Hybrid power automobile gearbox unit cooling system and cooling method

A cooling system and transmission technology, applied in transmission components, gear lubrication/cooling, transmission parts, etc., can solve the problem of inability to meet the precise cooling requirements of the transmission of hybrid electric vehicles, the oil temperature cannot quickly reach the suitable temperature of the transmission, and the speed change The efficiency of the box and its coupling mechanism is low, so as to ensure the cooling quality and efficiency, improve the cooling effect, and achieve the effect of rapid oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

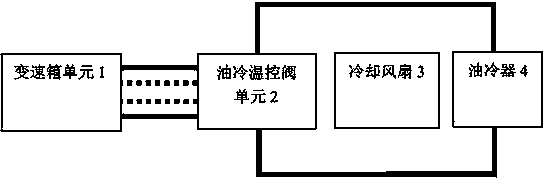

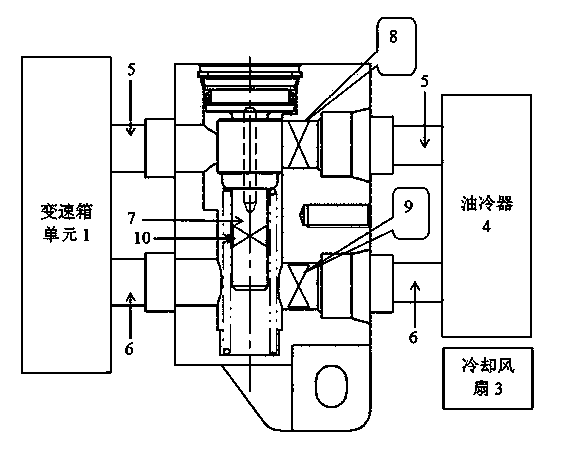

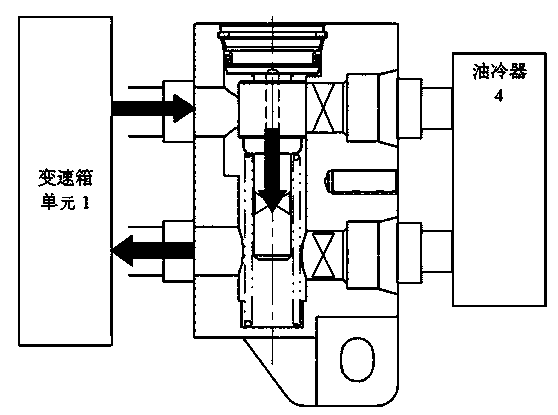

[0028] first combined with figure 1 Illustrate the basic working principle of the present invention, as attached figure 1 As shown, the transmission unit cooling system of the present invention as a whole includes a transmission unit 1, an oil cooling temperature control valve unit 2, an oil cooler 4 and a cooling fan 3, and the oil inlet and outlet of the transmission unit 1 are connected In the oil cooling temperature control valve unit 2, the oil from the gearbox unit flows into the oil cooling temperature control valve unit 2. There is a return flow path inside the oil cooling temperature control valve unit 2. At the same time, the oil cooling temperature control valve unit 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com