Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce crack propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

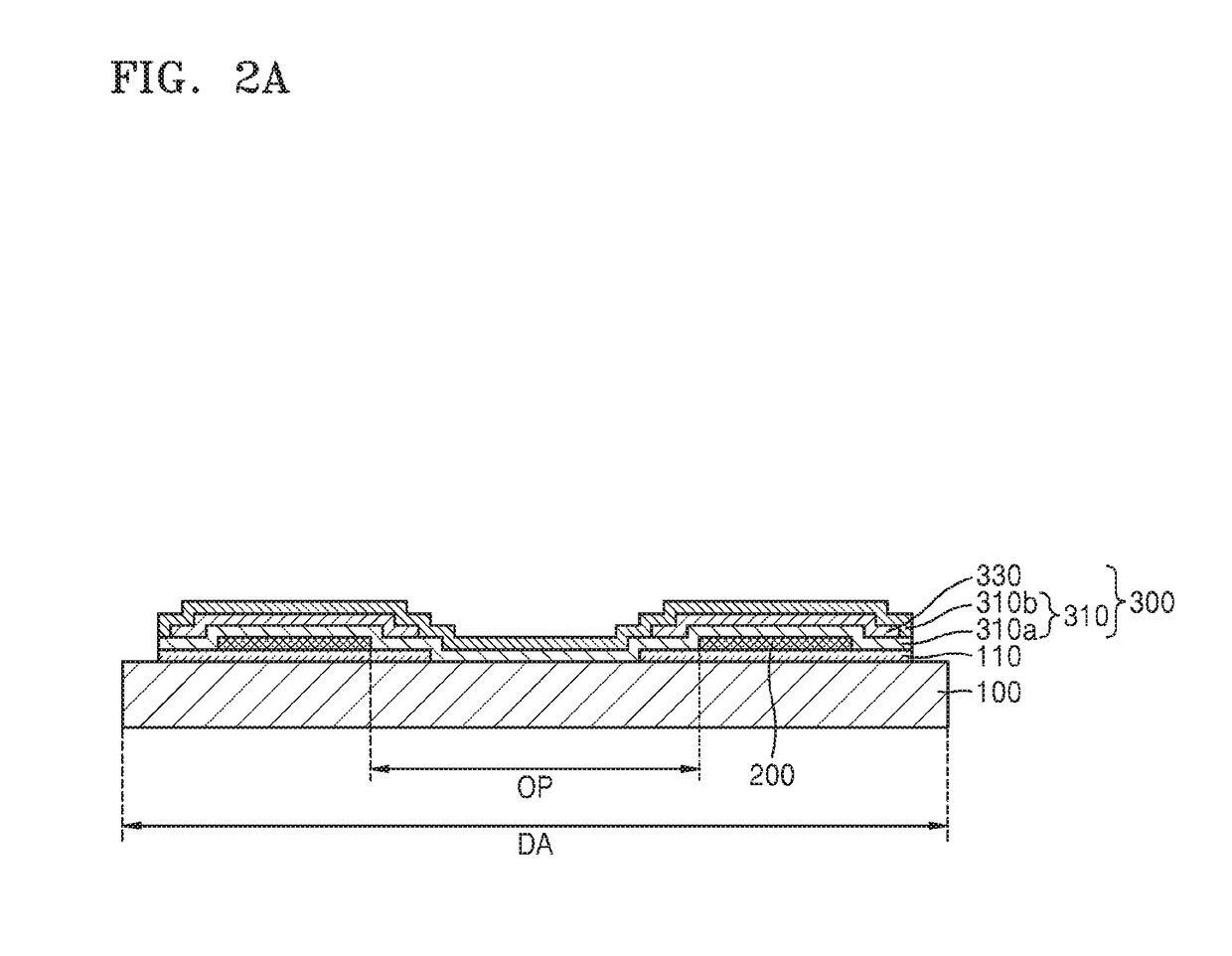

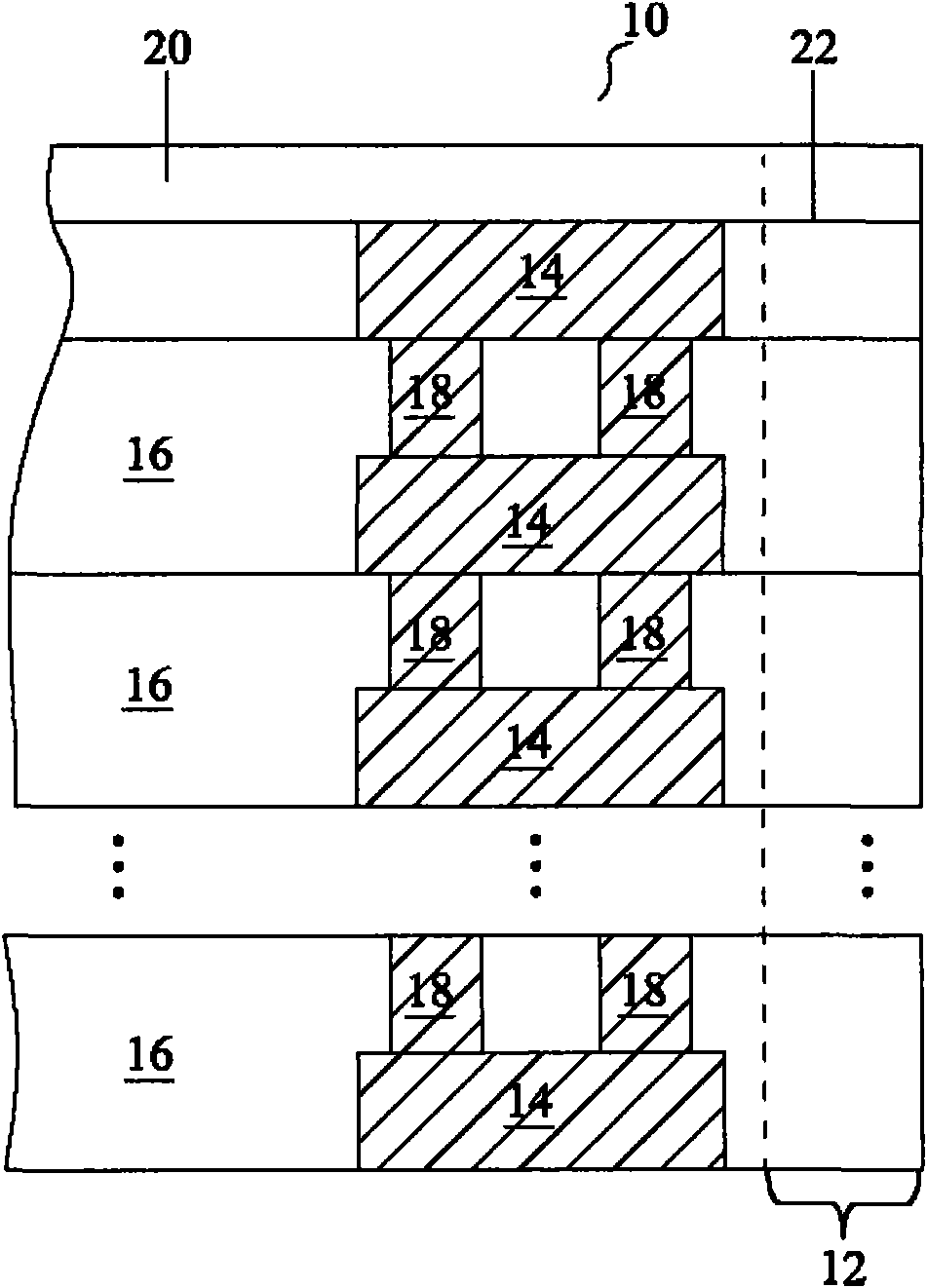

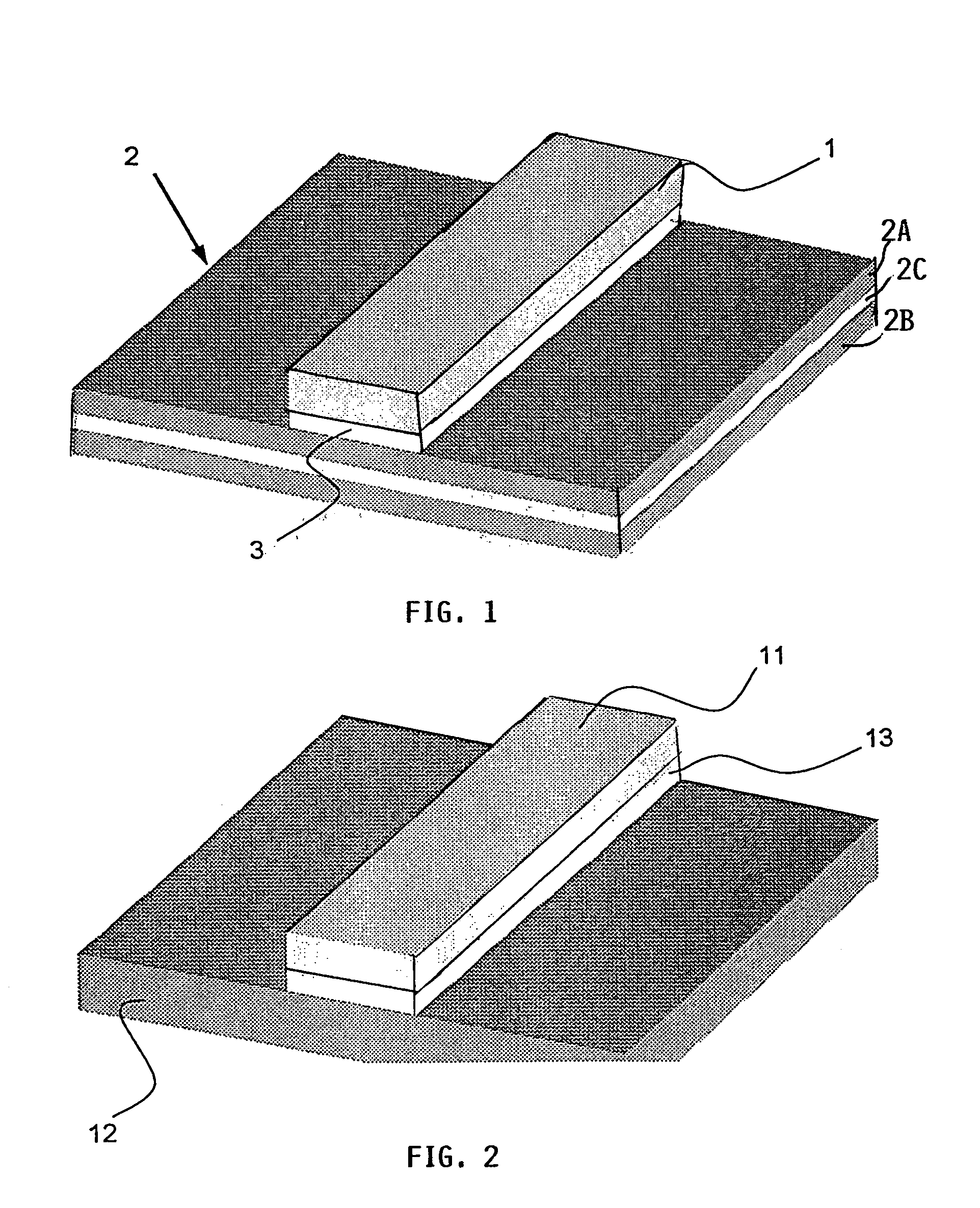

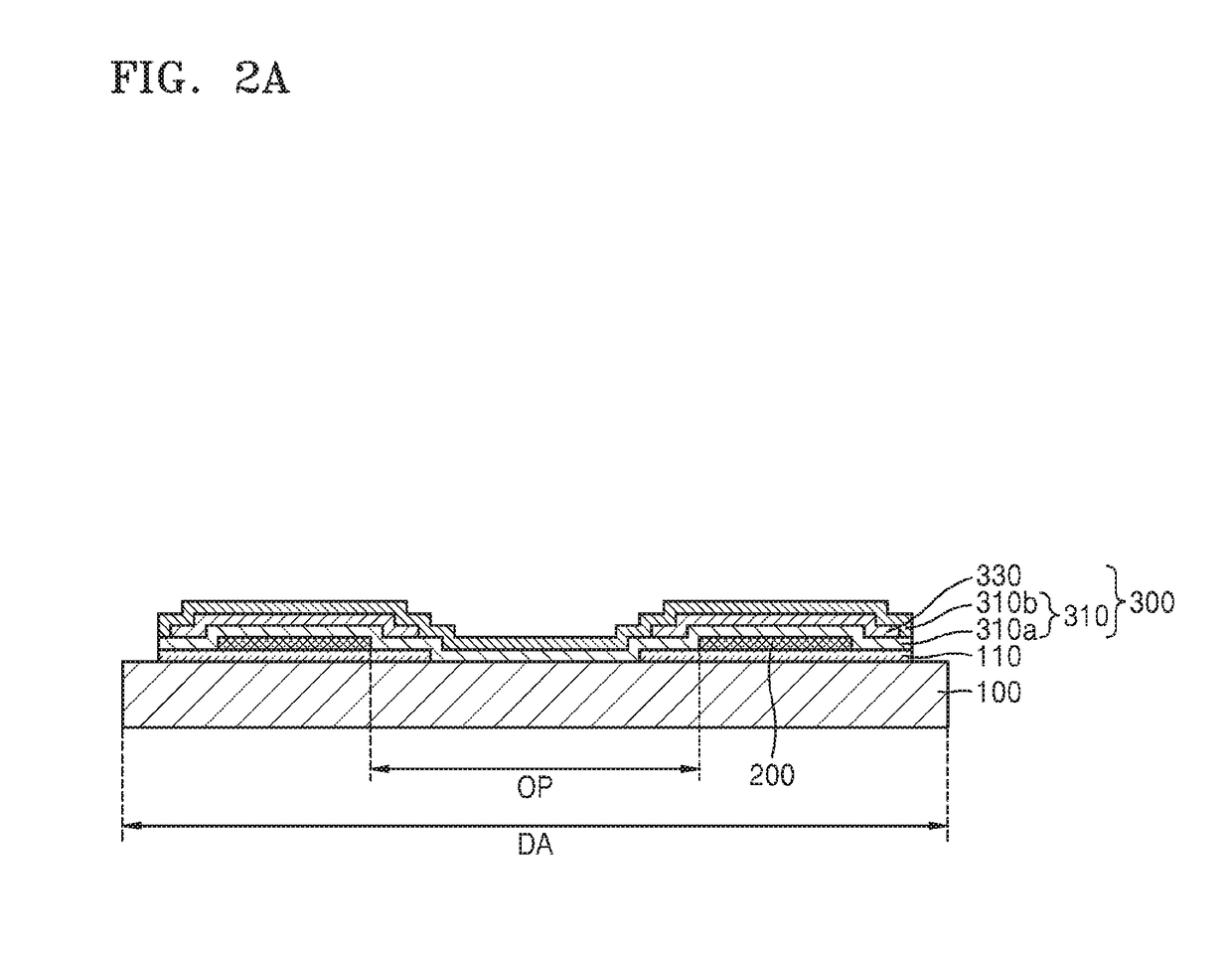

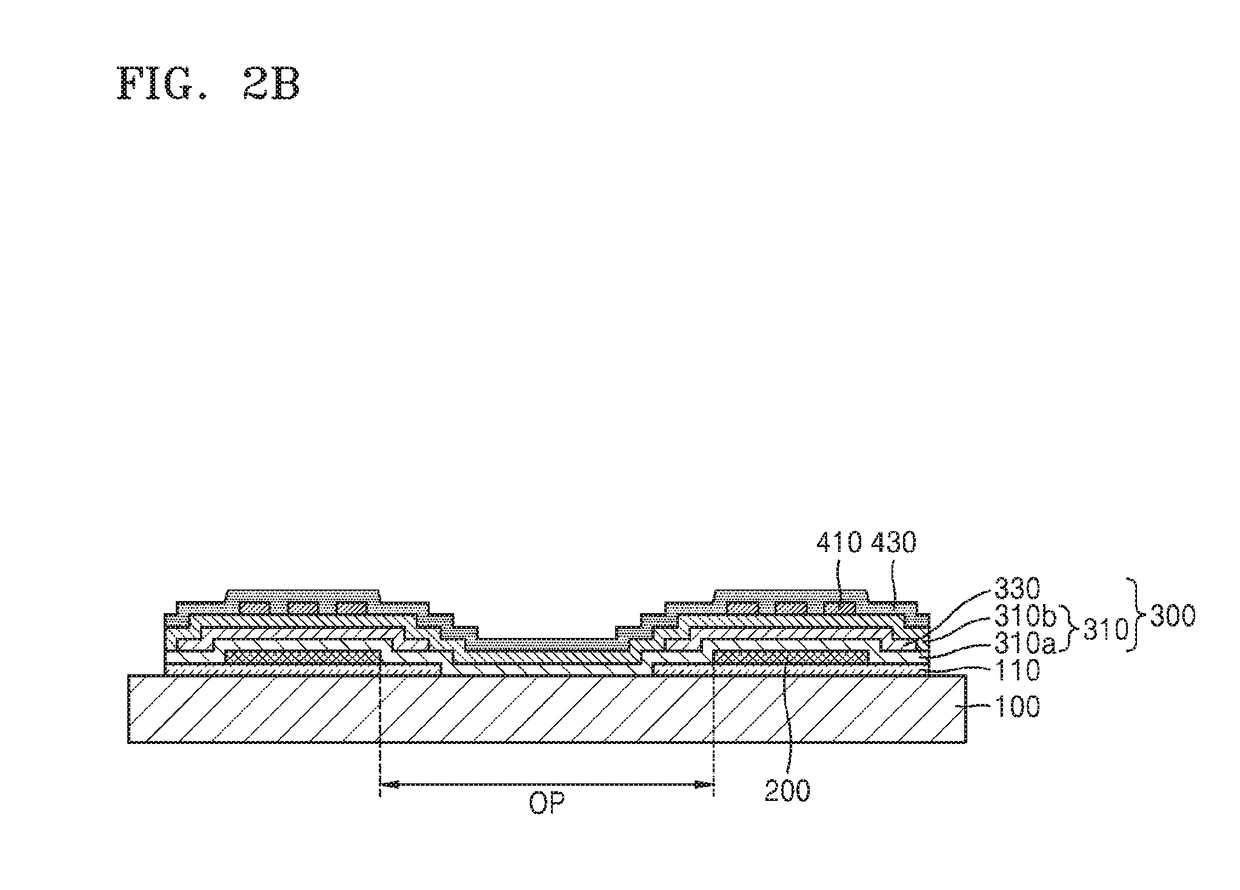

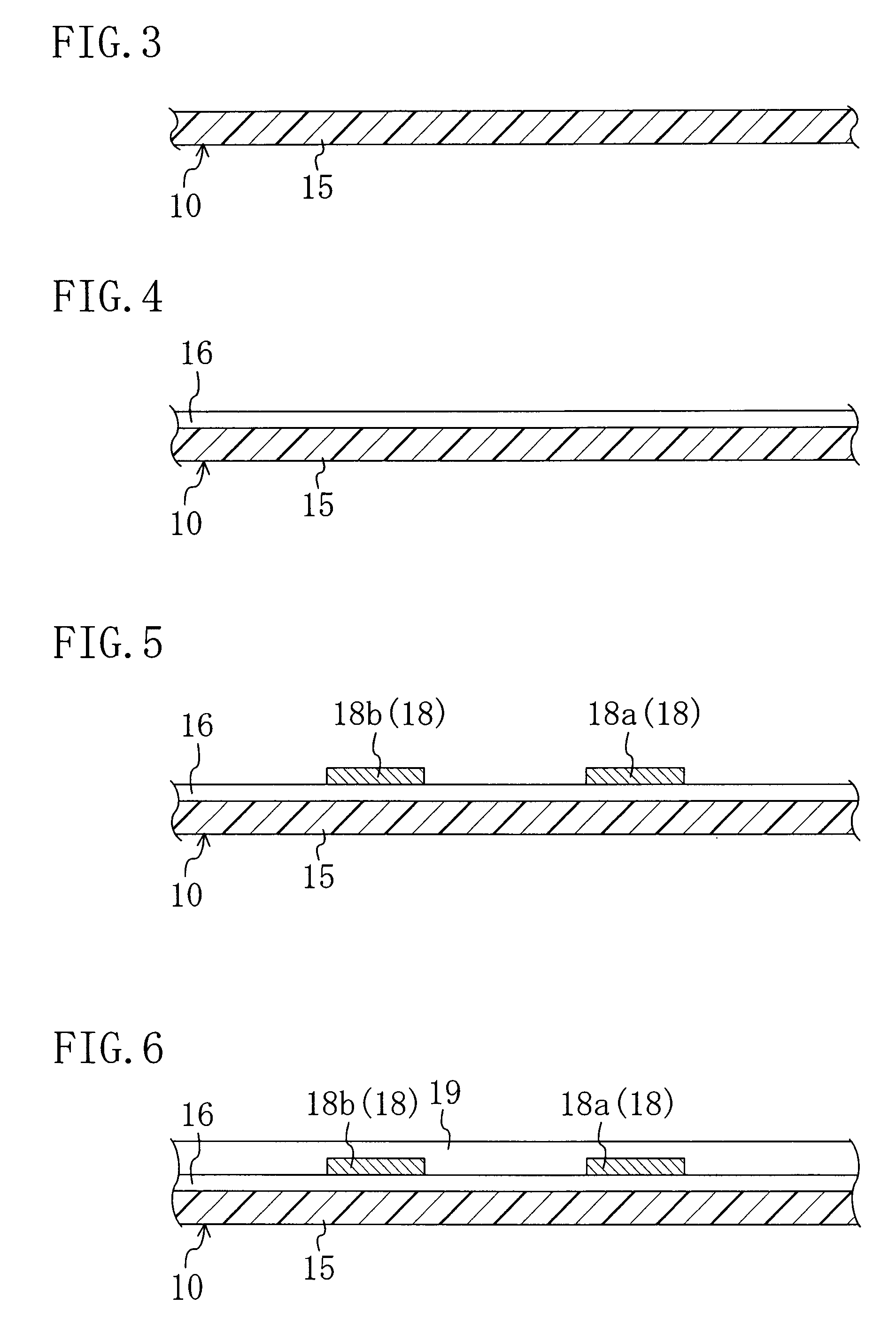

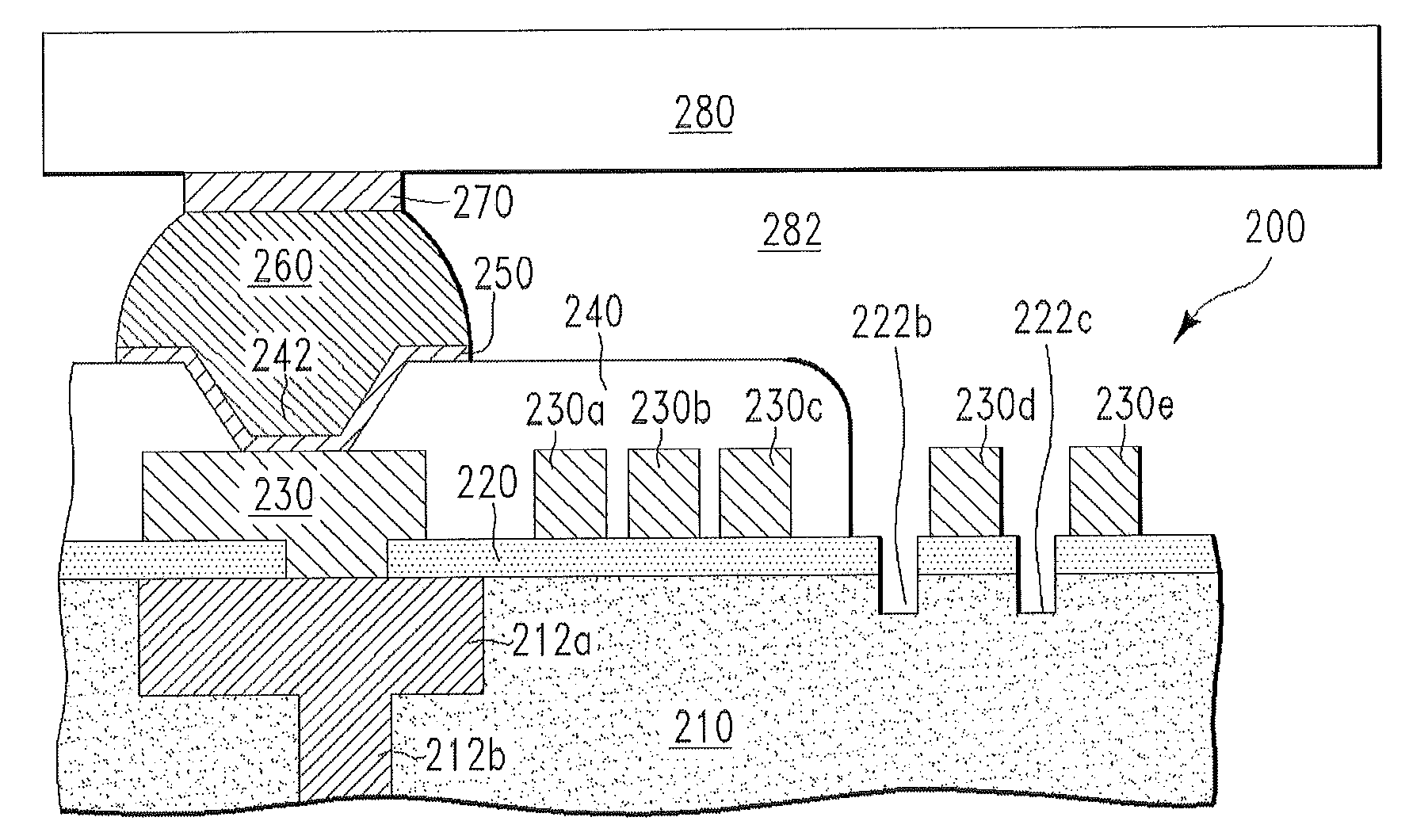

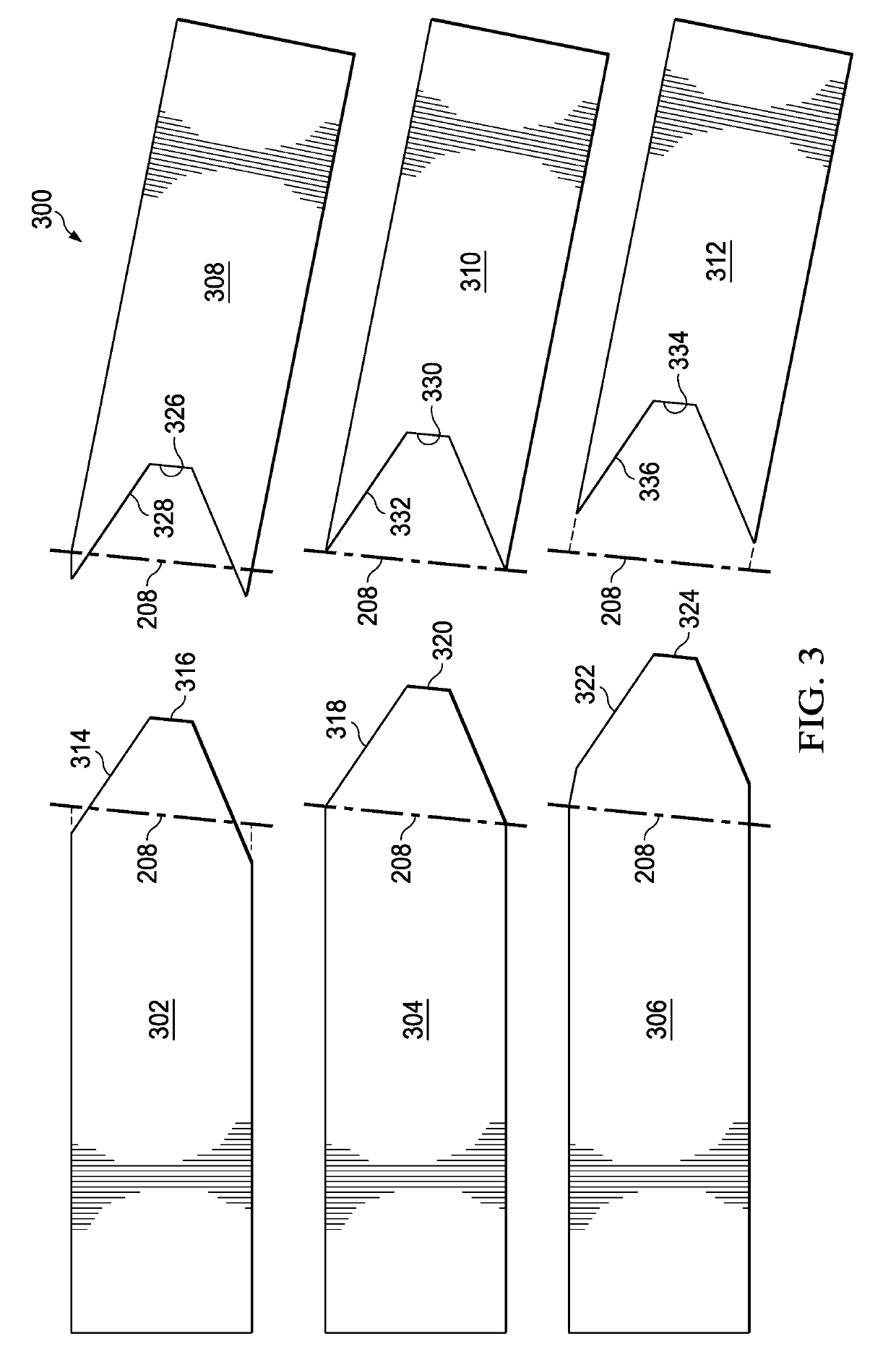

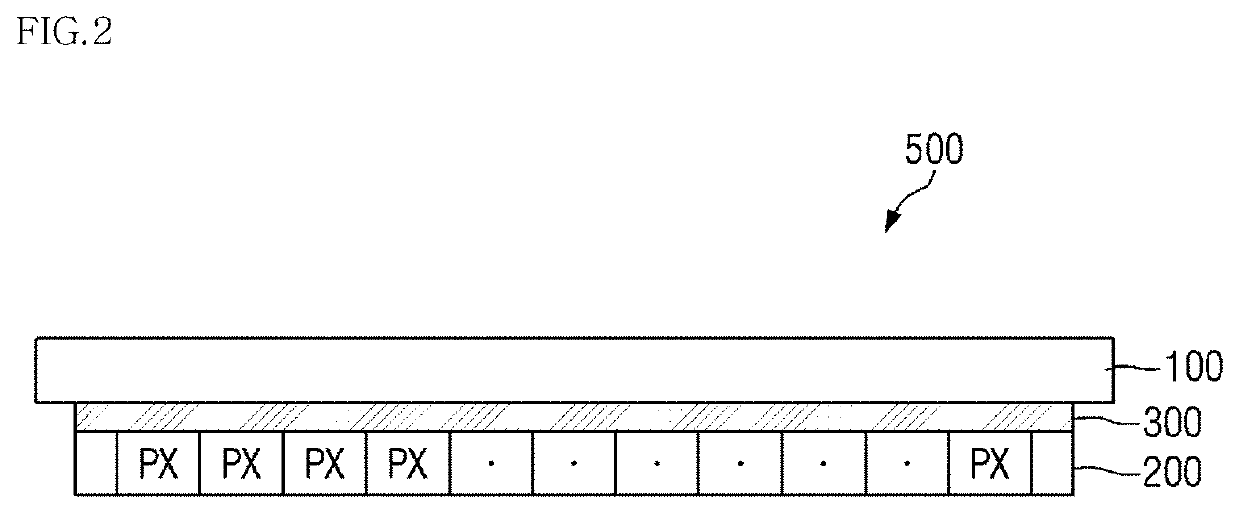

Display apparatus and method of manufacturing the same

ActiveUS20170237037A1Avoid spreadingReduce crackingVisual indicationSolid-state devicesElectrical and Electronics engineeringContact hole

A method of manufacturing a display apparatus includes providing a substrate, forming a display unit defining an opening portion in a display region over the substrate, forming a thin film encapsulation layer to seal the display unit, forming a touch electrode over the thin film encapsulation layer, forming a touch insulating film covering the touch electrode such that the thin film encapsulation layer and the touch insulating film are sequentially stacked and formed over the substrate in the opening portion, forming a touch contact hole by removing a portion of the touch insulating film to expose a portion of the touch electrode, and removing a portion of the touch insulating film and a portion of the thin film encapsulation layer formed in the opening portion to expose a portion of the substrate during the forming of the touch contact hole.

Owner:SAMSUNG DISPLAY CO LTD

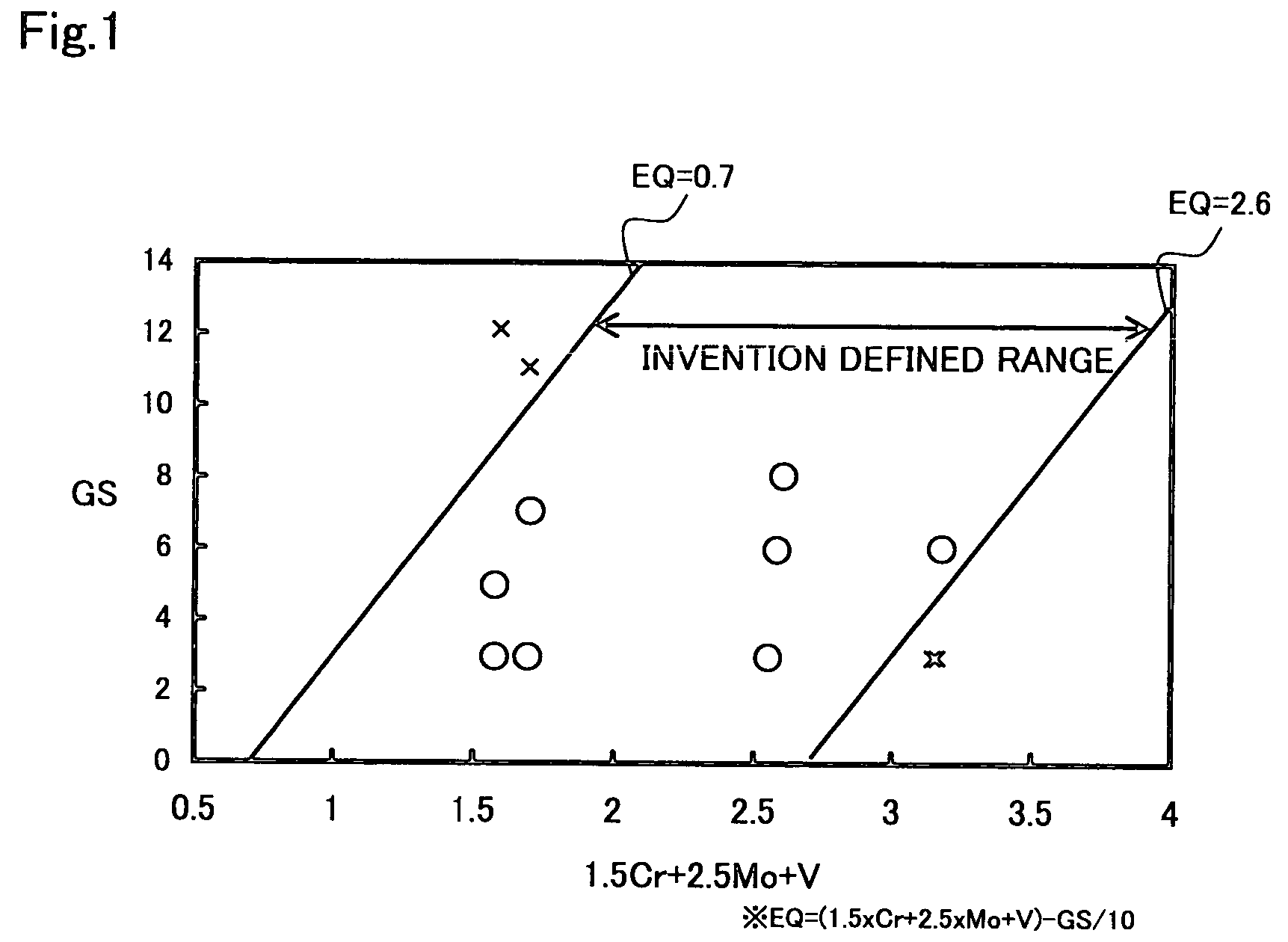

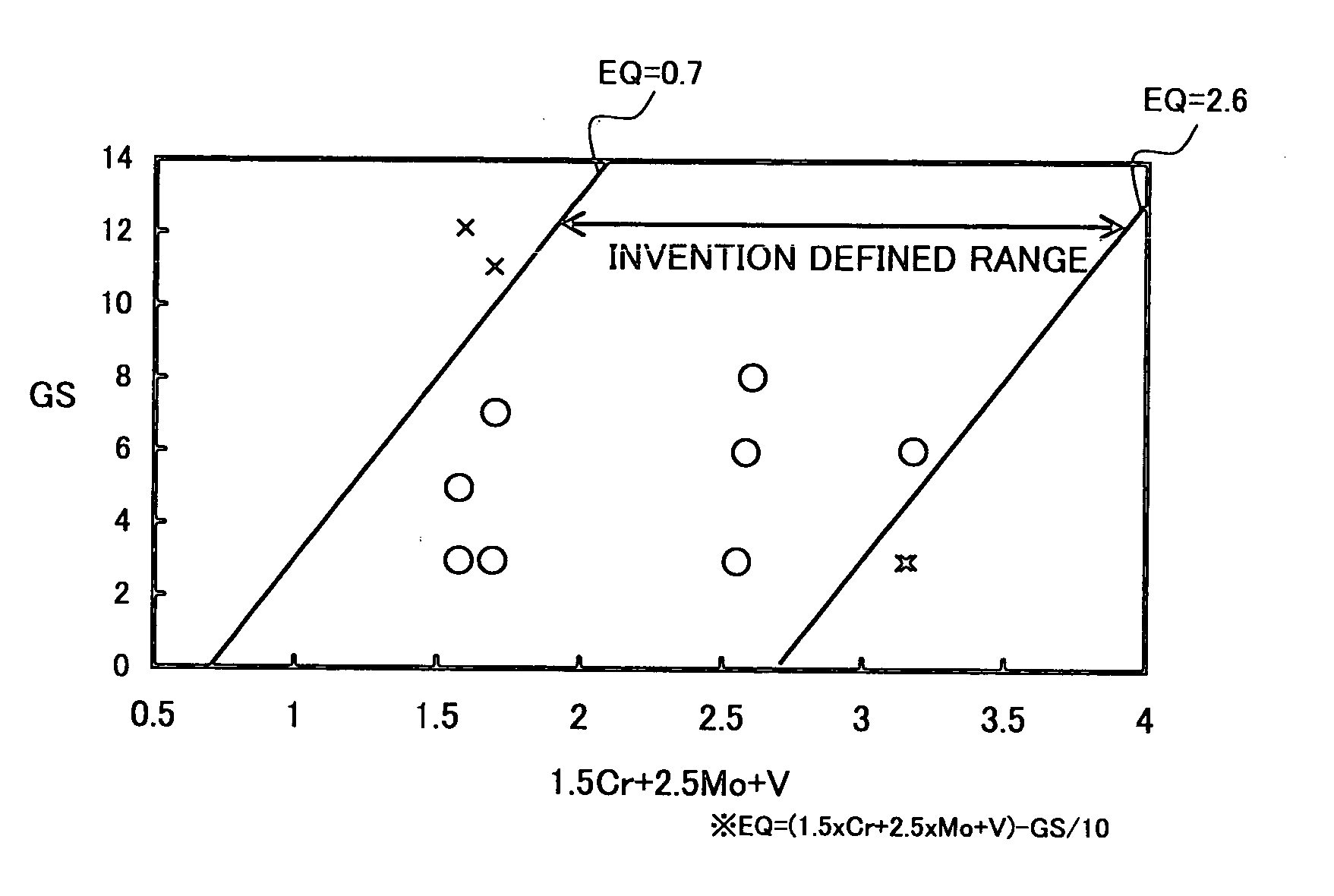

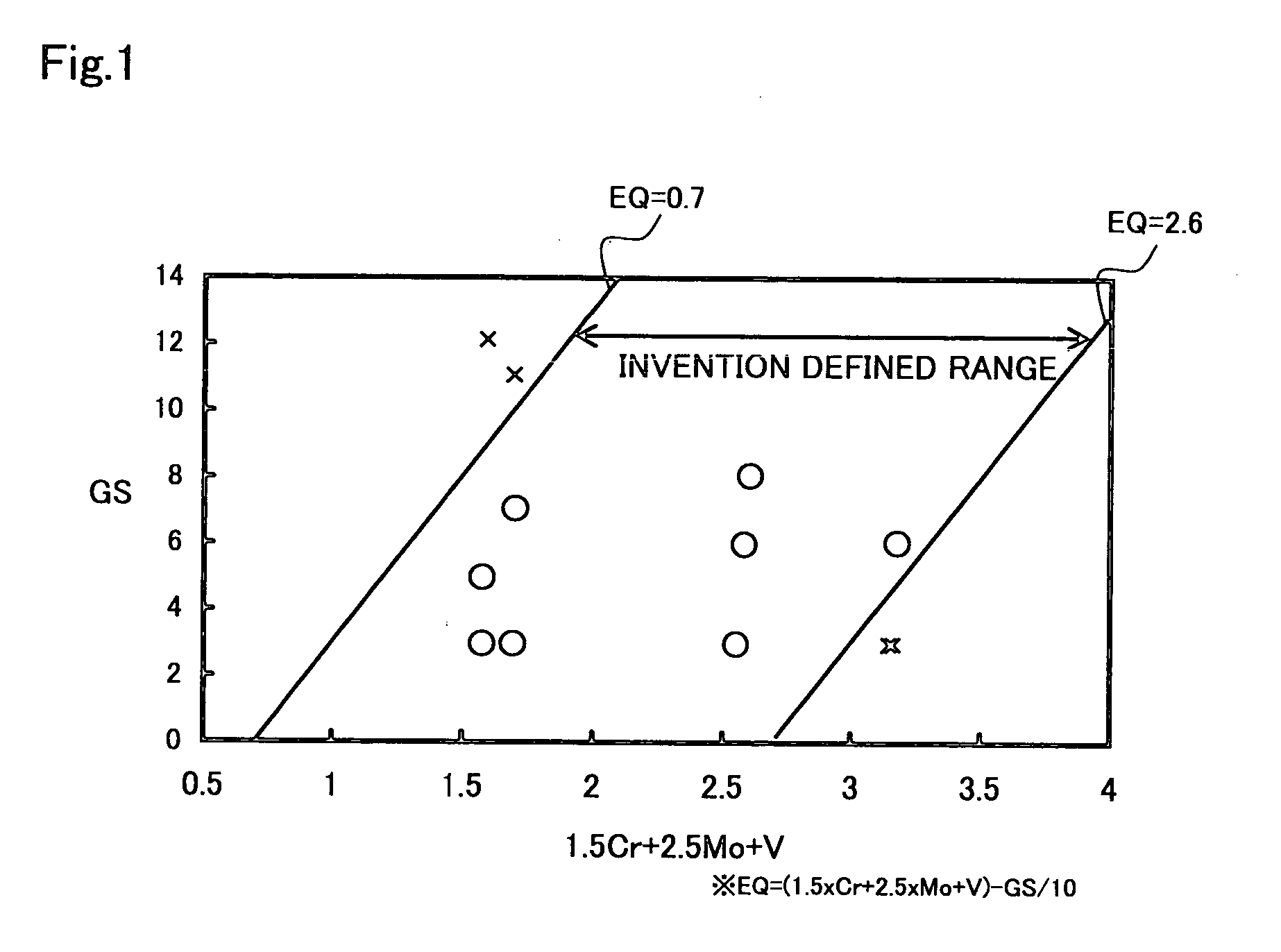

Steel product for oil country tubular good

ActiveUS7083686B2Increase resistanceReduce crack propagationHeat treatment process controlImpurityMaterials science

A steel product for oil country tubular good according to the invention comprises, in mass %, 0.10% to 0.35% C, 0.10% to 0.50% Si, 0.10% to 0.80% Mn, up to 0.030% P, up to 0.010% S, 0.30% to 1.20% Cr, 0.20% to 1.00% Mo, 0.005% to 0.40% V, 0.005% to 0. 100% Al, up to 0.0100% N, up to 0.0010% H, 0 to 0.01% Ca, 0 to 0.050% Ti, 0 to 0.050% Nb, and 0 to 0.0050% B, and the balance of Fe and impurities. The Cr, Mo, and V contents and the grain size GS satisfy expression (1):0.7≦(1.5×Cr+2.5×Mo+V)−GS / 10≦2.6 (1)

Owner:NIPPON STEEL CORP

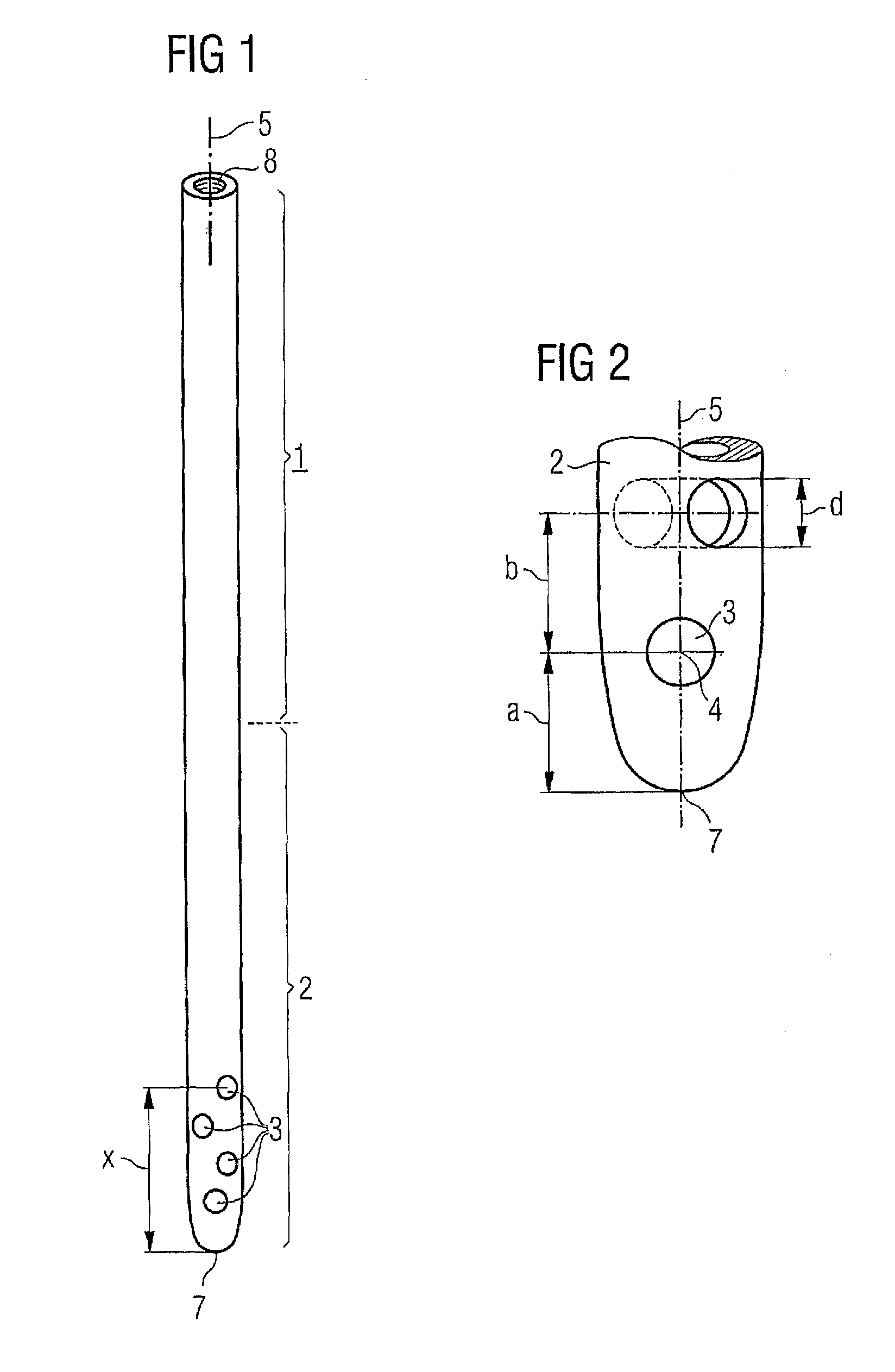

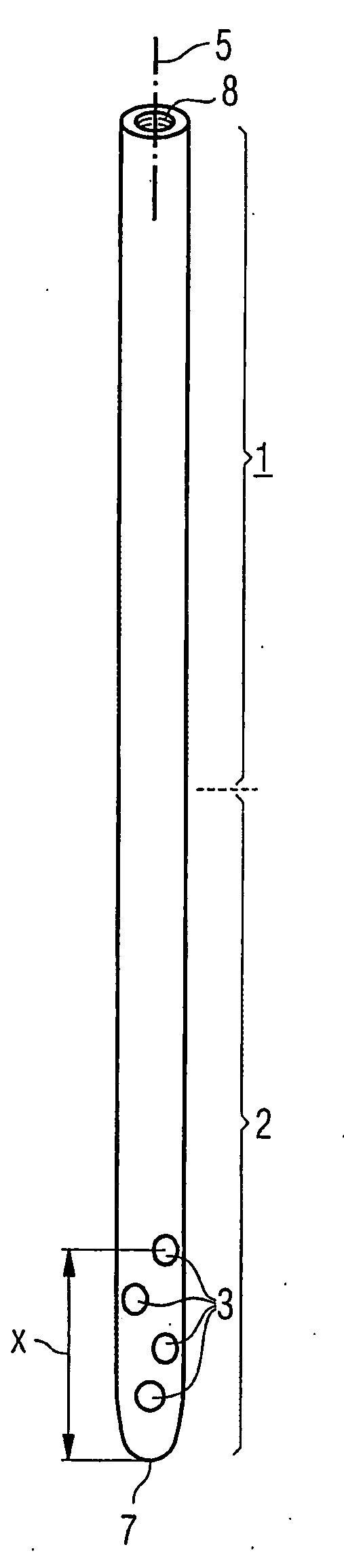

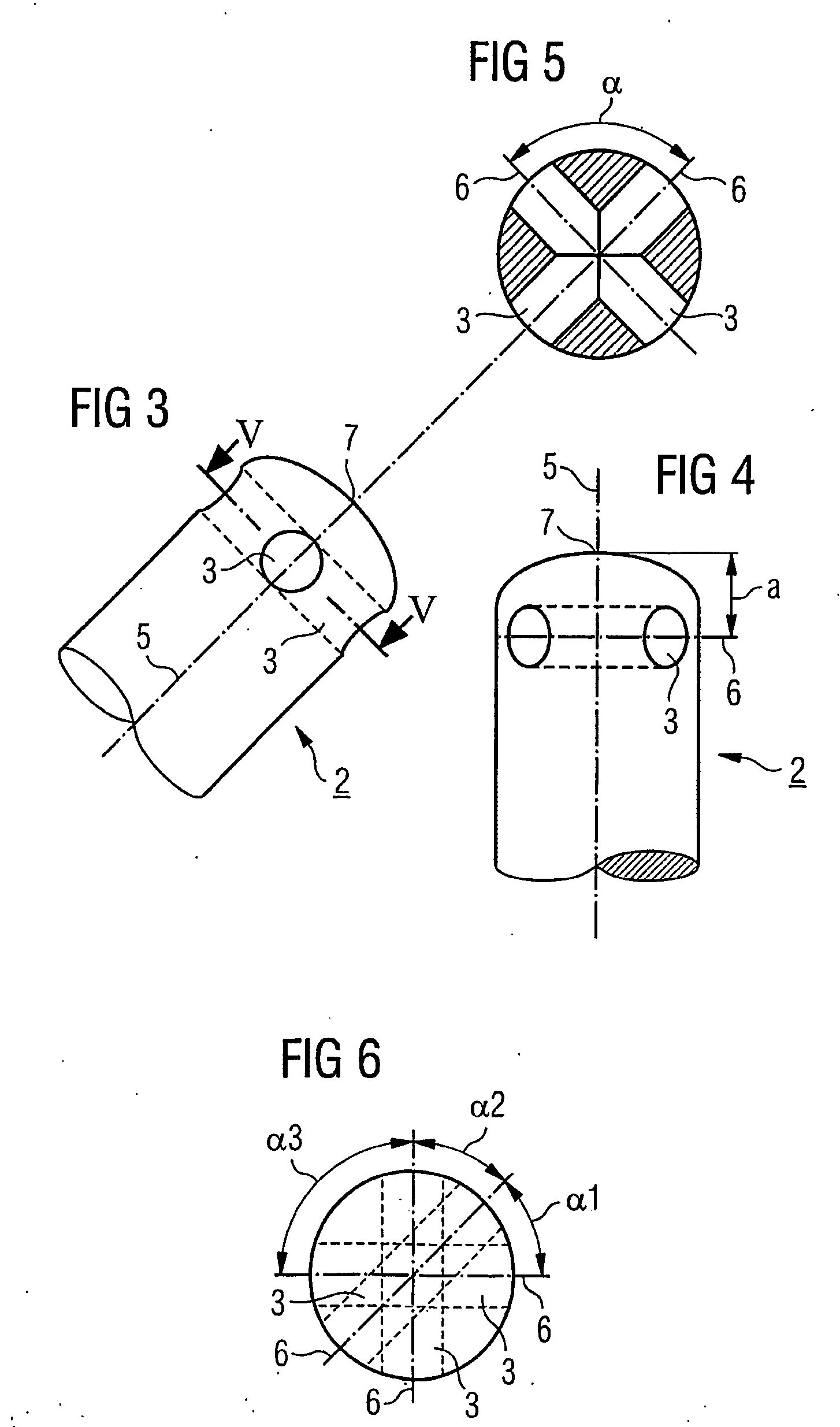

Intramedullary nail

ActiveUS8083742B2Increase surface contact areaStorage much simpler and less costlyInternal osteosythesisJoint implantsBiomedical engineeringInsertion device

Owner:AO TECH AG

Protection sealing ring used for preventing stress caused by cutting die

ActiveCN101615598AReduce crack propagationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention provides a semiconductor chip, comprising a semiconductor substrate; a plurality of low-k dielectric layers above the semiconductor substrate; a first passivation layer above a plurality of the low-k dielectric layers; and a second passivation layer above the first passivation layer. A first sealing ring is adjacent to an edge of the semiconductor chip, and the first sealing ring has an upper surface that is basically parallel and level with a bottom surface of the first passivation layer. The second sealing ring is adjacent to the first sealing ring and located at the inner side of the semiconductor chip. The second sealing ring comprises a bonding pad ring in the first passivation layer and the second passivation layer. A groove ring comprises at least a part that is directly formed above the first sealing ring, and extended downwards from a top surface of the second passivation layer at least to an interface between the first passivation layer and the second passivation layer.

Owner:TAIWAN SEMICON MFG CO LTD

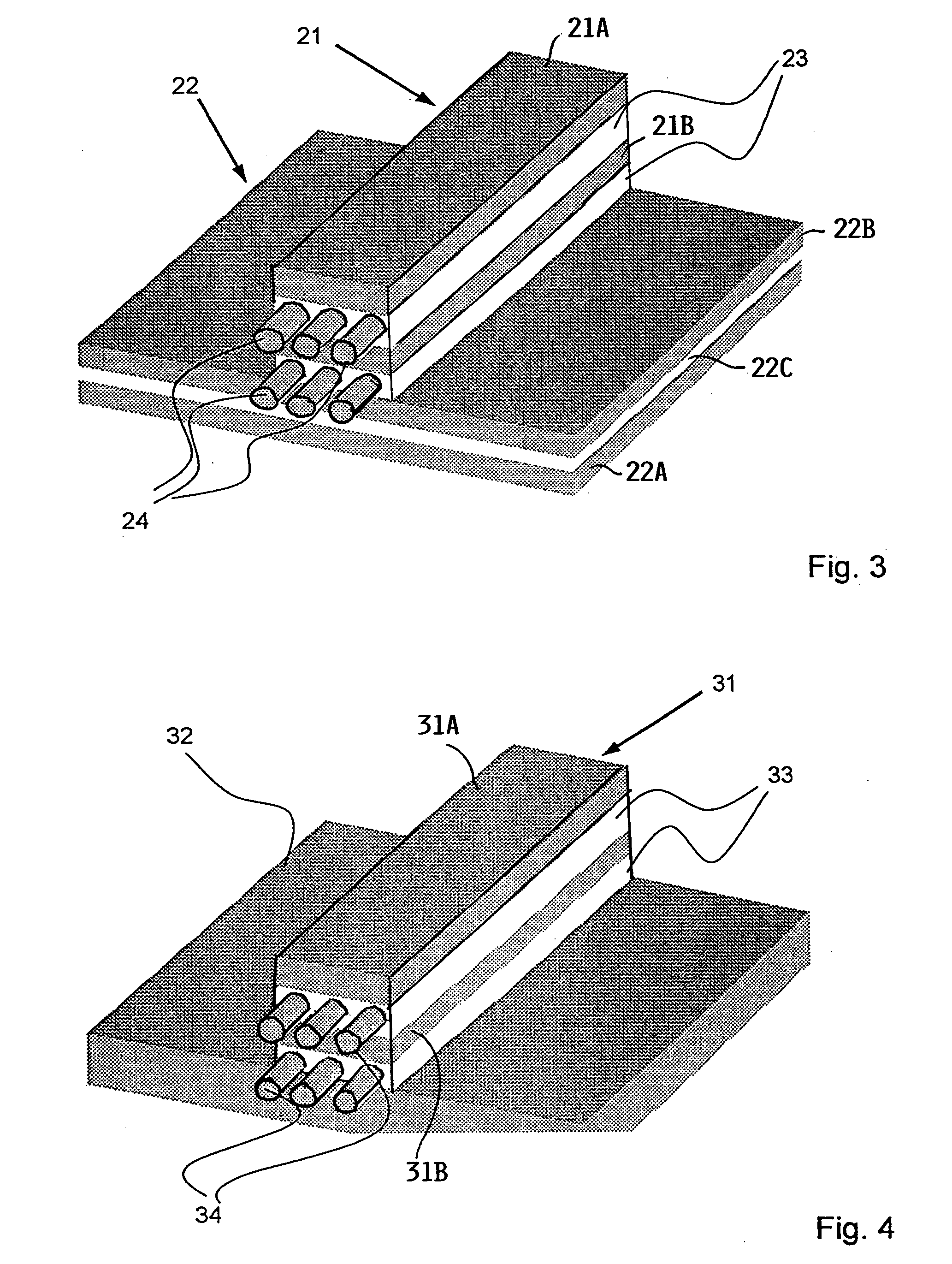

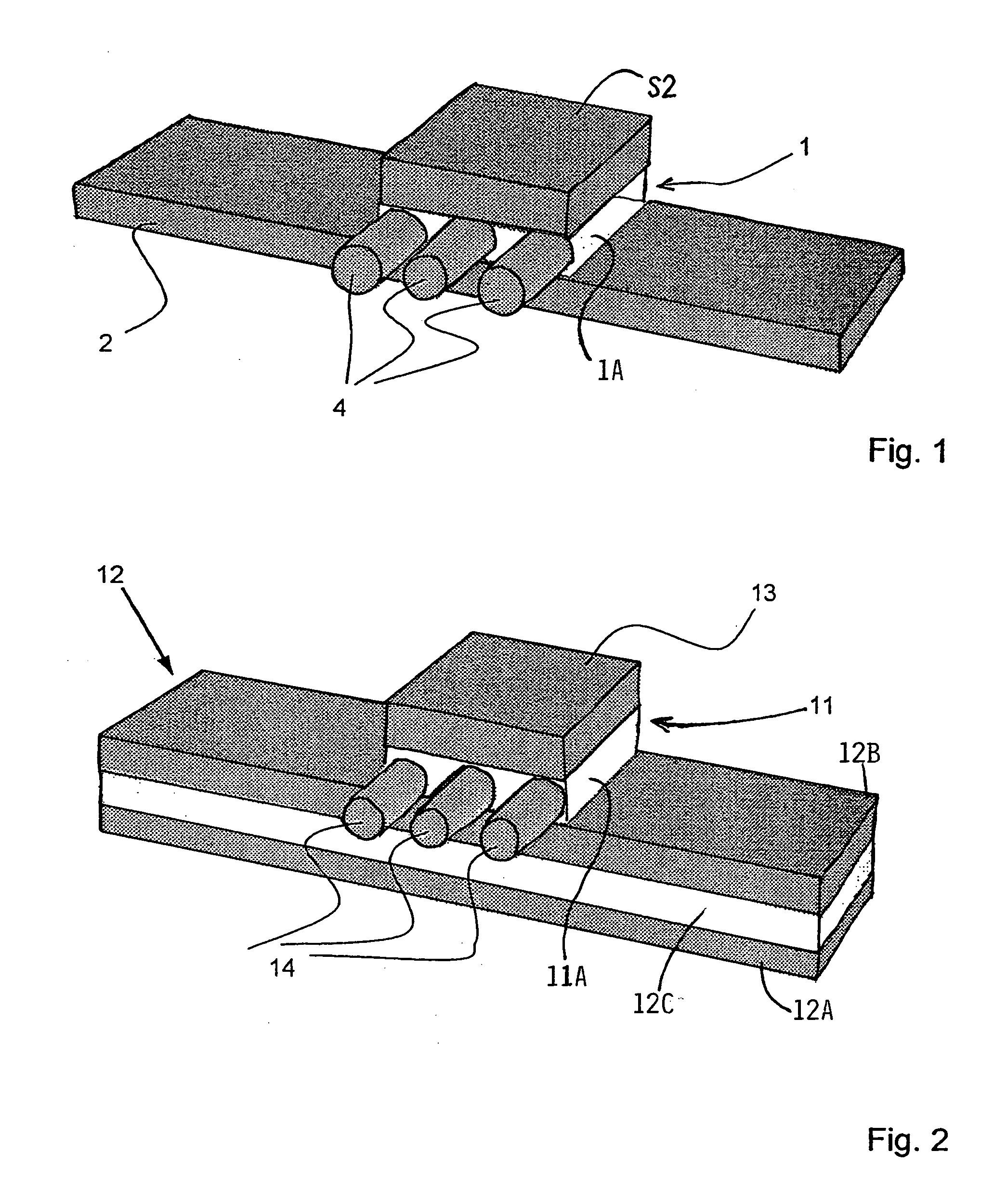

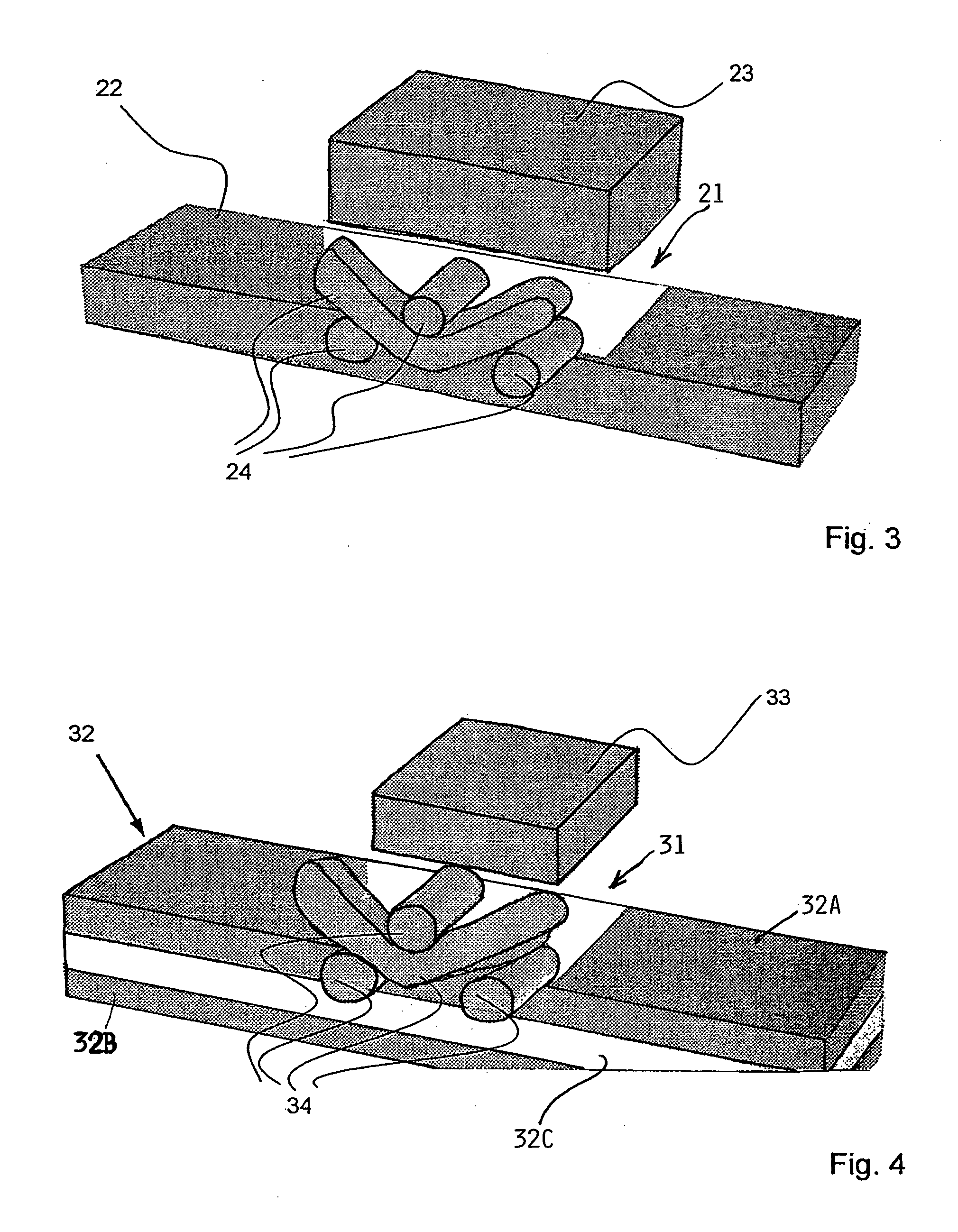

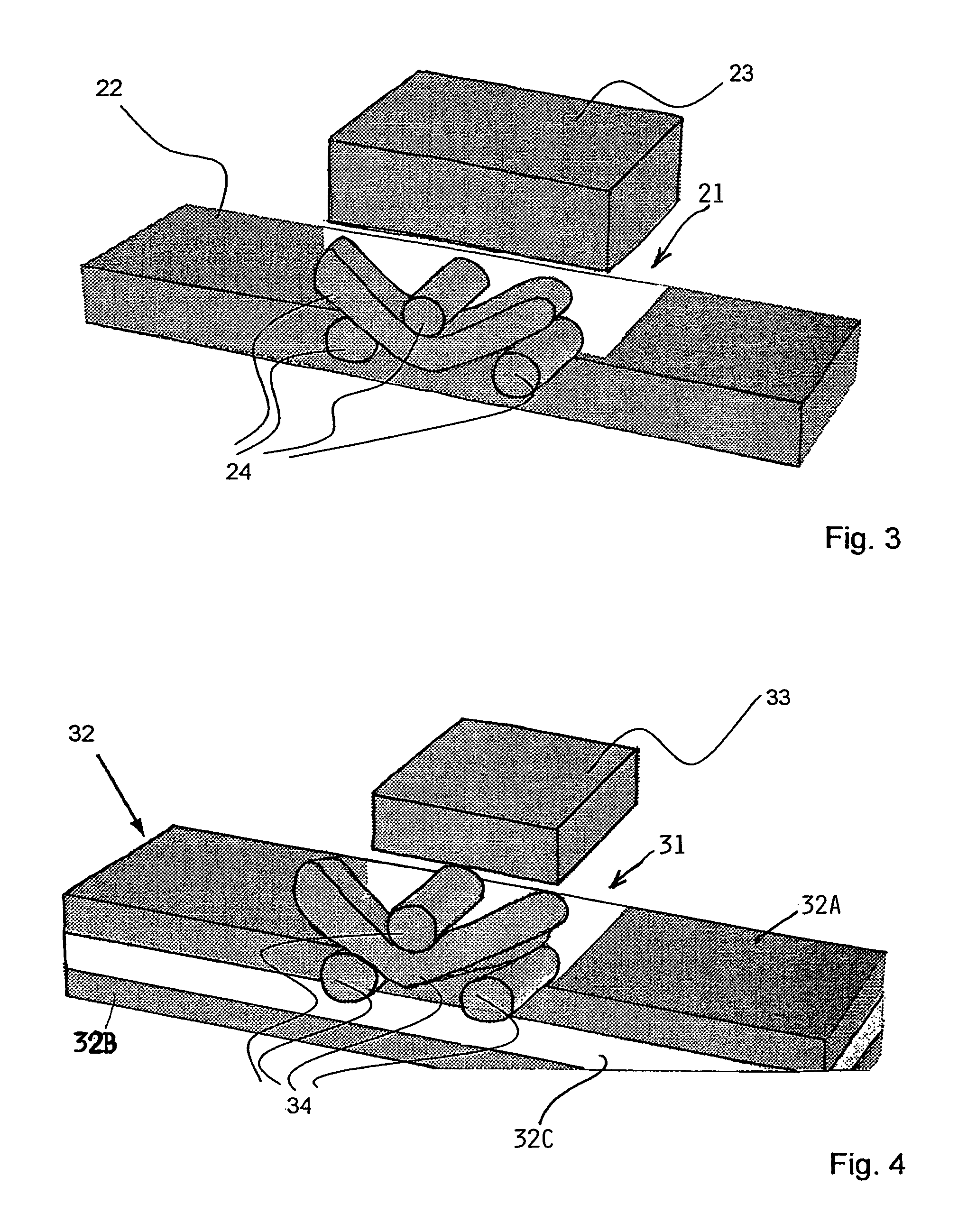

Lightweight structure particularly for an aircraft

ActiveUS20050112348A1Simple structureEasily damagedSynthetic resin layered productsNon-woven fabricsHigh intensityFibrous composites

An outer skin, for example of an aircraft body, is supported by a frame of longitudinal girders and circumferential ribs interconnecting the girders. Additionally, the outer skin is strengthened by reinforcing strips adhesively bonded to the outer skin between the ribs and girders. The reinforcing strips are made of material that is damage tolerant, for example high strength aluminum alloys and fiber composite materials are suitable for making the reinforcing strips. These reinforcing strips may extend in parallel to the stringers and / or the ribs and preferably form a lattice work. The reinforcing strips need not cross each other at right angles but should cross a crack propagation direction in the outer skin.

Owner:AIRBUS OPERATIONS GMBH

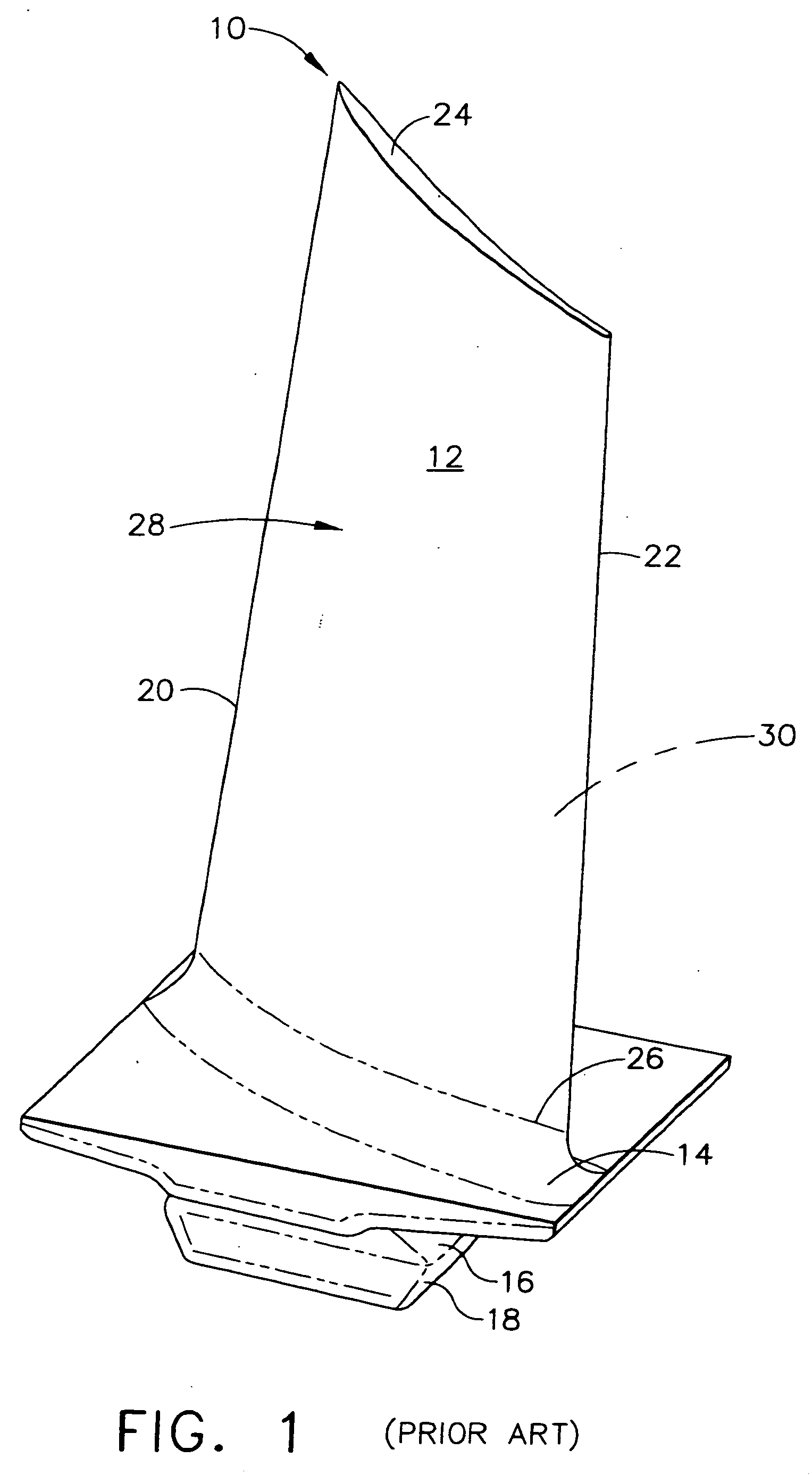

Fatigue-resistant components and method therefor

ActiveUS7229253B2Reduce crack propagationPropellersRotary propellersEngineeringResidual compressive stress

A metallic component is by at least one peripheral edge. The component includes at least one elongated treated zone having a length substantially greater than its width. This treated zone is spaced away from and disposed generally parallel to the peripheral edge of the component and the entire thickness of the component within the treated zone is in a state of residual compressive stress. Crack growth from the edge due to fatigue or damage is resisted.

Owner:GENERAL ELECTRIC CO

Intramedullary nail

ActiveUS20060235394A1Reduce crack propagationFixed securityInternal osteosythesisJoint implantsIntramedullary rodBiomedical engineering

The intramedullary nail has a longitudinal axis (5), a near end (1) with means (8) for coupling to an insertion device and a far end (2) with a tip (7) for insertion into the intramedullary canal of a long bone. The far end (2) is provided with at least two traversing through holes (3) with axes (6), all of said through holes (3) being grouped in said far end (2) within a distance x measured from said tip (7) to the axis (6) of the most distant hole (3). The nail is provided with at least a third through hole (3) with axis (6) in said far end (2) which contains the first and second holes (3) and the projection of the hole axis (6) of said through holes (3) in a plane orthogonal to said longitudinal axis (5) is such that at least two of said projected hole axis (6) are at an angle α greater than zero and less than 90° with respect to each other.

Owner:AO TECH AG

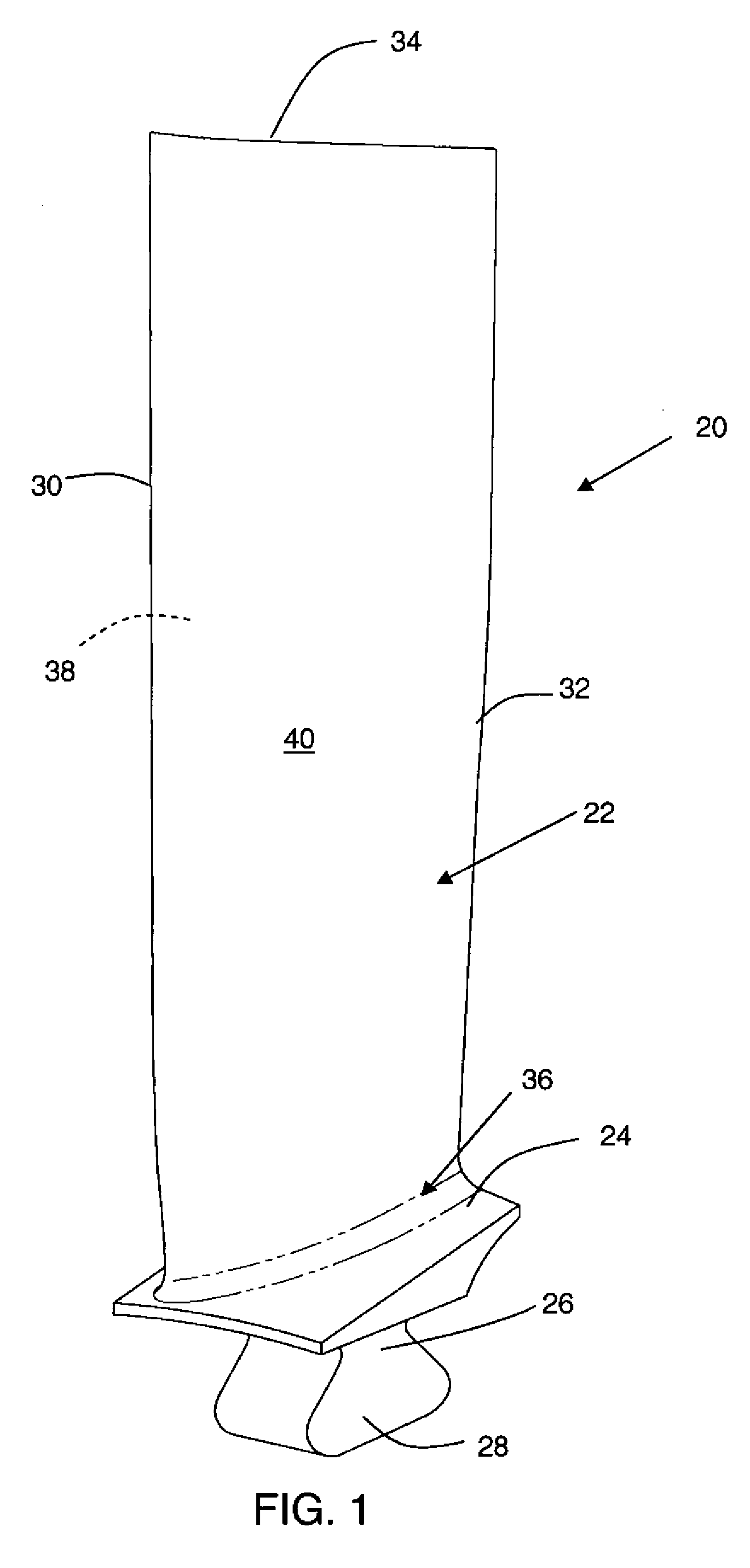

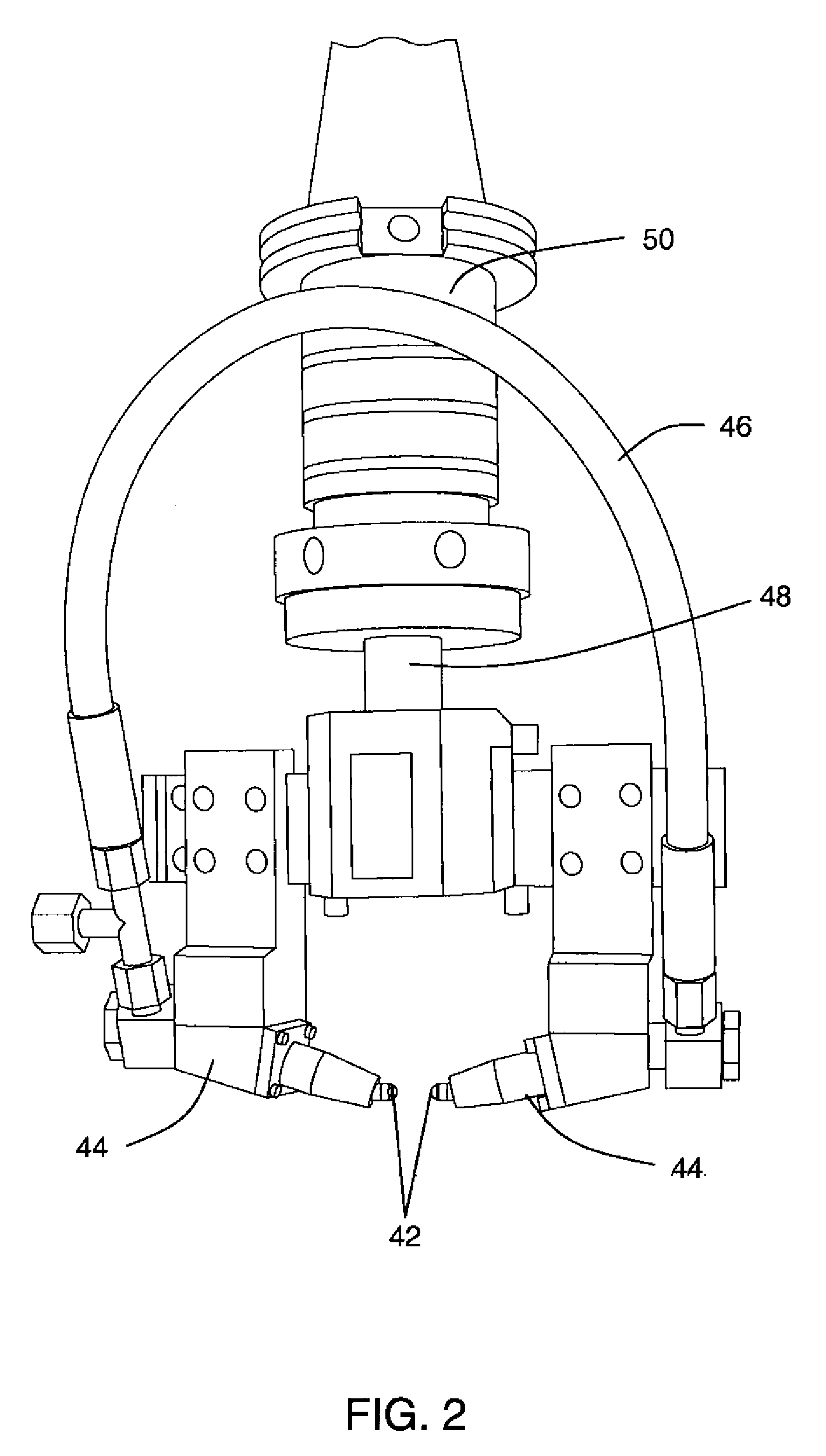

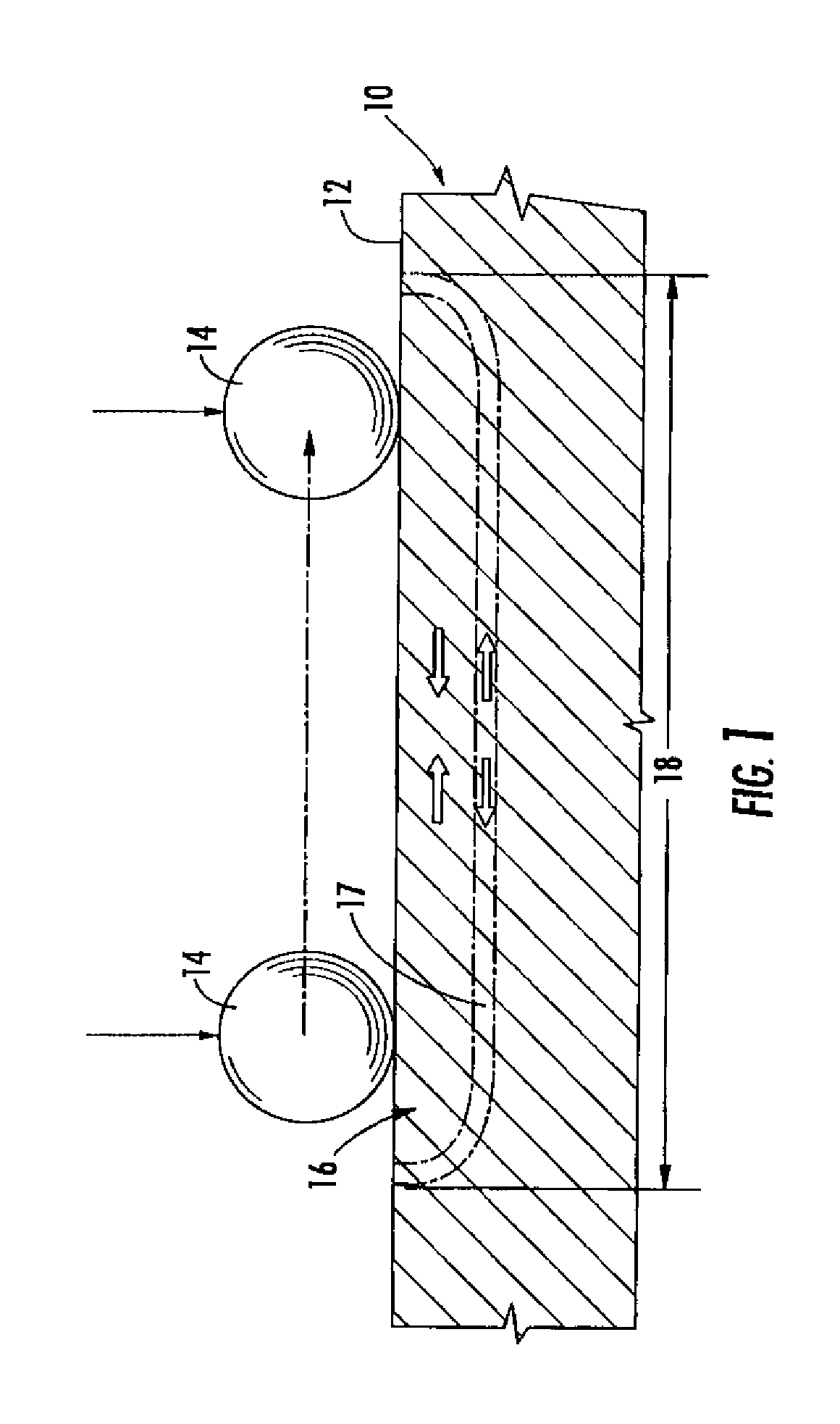

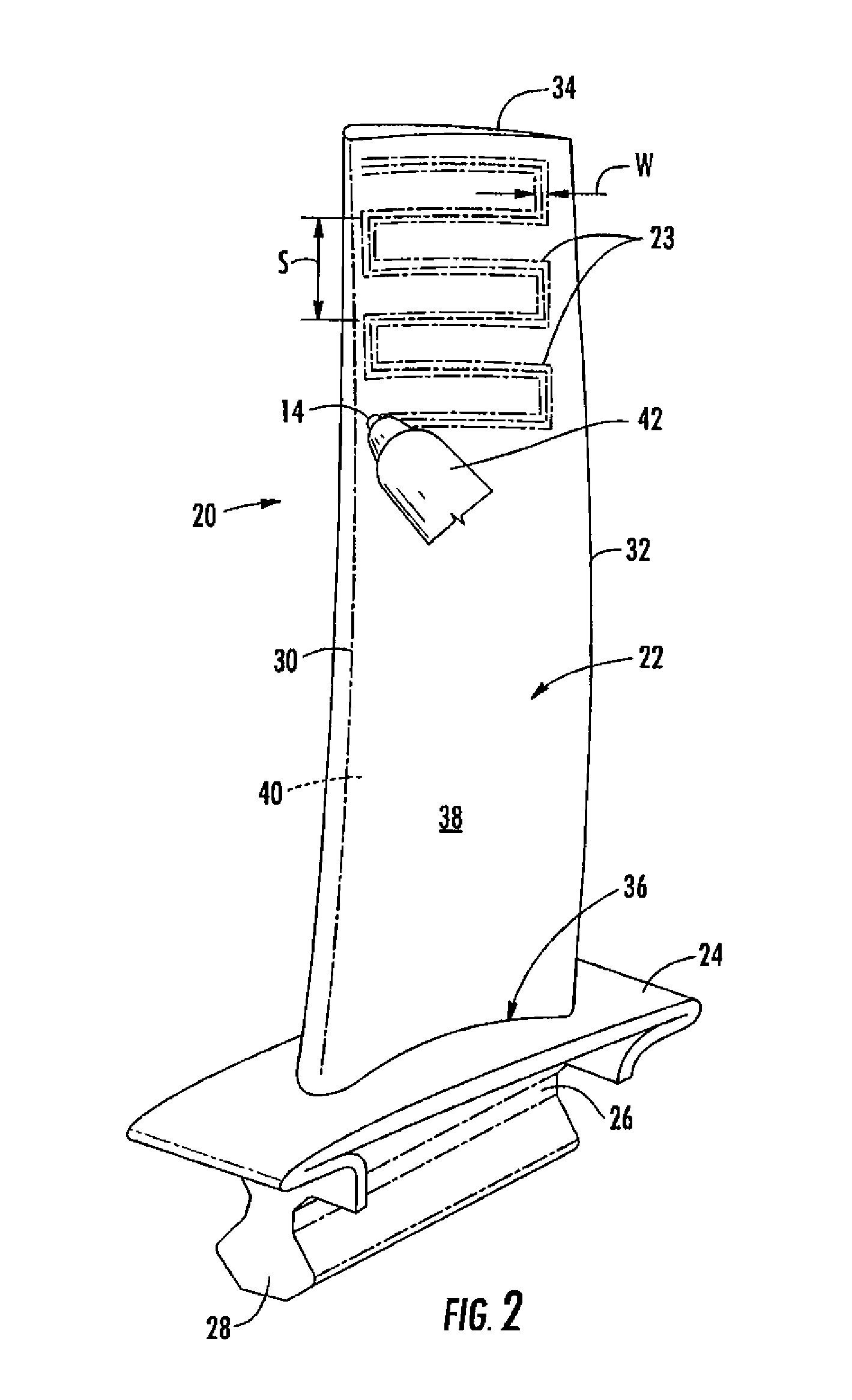

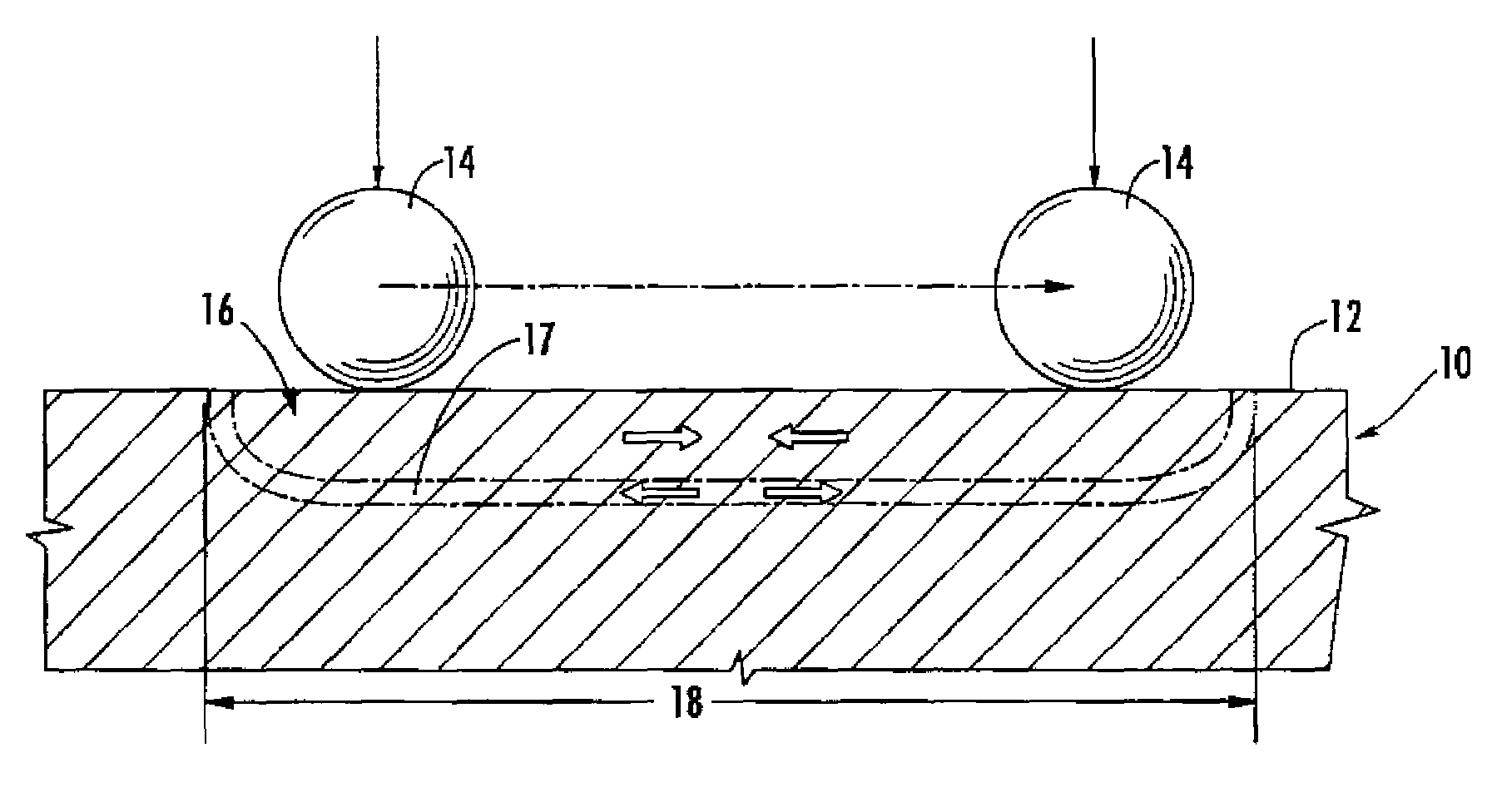

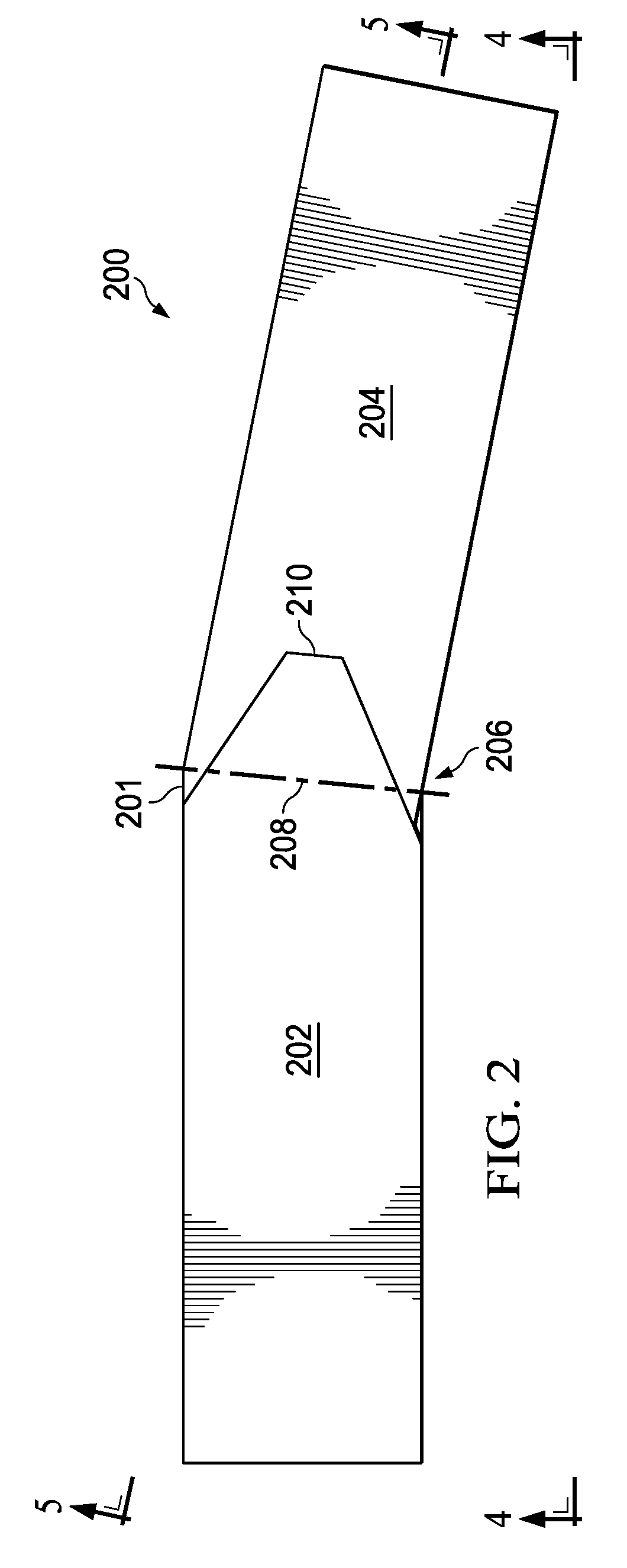

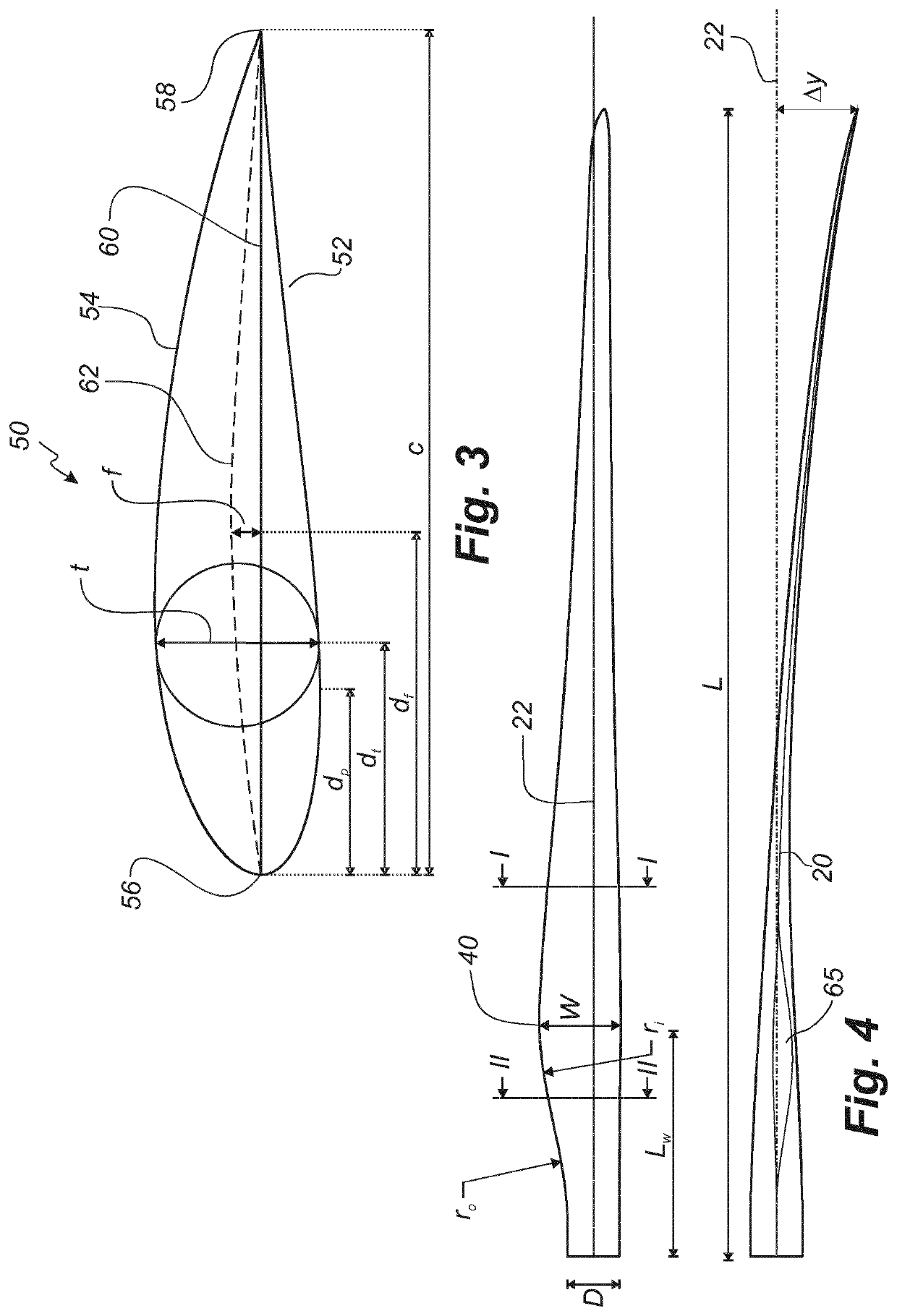

Method for increasing fatigue notch capability of airfoils

InactiveUS8051565B2Reduce crack propagationAvoid deformationBurnishing machinesEngine componentsLeading edgeOffset distance

A method of reducing crack propagation in an airfoil includes: providing an airfoil having a root spaced apart from a tip, spaced-apart leading and trailing edges, a suction side extending from the leading edge to the trailing edge, and an opposed pressure side extending from the leading edge and the trailing edge, supporting the airfoil against bending loads; and burnishing the airfoil using a burnishing element, so as to create at least one burnished section of residual compressive stress, the at least one burnished section being located adjacent the leading edge and spaced from the leading edge by an offset distance selected so as to avoid deformation of the leading edge.

Owner:GENERAL ELECTRIC CO

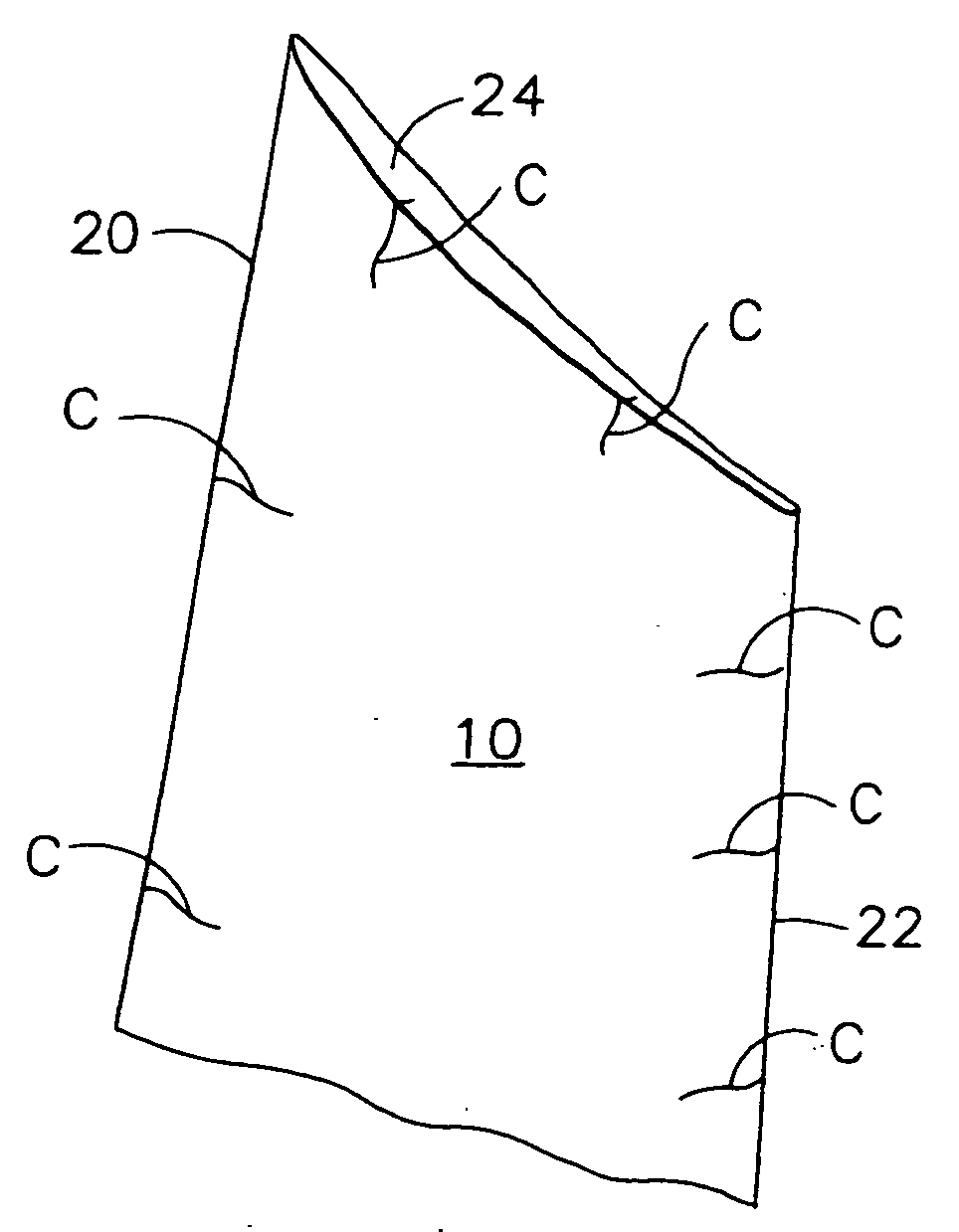

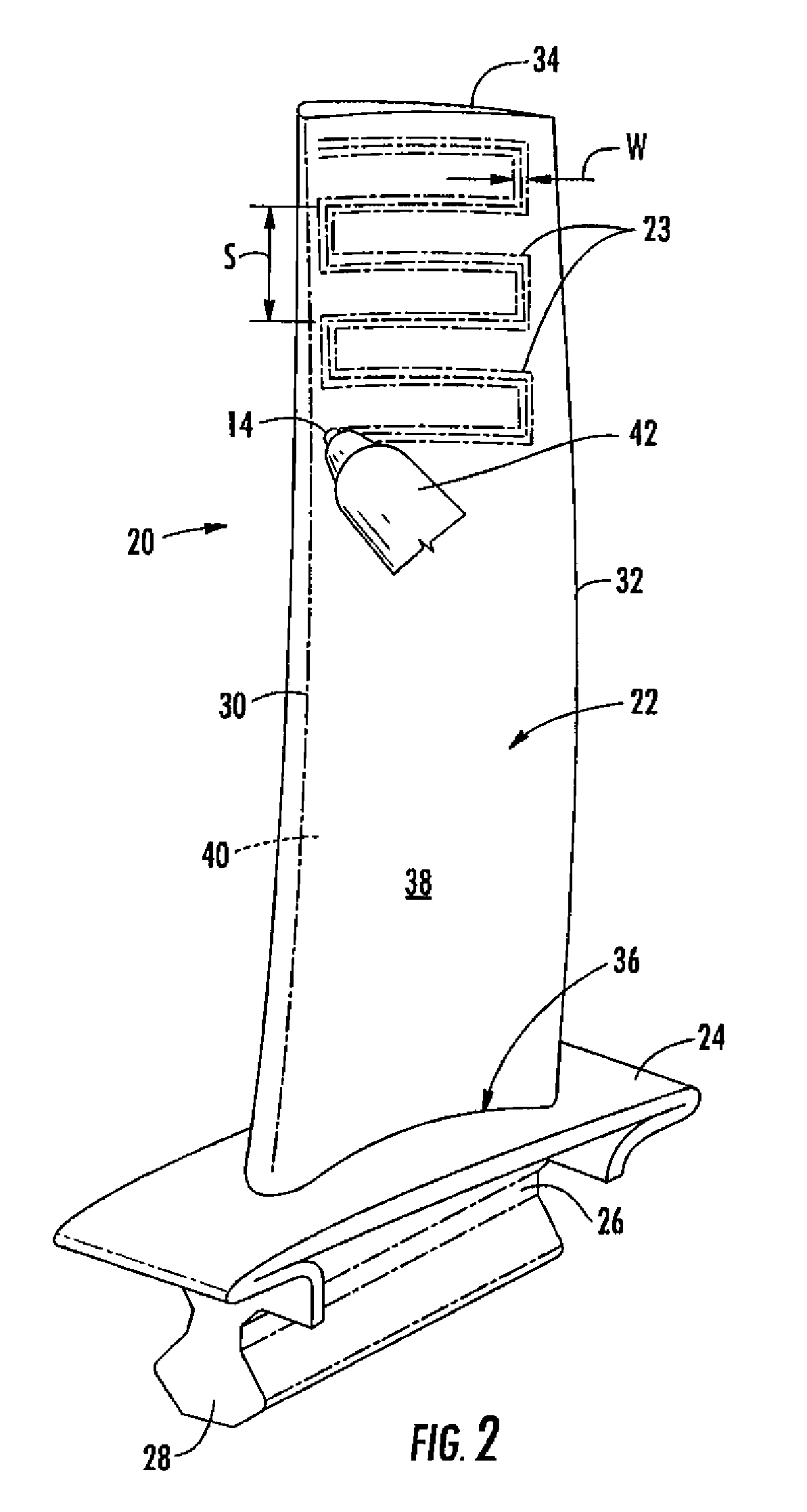

Fatigue-resistant components and method therefor

ActiveUS20060147311A1Reduce crack propagationPropellersRotary propellersEngineeringResidual compressive stress

A metallic component is by at least one peripheral edge. The component includes at least one elongated treated zone having a length substantially greater than its width. This treated zone is spaced away from and disposed generally parallel to the peripheral edge of the component and the entire thickness of the component within the treated zone is in a state of residual compressive stress. Crack growth from the edge due to fatigue or damage is resisted.

Owner:GENERAL ELECTRIC CO

Lightweight structure particularly for an aircraft

ActiveUS7285326B2Simple structureEasily damagedSynthetic resin layered productsNon-woven fabricsHigh intensityFibrous composites

An outer skin of an aircraft body is supported by a frame of longitudinal stringers and circumferential ribs or frame elements interconnecting the stringers. Additionally, the outer skin is strengthened by a reinforcing strip formation adhesively bonded to the inwardly facing surface of the outer skin between the ribs and stringers. The reinforcing strips are made of a material that is damage tolerant, for example high strength aluminum alloys and fiber composite materials are suitable for making the reinforcing strip formation. The reinforcing strips of the strip formation may extend in parallel to the stringers and / or the ribs and preferably form a lattice work. The reinforcing strips need not cross each other at right angles but should cross a crack propagation direction in the outer skin.

Owner:AIRBUS OPERATIONS GMBH

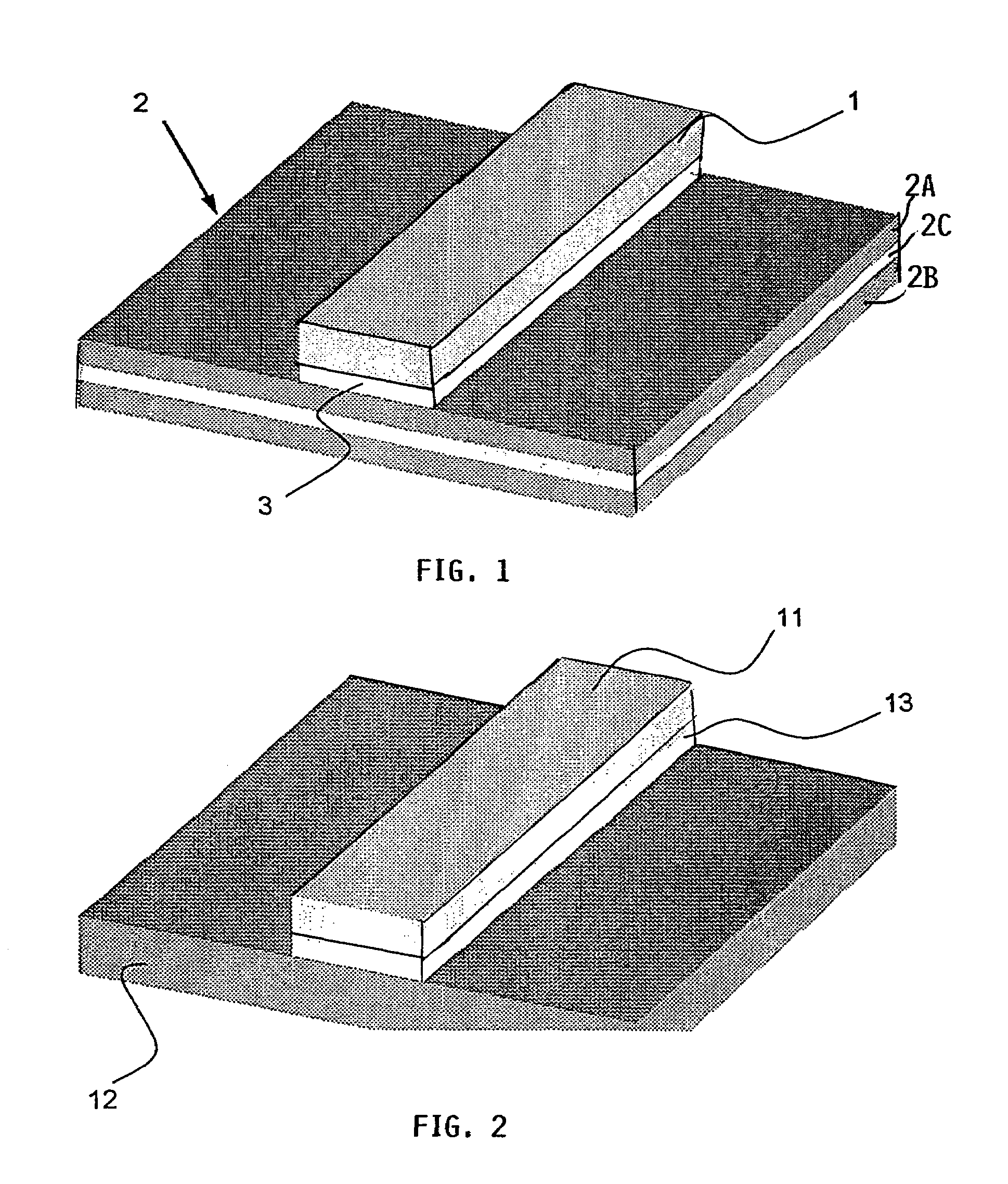

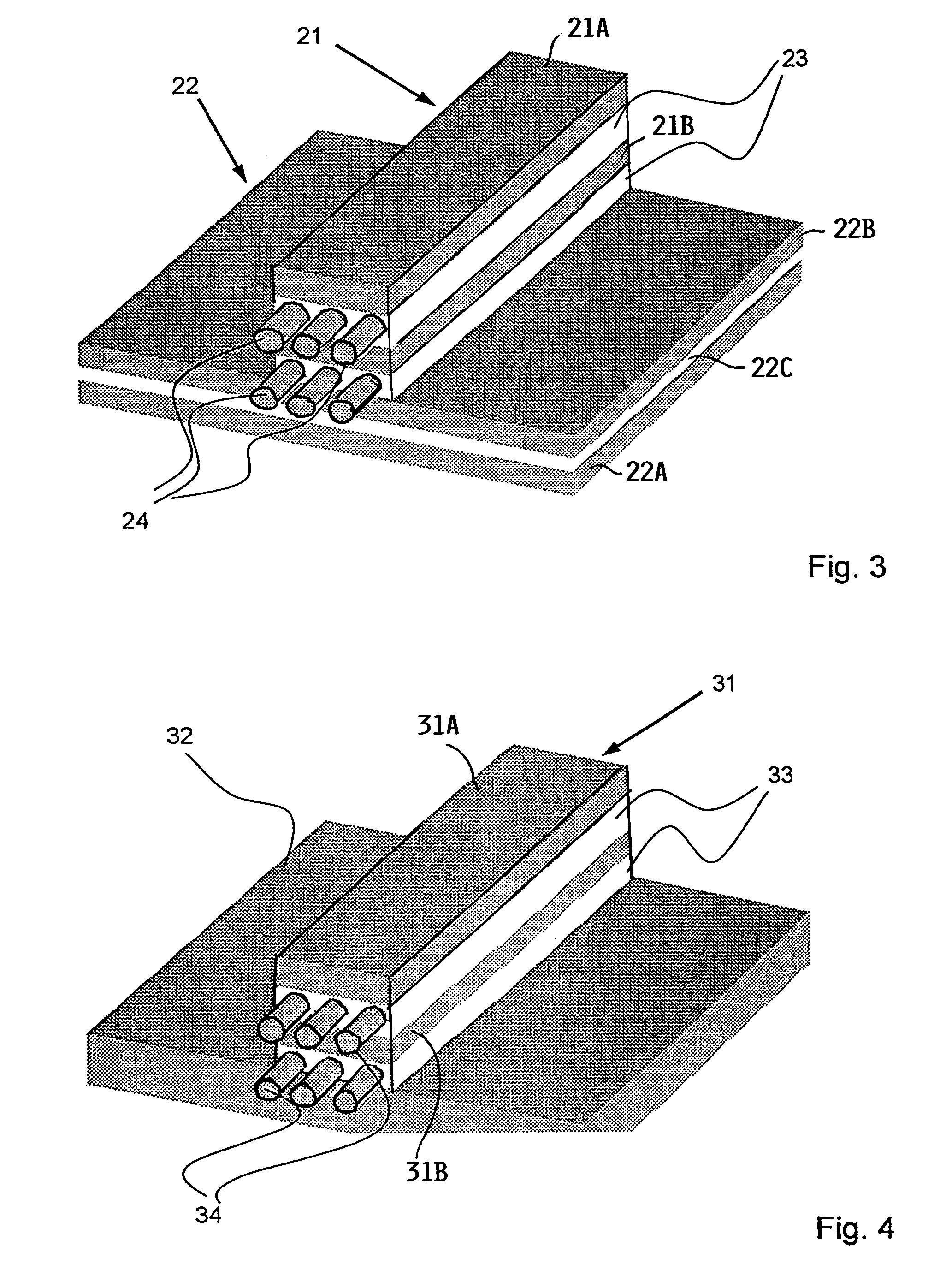

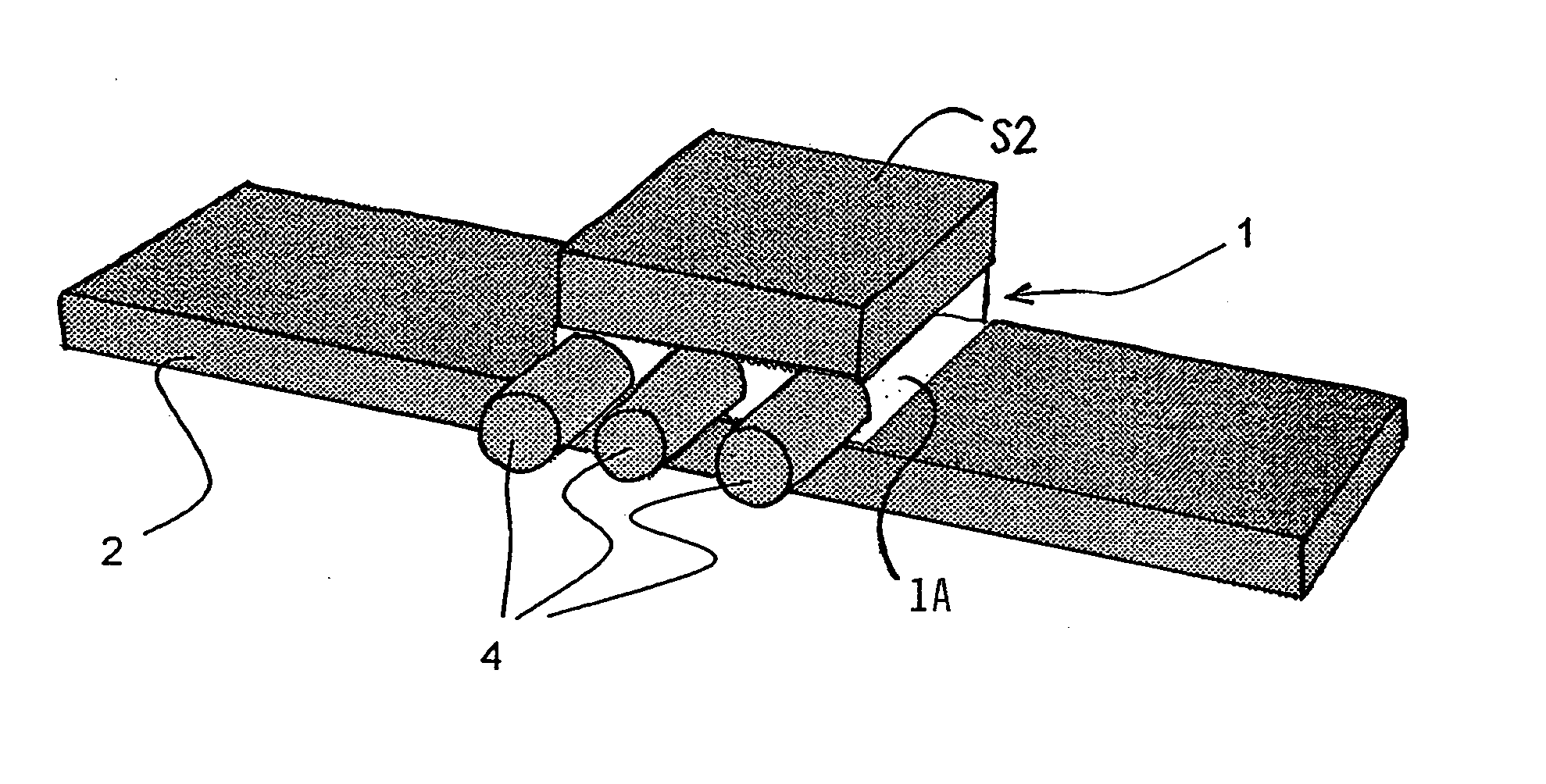

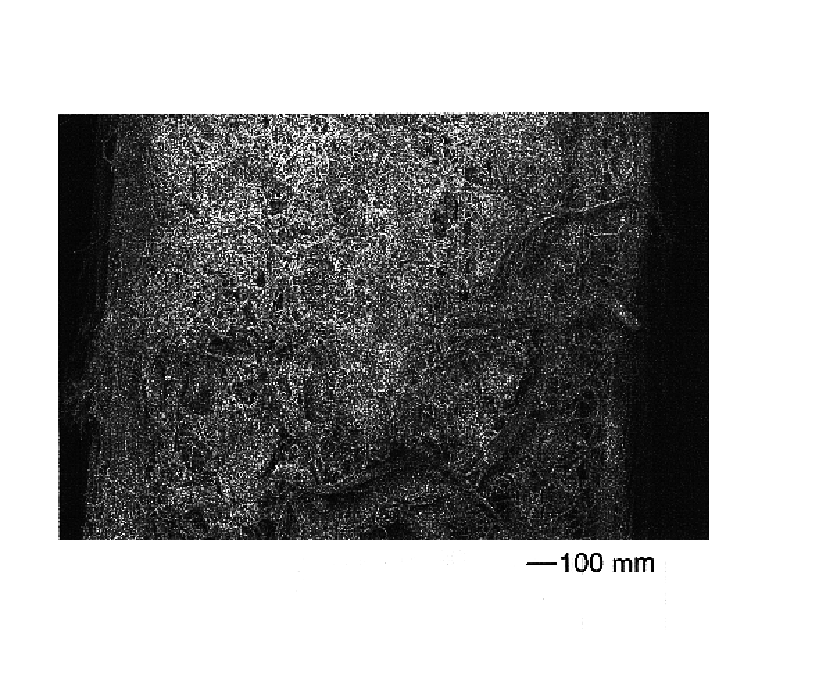

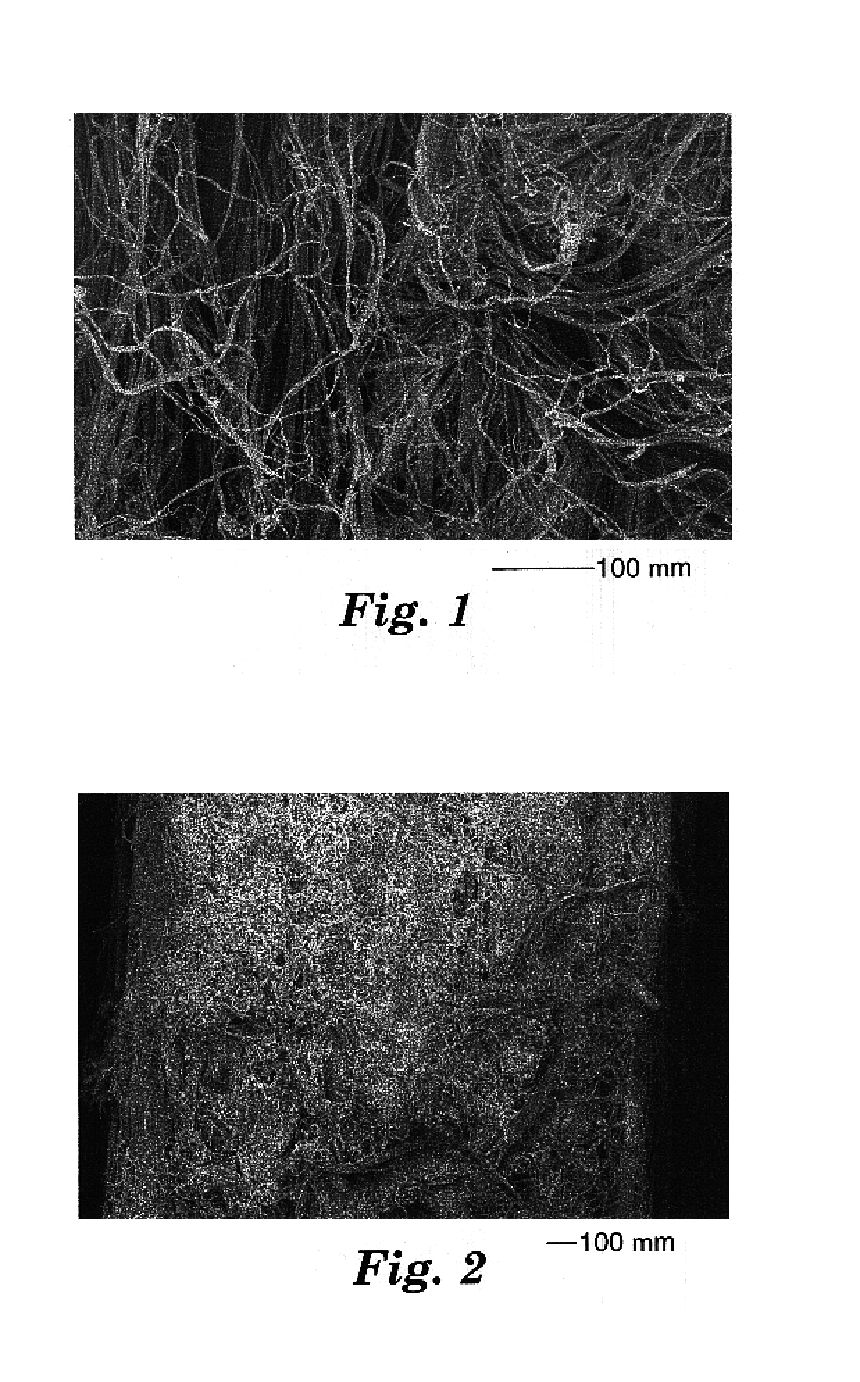

Lightweight structure especially for an aircraft and method for making such a structure

ActiveUS20050112347A1Decrease their propagationExtended service lifeNon-woven fabricsThin material handlingEngineeringParallel fiber

An additional fiber reinforced layer reduces crack propagation in a lightweight structure of an outer skin adhesively bonded to a reinforcing frame. For this purpose the additional fiber reinforced layer is interposed between the outer skin and the frame and adhesively bonded to the outer skin and to the frame. The additional layer has reinforcing fibers extending in parallel to each other or the reinforcing fibers are woven into a fabric embedded in a synthetic adhesive bonding material. The embedding of the parallel fibers or of the fiber fabric in the bonding material is performed either prior to the bonding or during the bonding of the additional layer to the outer skin and to the reinforcing frame.

Owner:AIRBUS OPERATIONS GMBH

Toughened cementitious composites

InactiveUS7192643B2Improve fracture toughnessReduce crack propagationLiquid surface applicatorsFilament/thread formingCementitious compositeToughness

The present invention relates to the field of toughening and reinforcing brittle matrix materials, and more specifically to the structural fibers made from an oriented film, which enhance the toughness of matrix materials such as concrete, cement, and other cementitious products.

Owner:3M INNOVATIVE PROPERTIES CO

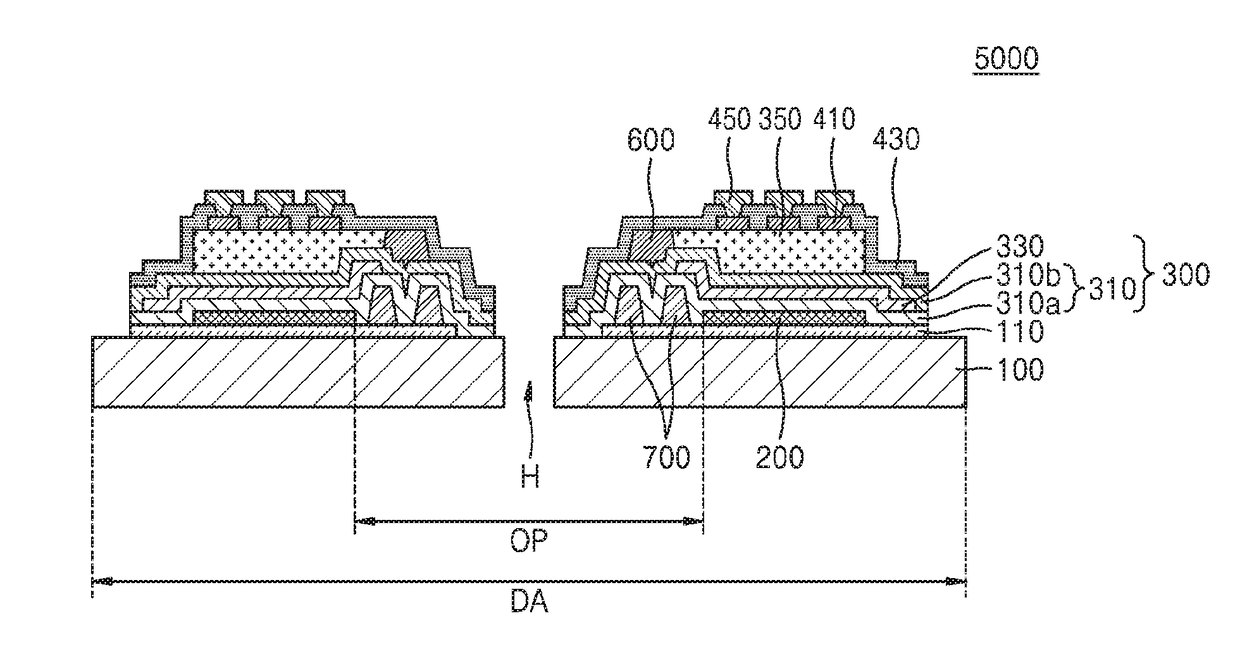

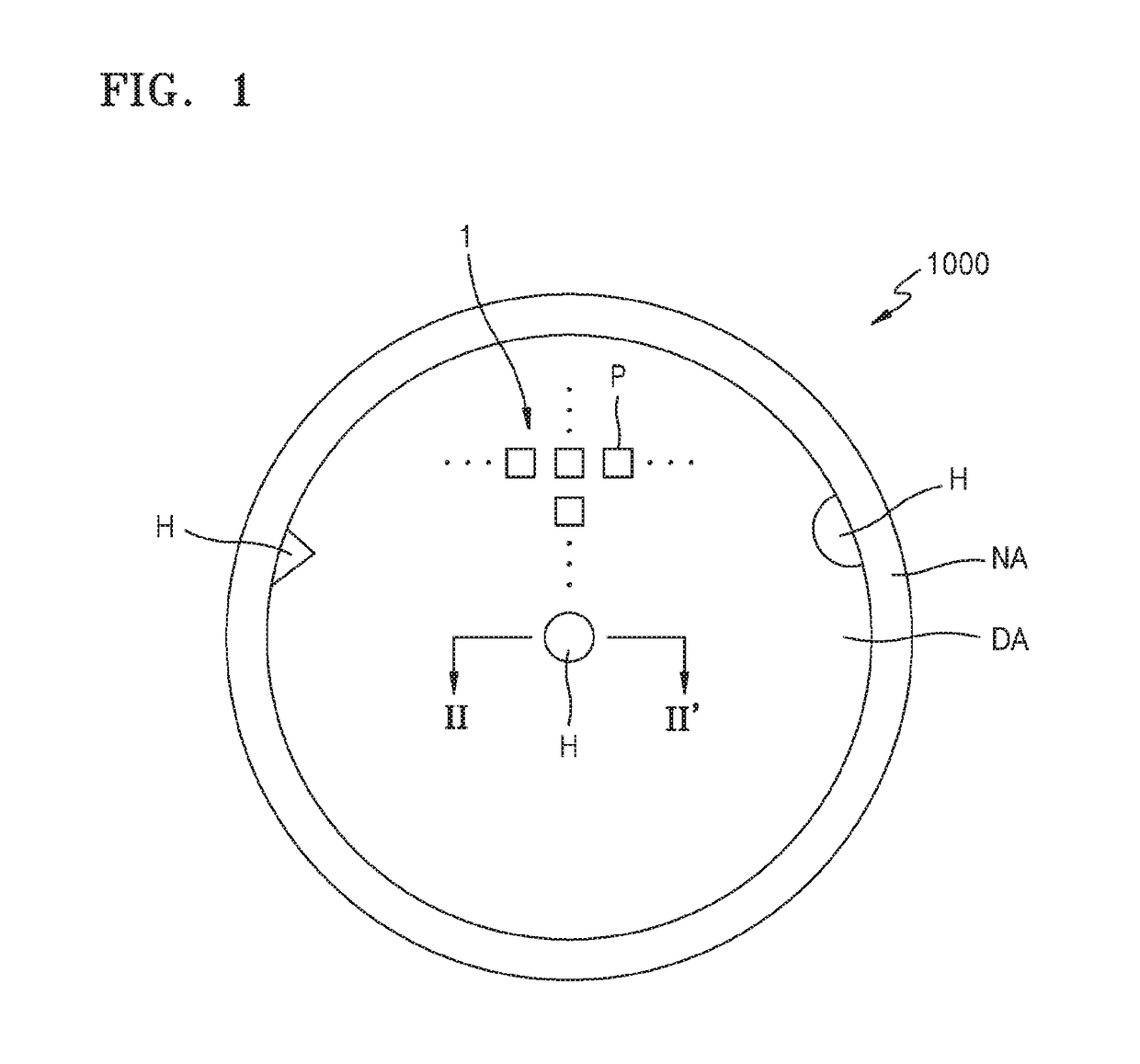

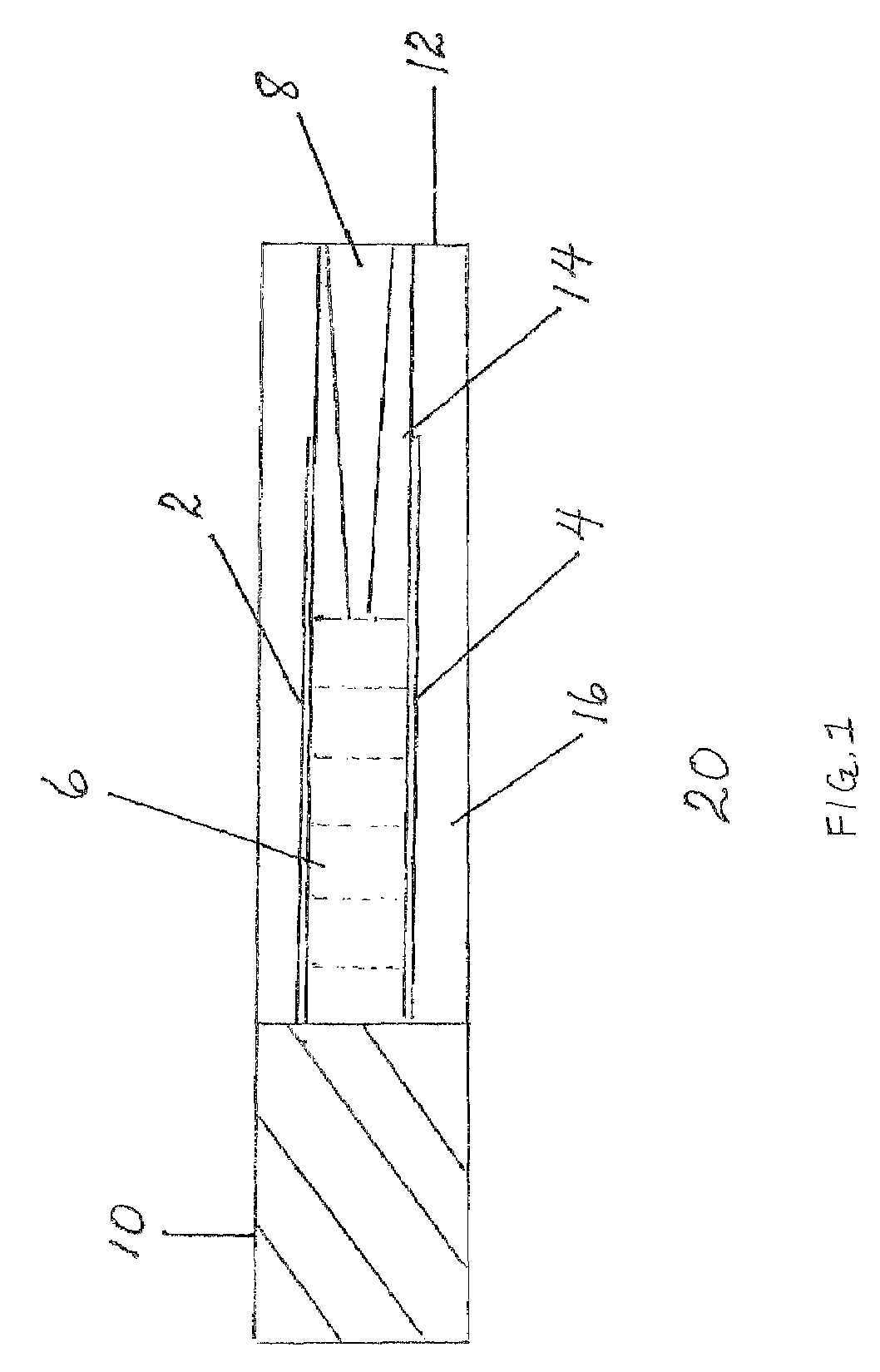

Display apparatus with substrate hole, and method of manufacturing the same

ActiveUS10230069B2Reduce crackingReduce crack propagationVisual indicationSolid-state devicesEngineeringElectrical and Electronics engineering

A method of manufacturing a display apparatus includes providing a substrate, forming a display unit defining an opening portion in a display region over the substrate, forming a thin film encapsulation layer to seal the display unit, forming a touch electrode over the thin film encapsulation layer, forming a touch insulating film covering the touch electrode such that the thin film encapsulation layer and the touch insulating film are sequentially stacked and formed over the substrate in the opening portion, forming a touch contact hole by removing a portion of the touch insulating film to expose a portion of the touch electrode, and removing a portion of the touch insulating film and a portion of the thin film encapsulation layer formed in the opening portion to expose a portion of the substrate during the forming of the touch contact hole.

Owner:SAMSUNG DISPLAY CO LTD

Steel product for oil country tubular good

ActiveUS20060018783A1High SSC resistanceReduce crack propagationHeat treatment process controlMetallurgyImpurity

A steel product for oil country tubular good according to the invention comprises, in mass %, 0.10% to 0.35% C, 0.10% to 0.50% Si, 0.10% to 0.80% Mn, up to 0.030% P, up to 0.010% S, 0.30% to 1.20% Cr, 0.20% to 1.00% Mo, 0.005% to 0.40% V, 0.005% to 0. 100% Al, up to 0.0100% N, up to 0.0010% H, 0 to 0.01% Ca, 0 to 0.050% Ti, 0 to 0.050% Nb, and 0 to 0.0050% B, and the balance of Fe and impurities. The Cr, Mo, and V contents and the grain size GS satisfy expression (1): 0.7≦(1.5×Cr+2.5×Mo+V)−GS / 10≦2.6 (1)

Owner:NIPPON STEEL CORP

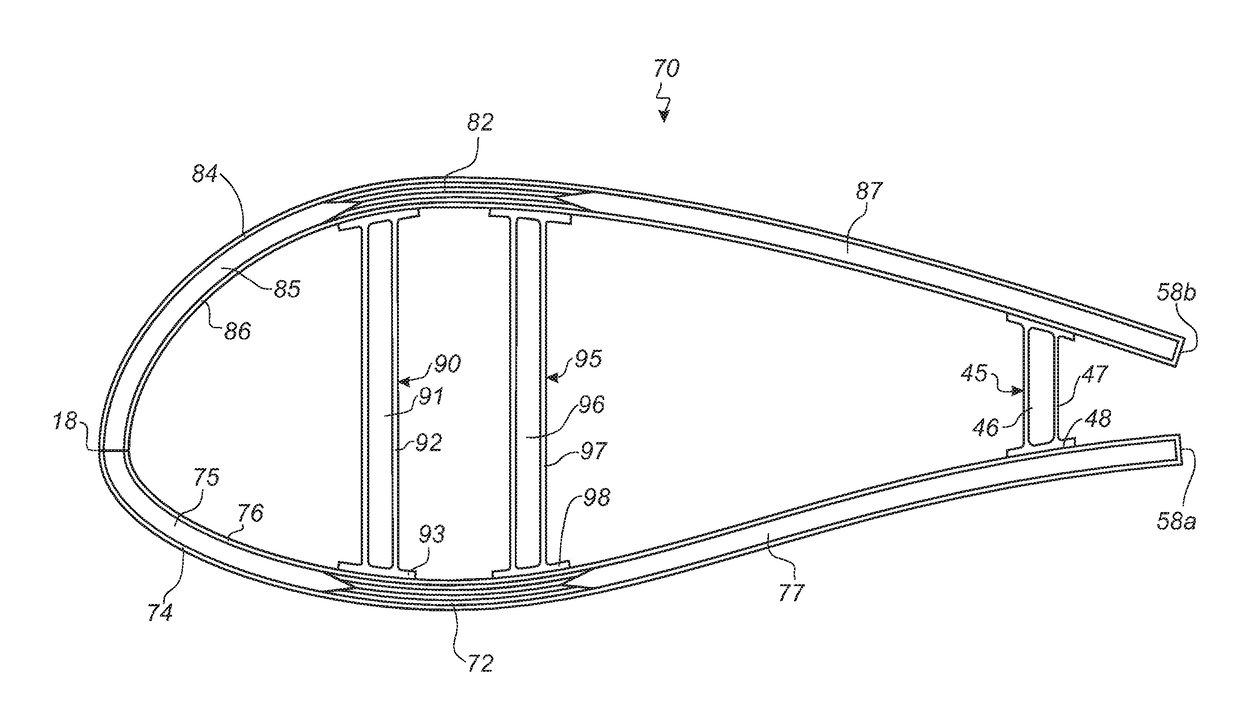

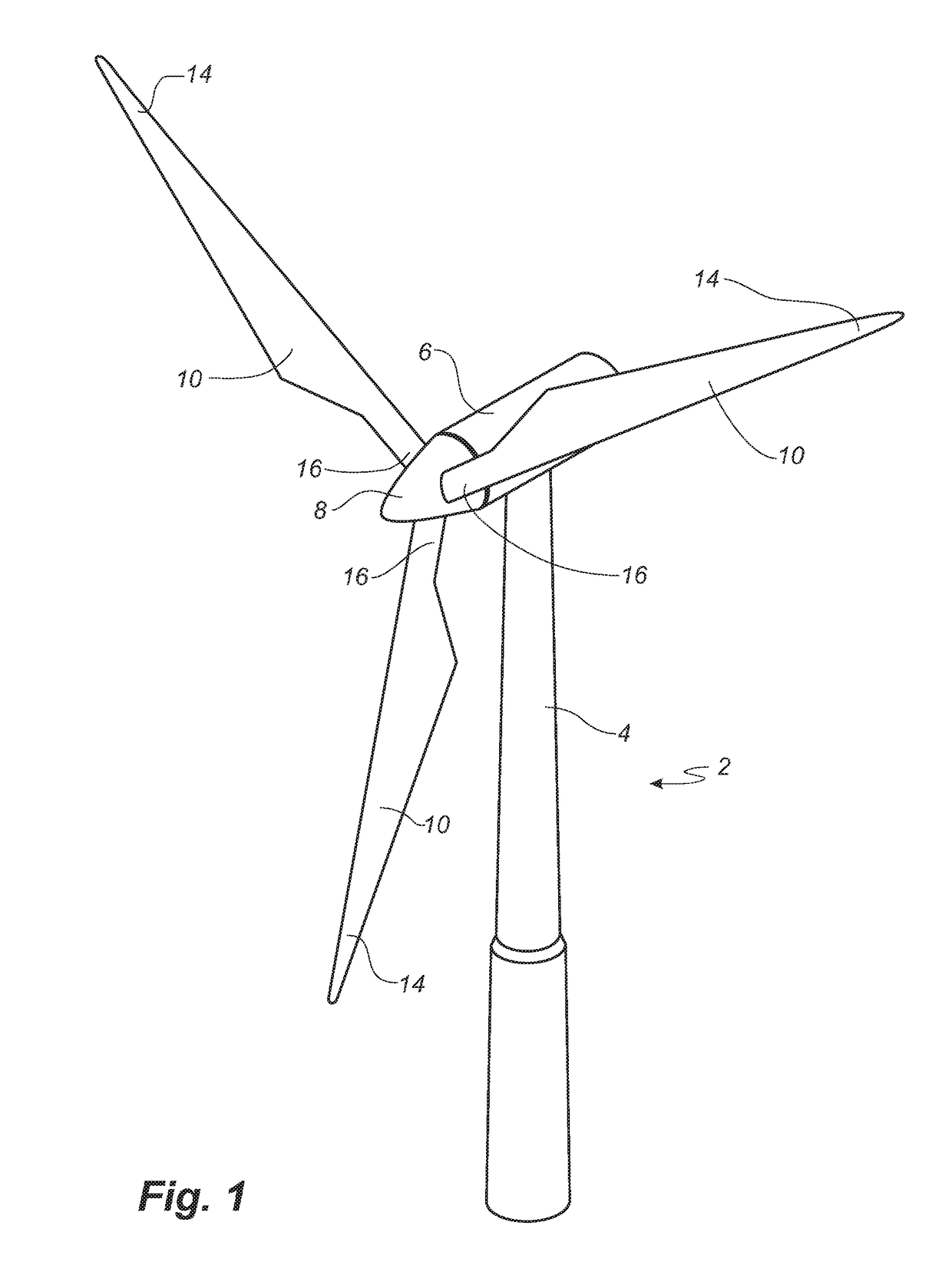

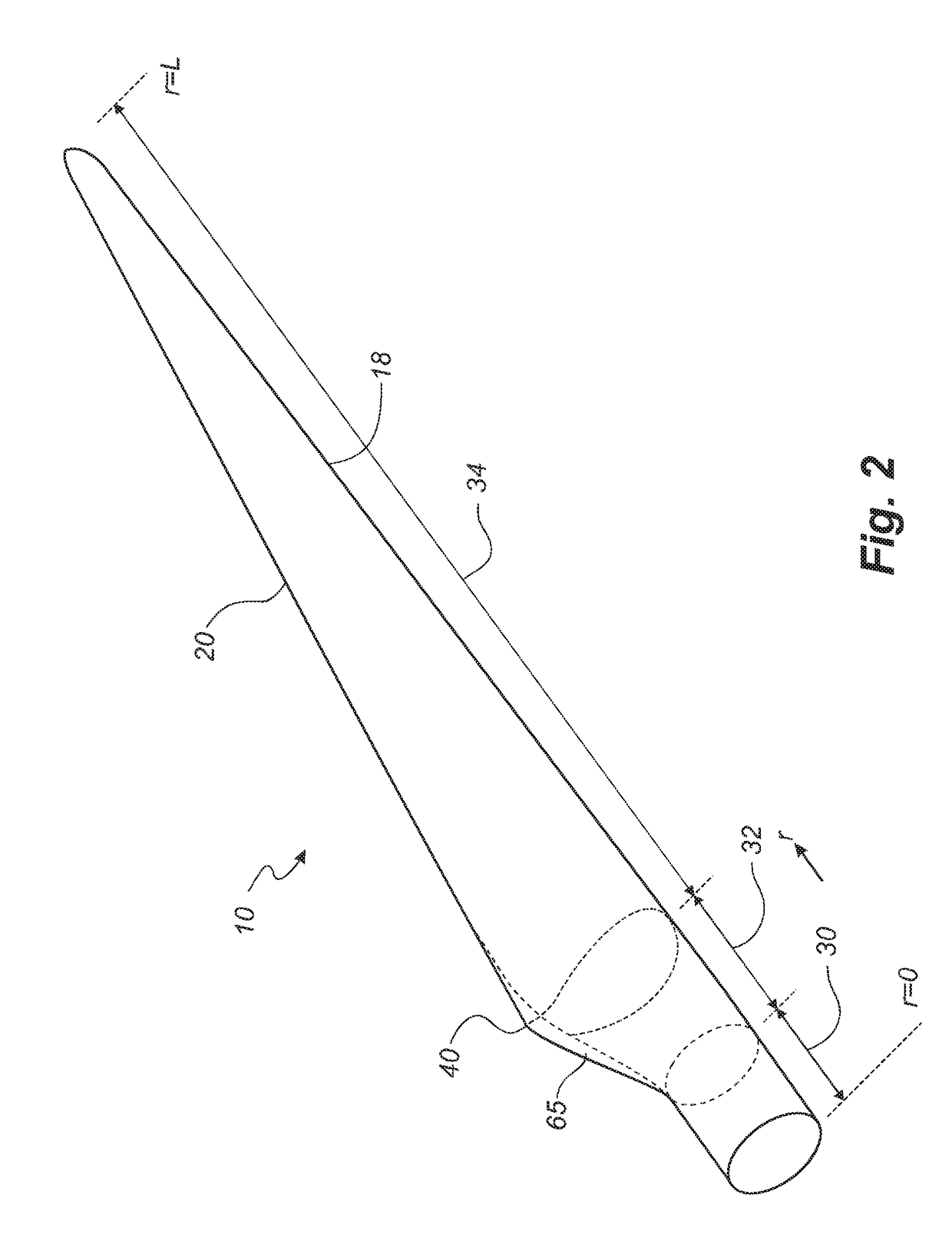

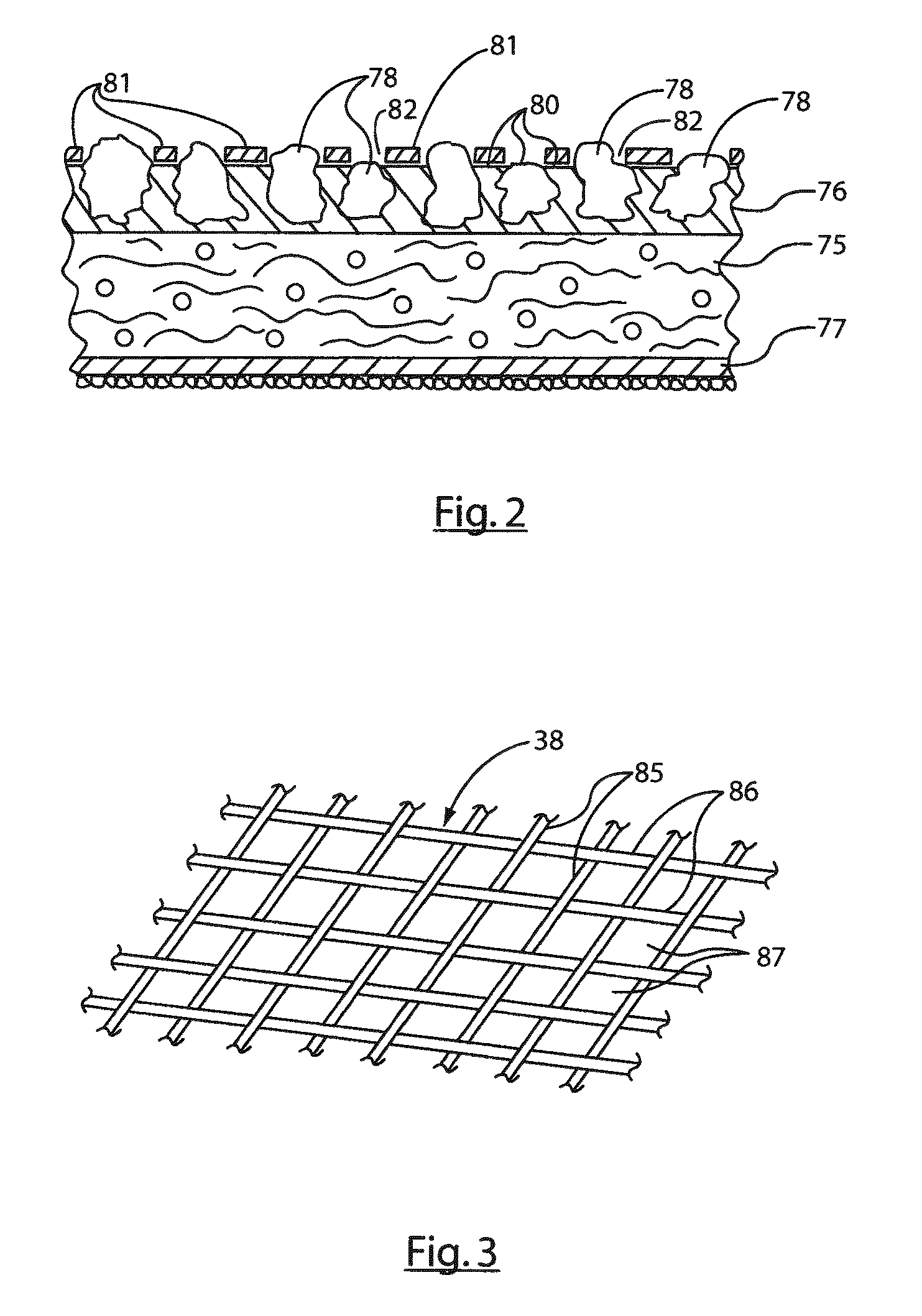

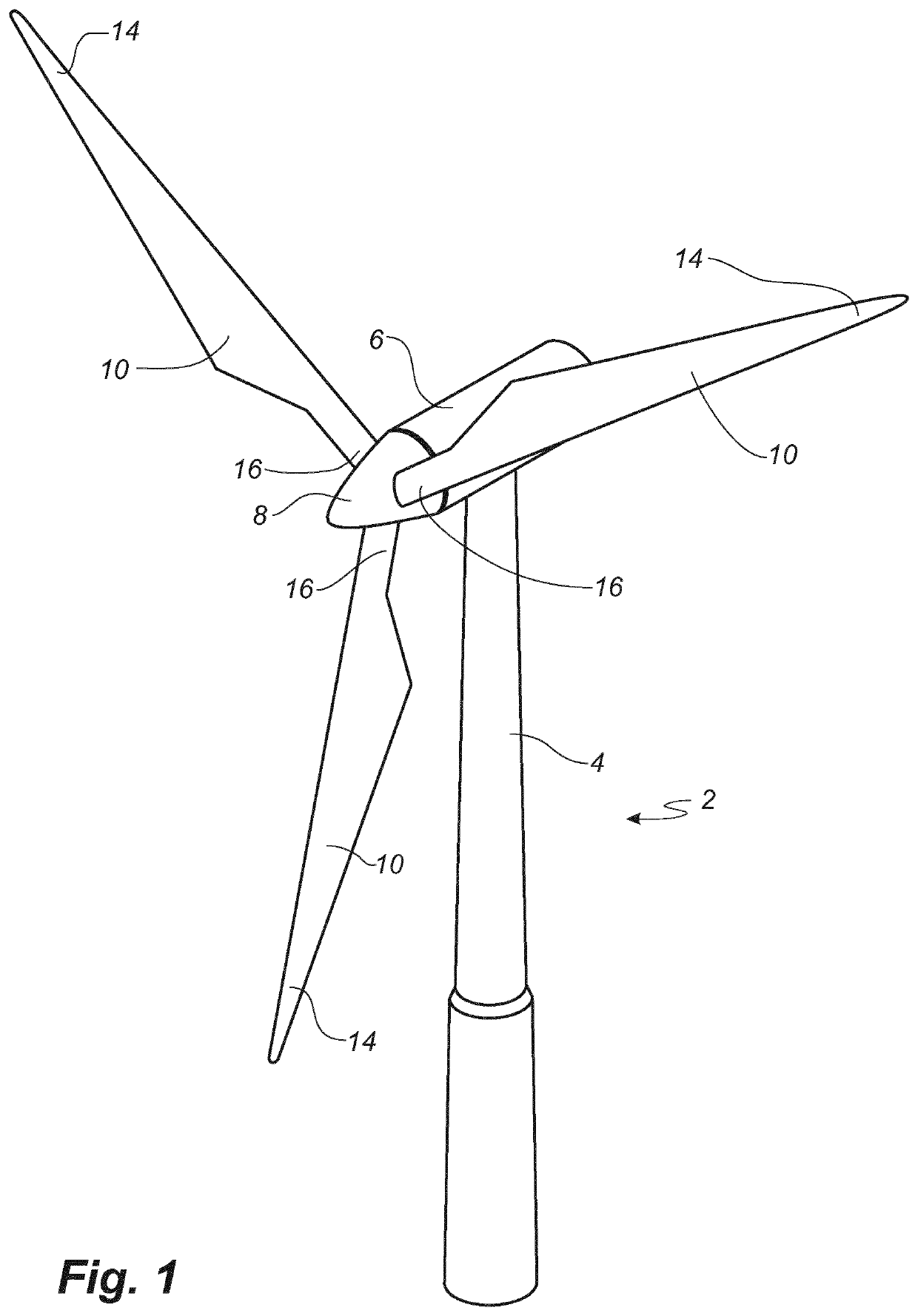

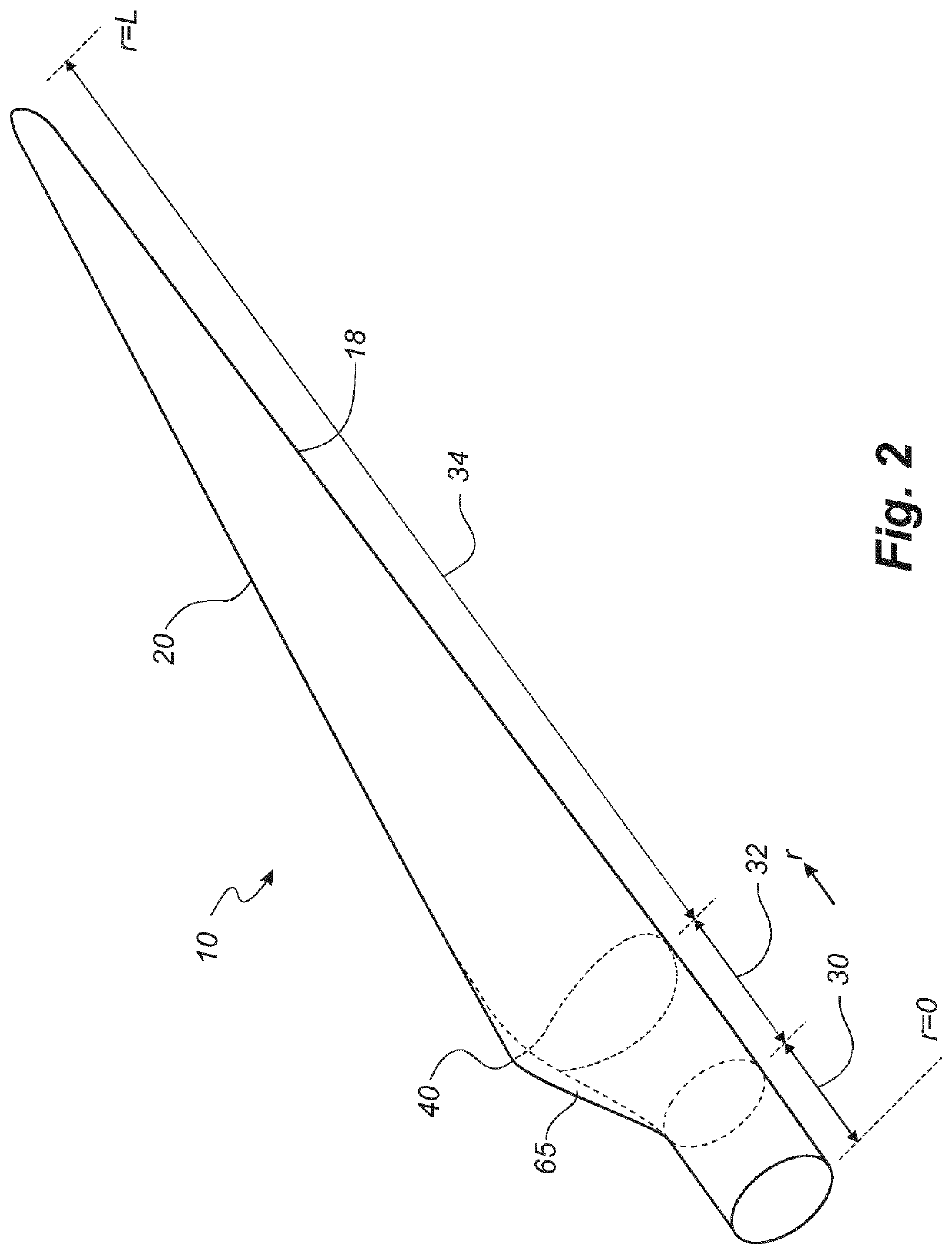

Wind turbine blade with a trailing edge spacing section

ActiveUS20180142670A1Improve structural stabilityGood structural supportFinal product manufactureMachines/enginesLeading edgeTurbine blade

A wind turbine blade is provided with two shell parts each at least partly made of a sandwich structure including an inner skin (76), an outer skin (74), and an intermediate core material (75, 77), wherein the shell parts are bonded together at least along their respective leading edges (18). The blade also comprises a longitudinally extending spacing section in which the respective trailing edges (58a, 58b) of the pressure side shell part and the suction side shell part are spaced apart, wherein a trailing edge shear web (45) is arranged between and connected to the sandwich structure of the suction side shell part (84, 86, 87) and the sandwich structure of the pressure side shell part (74, 76, 77).

Owner:LM WP PATENT HLDG

Impact-modified reaction resin

InactiveUS20130289164A1Long lastingImprove mechanical propertiesSingle unit pavingsPavement lightsHeat resistanceCore shell

The present invention comprises a novel formulation for marking trafficways, for example roads, which when compared with the prior art have improved mechanical properties and improved heat resistance during curing. The invention also relates to improved reactive resins for other applications than roadmarkings. The present invention in particular relates to reactive resins which comprise core-shell particles.

Owner:EVONIK ROEHM GMBH

Component of variable thickness having residual compressive stresses therein, and method therefor

InactiveUS20080003109A1Reduce crack propagationEngine fuctionsBlade accessoriesVariable thicknessVarying thickness

A method of reducing crack propagation includes: providing a metallic component having an exterior surface, and using a burnishing element to apply a varying to the exterior surface within a selected area, within which the component has a varying thickness, so as to create a region of residual compressive stress of surrounded by an interior boundary. The distance from the interior boundary to the exterior surface at any location within the selected area is independent of the thickness of the component at that location, and may be controlled by changing the pressure and / or an amount of overlap between burnished segments.

Owner:GENERAL ELECTRIC CO

Component of variable thickness having residual compressive stresses therein, and method therefor

InactiveUS7530792B2Reduce crack propagationPropellersPump componentsVariable thicknessVarying thickness

Owner:GENERAL ELECTRIC CO

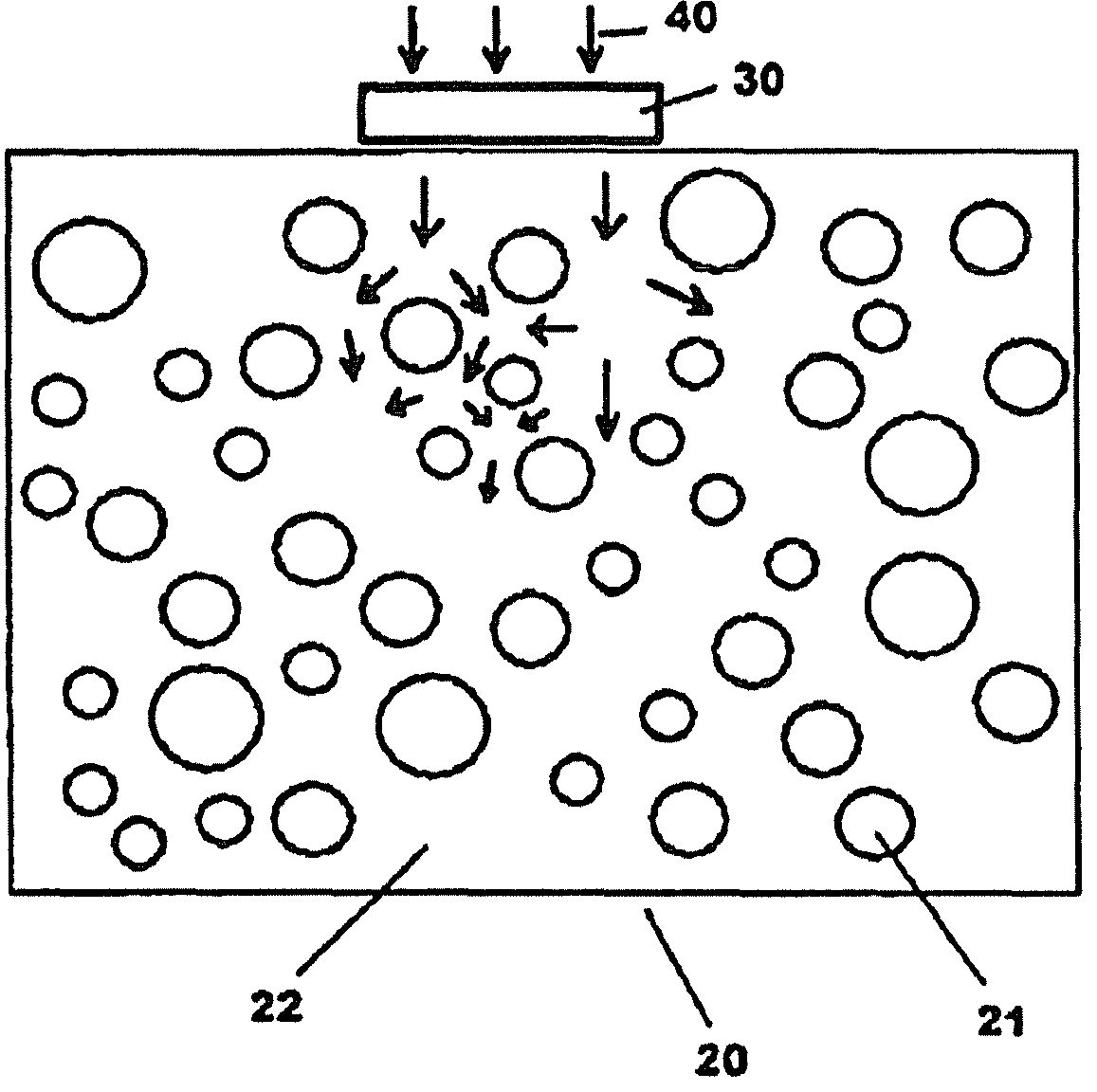

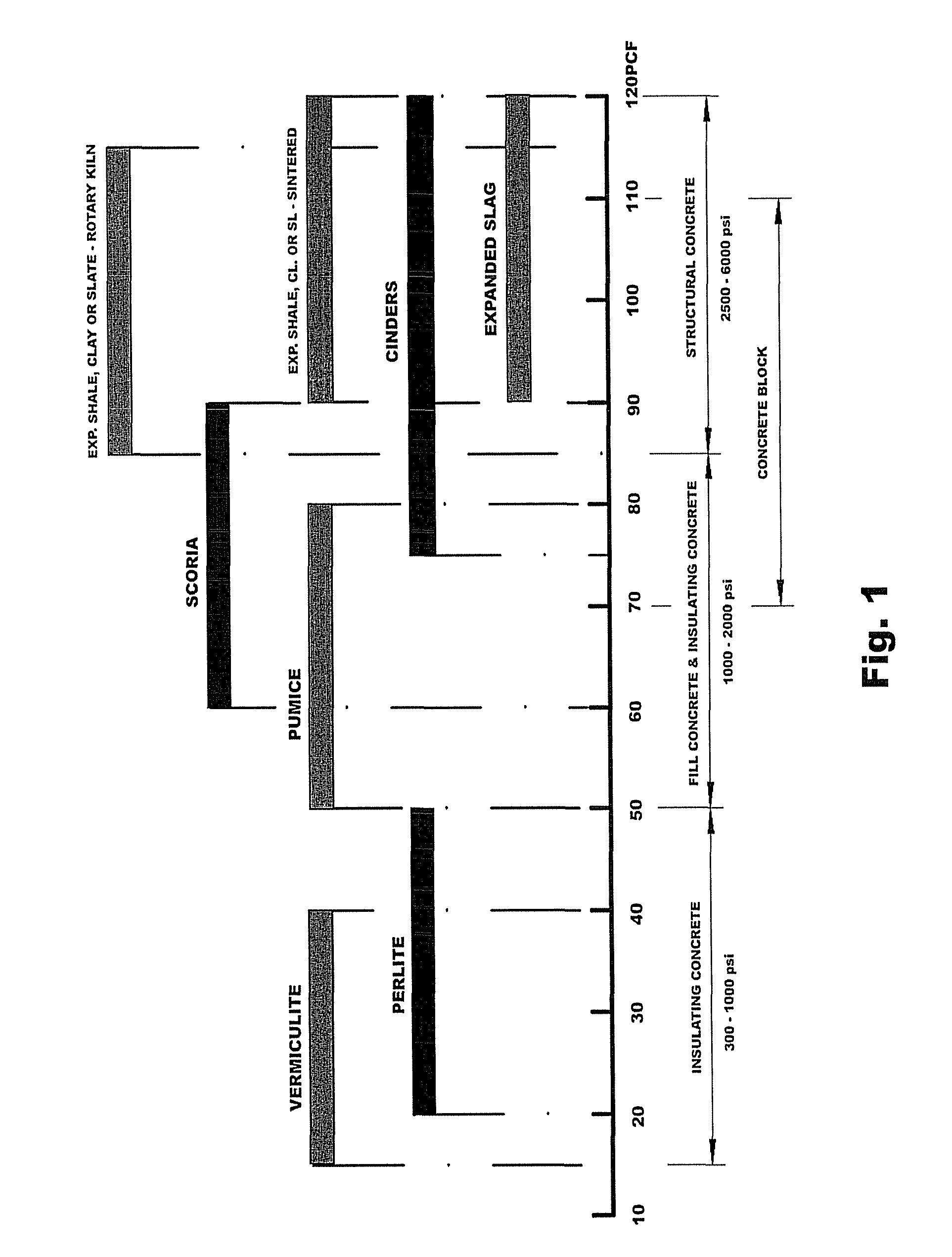

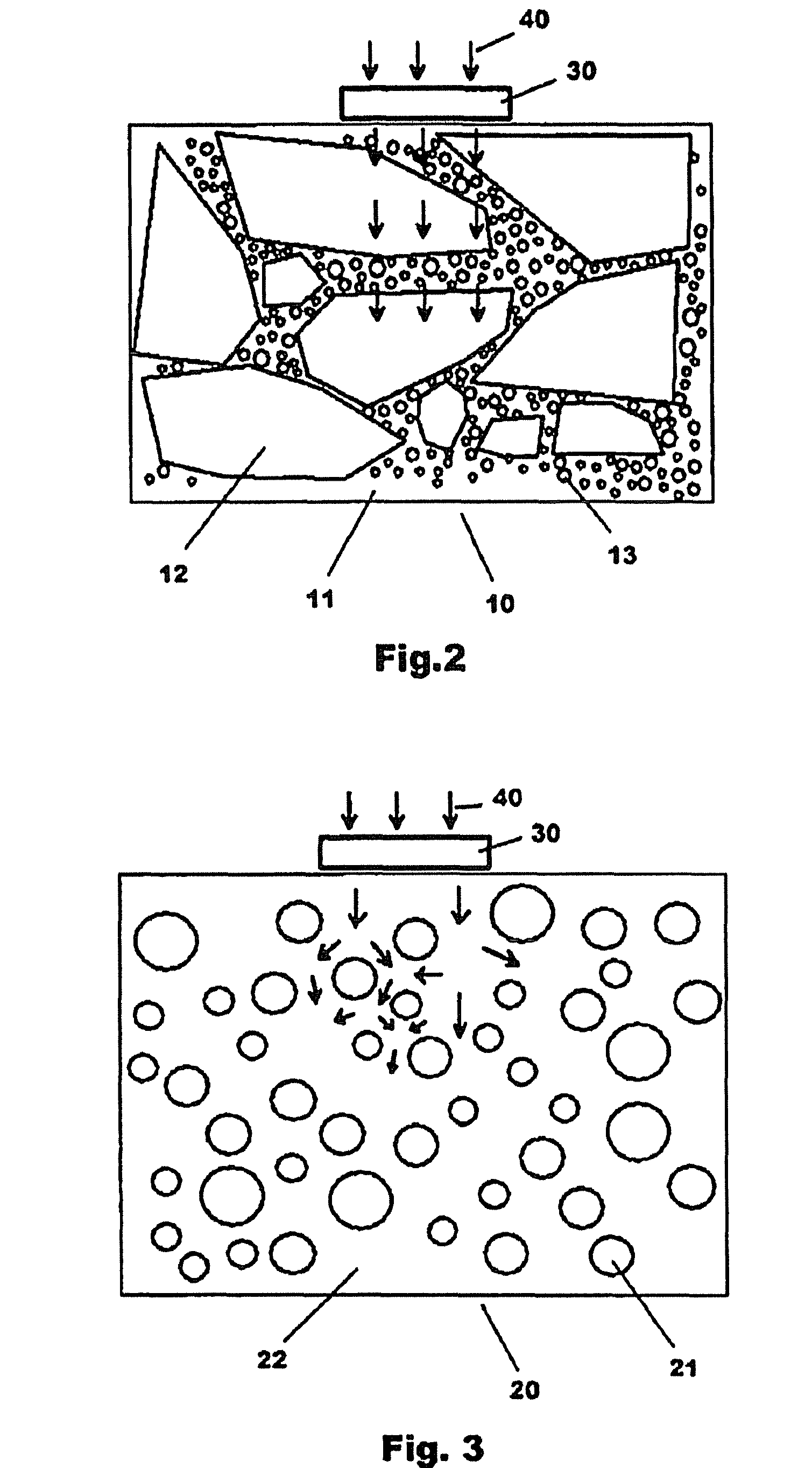

Lightweight structural concrete provided with various wood properties

InactiveUS7799129B2High strengthLow effective water to cement (w/c) ratioSolid waste managementCoatingsFiberPolystyrene bead

A lightweight structural concrete with screw-ability and nail-ability similar to wood is composed of a non-structural and ultra lightweight aggregate such as expanded perlite or a combination of expanded perlite and polystyrene beads of a particular size distribution and volume amount, entrained air cells of another specific size distribution and volume amount, and dense cementitious composition of a cement binder, a fine grade structural filler no larger than concrete sand grade, a pozzolan, and optional micro-fibers for reinforcement. This structural concrete matrix is optimized to hold 13 gauge T-nails and bugle head wood screws with thread ranging from 8 to 11 threads per inch and diameter of 0.10″ to 0.137″. The resulting concrete will have consistent screw-ability and nail-ability similar to that of wood.

Owner:BUI THUAN

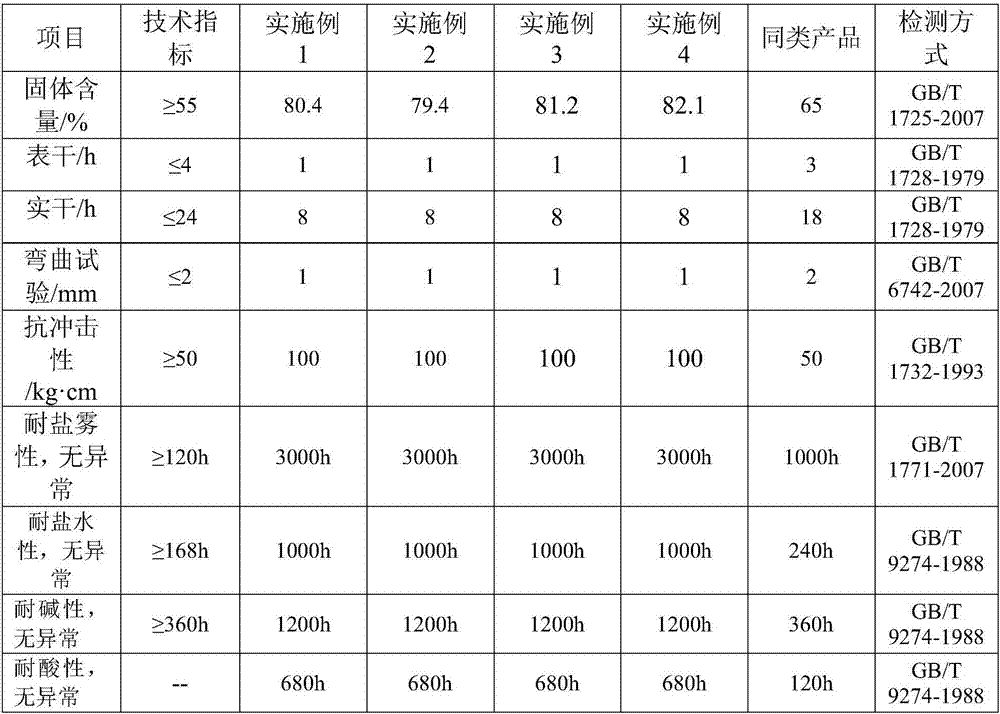

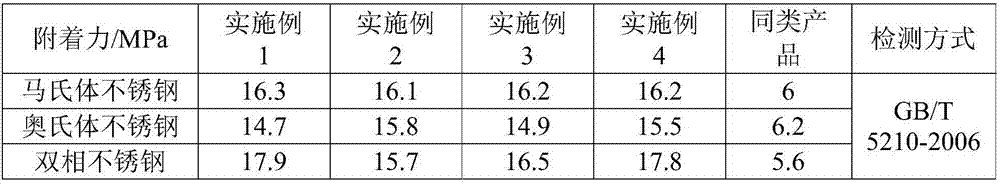

Anticorrosive coating for low surface treatment stainless steel substrate and preparation method of anticorrosive coating

ActiveCN107502140AStrong wetting abilityAvoid weak corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsPolyamidePre treatment

The invention discloses anticorrosive coating for a low surface treatment stainless steel substrate and a preparation method thereof and belongs to the technical field of the anticorrosive coating. The anticorrosive coating for the low surface treatment stainless steel substrate is prepared from a component A and a component B, wherein the weight ratio of the component A to the component B is 100 to (15 to 25); the component A is prepared from the following components: epoxy resin with low epoxy value, aminosilane, epoxy resin with high epoxy value, aluminum tripolyphosphate, compound zinc phosphate, precipitated barium sulfate, organic soil slurry, polyacrylate and a first solvent, wherein the first solvent comprises xylol, n-butyl alcohol and methyl isobutyl ketone; the component B is prepared from the following components in percentage by weight: polyamide resin, carboxyl-terminated nitrile butadiene rubber and a second solvent, wherein the second solvent comprises xylol and n-butyl alcohol. The anticorrosive coating disclosed by the invention is convenient to use and pre-treatment including sand blasting, electroplating, phosphatization and the like does not need to be carried out on a stainless steel product; a construction technology is simple and is suitable for stainless steel products or components with various sizes and shapes.

Owner:成都天合宏业科技发展有限公司

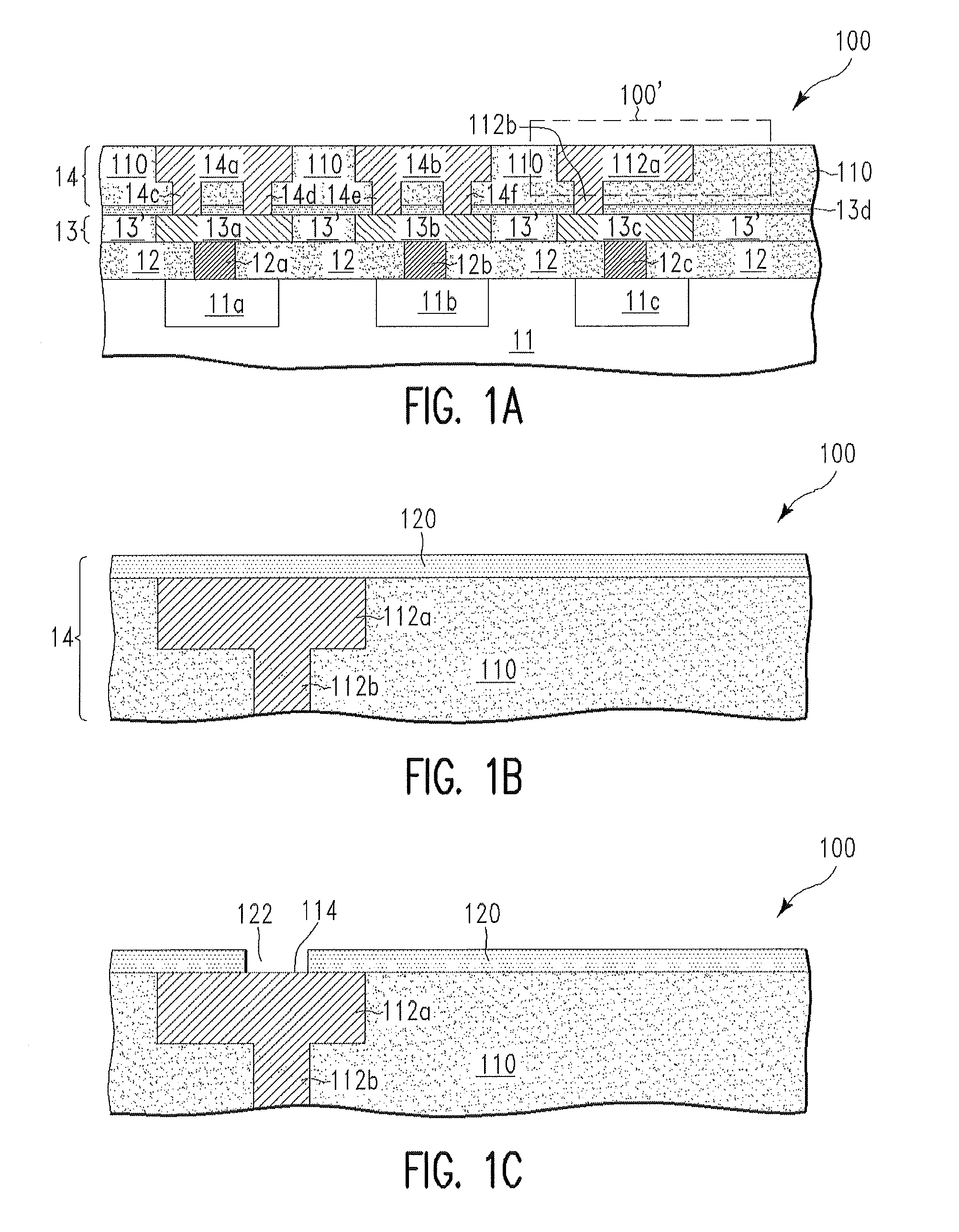

Crack trapping and arrest in thin film structures

InactiveUS7573130B1Easy to addCost effectiveSemiconductor/solid-state device detailsSolid-state devicesTrappingFilm structure

The present invention relates to a process for preparing a robust crack-absorbing integrated circuit chip comprising a crack trapping structure containing two metal plates and a via-bar structure sandwiched between said plates.

Owner:GLOBALFOUNDRIES INC

Circuit component, electrode connection structure and display device including the same

InactiveUS7957151B2Reduce harmReduce crack propagationDigital data processing detailsPrinted circuit aspectsDisplay deviceEngineering

An electrode connection structure including a first circuit component including a resin plate, a barrier film stacked on a surface of the resin plate, a circuit section formed on the barrier film and a first electrode provided on the surface of the resin plate on which the barrier film is stacked, and a second circuit component arranged to face the first circuit component and having a second electrode facing the first electrode, wherein the first and second electrodes are electrically connected via pressure applied thereto in the directions approaching each other and a portion of the barrier film surrounding the first electrode is at least partially removed from the surface of the resin plate.

Owner:SHARP KK

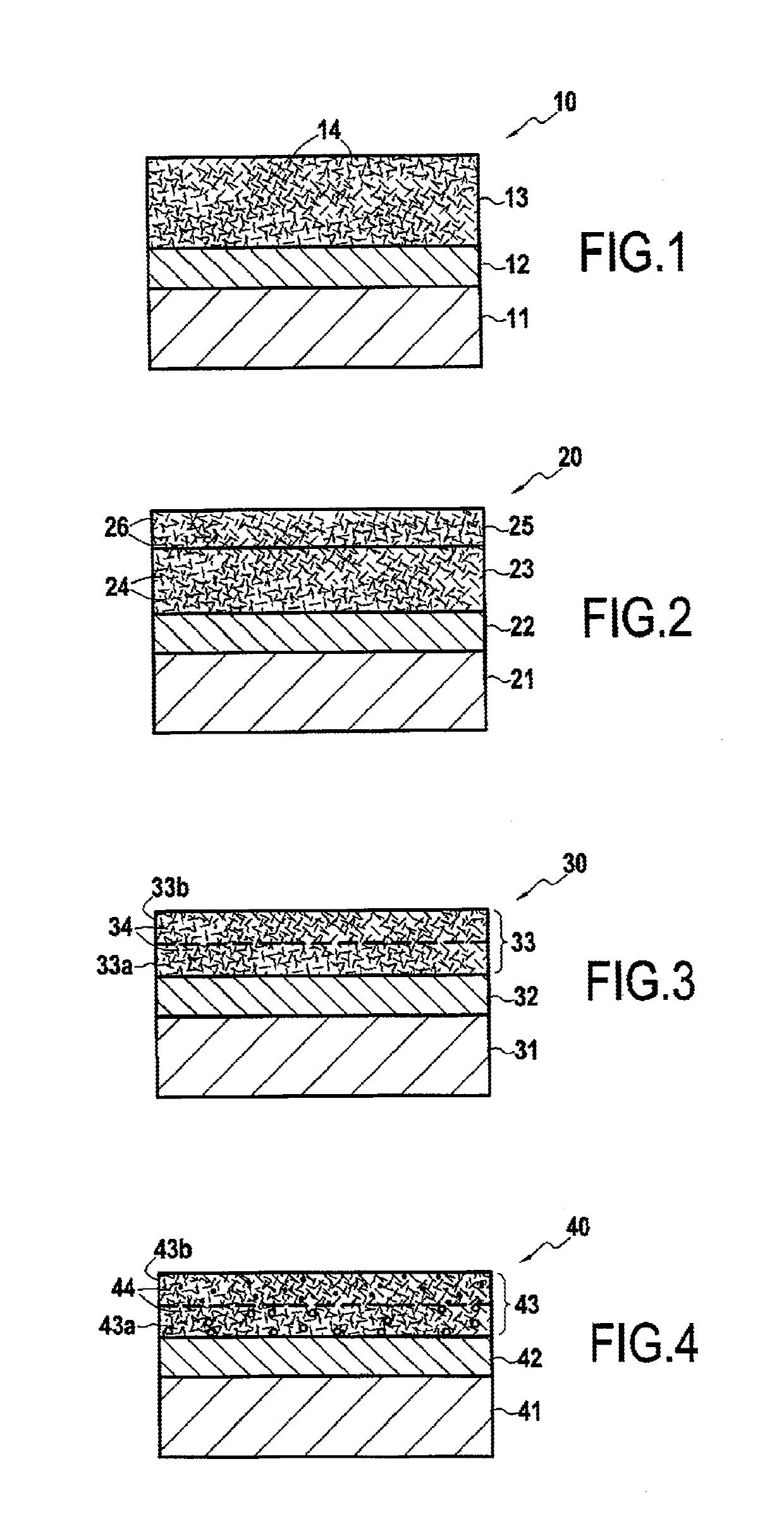

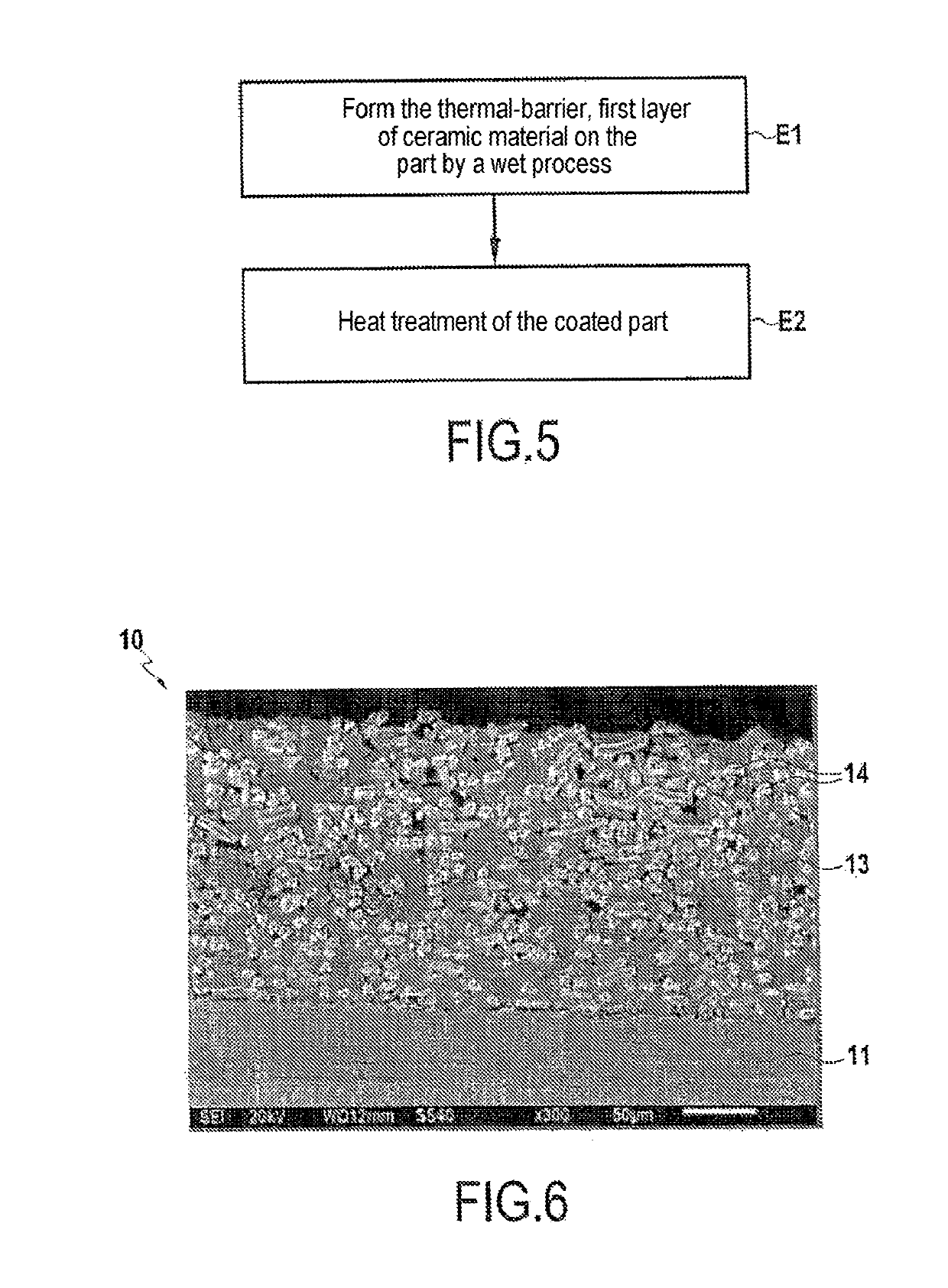

A turbine engine part coated in a thermal barrier, and a method of obtaining it

ActiveUS20190256983A1High mechanical strengthReduce crack propagationContinuous combustion chamberPropellersMagnesiumChemical composition

A turbine engine part coated in at least a first ceramic layer forming a thermal barrier and including a ceramic material with first ceramic fibers dispersed in the first layer. The first layer may have a chemical composition gradient between a material for forming a thermal barrier and a material for providing protection against calcium and magnesium aluminosilicates, which is present at a greater content in an outer zone of the first layer, and / or the first layer may be porous and may present a porosity gradient such that an outer portion of the first layer presents lower porosity.

Owner:CENT NAT DE LA RECHERCHE SCI +3

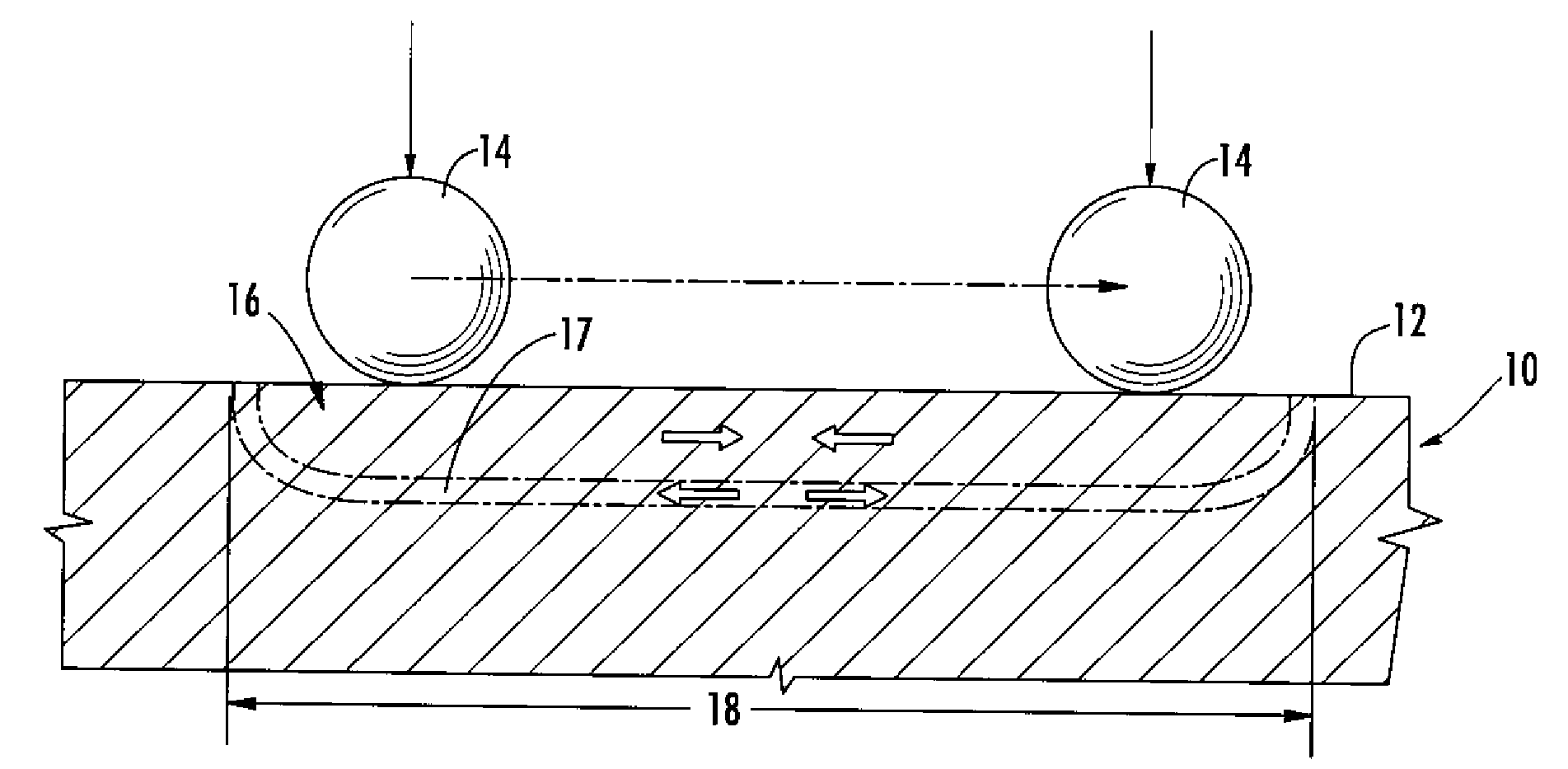

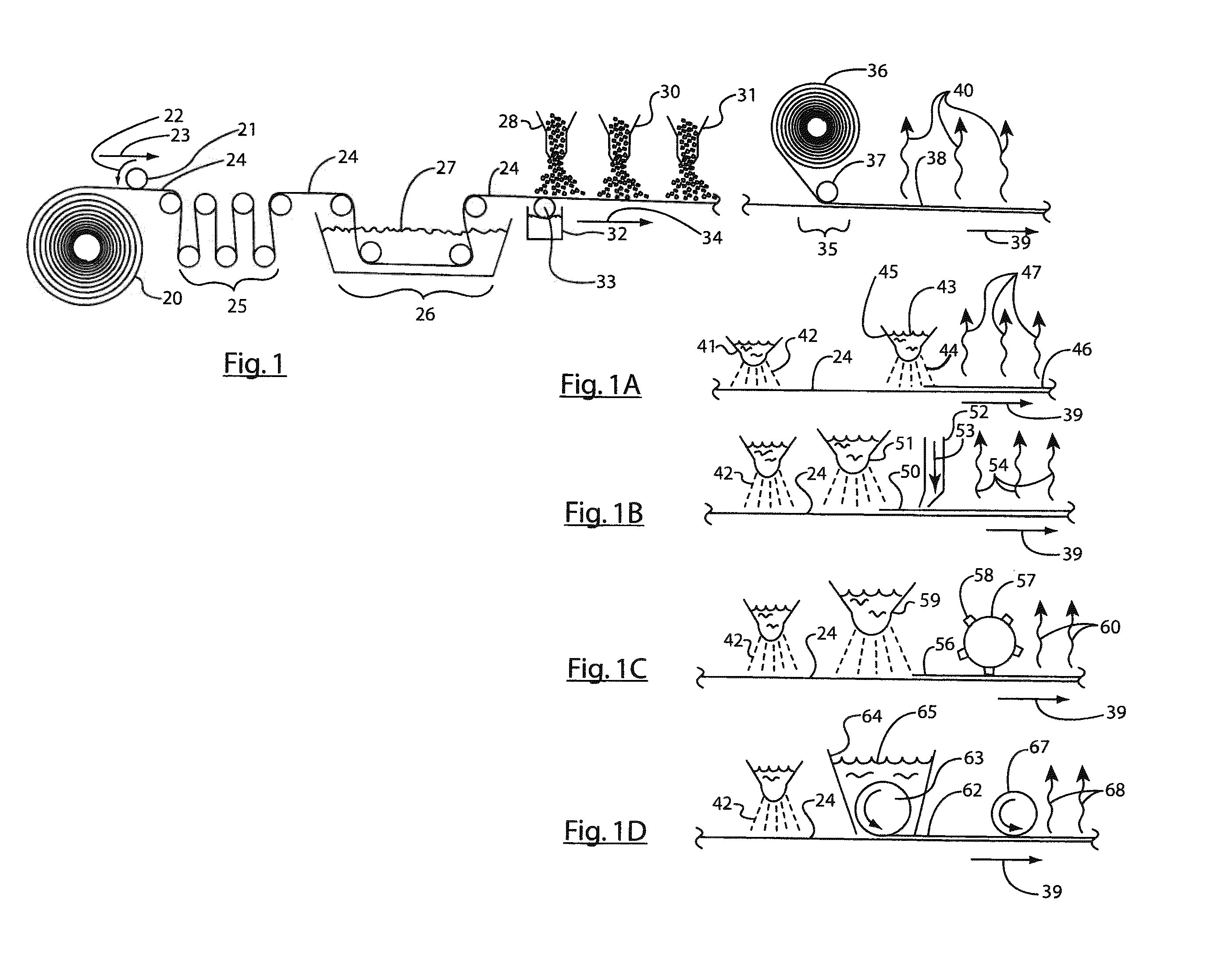

Roof covering material and method of manufacturing

ActiveUS9217249B2Reduce crack propagationLiquid surface applicatorsLamination ancillary operationsChemical treatmentFiber

A roof covering material is provided, as well as its method of manufacture, wherein a substrate, preferably of a fibrous material is provided, with a bituminous material, preferably asphalt coating, on opposite surfaces thereof, with granules being applied to an upper surface thereof and at least partially embedded in the bituminous material, and with a discontinuous top layer applied to the granule / bituminous material. The discontinuous top layer is preferably a polymeric material, and openings are provided therein, for passage of fluids therethrough, to avoid moisture, volatiles, and other fluid materials from being trapped beneath the top layer. Various techniques for application of the various materials, and for chemical treatment, are likewise provided.

Owner:CERTAINTEED CORP

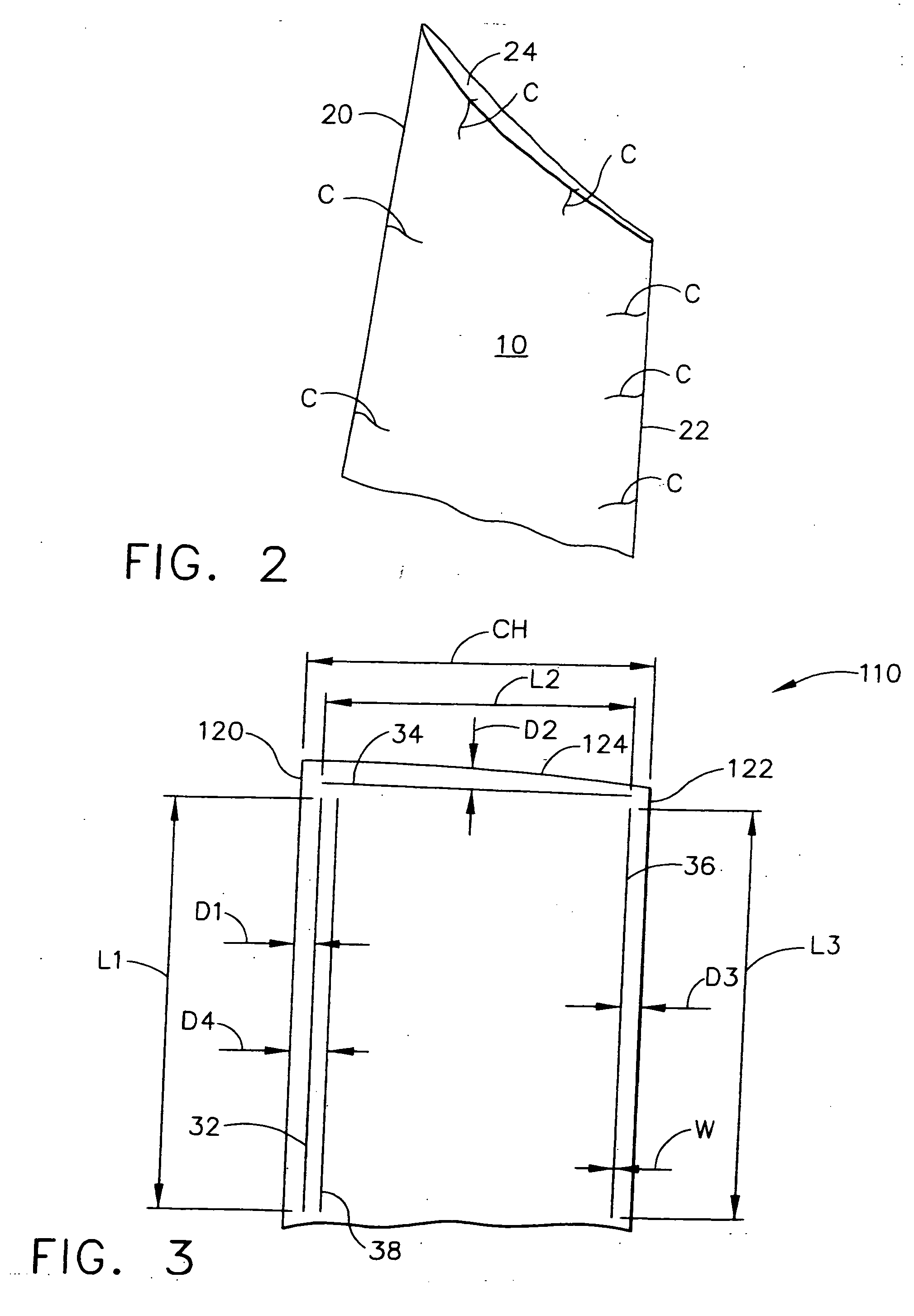

Roof Covering Material and Method of Manufacturing

ActiveUS20100203281A1Reduce crack propagationLiquid surface applicatorsLamination ancillary operationsChemical treatmentFiber

A roof covering material is provided, as well as its method of manufacture, wherein a substrate, preferably of a fibrous material is provided, with a bituminous material, preferably asphalt coating, on opposite surfaces thereof, with granules being applied to an upper surface thereof and at least partially embedded in the bituminous material, and with a discontinuous top layer applied to the granule / bituminous material. The discontinuous top layer is preferably a polymeric material, and openings are provided therein, for passage of fluids therethrough, to avoid moisture, volatiles, and other fluid materials from being trapped beneath the top layer. Various techniques for application of the various materials, and for chemical treatment, are likewise provided.

Owner:CERTAINTEED CORP

Lightweight structure especially for an aircraft and method for making such a structure

ActiveUS7753312B2High damage toleranceExcellent fatigue propertiesThin material handlingFuselagesSkin surfaceMechanical engineering

Owner:AIRBUS OPERATIONS GMBH

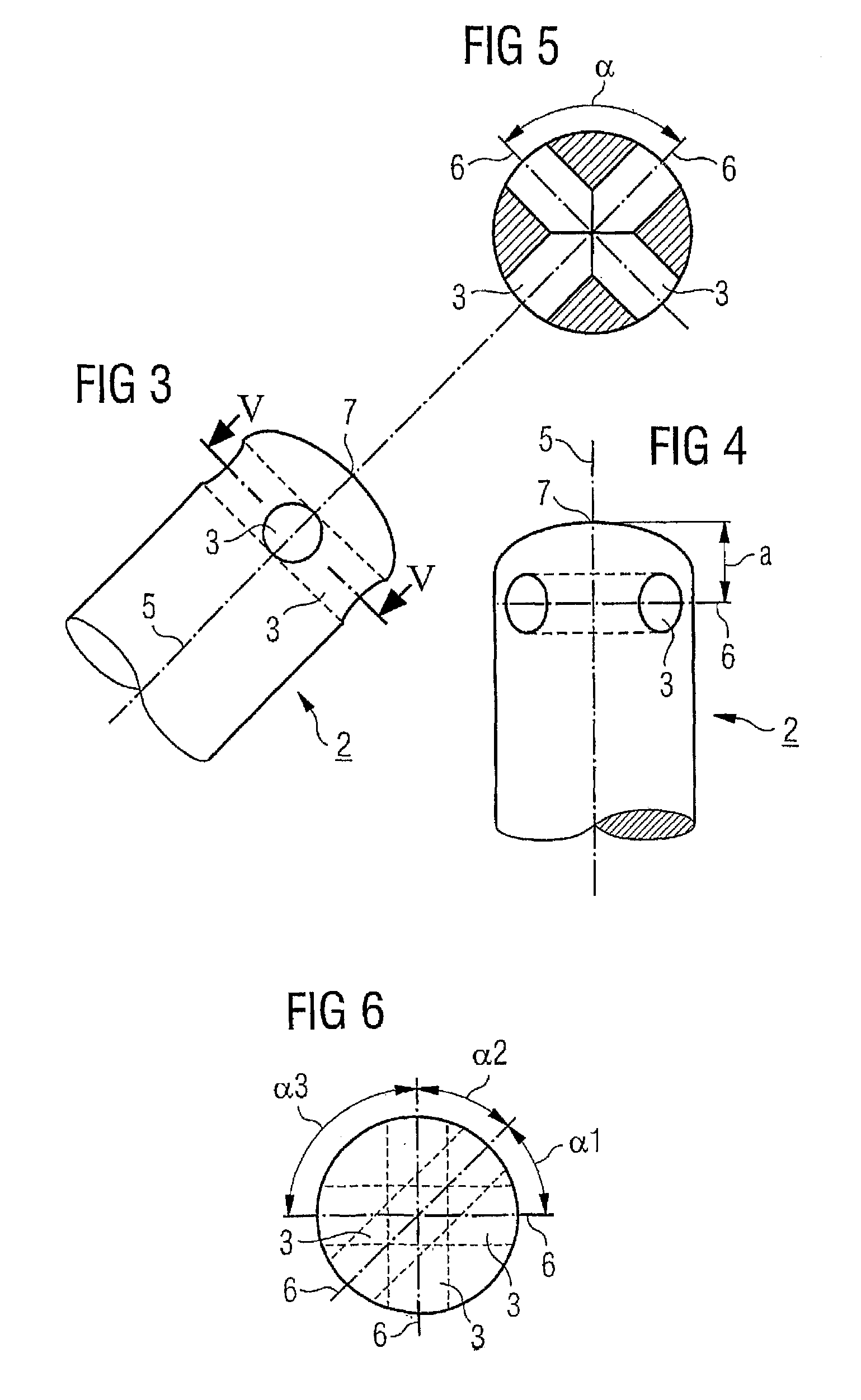

Semiconductor chips with crack stop regions for reducing crack propagation from chip edges/corners

InactiveUS7732932B2Reduce crack propagationSemiconductor/solid-state device detailsSolid-state devicesCrazingSemiconductor chip

Structures and a method for forming the same. The structure includes a semiconductor substrate, a transistor on the semiconductor substrate, and N interconnect layers on top of the semiconductor substrate, N being a positive integer. The transistor is electrically coupled to the N interconnect layers. The structure further includes a first dielectric layer on top of the N interconnect layers and P crack stop regions on top of the first dielectric layer, P being a positive integer. The structure further includes a second dielectric layer on top of the first dielectric layer. Each crack stop region of the P crack stop regions is completely surrounded by the first dielectric layer and the second dielectric layer. The structure further includes an underfill layer on top of the second dielectric layer. The second dielectric layer is sandwiched between the first dielectric layer and the underfill layer.

Owner:GLOBALFOUNDRIES INC

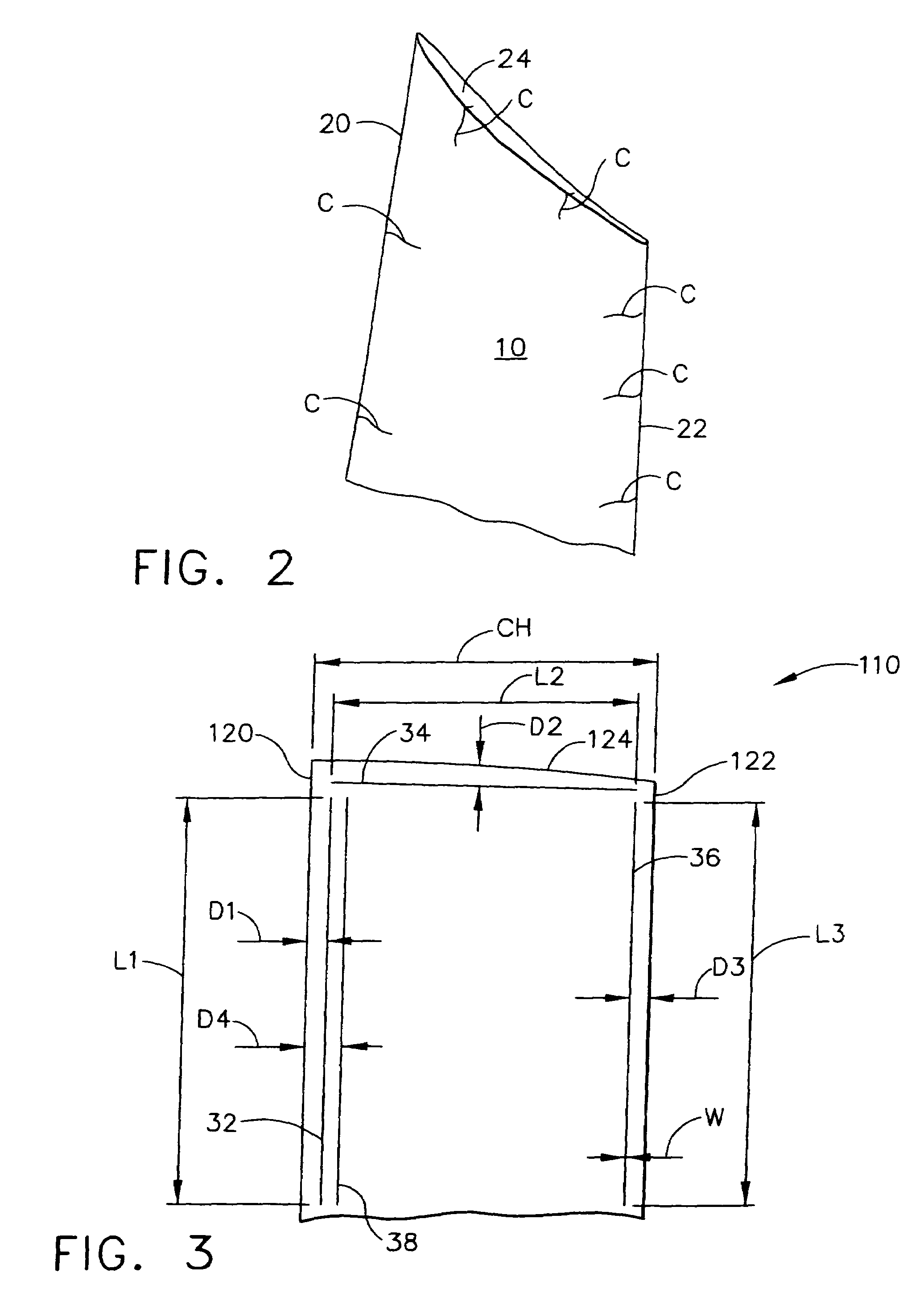

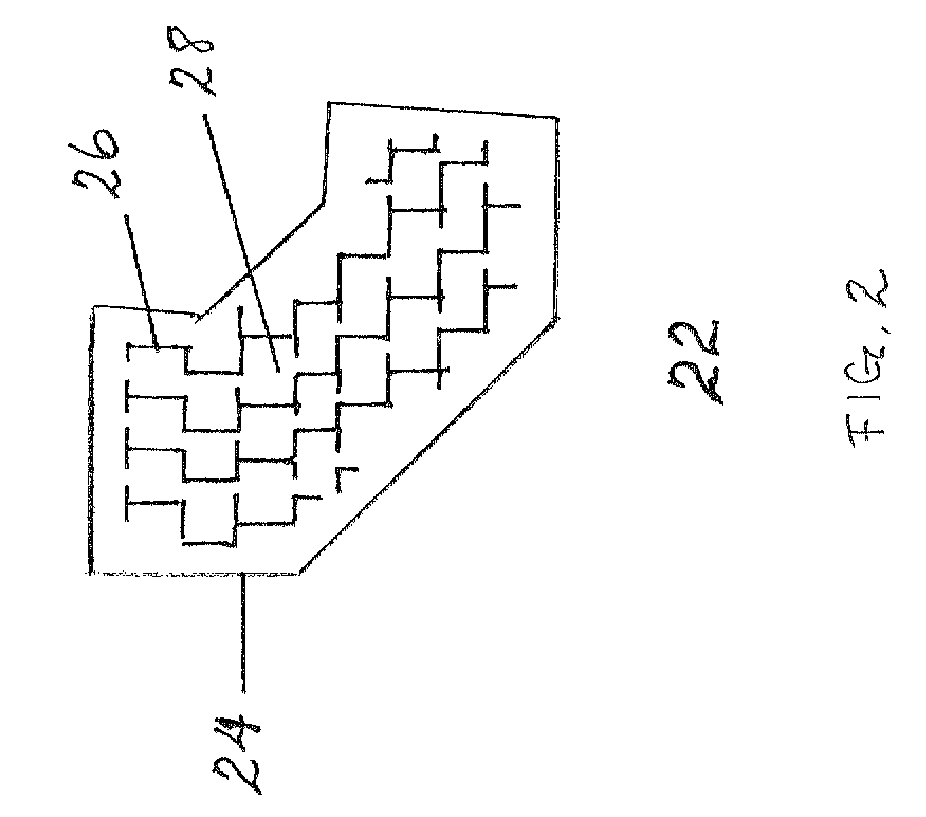

Composite Structure Splice and Method

PendingUS20190275753A1Relieve pressureDegrade composite structureElongated constructional elementsWeight reductionElectrical and Electronics engineeringComposite structure

A method for fabricating a composite structure. A first section for the composite structure is formed in which the first section has a first end with a chevron shape, wherein first composite layers in the first section has a first step pattern at the first end. A second section for the composite structure is formed in which the second section has a second end with a counterpart shape to the chevron shape and in which second composite layers in the second section have a second step pattern at the second end. The first end the second end are positioned such that a first composite layer in the first composite layers in the first step pattern overlap the second composite layers in the second step pattern at a splice location.

Owner:THE BOEING CO

Glass article and display device including the same

PendingUS20210188700A1Mitigate propagation of crackShort processing timeElectrical equipmentGlass/slag layered productsCovalent bondCrystallinity

A glass article includes: a glass phase including a first structure in which a silicon atom is covalently bonded to four first oxygen atoms; and a plurality of crystals dispersed in the glass phase. The crystals include beta-quartz crystals, each of the beta-quartz crystals includes the first structure and a second structure in which aluminum is covalently bonded to four second oxygen atoms, and a crystallinity of the beta-quartz crystals is in a range of about 40% to about 50%.

Owner:SAMSUNG DISPLAY CO LTD

Wind turbine blade with a trailing edge spacing section

ActiveUS11028824B2Good structural supportLess-prone to buckling effectFinal product manufactureMachines/enginesLeading edgeSuction force

A wind turbine blade is provided with two shell parts each at least partly made of a sandwich structure including an inner skin (76), an outer skin (74), and an intermediate core material (75, 77), wherein the shell parts are bonded together at least along their respective leading edges (18). The blade also comprises a longitudinally extending spacing section in which the respective trailing edges (58a, 58b) of the pressure side shell part and the suction side shell part are spaced apart, wherein a trailing edge shear web (45) is arranged between and connected to the sandwich structure of the suction side shell part (84, 86, 87) and the sandwich structure of the pressure side shell part (74, 76, 77).

Owner:LM WP PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com