Method for comprehensive reuse treatment of rare-earth sodium saponification wastewater

A treatment method, sodium saponification technology, is applied in the field of comprehensive reuse of rare earth sodium saponification wastewater, which can solve the problems of increasing the burden of environmental protection and wasting resources, and achieve the effects of reducing wastewater discharge, reducing water volume, and preventing pollution and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

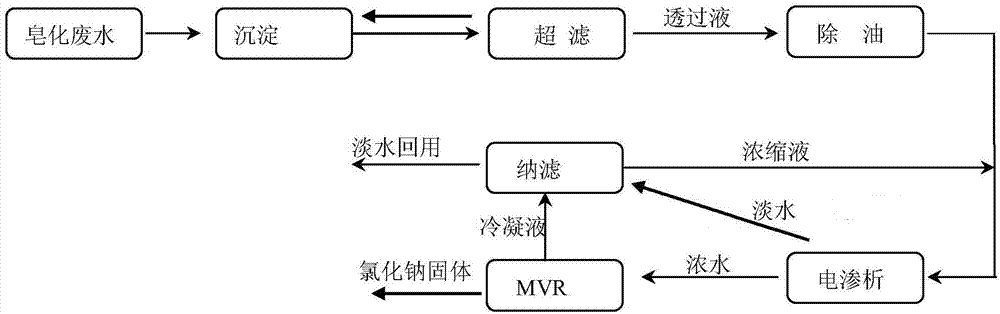

[0031] Referring to the accompanying drawings, the pretreatment of steps (1) and (2) is first performed on the rare earth sodium saponification wastewater entering the process of the present invention: the sodium saponification wastewater is treated with a precipitation and ultrafiltration system, large particles are removed by precipitation, and ultrafiltration is carried out. Filtration (UF) to remove small particle suspended solids and colloids; in step (1), the recovery rate of ultrafiltration is controlled to be more than 95%, and the removal rate of the total suspended solids TSS is more than 90%. The above parameters can also be adjusted according to the needs of subsequent processing. The water produced by the ultrafiltration system enters the treatment in step (2), and the concentrated water enters the sedimentation tank for precipitation. The parameters of product water quality after treatment in step (1) are: NaCl=10-15% (mass percentage), TSS<10mg / L; rare earth ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com