Full FRP (Fiber Reinforced Plastics) bar reinforced ECC-concrete combined beam component and preparation method thereof

A technology of concrete and composite beams, which is applied in the direction of building components, building reinforcements, joists, etc., can solve problems such as poor ductility, interface bonding failure, FRP tendon fracture, etc., and achieve good durability, strong energy dissipation capacity, good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

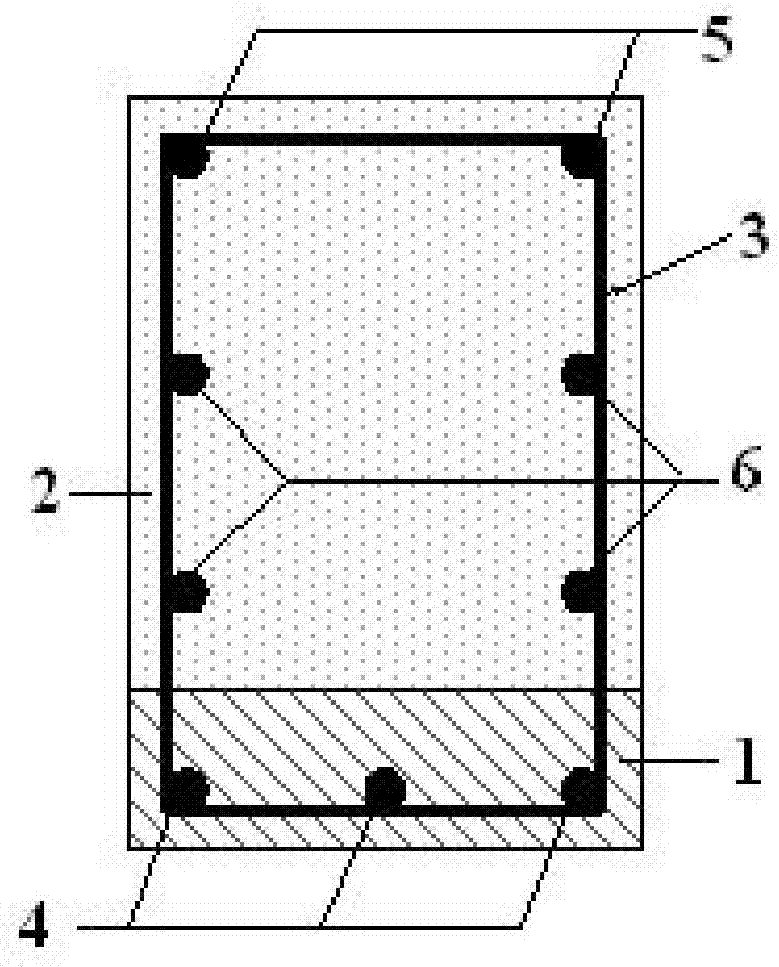

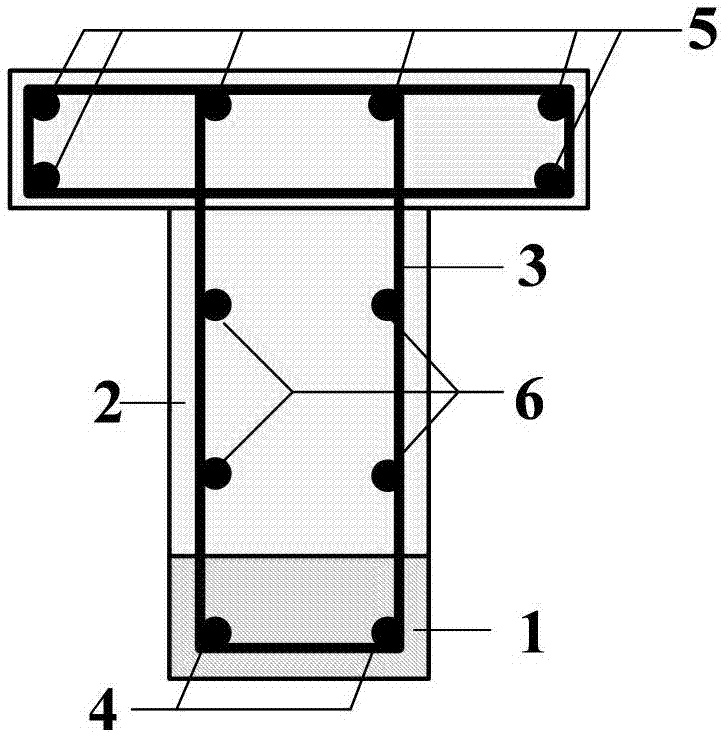

[0022] Such as figure 1 and 2 As shown, a fully FRP tendon reinforced ECC-concrete composite beam member includes the lower ECC layer 1 and the upper concrete layer 2, and also includes the FRP tendon skeleton, which is composed of longitudinal tension FRP tendons 4, FRP tendon stirrups 3. The FRP ribs are composed of 6 and vertical erected FRP tendons 5. The longitudinal tensile FRP tendons 4 are placed at the bottom of the beam member and are located inside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com