High-toughness pipe pile and manufacturing method thereof

A durable and tubular pile technology, which is applied in the fields of port engineering pile foundation, bridge engineering, and civil engineering, can solve the problems of pile body cracking, pile top damage, and poor concrete impact resistance, so as to prolong the service life and save maintenance costs , eradicate the effect of poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

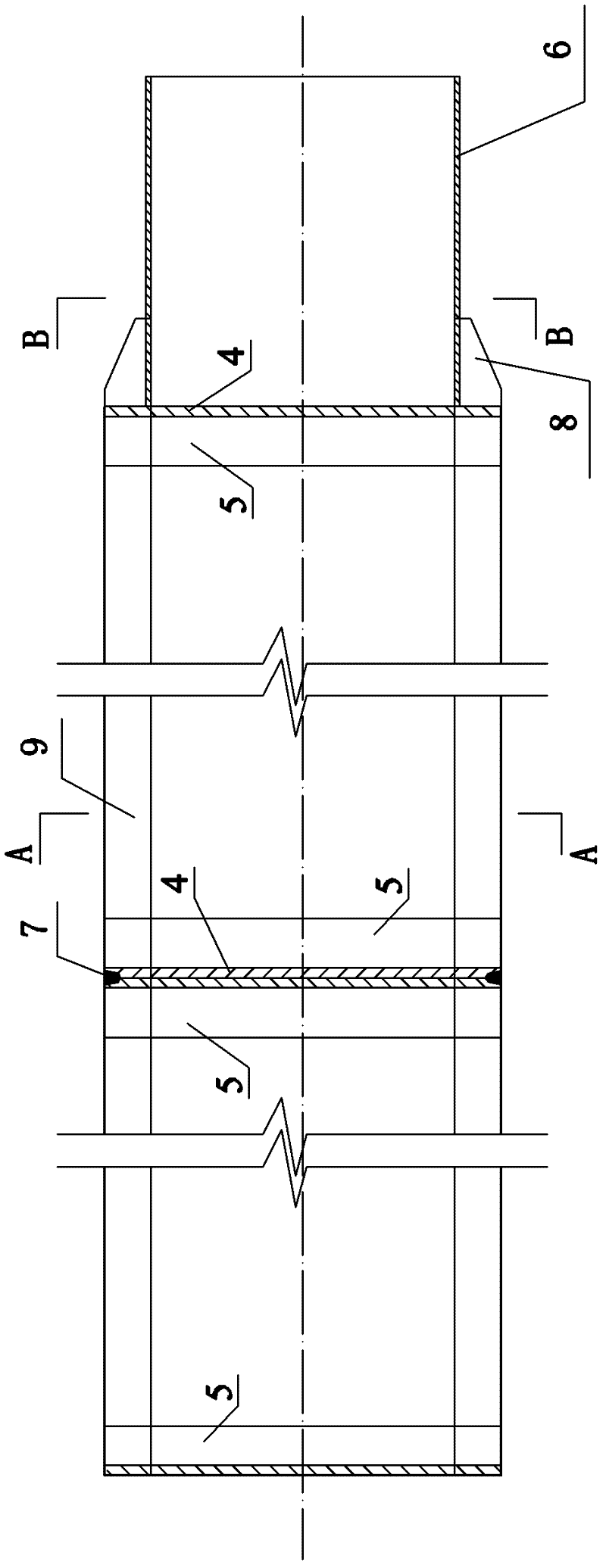

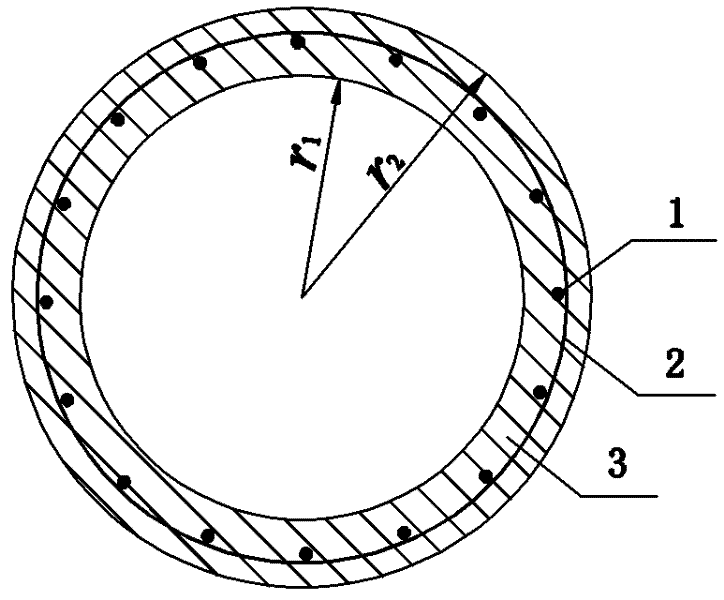

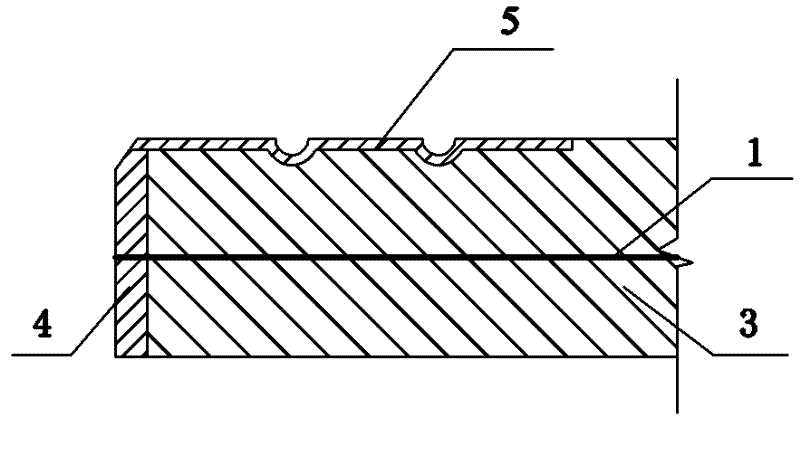

[0031] Referring to the accompanying drawings, the high-durability pipe pile of the present invention is composed of several pipe joints; among them, each pipe joint uses UHTCC as the pipe pile base 3, and longitudinal steel bars 1 are arranged in the pipe wall along the length direction of the pipe pile, and the longitudinal steel bars 1 are surrounded Spiral stirrups 2 are provided, and steel end plates 4 and steel hoops 5 are provided at both ends of each pipe joint. The longitudinal reinforcement 1 is welded to the steel end plate 4 by plug welding, and each pipe joint is The end plate 4 is welded and connected as a whole.

[0032]The UHTCC is composed of short fibers and a mortar matrix, the type of short fibers added is one or more of polyvinyl alcohol fibers, polyethylene fibers, and aromatic polyamide fibers, and the volume dosage is 1~2% of the total volume of UHTCC. 3%; the weight ratio of the components of the mortar matrix is cement: water: fine aggregate: fly as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com