Method for recycling tail water of brewing wastes

A technology of water resources and waste, applied in the field of brewing, can solve the problems of not extracting useful ingredients, etc., achieve the effect of maximum utilization value, reduction of waste water discharge, and improvement of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

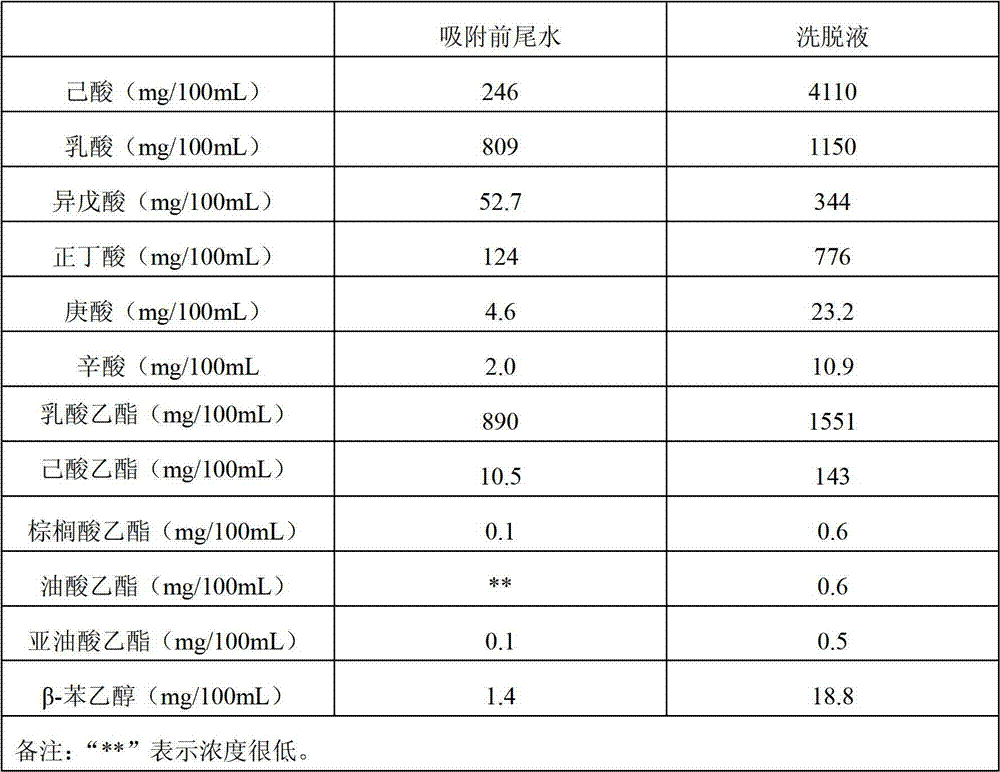

[0015] The method for resource utilization of brewing waste tail water of the present invention comprises the following steps: packing a porous material into a column as an adsorption column, passing the tail water through the adsorption column, using wine, non-toxic alcohol or ester as an eluent to elute, collecting and washing dehydration.

[0016] Wherein, the main component of the porous substance is inorganic carbon, the porosity is not less than 50%, and the specific surface area is not less than 1m 2 / g.

[0017] Wherein, the inorganic carbon is powdered activated carbon or granular activated carbon.

[0018] Among them, the adsorption saturation of the tail water passing through the adsorption column is judged according to the following criteria: the relative difference between the content of the main extracted components in the effluent and the influent after the tail water passes through the adsorption column is less than 5%, which can be considered as adsorption sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com