Heat-resistant copper foil and method for producing same, circuit board, and copper-clad laminate board and method for manufacturing same

A technology of heat resistance and copper foil, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., to achieve excellent high-frequency characteristics, high heat-resistant adhesion, and excellent effects of copper foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

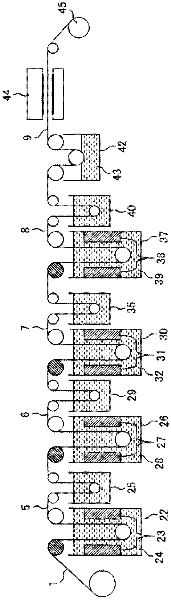

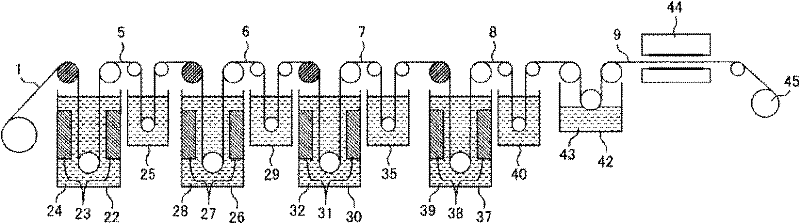

Method used

Image

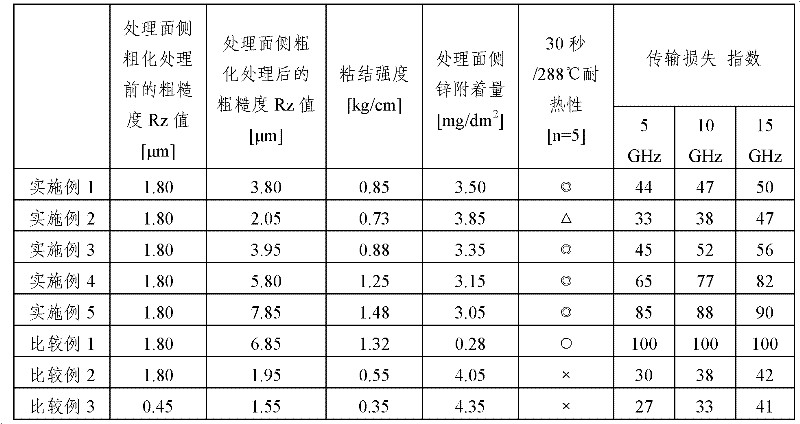

Examples

Embodiment 1

[0064] The following copper foil (electrodeposited copper foil manufactured by Furukawa Electric Co., Ltd.) was used, which was an untreated electrodeposited copper foil with a thickness of 0.035 mm produced under known electrolytic foil production conditions, and the shape of the matte surface side (plating liquid surface side) was rough. The thickness is 1.8 μm in terms of the Rz value specified in JIS-B-0601, and its elongation at normal temperature is 6.2%. On the matte side, surface treatment is applied under the following conditions.

[0065] [Primary Copper Roughening Particle Formation Bath Composition and Treatment Conditions]

[0066] Use copper sulfate, calculated as metallic copper 23.5g / l

[0067] Sulfuric acid·····100g / l

[0068] Use sodium molybdate, calculated as molybdenum 0.25g / l

[0069] Hydrochloric acid, calculated as chloride ion 0.002g / l

[0070] Ferrous sulfate, calculated as metallic iron... 0.20g / l

Embodiment 2

[0098] Using the untreated copper foil used in Example 1, the same roughening and surface treatment as in Example 1 were performed so that the roughness of the obtained surface treatment side was about 2.0 μm in terms of Rz value, and the same as in Example 1 was performed. Evaluation assay. The results are shown in Table 1.

Embodiment 3

[0100] Using the untreated copper foil used in Example 1, the same roughening and surface treatment as in Example 1 were performed so that the roughness of the obtained surface treatment side was about 4.0 μm in terms of Rz value, and the same as in Example 1 was performed. Evaluation assay. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com