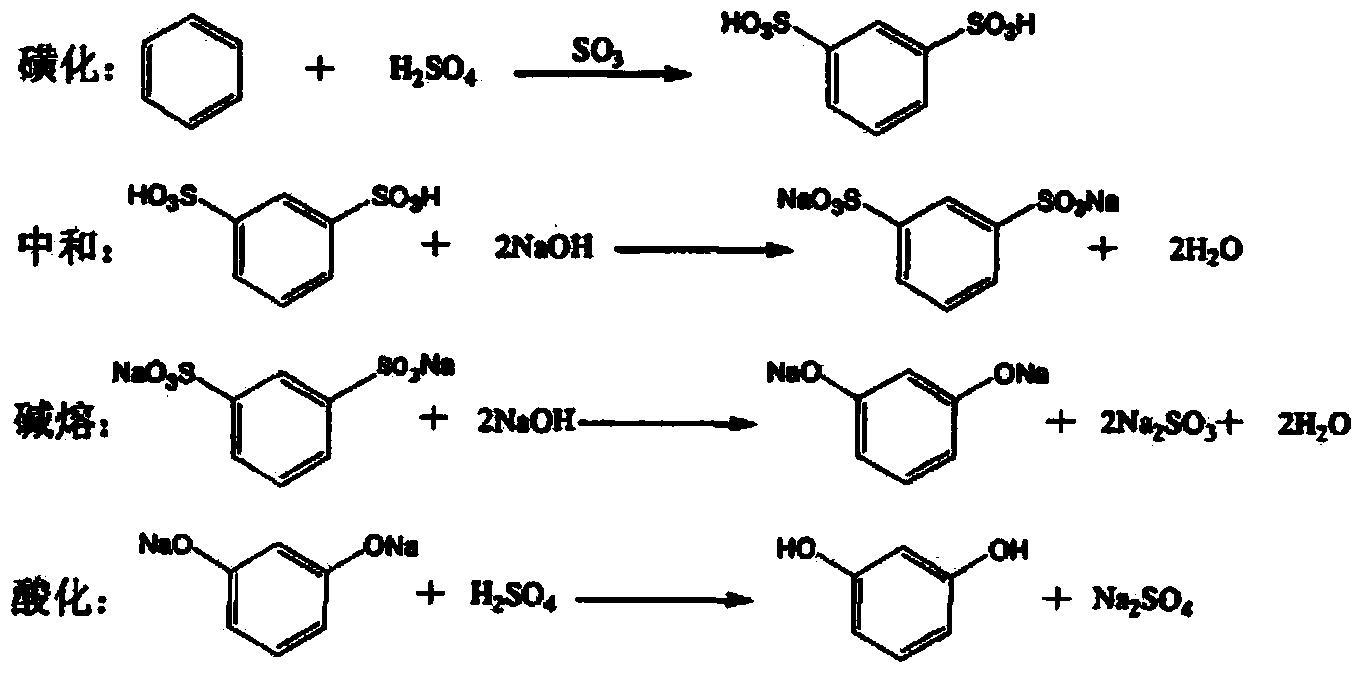

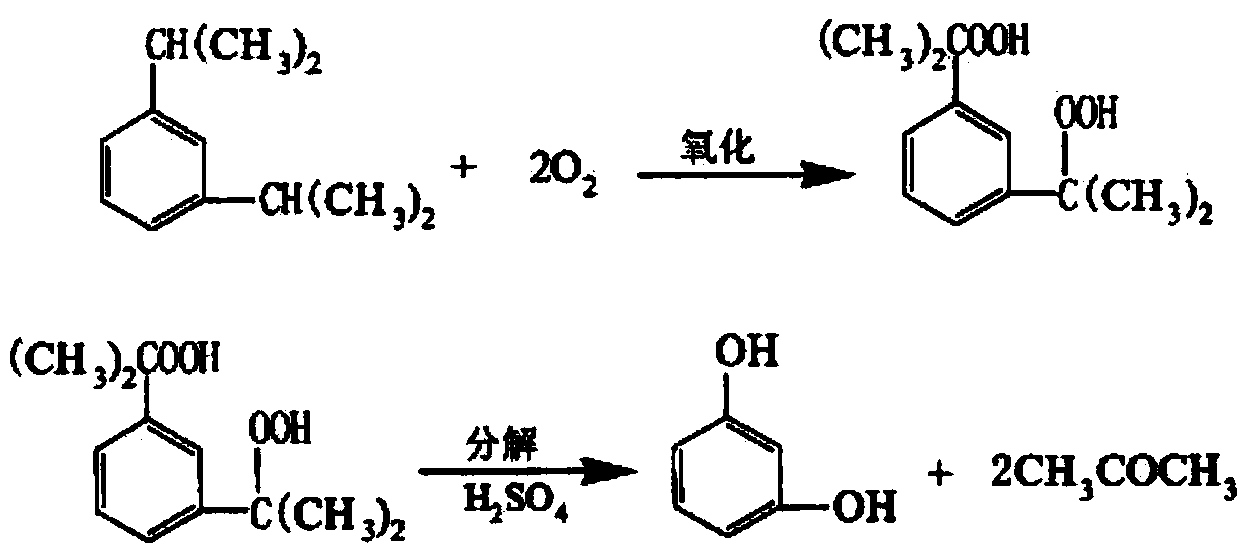

Process of producing resorcinol by hydrolyzing m-phenylenediamine

ActiveCN103848724AReduce pollutionReduce waste water dischargeOrganic chemistryOrganic compound preparationSolventChemistry

The invention relates to a process of producing resorcinol by hydrolyzing m-phenylenediamine. The process comprises the following steps: 1) adding m-phenylenediamine, an acid catalyst, a solid superacid catalyst and water in proportion into a high pressure hydrolysis reaction kettle, and uniformly mixing to obtain a mixed reaction liquid; 2) heating the reactor to hydrolyze m-phenylenediamine to obtain a resorcinol hydrolyzing reaction liquid; 3) carrying out filtration and solvent extraction on the hydrolyzing reaction liquid to obtain a resorcinol coarse product; and 4) carrying out reduced pressure distillation on the resorcinol coarse product to obtain a resorcinol finished product. The process provided by the invention is less in pollution, less in wastewater discharge, easy to control process condition and high in product yield.

Owner:NANJING UNIV OF TECH

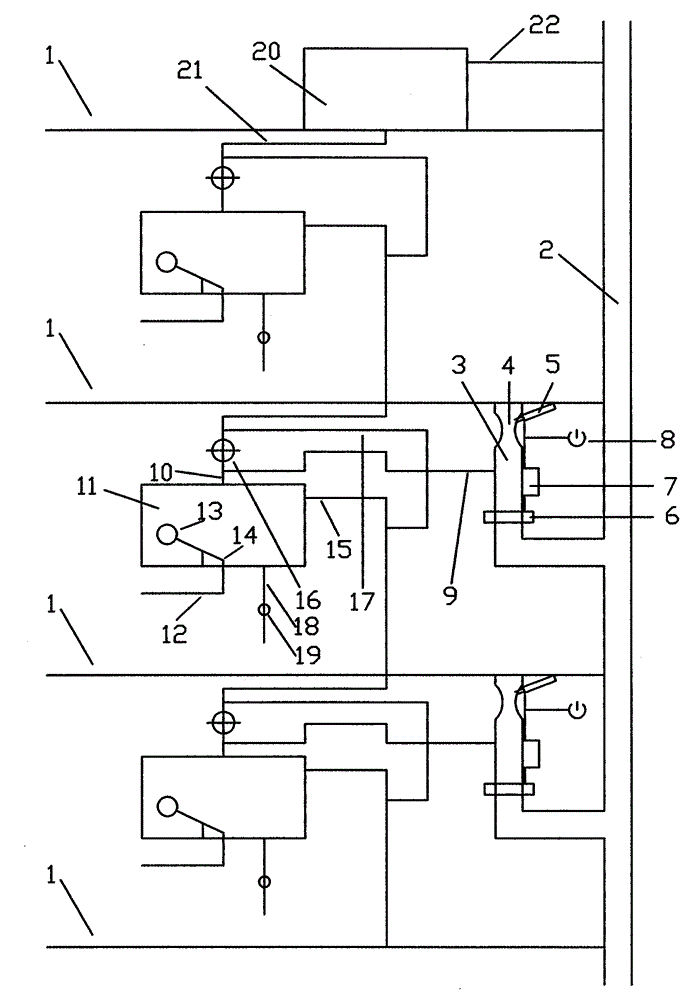

Copper chloride corrosion device and method for printing roller

ActiveCN105479965AReduce waste water dischargeReduce labor efficiency of workersPrinting pre-treatmentCopper chlorideCorrosion

The invention relates to the technical field of gravure plate making, in particular to a copper chloride corrosion device and method for a printing roller. The copper chloride corrosion device comprises a corrosive liquid groove used for containing corrosive liquid, a detection sensor used for detecting the concentration of raw materials in the corrosive liquid, and an automatic sample adding device used for automatically adding the raw materials. The detection sensor is electrically connected with the automatic sample adding device. According to the corrosion device, emission of waste water can be reduced, labor efficiency of workers is lowered, and the corrosion quality is obviously improved. The corrosion method is simple in technology and convenient to operate and control; the problems that corrosion is uneven, lateral corrosion is severe and corrosion is difficult to control can be solved, wherein the problems are likely to happen in the corrosion process; and in addition, stability of the corrosive liquid can be ensured.

Owner:DONGGUAN YUNCHENG PLATE MAKING

Method for preparing cellulose acetate butyrate with high hydroxyl content

ActiveCN110642954AReduced hydrogenolysis reaction timeReduce waste water dischargeCelluloseHydrogenolysis

The invention discloses a method for preparing cellulose acetate butyrate with a high hydroxyl content. The method comprises the following steps: cellulose activation, cellulose esterification and cellulose hydrogenolysis to obtain cellulose acetate butyrate with the hydroxyl content of 4-6 wt%. The method removes acyl groups of the cellulose acetate butyrate by adopting a hydrogenolysis process to obtain high-content hydroxyl groups, so a large amount of acid wastewater generated by hydrolysis through adding water is avoided, the reaction time is remarkably shortened, the production cost is greatly reduced, and the method is suitable for industrial production.

Owner:WANHUA CHEM GRP CO LTD

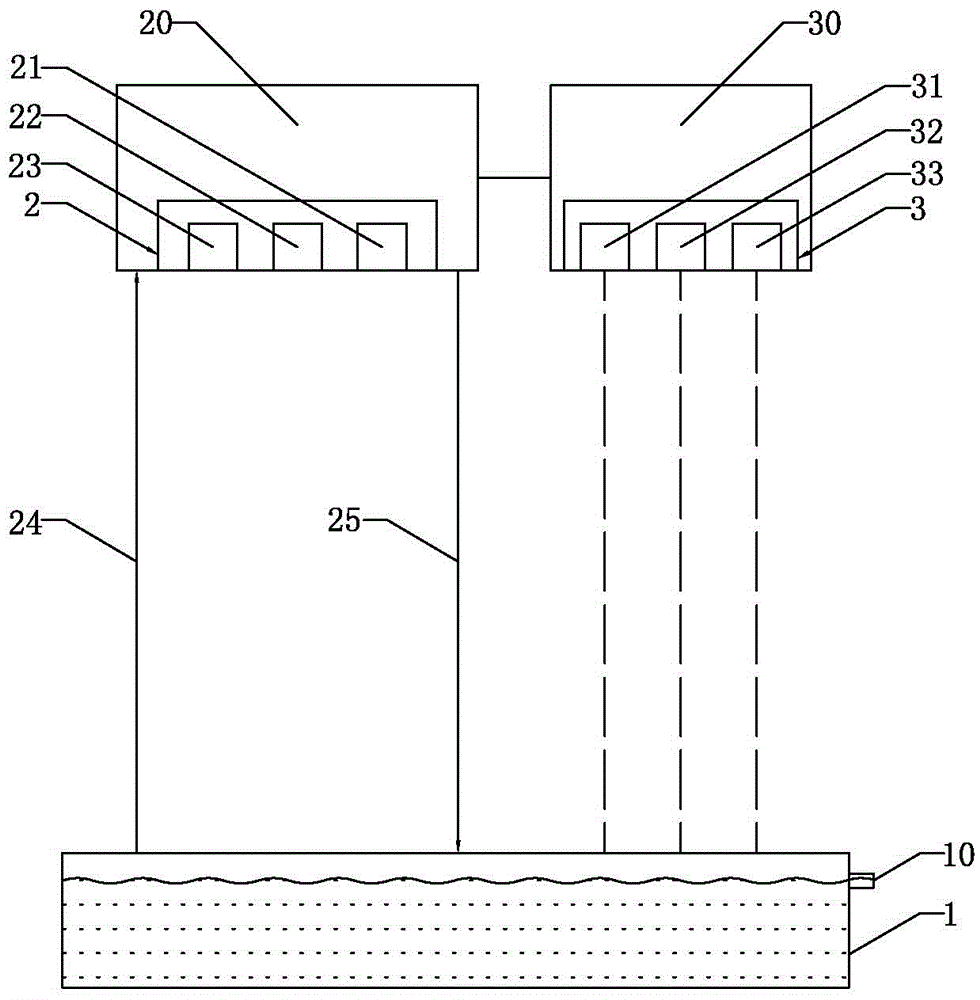

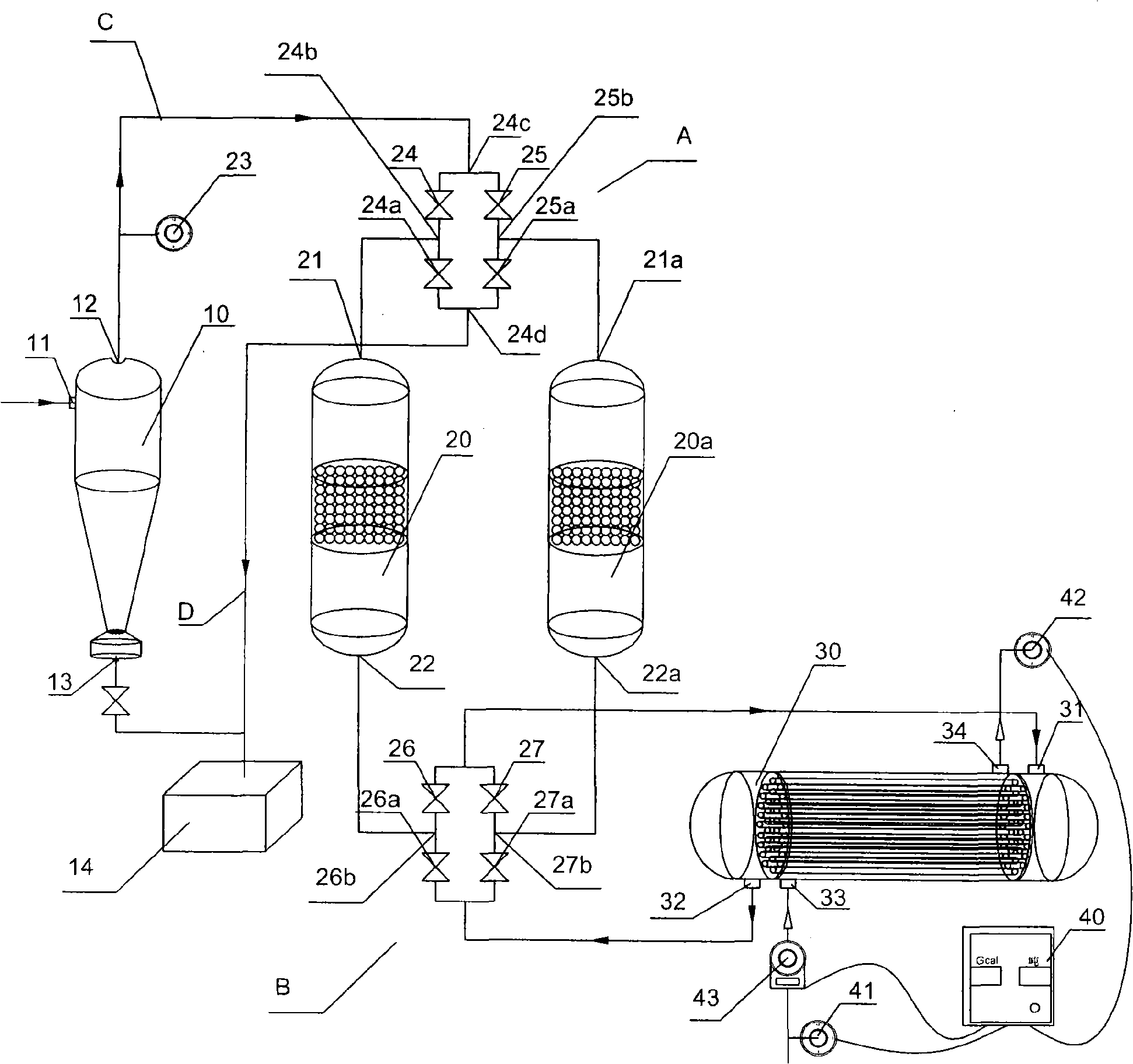

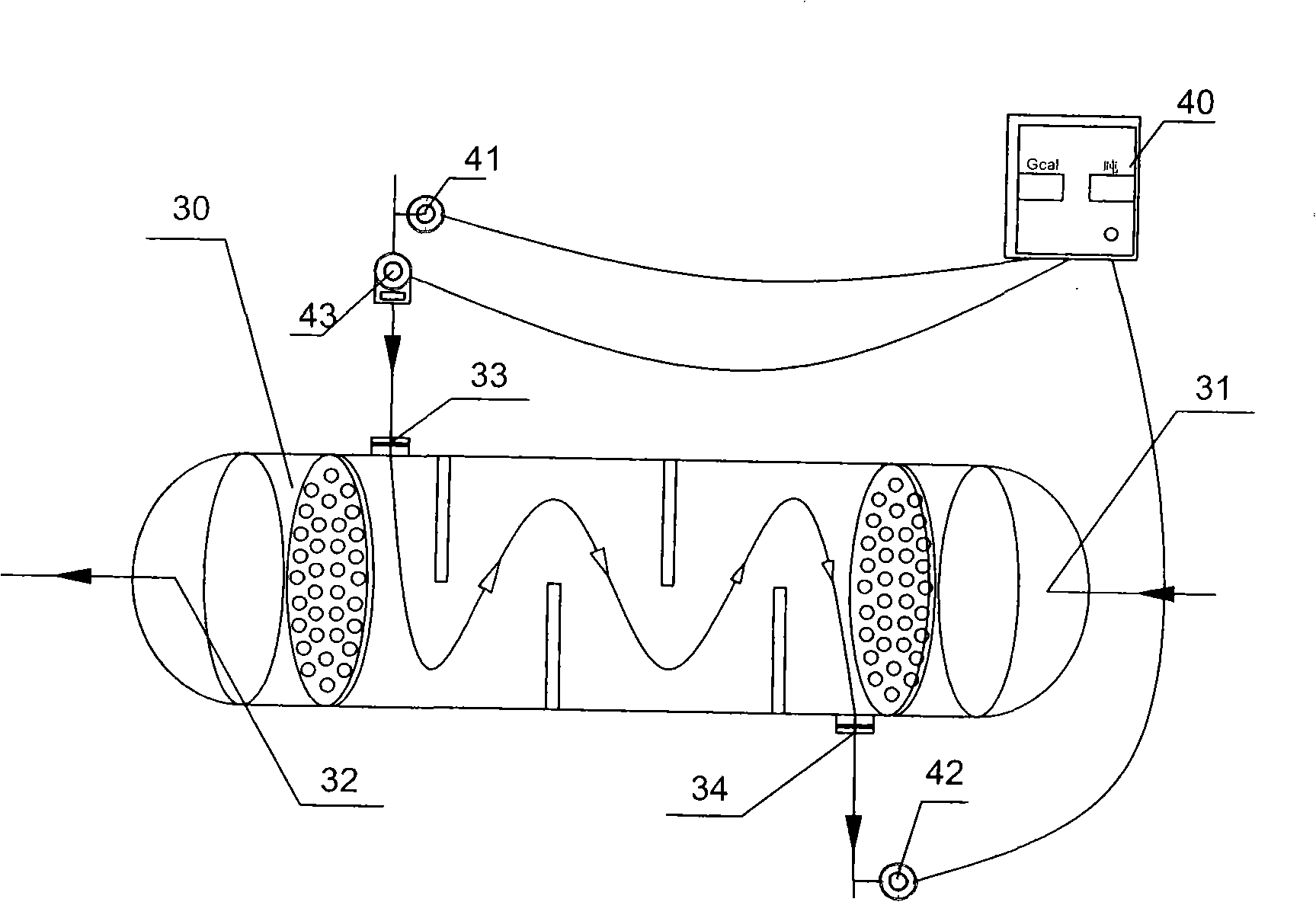

Waste water heat energy recovery system

InactiveCN101493291AImprove heat exchange efficiencyReduce waste water dischargeWater/sewage treatmentStationary tubular conduit assembliesProcess engineeringThermal energy

The invention provides a recovery system for waste hot water heat energy, belonging to the field of industrial waste water heat energy recovery. Heat energy recovery systems commonly adopted at home have the problems that heat exchange efficiency is low, a filter is not capable of automatic back flush and needs a large quantity of clear water, a heat exchanger has the problems of blockage and serious pollution and on-line display and accumulative calculation of heat energy are not feasible. The system of the invention comprises a centrifugal filtering device, a granule filtering device for automatic switch operation and back flush, a heat exchanger for heat exchange between cool water and hot water, a system for automatic switch operation and back flush of the filter, a heat energy integrating device of the whole recovery system and the like. The heat energy recovery system provided by the invention can realize automatic operation and control over back flush process of the filter, improve efficiencies in impurity filtration of the waste water and heat exchange and provide functions of accumulative calculation and on-line display of heat energy so as to realize real-time monitoring to the system performance.

Owner:仁新节能环保设备(上海)有限公司

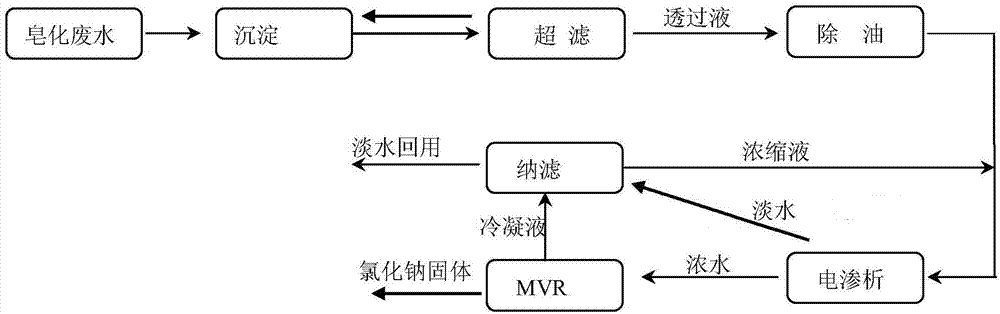

Method for comprehensive reuse treatment of rare-earth sodium saponification wastewater

ActiveCN103693790AAvoid contamination and cloggingReduce waste water dischargeWaste water treatment from metallurgical processMultistage water/sewage treatmentUltrafiltrationChemistry

The invention provides a method for comprehensive reuse treatment of rare-earth sodium saponification wastewater. According to the method, the sodium saponification wastewater is firstly subjected to precipitation, ultrafiltration and degreasing pretreatment, and then, an electrodialysis system, a mechanical vapor recompression (MVR) system and nanofiltration treatment are adopted. According to the method, a pretreatment, membrane integration and MVR integrated technology is adopted to treat rare earth smelting wastewater in an innovative manner, final permeate is reused to production, the smelting wastewater is subjected to concentration and desalination by using respective characteristics of ultrafiltration, electrodialysis, a nano-filtration membrane and MVR, saline matters in the wastewater are transformed into solid crystals, desalinated water can be reused as pure water, and the wastewater and an extractant can be recovered, so that water resources are recycled; on the premise that a relatively high extractant and water recovery rate is achieved, industrial production operation is finally realized more economically, so that benefits for enterprises are created, the production and operating costs are lowered by over 30%, and the market competitiveness of rare earth smelting enterprises is improved.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

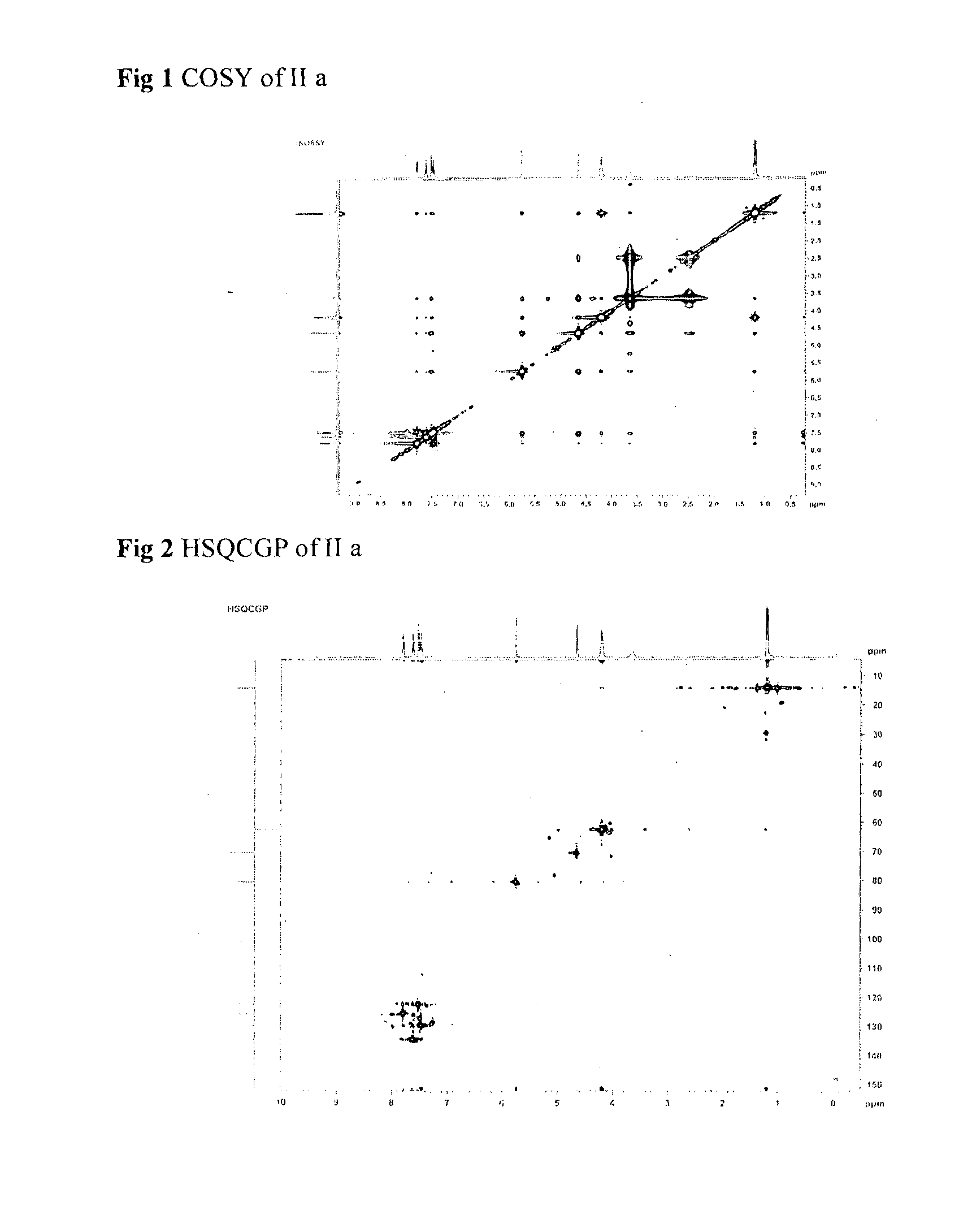

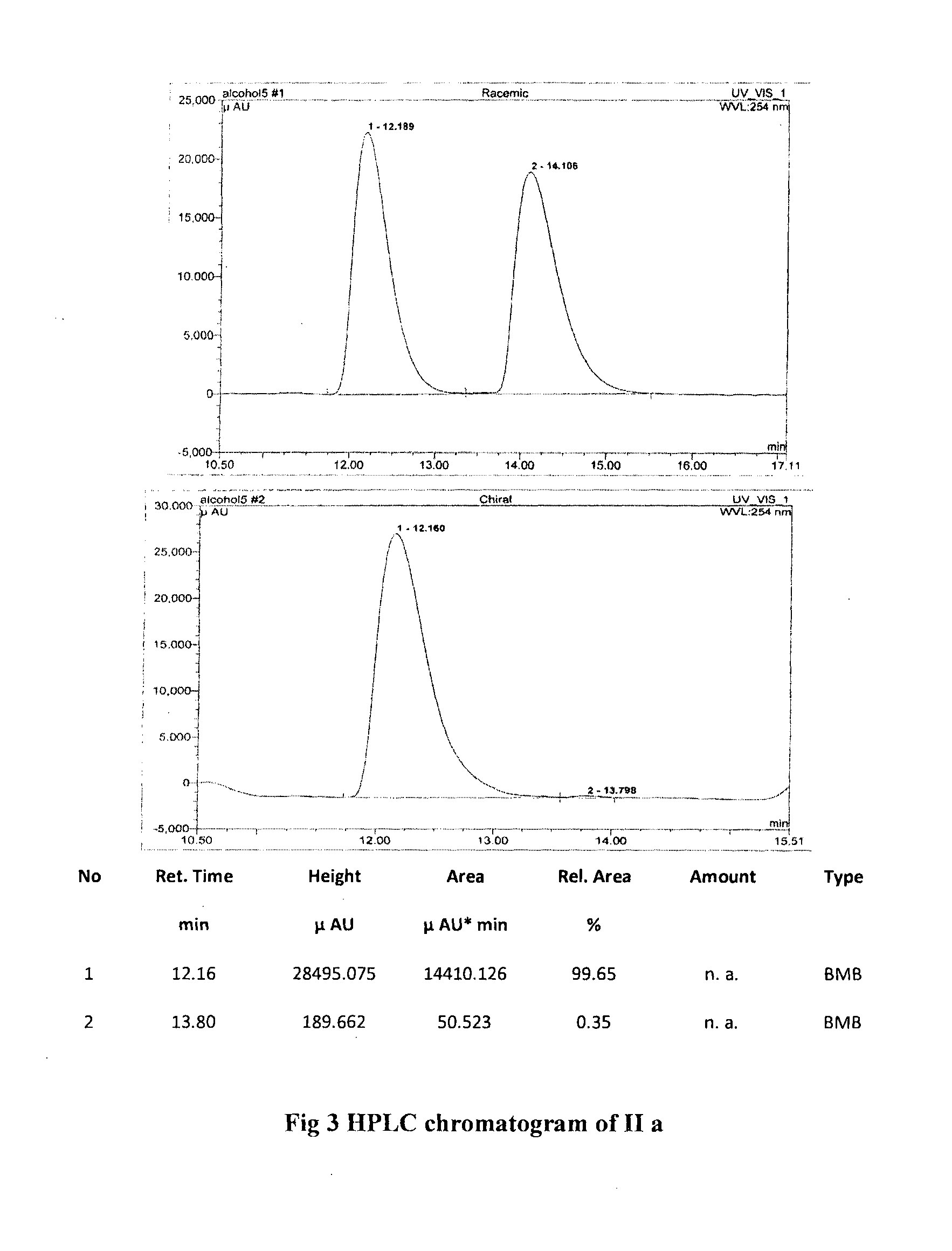

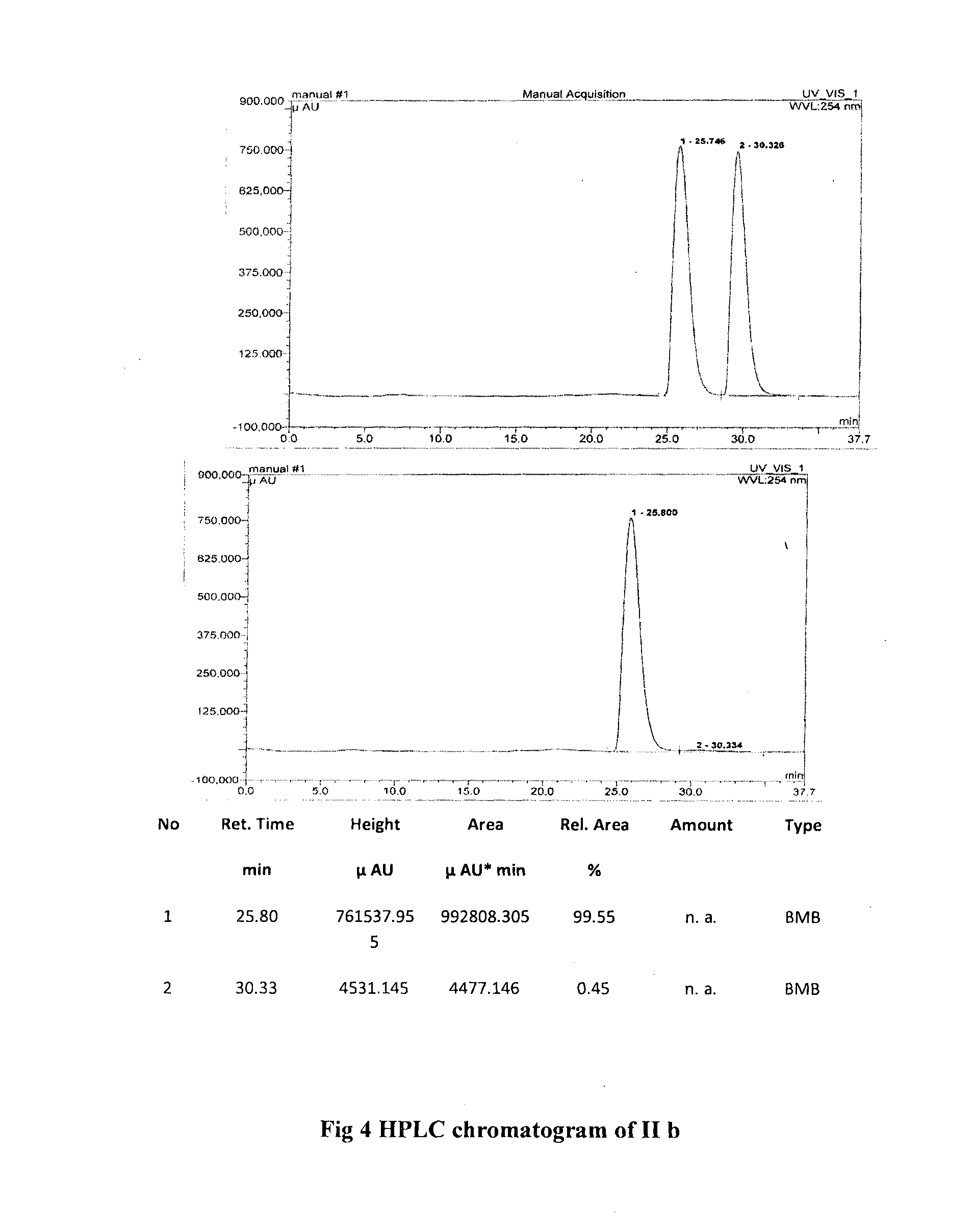

Single step enantioselective process for the preparation of 3-substituted chiral phthalides

The present invention discloses single step, highly enantioselective catalytic oxidative cyclization process for the synthesis of 3-substituted chiral phthalides. In particular, the invention discloses asymmetric synthesis of chiral phthalides via synergetic nitrile accelerated oxidative cyclization of o-cyano substituted aryl alkenes in high yield and enantiomeric excess (ee) in short reaction time. Also, disclosed herein is “one-pot” asymmetric synthesis of biologically important natural compounds having 3-substituted chiral phthalide structural framework in the molecule.

Owner:COUNCIL OF SCI & IND RES

Method of processing polybutadiene polymer industrial waste water

InactiveCN1463930AReduce waste water dischargeReduce COD valueWater/sewage treatment by flocculation/precipitationWater treatmentIndustrial waste water

The present invention provides the treating process of technological waste water from the production of grafted polybutadiene for ABS resin. Waste water after washing polybutadiene polymerizing reactor and waste water after washing polybutadiene grafting and polymerizing reactor are treated separately to reuse the effective components and lower the COD value of waste water. The waste water treating process can reduce the water treating load in subsequent water treatment, utilize useful material in waste water and raise yield of product.

Owner:PETROCHINA CO LTD

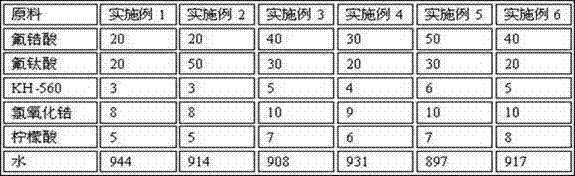

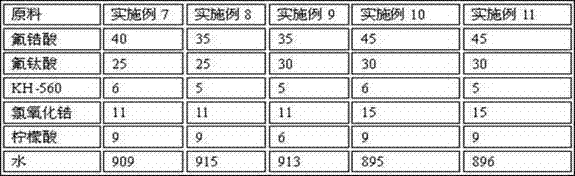

Silane surface treating agent and preparation method thereof

ActiveCN103773234AReduce waste water dischargeFew control parametersMetallic material coating processesChemistrySilane coupling

The invention discloses a silane surface treating agent, which is prepared from the following raw materials by mass percent: 2-5% of hexafluorozirconic acid, 2-5% of hexafluorotitanic acid, 0.3-0.6% of silane coupling agent, 0.8-1.5% of zirconium oxychloride, 0.5-1% of citric acid and the balance of water. By adopting the silane surface treating agent disclosed by the invention, the sewage sludge treatment cost can be saved, consumption of raw water is saved, the silane surface treating agent can be used at normal temperature, a heating energy source is saved, the maintenance cost can be reduced, and the manpower cost is saved.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

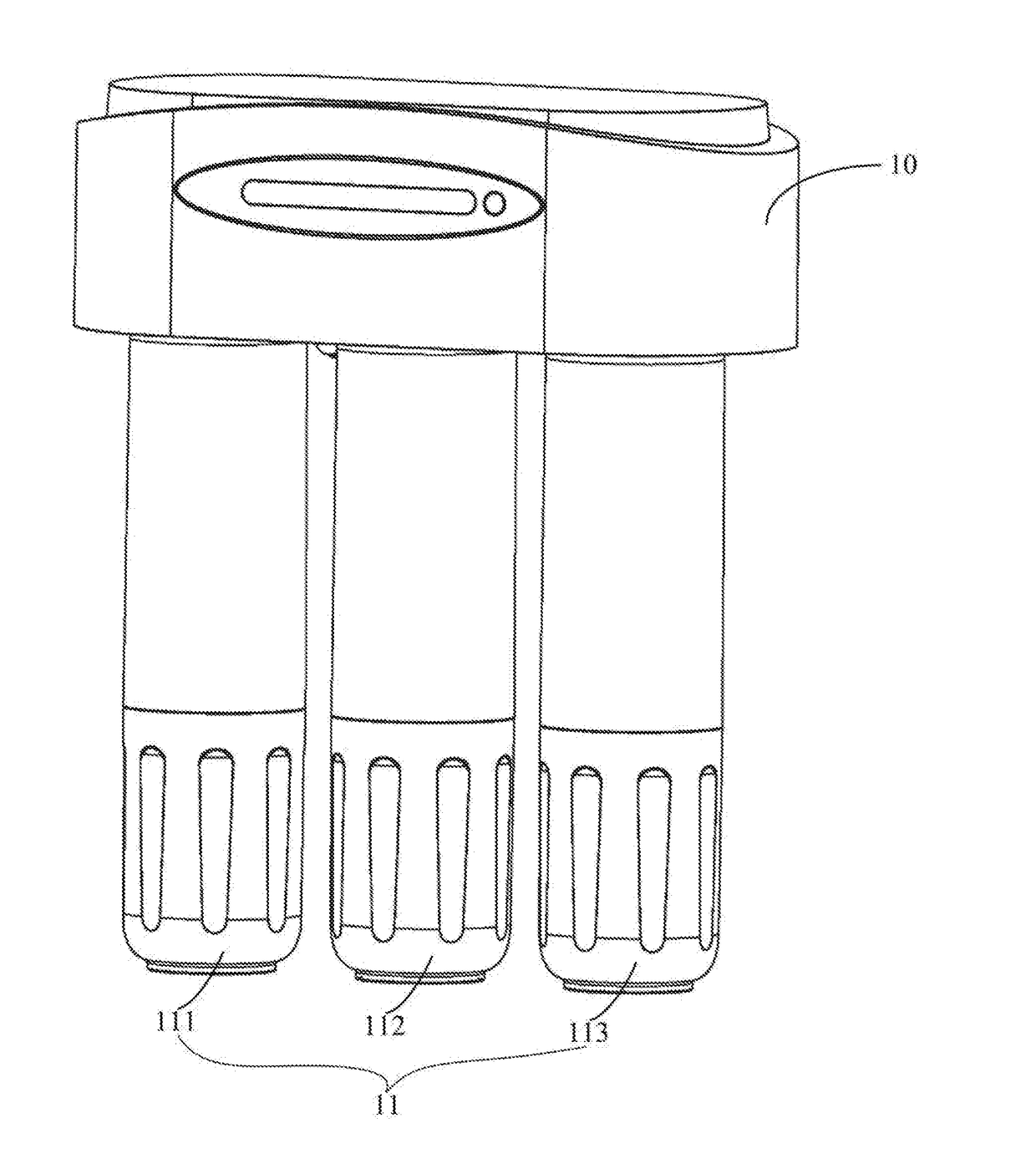

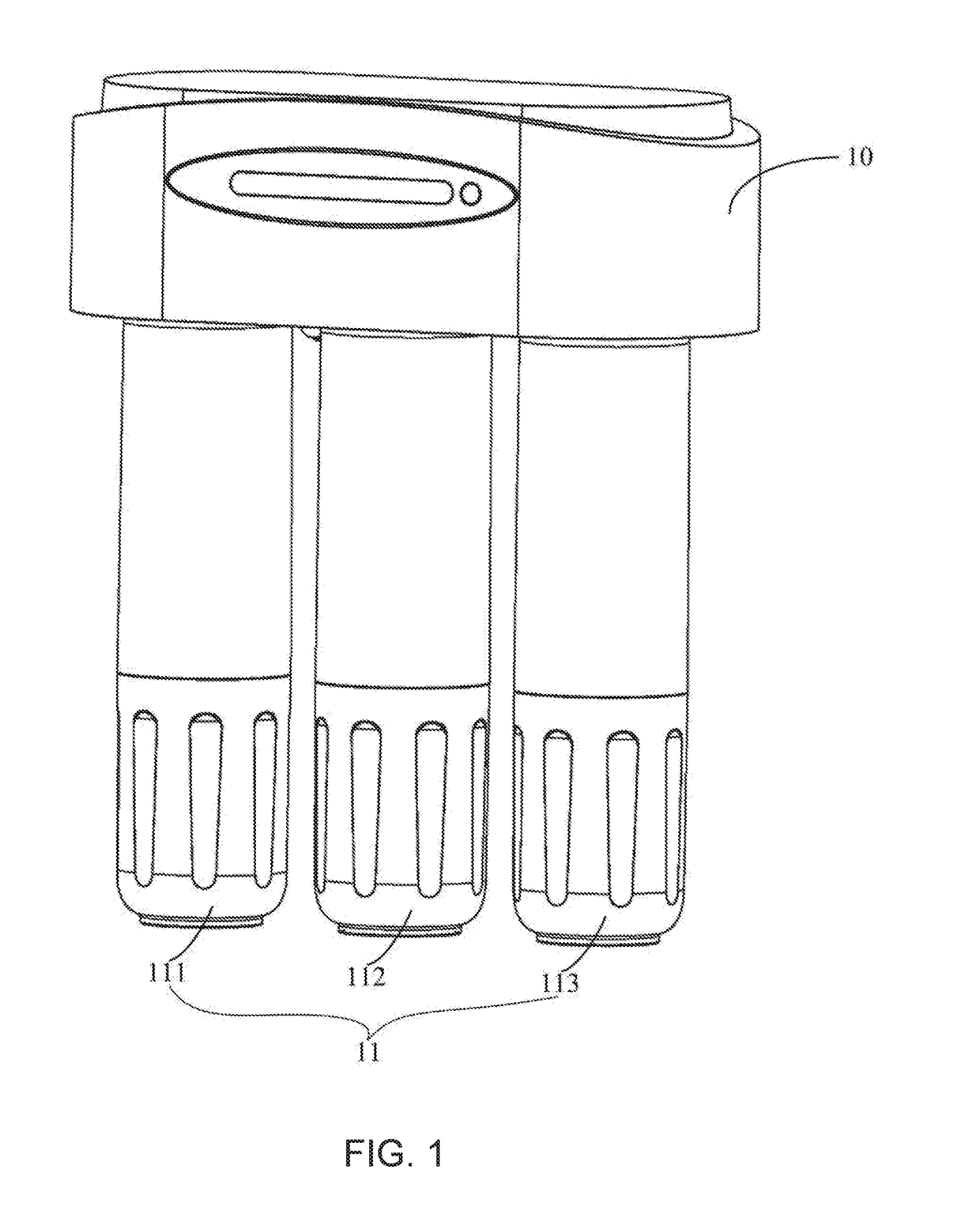

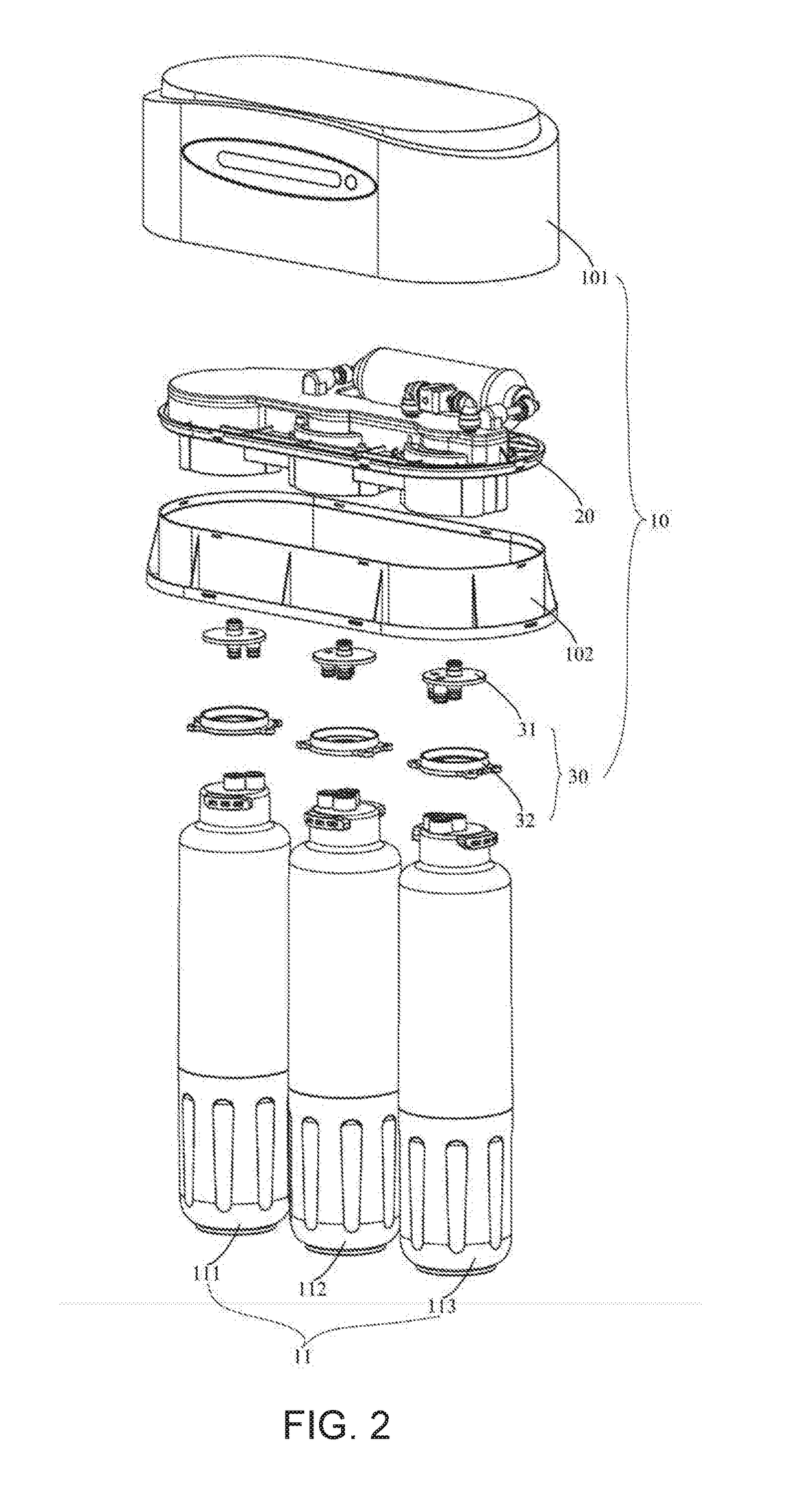

Reverse osmosis filtration system without pressure tanks

InactiveUS20170259211A1Quality assuranceReduce waste water dischargeMembranesWater/sewage treatment bu osmosis/dialysisWater storageFiltration

The present invention provides a reverse osmosis filtration system without pressure tanks consisting of a filter element connecting member and external filter elements and having a raw water inlet, a pure water outlet and a wastewater outlet. In the reverse osmosis filtration system of the present invention, filter elements can be quickly and easily installed for avoiding leakage occurs during the installation or replacement of the filter elements, so that users can conveniently install or replace the filter elements by themselves and purposes of convenient operation and leakage prevention can be achieved. Meanwhile, water storage pressure tanks and pumps are omitted in the reverse osmosis filtration system of the present invention for reducing manufacturing costs and effectively avoiding secondary pollution.

Owner:KEMFLO NANJING ENVIRONMENTAL TECH +2

Method and device capable of realizing diversion automatic detection and cyclic utilization of sanitary wastewater

InactiveCN105887994ASave waterReduce waste water dischargeGeneral water supply conservationDomestic plumbingSpecial designWater pipe

The invention provides a method and a device capable of realizing diversion automatic detection and cyclic utilization of sanitary wastewater, belonging to the technical field of energy conservation and environmental protection as well as water conservation and pollution reduction. According to the method and the device, a magnetic valve controlled through the manner of setting the electric conductivity is used, so that the automatic detection on the diversion of high-pollution wastewater and low-pollution wastewater is realized, and the low-pollution wastewater enters a water storage tank through diversion for recycling. Through the special design of the water storage tank, tap water can be automatically replenished to the water storage tank when the recycled water amount is insufficient. A user can select whether to fill the water storage tank with recycled water or tap water, and if the recycled water is not selected or the residual recycled water is available, the recycled water can flow into a water inlet pipe of the lower-layer water storage tank through a diversion pipe or an overflow pipe for recycling. The sufficient recycled water amount is guaranteed by collecting rainwater, and disinfection, deodorization and decoloration are realized by adding with medicinal agents. The recycled water is supplied to a water tank of a closestool or directly supplied to the closestool, so that the utilization of the recycled water is realized, therefore, a plurality of purposes including the diversion automatic detection on the water quality, the cyclic recycling, no need of additional power support, the sufficient recycled water amount, and the guarantee on the water quality are successfully realized.

Owner:叶昌阳

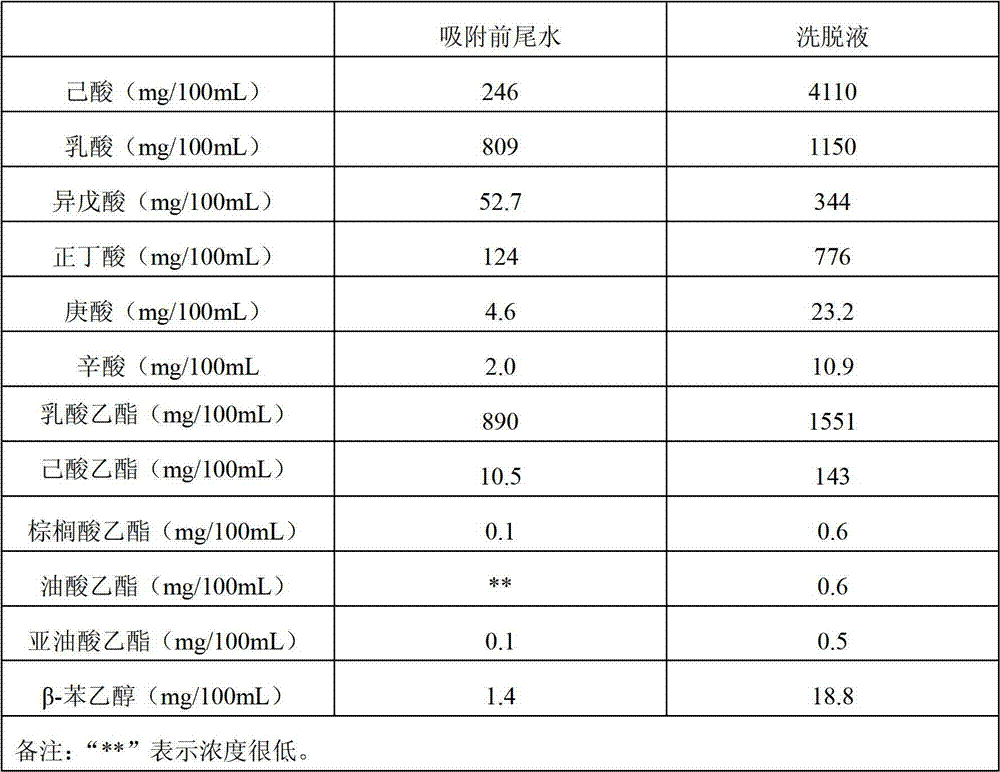

Method for recycling tail water of brewing wastes

ActiveCN102766554AReduce waste water dischargeImprove use valueBy-product recoveryAlcoholic beverage preparationChemistryBrewing

The invention relates to a method for recycling tail water of brewing wastes, belonging to the technical fields of brewing and environment protection. The invention aims at providing a method for extracting trace components for wine from the tail water of the brewing wastes. The method for extracting the trace components for wine from the tail water of the brewing wastes comprises the following steps: filling porous substances to a column to be used as an adsorption column, passing the tail water by the adsorption column, eluting by wine, non-toxic alcohol or ester as an eluent, and collecting the eluate. According to the invention, the available components in the tail water are extracted in a pure physical process by the method, so that the method has an important application value in the brewing industry.

Owner:SICHUAN YIBIN WULIANGYE GROUP +1

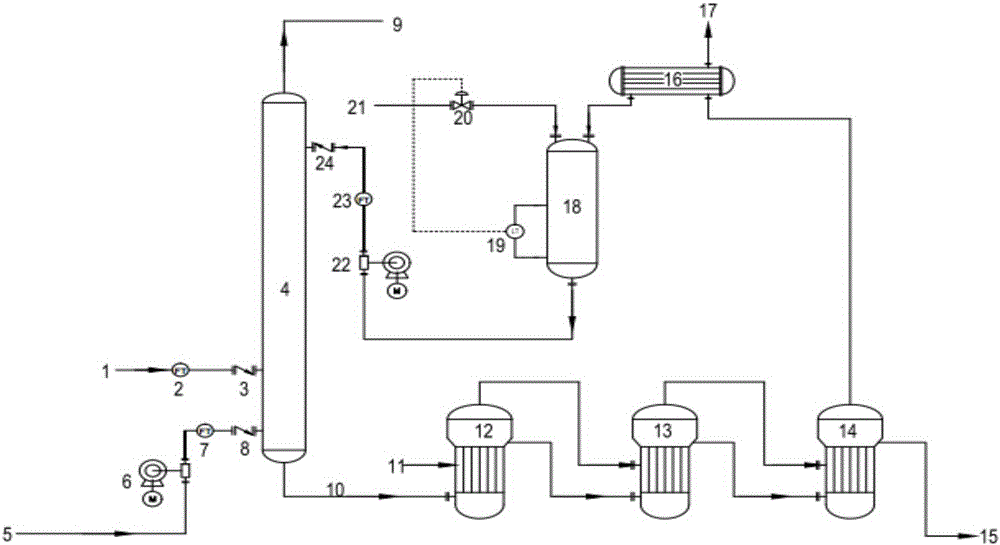

Grease high-pressure hydrolysis production method and production device by recycling sweet water

InactiveCN105255594AReduce waste water dischargeReduce sewage treatment costsFatty acids production/refiningNon-miscible liquid separationTriple effectChemistry

The invention relates to a grease high-pressure hydrolysis production method and a production device by recycling sweet water, and aims to provide the method and the device to effectively reduce waste water discharge. The technical scheme is characterized in that the grease high-pressure hydrolysis production method by recycling the sweet water comprises the following steps that (1) process water and grease countercurrent meet in a hydrolysis tower; (2) fatty acid and glycerin are generated; (3) the fatty acid with small density is discharged from the top part of the hydrolysis tower, and the sweet water with large density is discharged from the bottom part of the hydrolysis tower; (4) crude glycerin is obtained, and steam becomes evaporator condensate; (5) the evaporator condensate is recycled to replenish the process water. The grease high-pressure hydrolysis production device by recycling the sweet water comprises the hydrolysis tower and a triple effect evaporator, wherein a grease inlet, a high pressure steam inlet and a process water inlet are respectively formed in the hydrolysis tower; a condenser and a condensate water collecting tank are sequentially connected between a steam outlet of the triple effect evaporator and the process water inlet of the hydrolysis tower; the triple effect evaporator is also provided with a discharge hole for discharging the crude glycerin.

Owner:HANGZHOU OIL & FAT CHEM +1

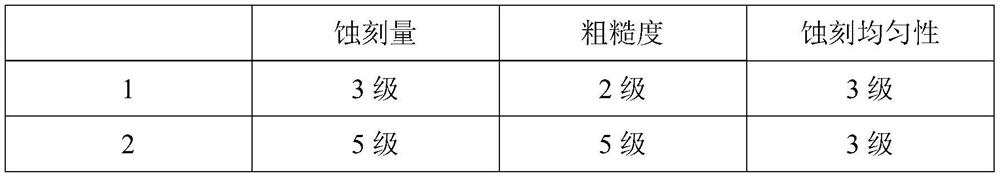

Copper surface roughening agent capable of being electrolytically regenerated and recycled and preparation method thereof

InactiveCN112323068AReduce waste water dischargeIncreased diffusion rateActive agentSurface-active agents

The invention relates to the technical field of metal etching, in particular to a copper surface roughening agent capable of being electrolytically regenerated and recycled and a preparation method thereof. The coarsening agent can be used for coarsening a copper surface in the manufacturing process of a PCB and an FPC and can be recycled and regenerated in an electrolysis mode to reduce wastewater discharge in an existing operation mode. Ferric iron and the copper surface are promoted to be in contact to generate a redox reaction by using ferric salt in the environment of an inorganic acid aqueous solution, part of copper atoms on the copper surface generate divalent copper ions and dispersed in the roughening agent to generate etching, an applicant finds that by adding a surfactant and the like, the diffusion rate of ferric iron to the copper surface can be increased, the dispersion of the bivalent copper ions into the solution can be promoted, and the etching amount at normal temperature within a short time can be increased; and by selecting proper accelerators, inhibitors and the like, the roughness and the uniformity degree of etching are favorably regulated and controlled, and the adhesion force and the adhesion stability of the copper surface are favorably improved.

Owner:深圳市煜杰兴电子材料有限公司

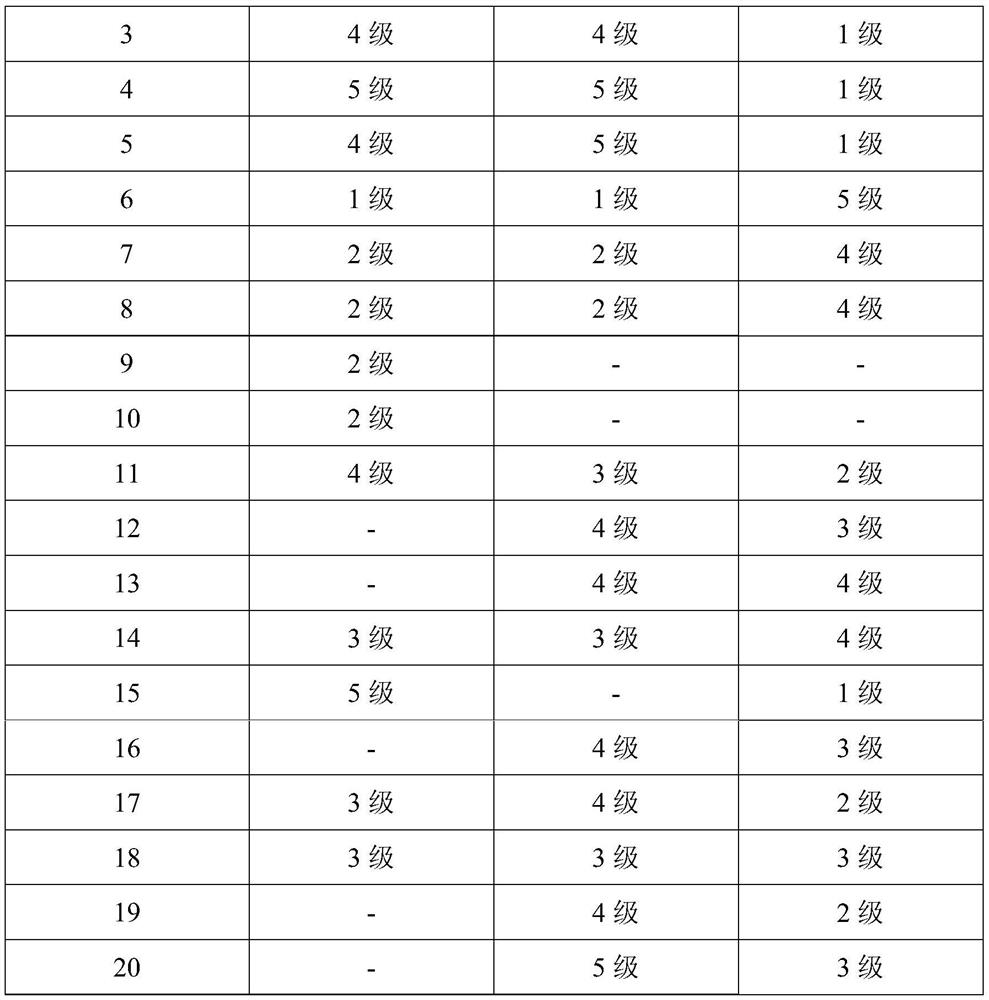

Device and method for optimizing power plant condensate polishing operation control

PendingCN106745406AReduce waste water dischargeImprove water qualityWater treatment parameter controlWater/sewage treatmentAutomatic controlSaline water

The invention discloses a device and method for optimizing power plant condensate polishing operation control. A bypass adjustment automatic control system is additionally mounted on a condensate polishing equipment bypass, the opening degree of a control valve is automatically adjusted according to water quality measurement results of condensate and condensate polishing effluent and set condensate polishing effluent quality control standards, full-flow polished condensate of a certain ratio is enabled to flow through a bypass system, and the operation burden of condensate polishing equipment can be alleviated. Compared with a conventional full-flow condensate polishing operation control mode, the method and the device are capable of greatly alleviating the operation burden of the condensate polishing equipment, prolonging the operation cycle of condensate polishing, reducing the acid-alkali consumption, the desalting water consumption and the wastewater discharge amount in frequent regeneration of the condensate polishing system, alleviating the operation intensity of operators and improving the water quality of a power plant, and have remarkable effects of energy conservation and consumption reduction.

Owner:XIAN THERMAL POWER RES INST CO LTD

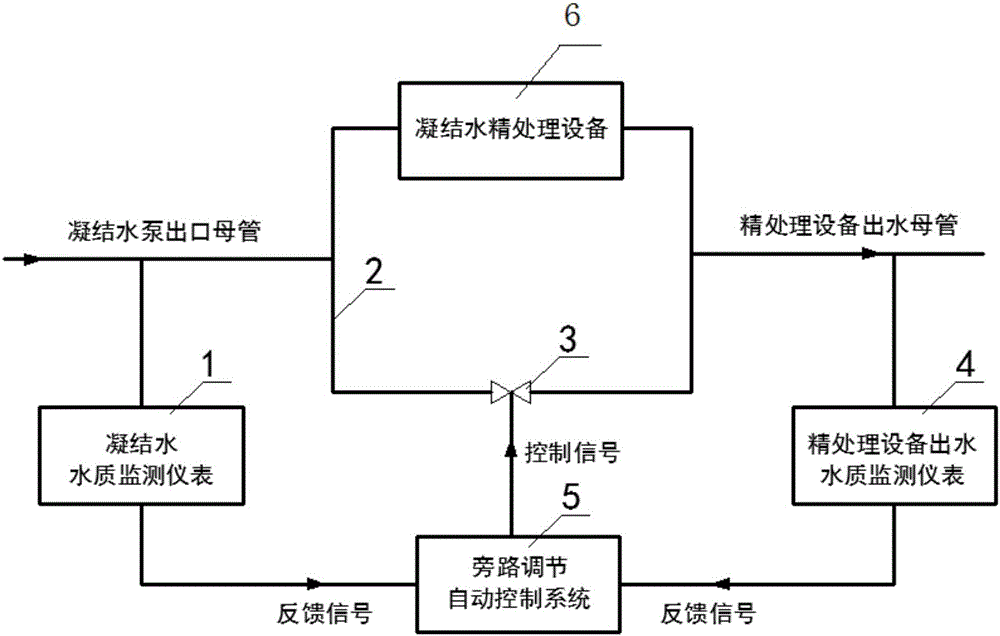

Process for recycling NaNO3 multilevel leaching liquid prepared by saltier ore

ActiveCN101306823ALess water consumptionReduce waste water dischargeAlkali metal nitratesPre treatmentSodium nitrate

The invention relates to a method for recycling multistage leaching solution and washing solution in NaNO3 extraction process by leaching of pretreated sodium nitrate ores. The pretreated sodium nitrate ores are leached, and then the leaching solution is reused in a next stage of leaching process after cold crystallization. Because the leaching solution and other working fluids are recycled, the waste discharge amount is less, even that the product washing solution from the last stage can be normally discharged to a salt field, evaporated, concentrated and recycled. The inventive method takes full use of the washing solution and the cold separation solution; and has the advantages of reduced water consumption, reduced amount of wastewater discharge, reduced amount of tail washings to be discharged to the salt field, reduced construction area of the salt field, reduced investment, reduced production cost, simple process, and easy operation.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS +1

Semiconductor processing device

ActiveCN103187240AReduce dosageReduce waste water dischargeSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringTransducer

The invention discloses a semiconductor processing device which comprises a semiconductor processing module and a fluid transfer module. The fluid transfer module comprises a support frame, a plurality of base plates, various valves, a pump, a meter, a transducer, connectors and pipelines, wherein the base plates are assembled on the support frame and form a fluid space, the various valves, the pump, the meter, the transducer, the connectors and the pipelines are used for transferring fluid, at least one base plate is provided with mounting holes, and each valve is provided with an end portion which is communicated with an end port, penetrates through the base plates and extends into the fluid space. The fluid transfer module has the advantages of being simple in structure, convenient to flexible to assemble and easy to maintain. Further, assemblies can be changed conveniently and the like.

Owner:WUXI HUAYING MICROELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com