Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Avoid defects such as cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

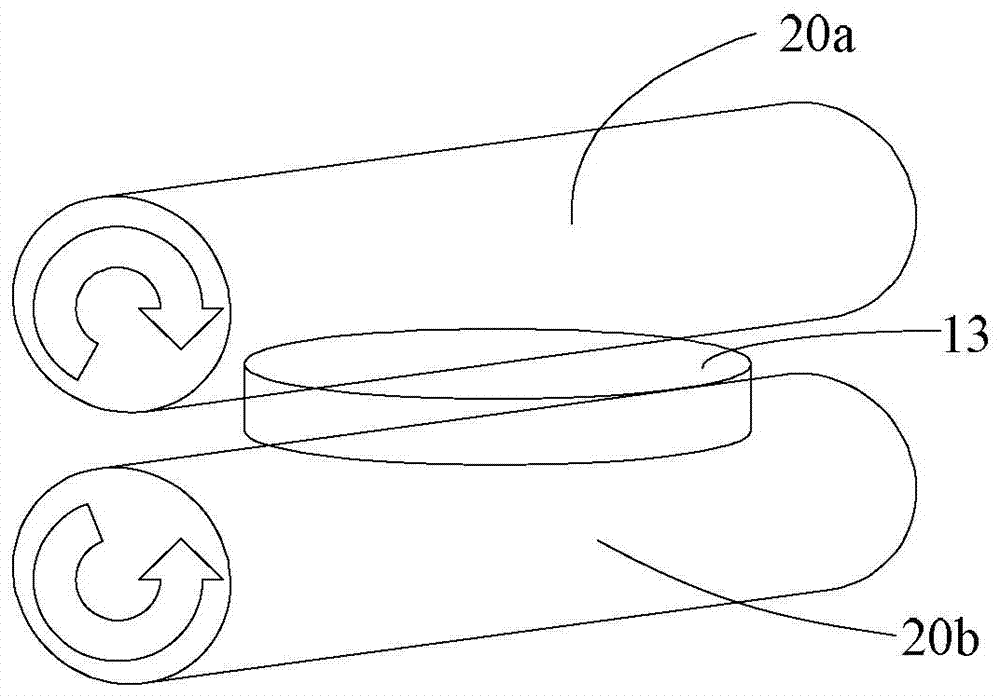

Method for preparing metallic support type solid oxide fuel cell

InactiveCN101562255AAvoid defects such as crackingAvoid cathodic activity reductionFinal product manufactureSolid electrolyte fuel cellsFuel cellsSlurry

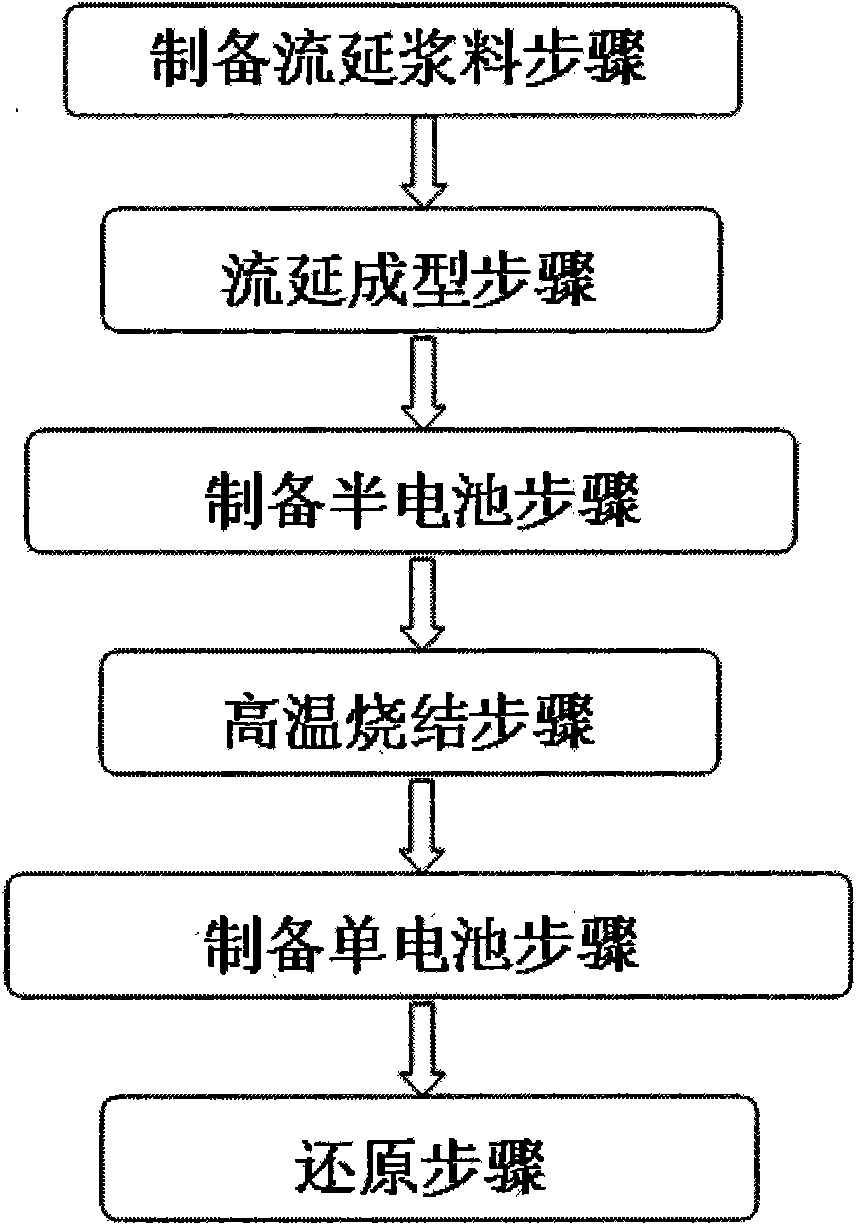

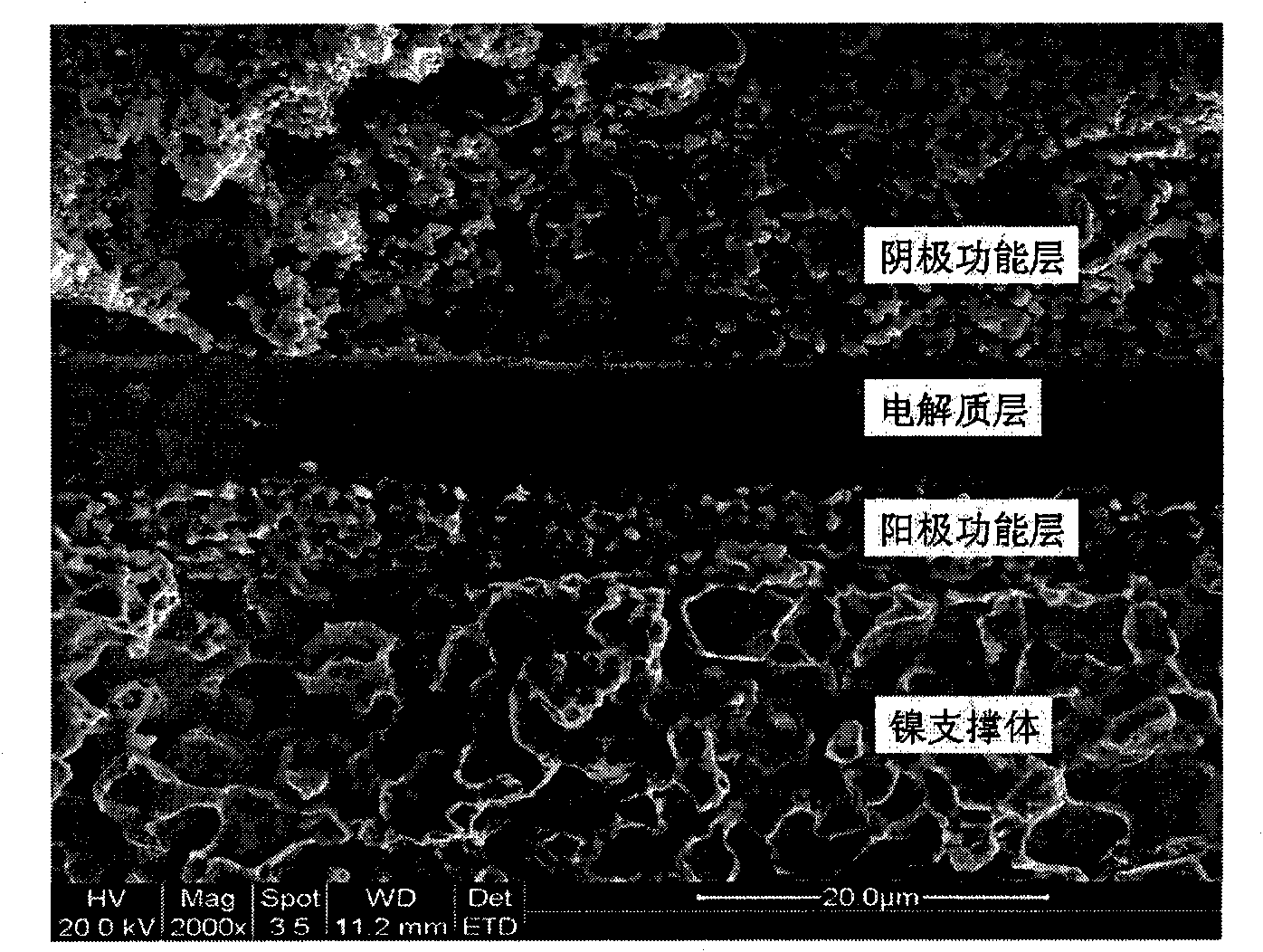

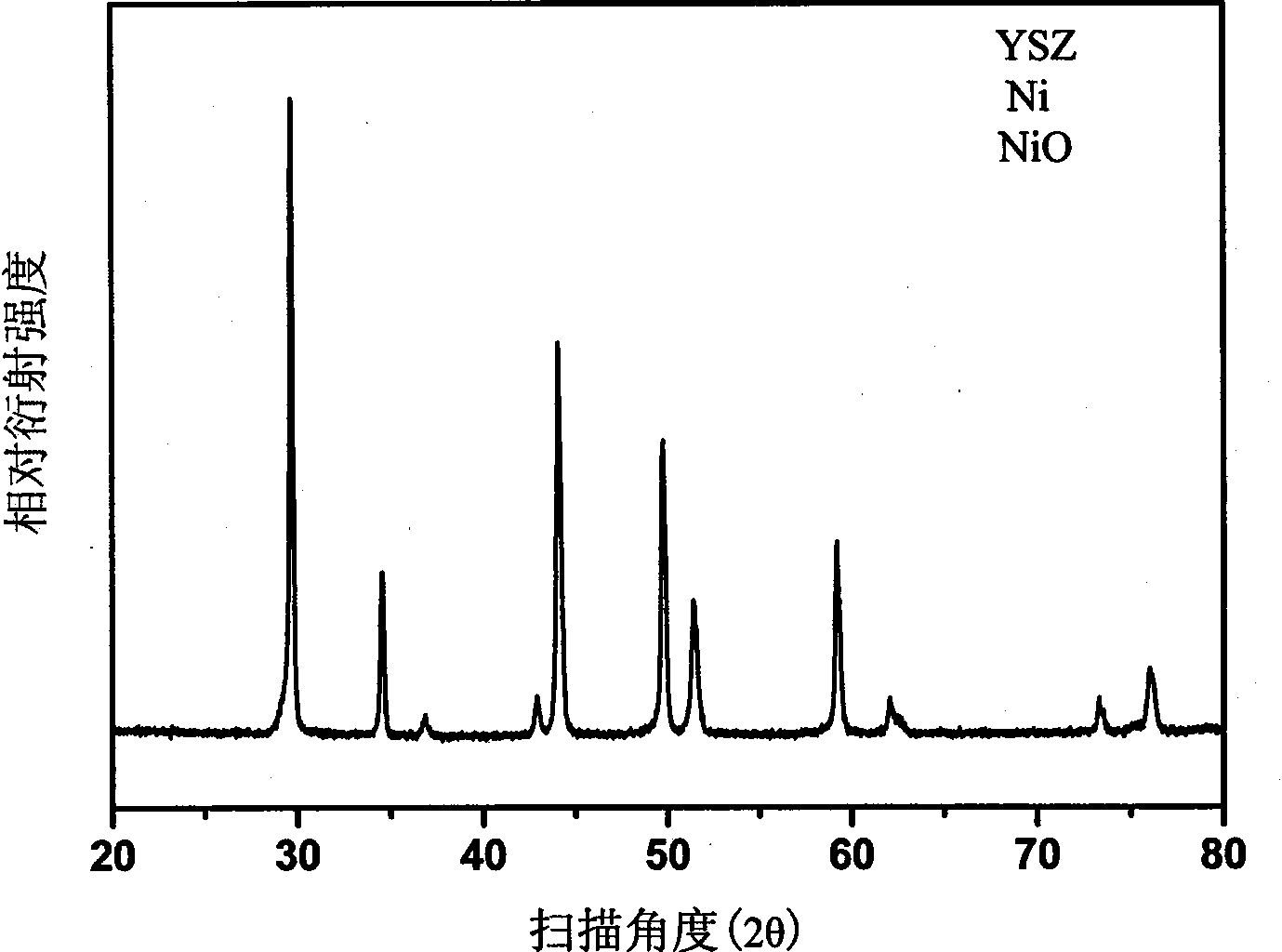

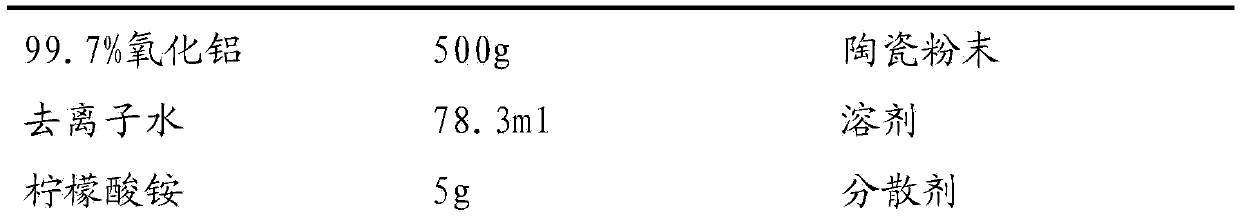

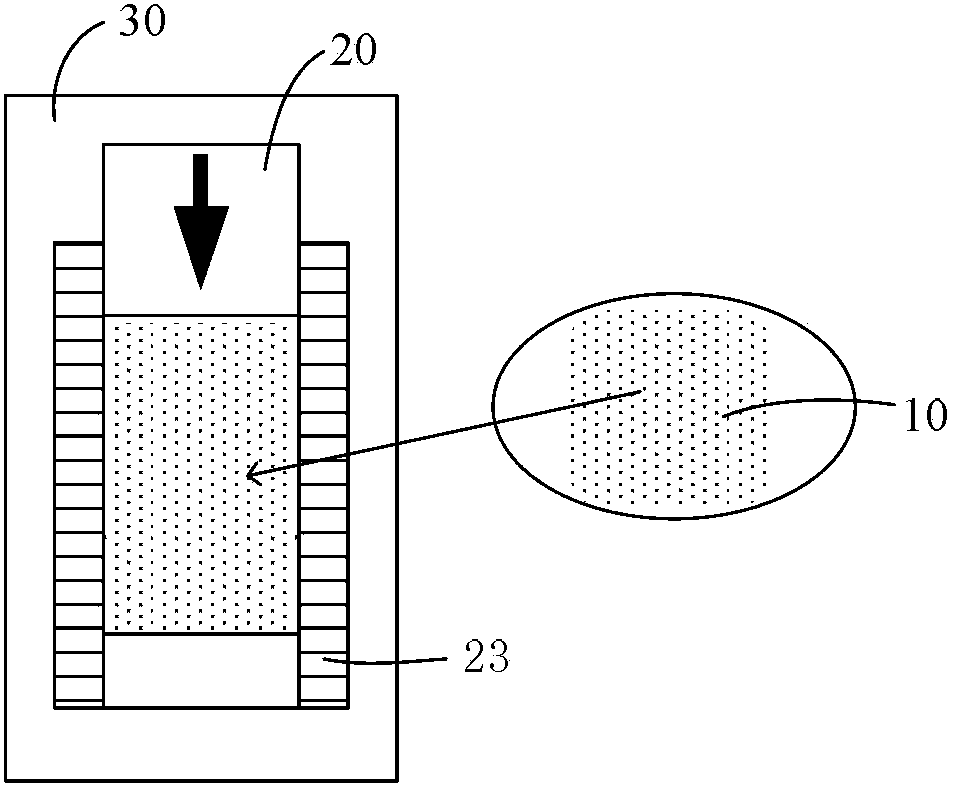

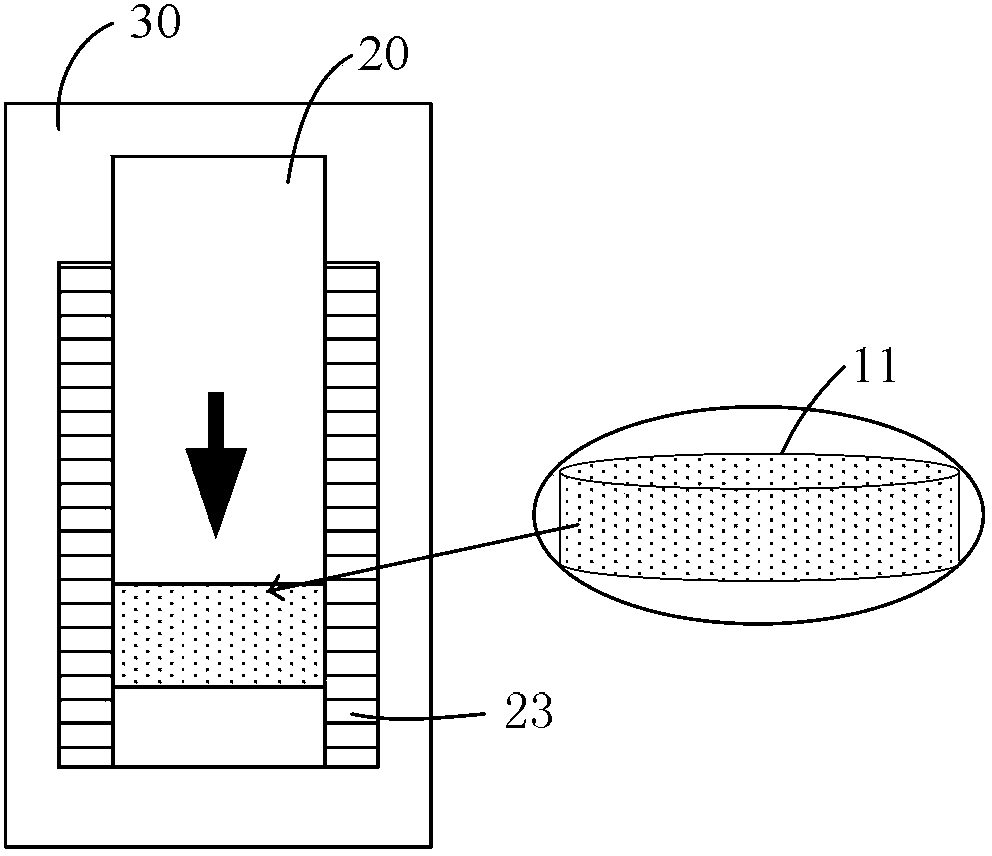

The invention provides a method for preparing a metallic support type solid oxide fuel cell, and belongs to a method for preparing a solid oxide fuel cell (SOFC). The invention aims to simplify process, lower cost and prepare the fuel cell with excellent electric property. The method comprises the following steps: (1) a tape casting slurry preparation step; (2) a tape casting formation step; (3) a half cell preparation step; (4) a high-temperature sintering step; (5) a monocell preparation step; and (6) a reducing step. The method has the advantages of wide raw material source, simple preparation process and low cost; and the open-circuit voltage of the prepared SOFC, which is measured at a temperature of 750 DEG C, is 1.01V, the maximum power density is 0.64w / cm, so that the SOFC can be applied to the preparation of the large-area metallic support type solid oxide fuel cell.

Owner:中博源仪征新能源科技有限公司

Method for preparing cermet material

ActiveCN101423901AHigh strengthImprove bending strengthAldehyde/ketone condensation polymer adhesivesOrganic acidFlexural strength

The invention provides a method for preparing cermet materials. The method comprises the following steps of well mixing raw cermet materials with binder, performing crushing and injection molding so as to obtain blanks, degreasing the obtained blanks and sintering the degreased blanks in a vacuum environment, so as to obtain the cermet materials, wherein the binder consists of paraffin, ethylene-vinyl acetate copolymer, high-density polyethylene and organic acid, and the organic acid is oleic acid and / or stearic acid. By using the binder consisting of the paraffin, the ethylene-vinyl acetate copolymer, the high-density polyethylene and the organic acid selected from the oleic acid and / or the stearic acid, the method avoids the blistering, deformation, cracking and other defects of the blanks in a degreasing process, so as to ensure that the obtained cermet materials have better strength and bending-resistant strength.

Owner:靖江市华信科技创业园有限公司

Water-based gel casting method for structural ceramics

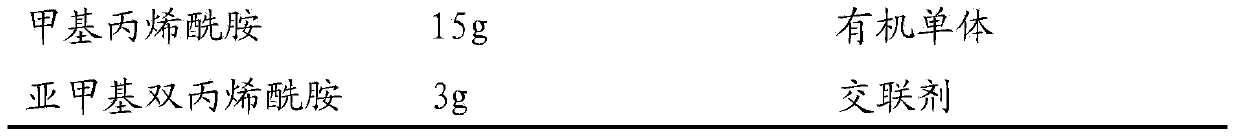

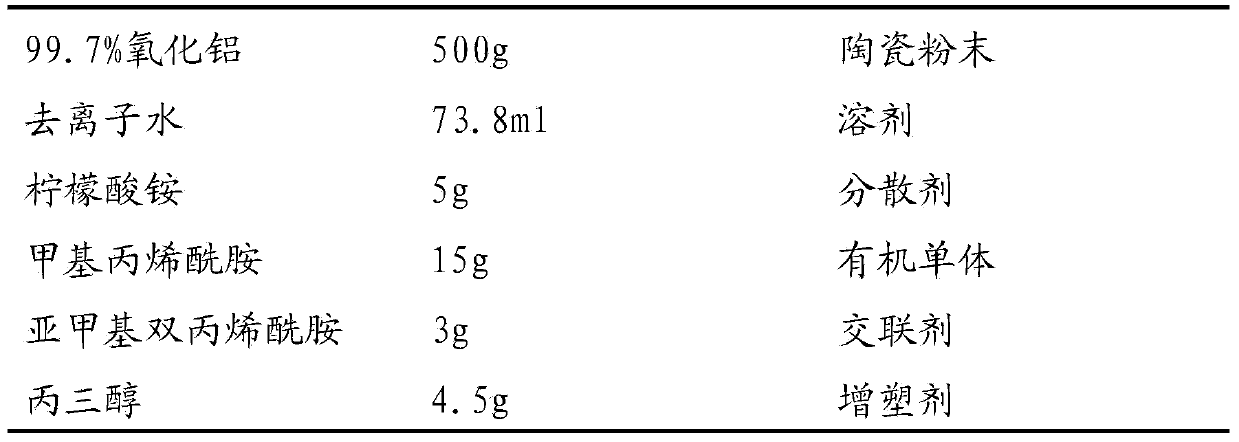

The invention provides a water-based gel casting method for structural ceramics. Organic monomers, cross-linking agents and dispersing agents are dissolved in deionized water to be prepared into a mixed solution. Plasticizers are added in the mixed solution to be prepared into a raw material solution. Ceramic powder is added in the raw material solution and subjected to ball milling to obtain a ceramic slurry; initiators and stimulation agents are added in the ceramic slurry, bubbles dissolved in the ceramic slurry are removed in vacuum after the mixture is evenly stirred, and the mixture is injected in molds to be molded to obtain solidified wet ceramic blanks; the solidified wet ceramic blanks are dried to obtain dry blanks, and the dry blanks are subjected to processing and thermal treatment to be produced into ceramic products. In the technological process, glycerol or Tween 80 is used as plasticizers, so that the plasticity of the molded blanks is improved, residual stress of the blanks is reduced, defects such as cracking during drying are prevented, the ceramic blanks are high in compactness, good in plasticity, uniform in structure and suitable for batch industrial production.

Owner:无锡特科精细陶瓷有限公司

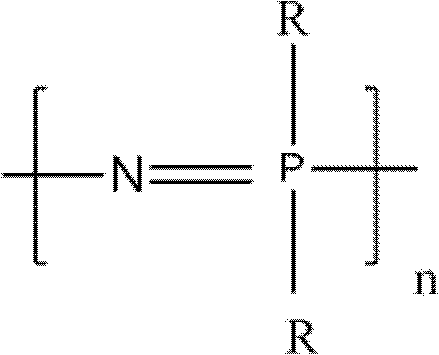

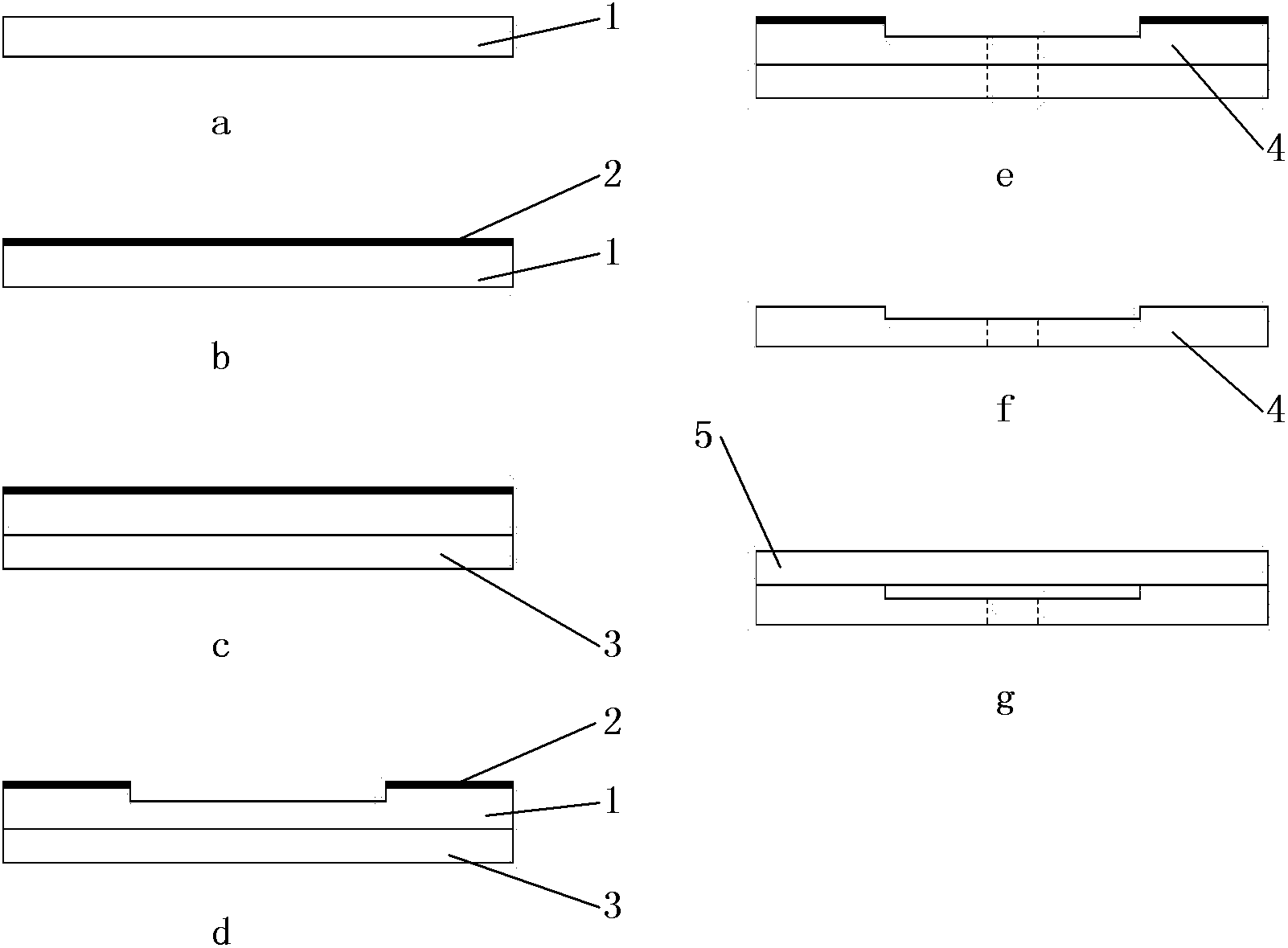

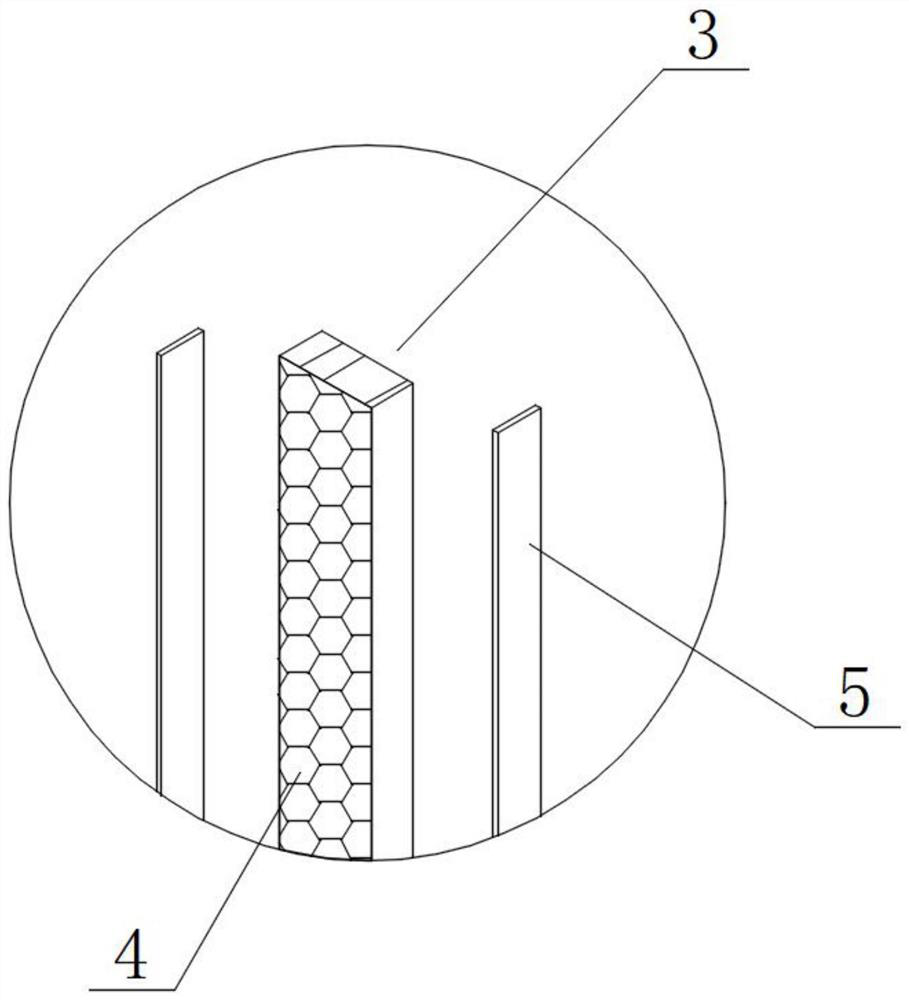

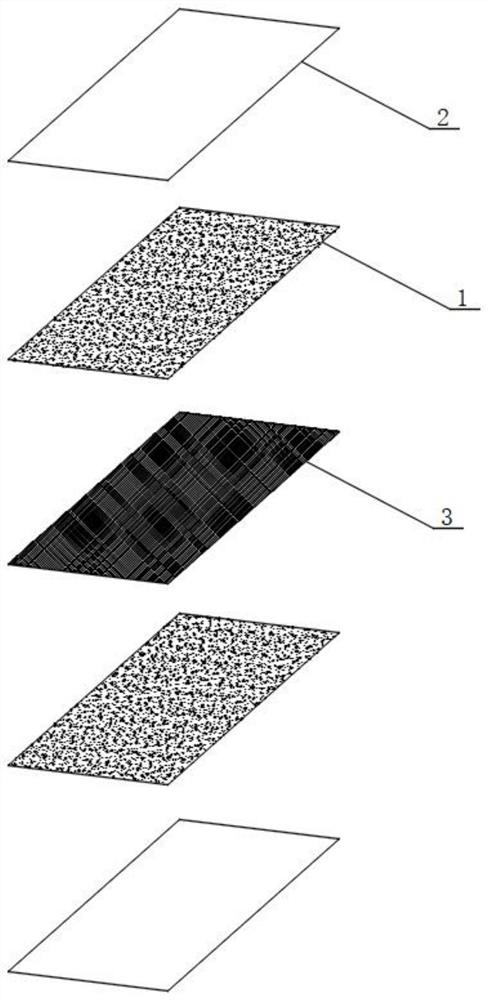

Polyphosphazene composition, solar cell back film with polyphosphazene coatings and preparation method of solar cell back film

ActiveCN102618042AGood flexibilityImprove ductilityFinal product manufactureCoatingsPolyesterMicro nano

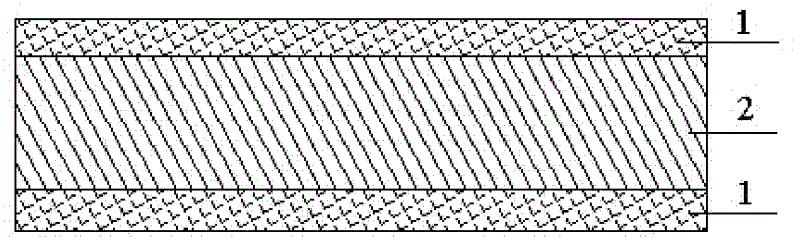

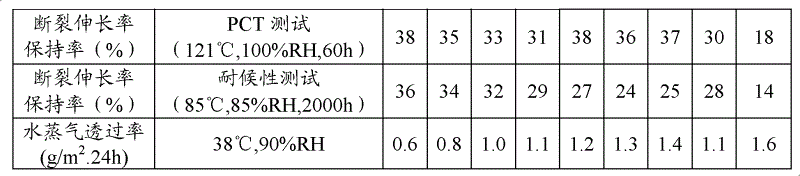

The invention relates to the technical field of solar photovoltaic cells, in particular to a polyphosphazene composition, a solar cell back film with polyphosphazene coatings and a preparation method of the solar cell back film in order to solve the problems that: in the prior art, the solar cell back film is complicated in preparation process and poor in weathering resistance. The polyphosphazene composition comprises 55-89 parts by weight of polyphosphazene material, 1-15 parts by weight of polyphosphazene micro-nano material, and 10-30 parts by weight of solvent. The solar cell back film has a three-layer structure, wherein the middle layer is a base film made from a polyester material, and the two outer layers are respectively polyphosphazene coatings made from a polyphosphazene material and a polyphosphazene micro-nano material. The solar cell back film has a simple structure and excellent weathering resistance, and the polyphosphazene coatings and the base film material have better compatibility. The preparation method is simple in production process and is easy to operate.

Owner:合肥长阳新材料科技有限公司

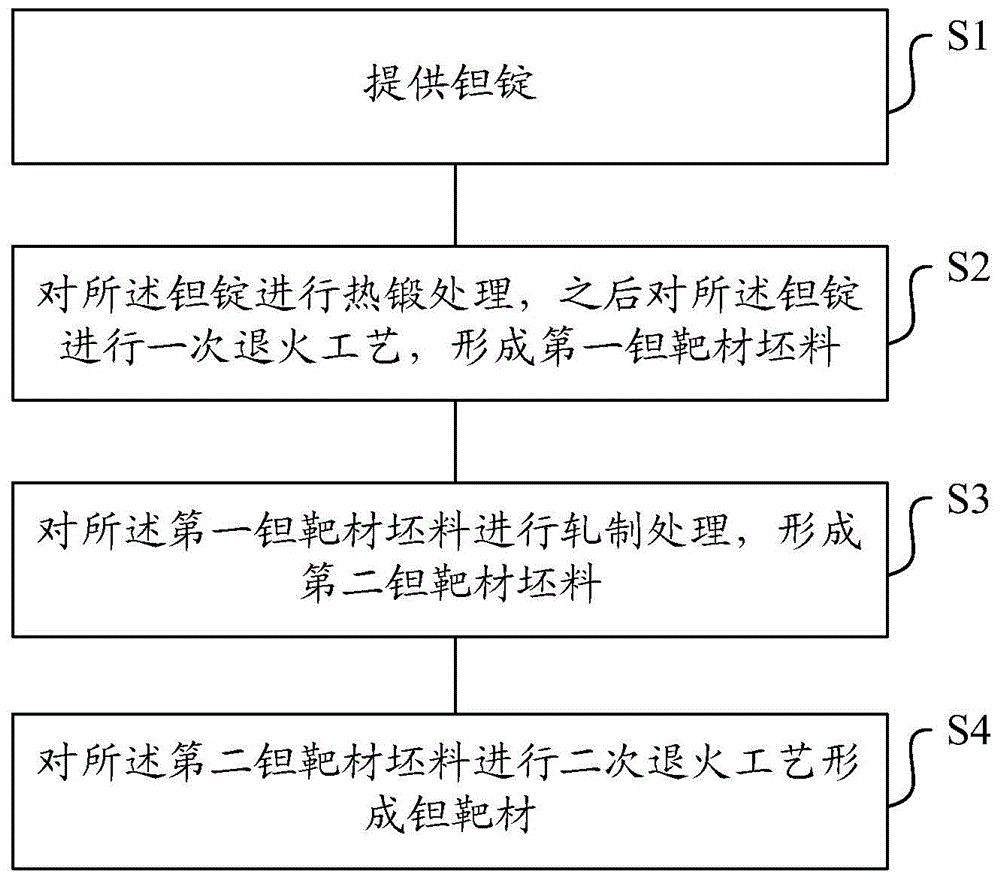

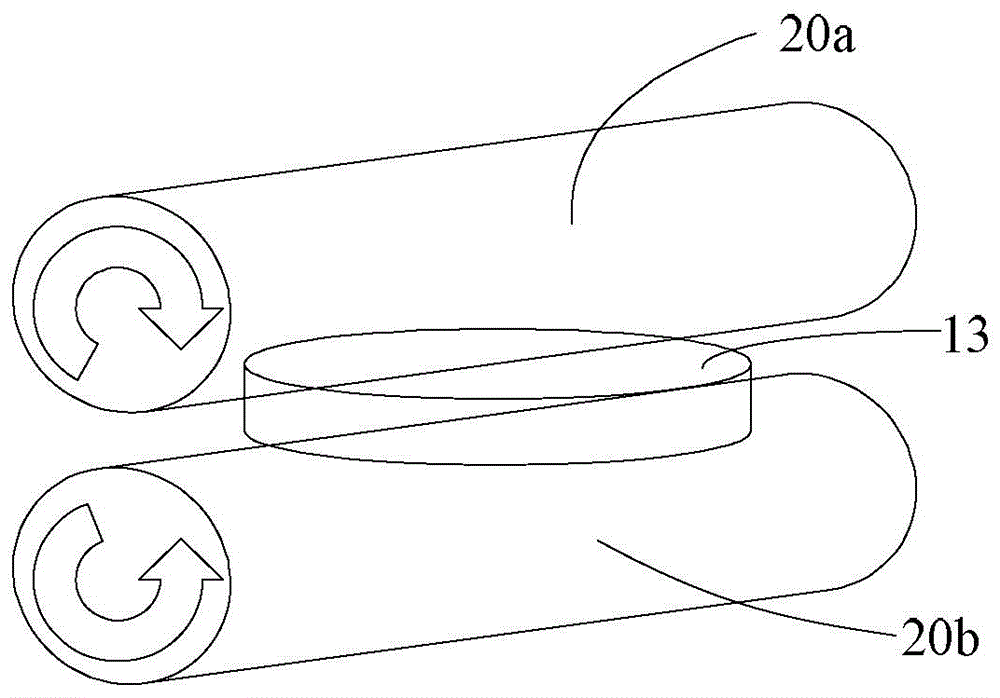

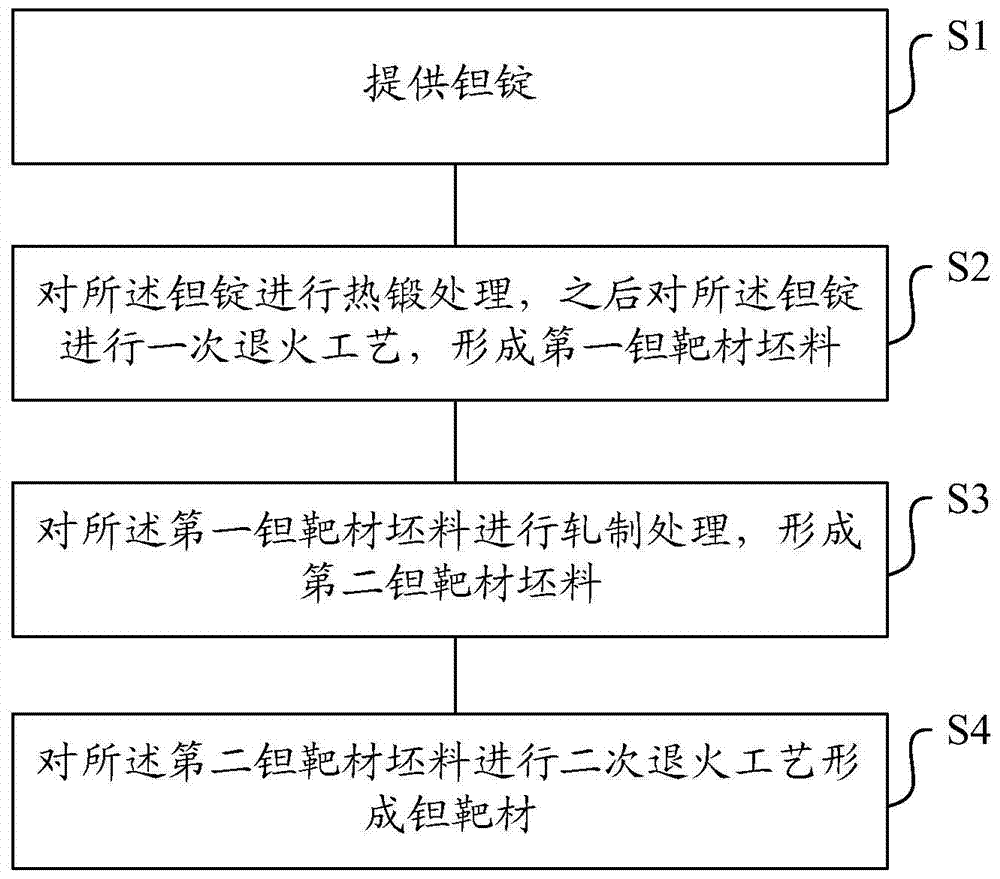

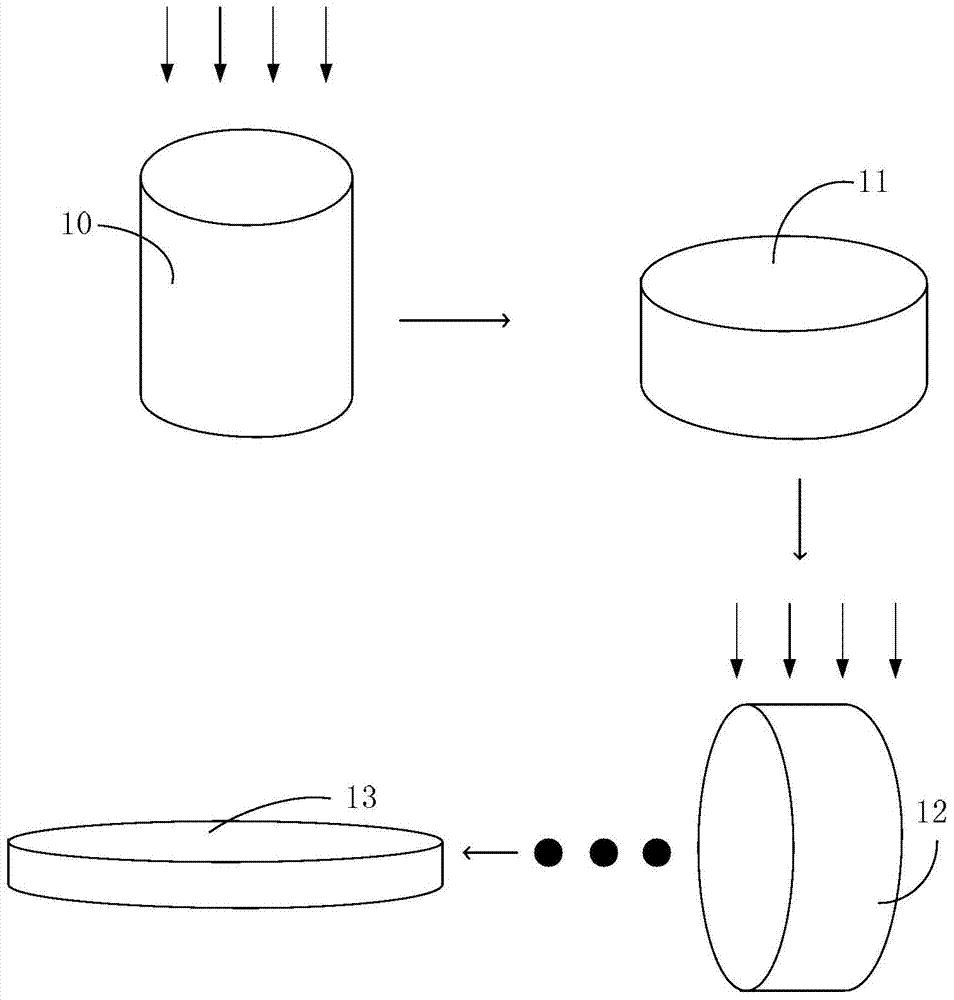

Method for manufacturing tantalum target material

ActiveCN104419901ASimple internal structureStress reliefVacuum evaporation coatingSputtering coatingIngotTantalum

The invention provides a method for manufacturing a tantalum target material. The method comprises the following steps: firstly, carrying out hot forging on a tantalum ingot and then carrying out first annealing on the hot-forged tantalum ingot to form a first tantalum target material billet; rolling the first tantalum target material billet to form a second tantalum target material billet; and carrying out second annealing on the second tantalum target material billet to obtain the tantalum target material. The tantalum target material formed according to the technical scheme has fine internal grains and uniform internal microstructure and thus the defects such as delamination inside the tantalum target material are effectively avoided, the sputtering rate of the tantalum target material and the quality of the formed tantalum film in the subsequent use process are improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

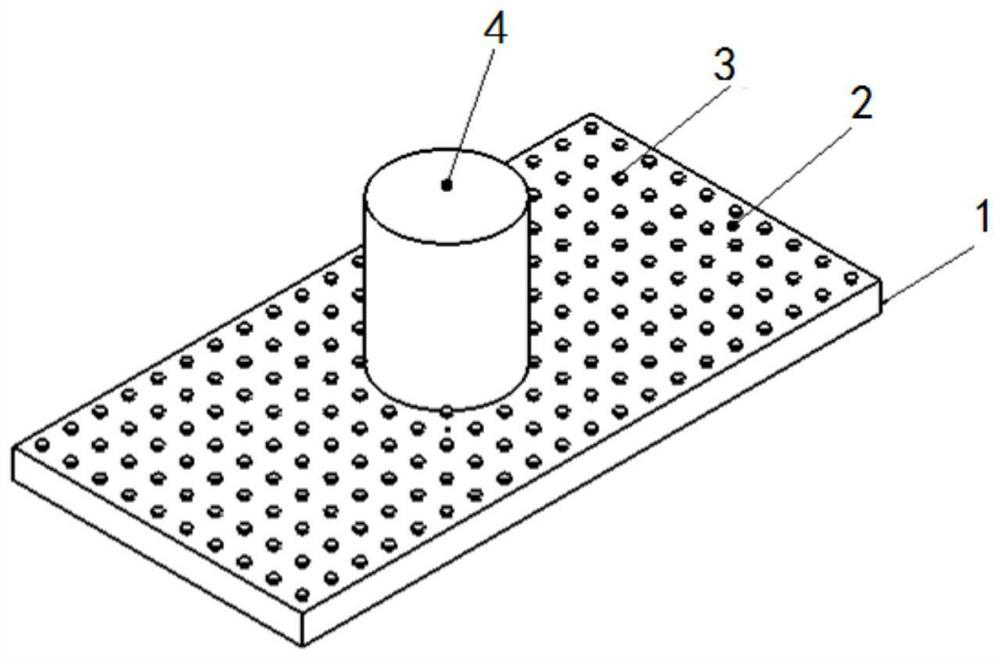

Anti-deformation co-combustion sintering fixture and material thereof

InactiveCN108687343AEfficient anti-deformationIncrease profitTransportation and packagingMetal-working apparatusPolyesterManufacturing cost reduction

The invention discloses an anti-deformation co-combustion sintering fixture. The anti-deformation co-combustion sintering fixture comprises a base body. The base body comprises a base and assembling structures making contract with the surface of a to-be-sintered workpiece. The material shrinkage rate of the anti-deformation co-combustion sintering fixture is identical with or close to that of thesurface of the to-be-sintered workpiece. The material sintering temperature of the anti-deformation co-combustion sintering fixture is higher than that of the surface of the to-be-sintered workpiece.The assembling structures are a plurality of protrusions or grooves. The invention further discloses a material of the anti-deformation co-combustion sintering fixture. The material is prepared from,by weight, 50%-60% of powder, 10%-20% of water-soluble polyester, 10%-20% of polypropylene, 8%-10% of fatty acid amide phosphate, 3%-5% of a coupling agent, 0.3%-0.5% of a stabilizer and 0.2%-0.5% ofan antioxidizer. According to the anti-deformation co-combustion sintering fixture and the material thereof, sintering deformation of an injection-formed surface shell of titanium alloy powder can beprevented, the product defective rate caused by sintering deformation is greatly decreased, the productivity is improved, and the manufacturing cost is reduced.

Owner:东莞市依诺电子科技有限公司

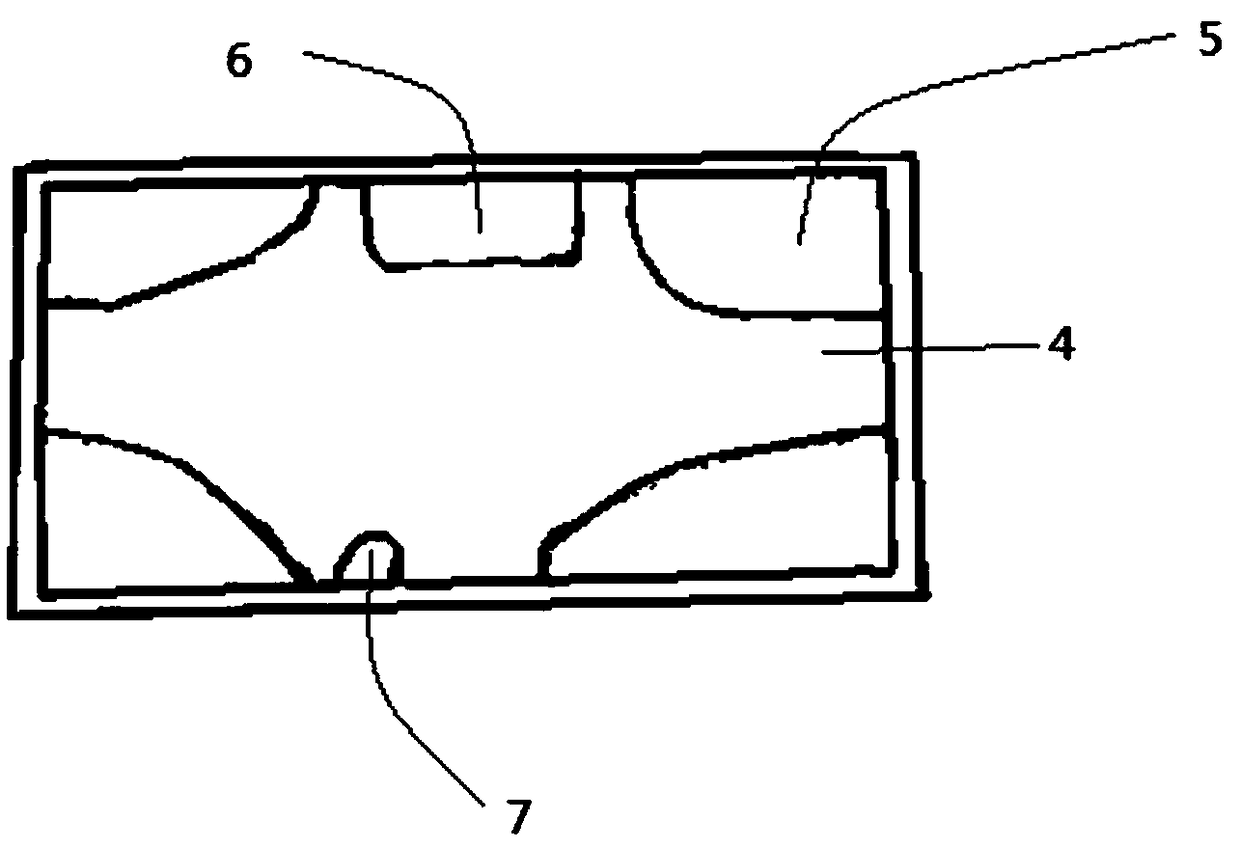

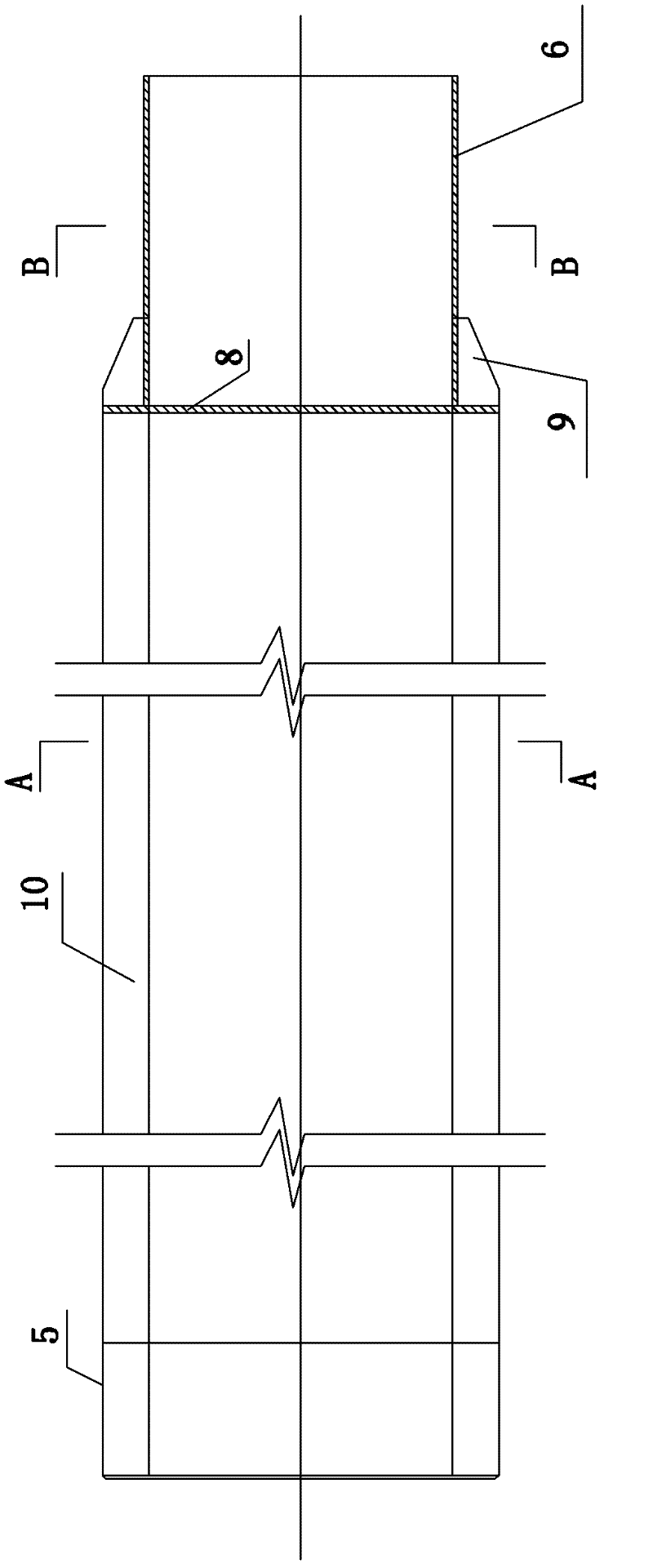

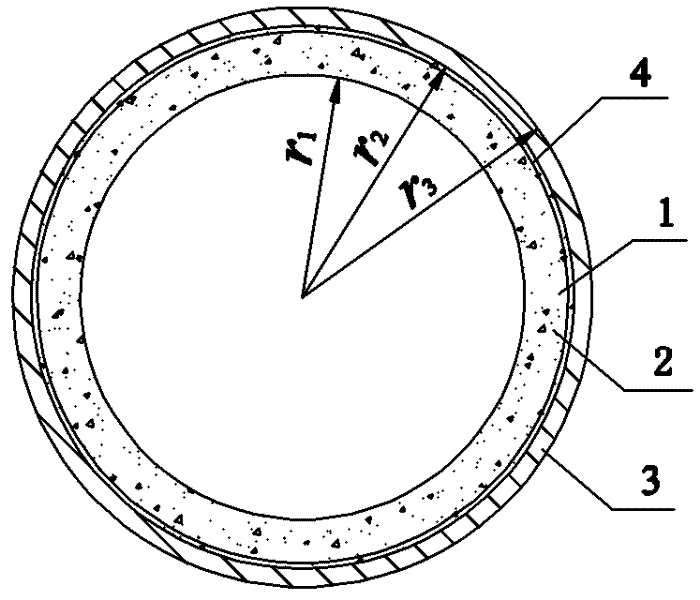

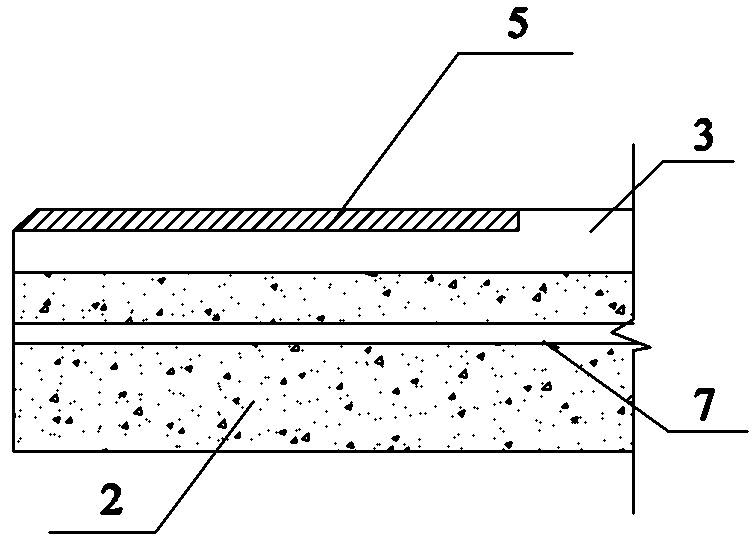

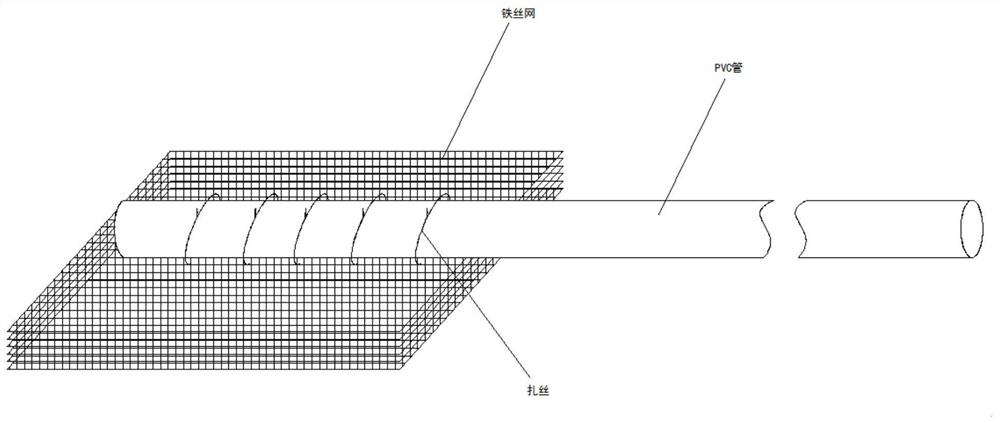

Prestressed composite superimposed large-diameter tube pile and manufacturing method thereof

ActiveCN102337742AExcellent impact resistance and durabilityImprove crack resistanceCeramic shaping apparatusBulkheads/pilesSteel tubeSteel plates

The invention provides a prestressed composite superimposed large-diameter tube pile and a manufacturing method thereof. The tube pile is characterized in that tube sections adopt an ultra high performance fiber reinforced cementitious composite (UHPFRC) as a substrate; ultra high toughness cementitious composite (UHTCC) crack-control protective layers are arranged outside the UHPFRC; a steel plate hoop is arranged on the periphery of the top of the tube section at the top of the pile; a flange plate is arranged at the bottom end of the tube section at the bottom of the pile; spiral stirrups are arranged in tube walls and preserved ducts are arranged in the tube walls; the tube sections are spliced into a whole by tensioning longitudinal prestressed tendons passing through the preserved ducts; the preserved ducts are densely filled by injecting cement paste after the longitudinal prestressed tendons are tensioned; steel tube pile tips are connected with the flange plate of the tube section at the bottom of the pile by welding; and stiffening plates are arranged at the intersections of the steel tube pile tips and the flange plate. According to the invention, the ductility, impact toughness and durability of the tube pile are fully improved.

Owner:浙江固邦新材料有限公司

Water tank and horizontal single-cylinder evaporative diesel engine with same

InactiveCN102733927AHigh strengthEconomical and beautiful designMachines/enginesEngine cooling apparatusSynthetic materialsDie casting

The invention relates to a water tank and a horizontal single-cylinder evaporative diesel engine with the same. A vertical groove is arranged on the surface, corresponding to a connecting hole, of a vertical shell body of the existing split type water tank, so that the beauty of the existing split type water tank is influenced. According to invention, the port of the edge of an inner chamber of an upper body of the water tank is provided with a boss without a corresponding vertical groove on the external wall of the water tank; the boss is provided with a screw hole corresponding to a through hole, wherein a connecting fastening piece penetrates through the through hole which is formed on the port of the edge of a lower body of the water tank; a vertical face shell body, corresponding to the boss, of the upper body of the water tank is positioned on the outer side of the connecting screw hole; and a reinforcing rib for reinforcement is arranged between the boss and the shell body. A mold is designed to have an interior core withdrawing structure for manufacturing the upper body of the water tank. The water tank provided by the invention can be applied to manufacturing of aluminum alloy die-casting or injection-molding water tank with smooth streamline appearance. The upper body of the water tank made of synthetic materials which are subjected to injection molding can be assembled with the lower body formed by aluminum alloy which are subjected to die-casting.

Owner:蒋一民 +1

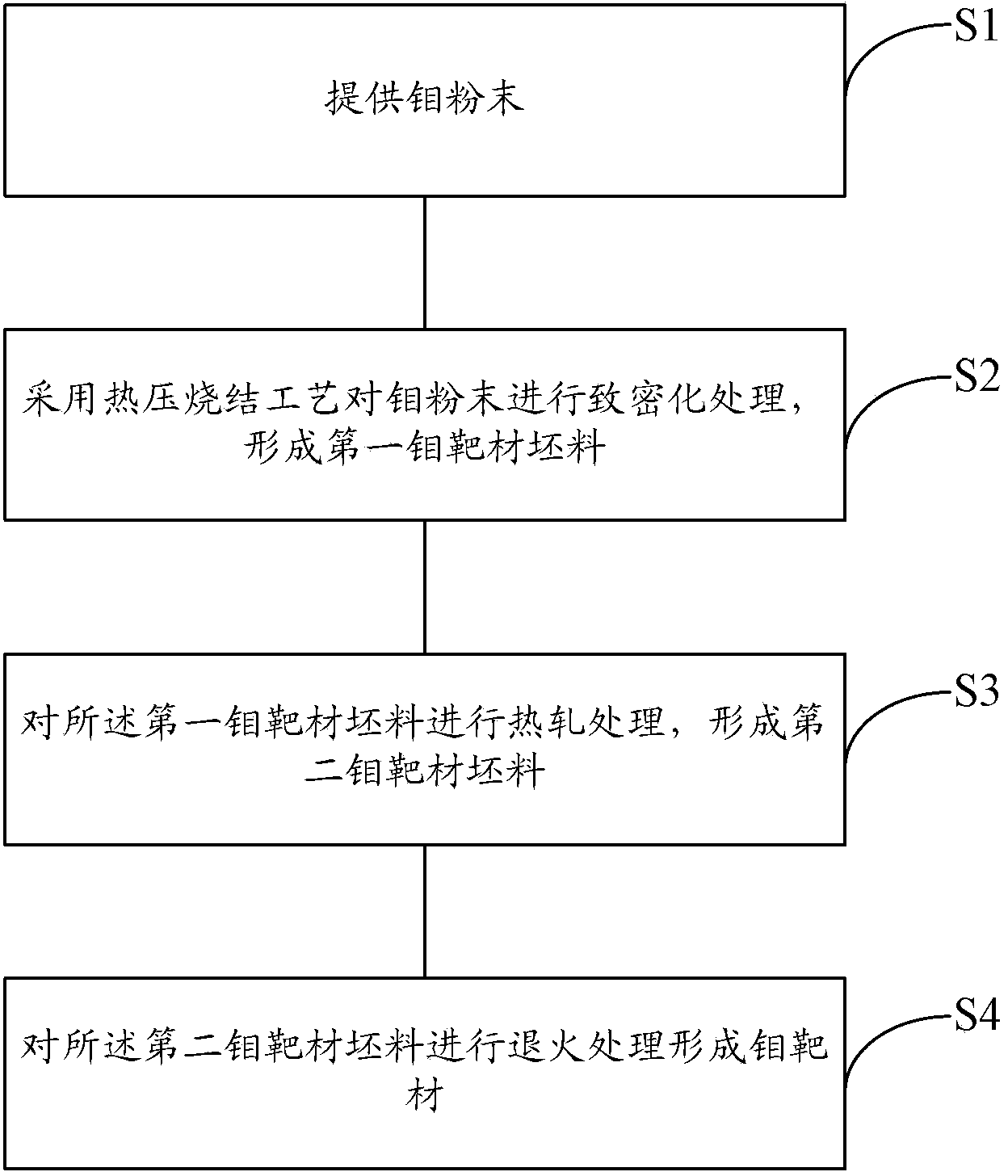

Method for manufacturing molybdenum target material

ActiveCN104342619AAchieving the first densificationIncreased dislocation densityVacuum evaporation coatingSputtering coatingSputteringMicrometer

A method for manufacturing a molybdenum target material comprises the steps that densification processing of molybdenum powder can be achieved through a hot pressed sintering technology; a first molybdenum target material blank can be obtained; further densification processing of the first molybdenum target material blank can be achieved gradually through a multi-stage hot rolling processing technology, and therefore the molybdenum target material with the molybdenum particle grain smaller than 50 micrometers, and the density higher than 99.94 percent can be obtained. Compared with a molybdenum target material obtained through a conventional molybdenum target material manufacturing method, the molybdenum target material obtained through the method is smaller and evener in molybdenum particle grain and high in density, has the better electrical properties and mechanical machining properties, and completely meets the molybdenum target material sputtering requirement.

Owner:广东江丰电子材料有限公司

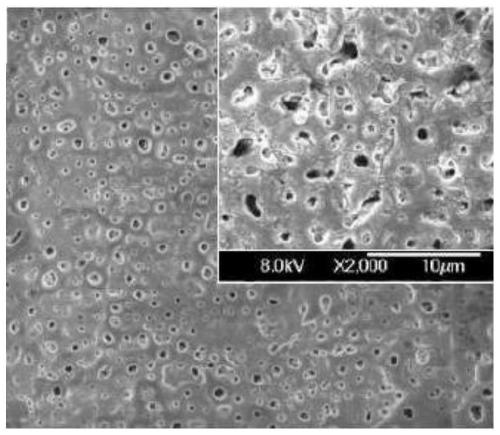

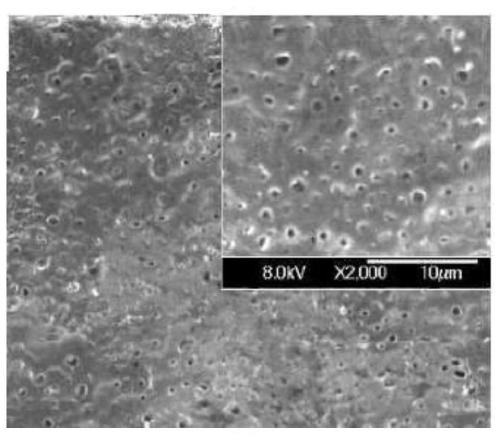

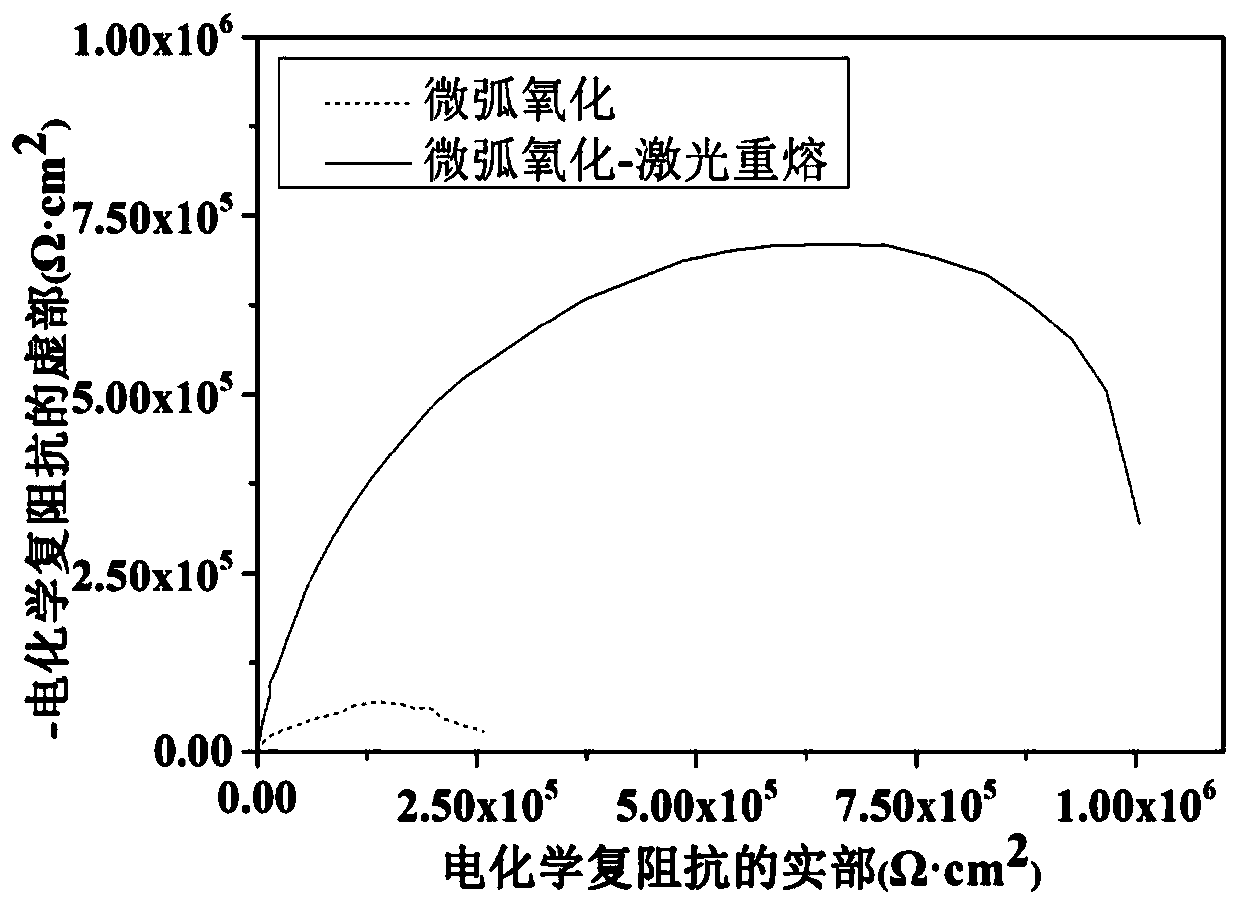

Method for improving corrosion resistance of surface of magnesium alloy on basis of micro-arc oxidation and laser remelting

InactiveCN110079850AImprove surface corrosion resistanceImprove corrosion resistanceAnodisationLiquid surface applicatorsEnvironmental resistanceMicro arc oxidation

The invention discloses a method for improving corrosion resistance of the surface of magnesium alloy on the basis of micro-arc oxidation and laser remelting. Firstly, after micro-arc oxidation treatment is conducted on the surface of the magnesium alloy, a layer of ceramic film is obtained, the film layer is prefilled with a thin layer of graphene oxide particles through ultrasonic oscillating, then microcracks and holes of the ceramic film are filled with molten graphene oxide particles effectively through laser remelting technology, and thus corrosion resistance of the surface of the magnesium alloy is improved greatly. The method is environmentally friendly in process and high in repeatability, and a novel way is developed for improving the corrosion resistance of the surface of the magnesium alloy.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

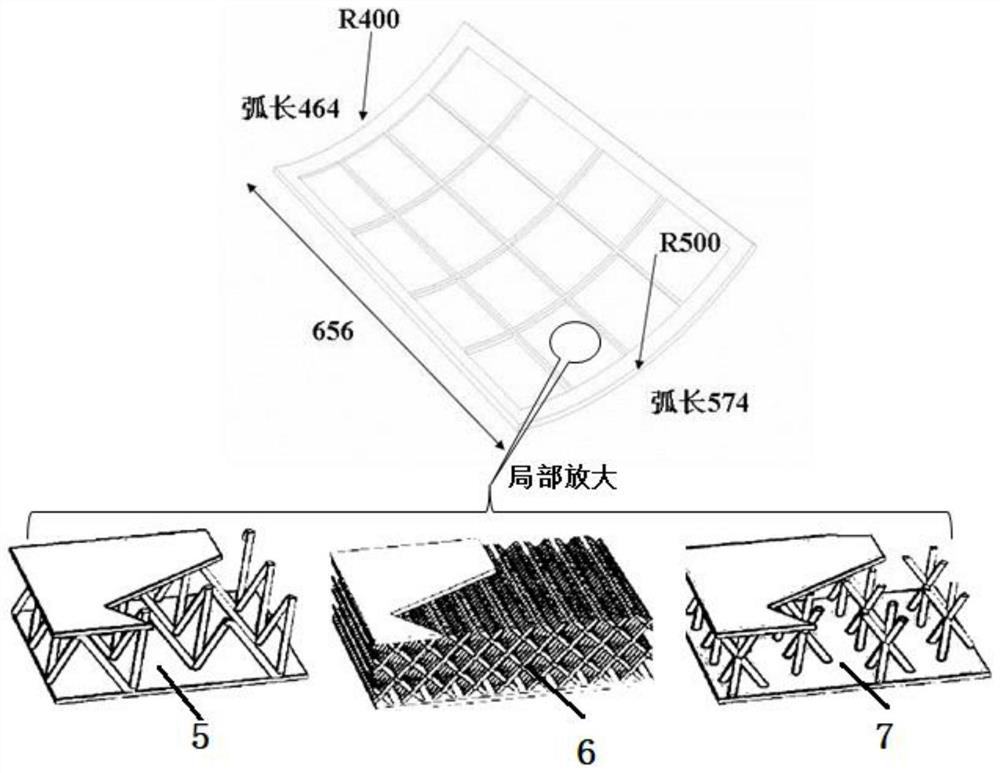

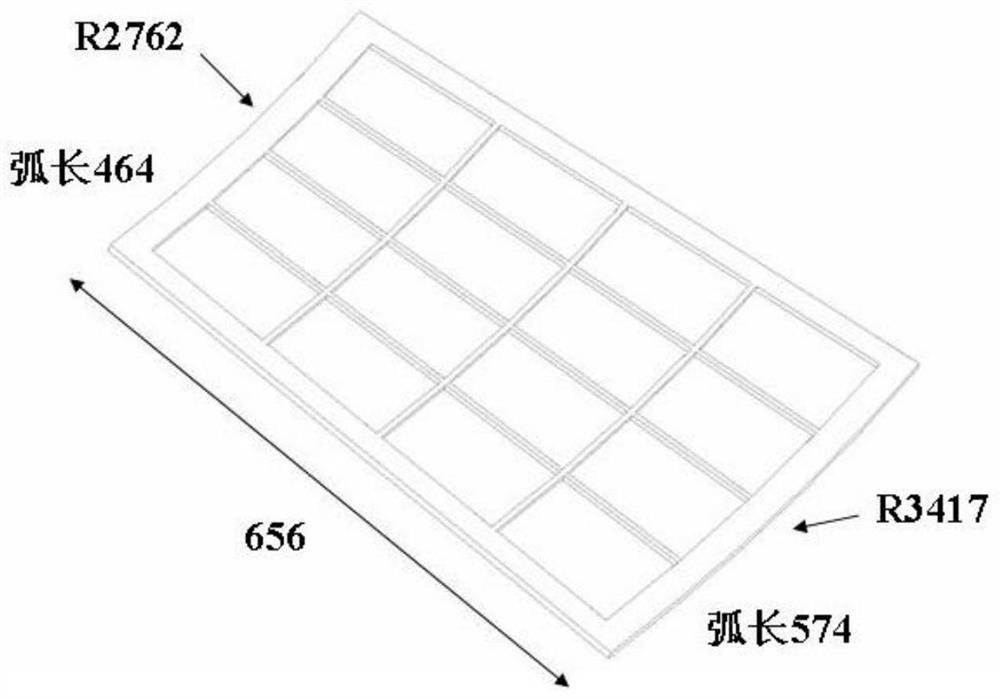

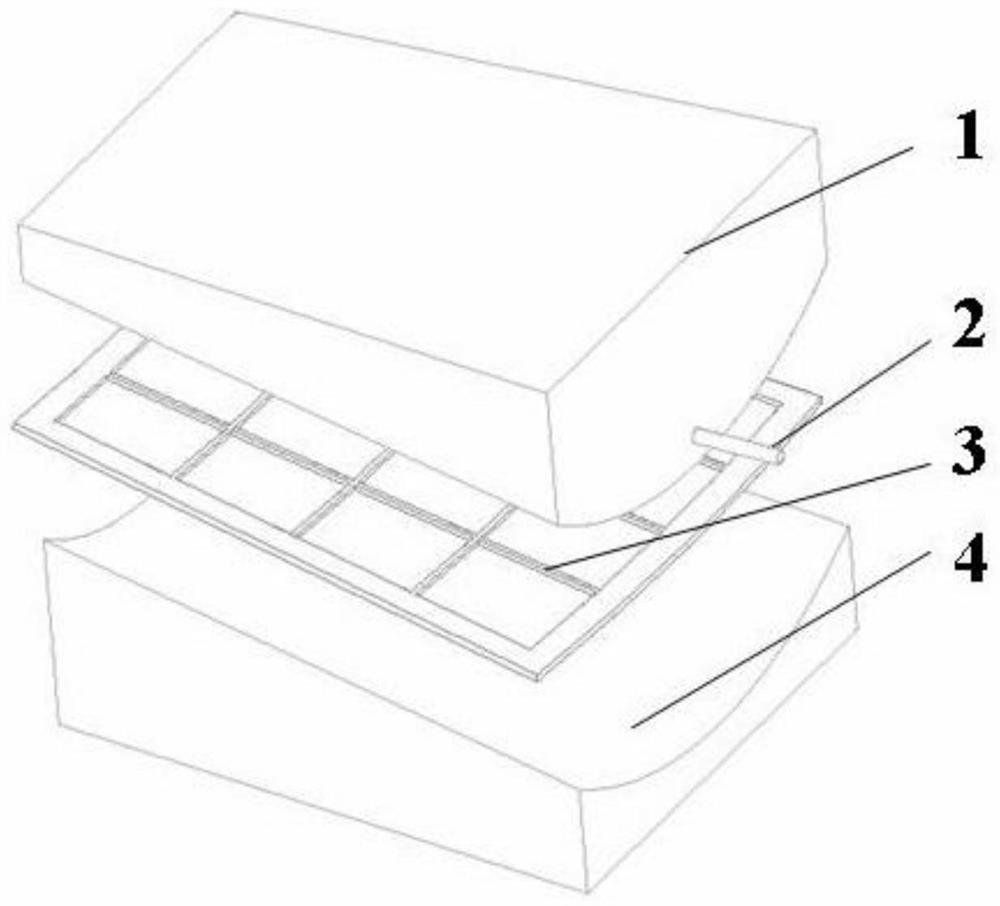

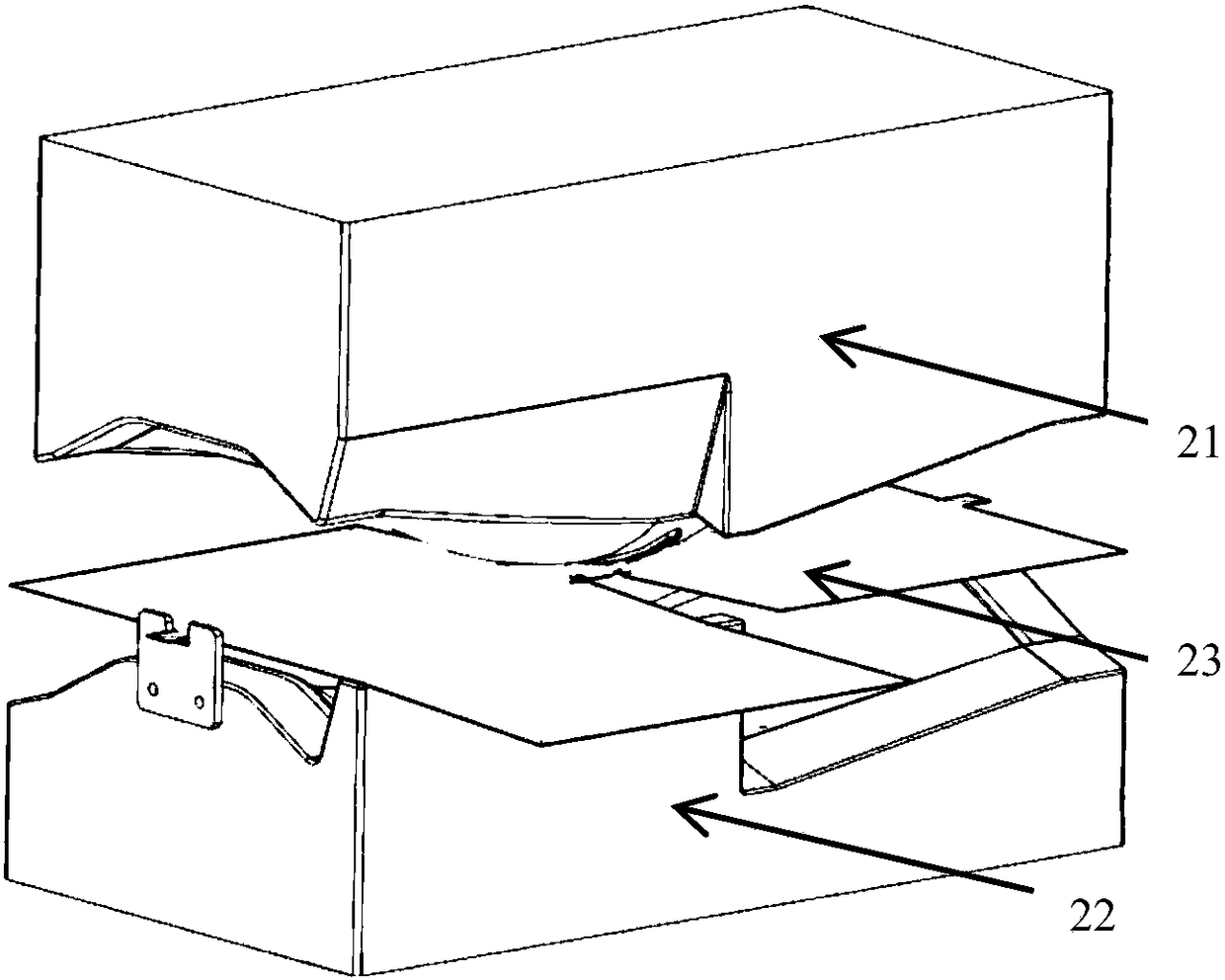

Additive hot-pressing inflatable composite forming method for topological structure wallboard

ActiveCN111744983AImprove integrityImprove surface qualityShaping toolsIncreasing energy efficiencyStructural engineeringClosed cavity

The invention discloses an additive hot-pressing inflatable composite forming method for a topological structure wallboard, belongs to the technical field of precision sheet metal processing, and solves the defects of poor integrity, difficulty in appearance precision control or higher cost in existing technical processing. The forming method comprises the following steps of step 1, determining positions of reinforcing ribs and a topological structure of a topological structure wallboard blank required by hot-pressing forming; step 2, preparing the topological structure wallboard blank by an additive; step 3, manufacturing a hot-pressing forming die of the topological structure wallboard; step 4, placing the topological structure wallboard blank in a cavity of a hot-pressing forming die, and performing hot-pressing forming on the topological structure wallboard blank; and step 5, forming a closed cavity between the topological structure wallboard blank and an upper die, communicating the closed cavity with an external gas source through a vent hole, and performing ventilation and pressurized correction on the closed cavity in order to enable a curved surface part between the reinforcing ribs of the topological structure wallboard to form a smooth curved surface. According to the method, the surface quality of parts is improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Ceramic green body, ceramic plate and preparation method of ceramic green body

ActiveCN113443893AImproves Strength and ToughnessSmall coefficient of thermal expansionClaywaresTalcBall clay

The invention relates to the technical field of ceramics, in particular to a ceramic green body, a ceramic plate and a preparation method of the ceramic green body, the ceramic green body is mainly prepared from the following raw materials in parts by weight: 30-40 parts of ball clay, 10-20 parts of calcined kaolin, 2-5 parts of bentonite, 6-10 parts of lithium feldspar, 8-12 parts of diopside, 8-15 parts of sylvine powder, 5-10 parts of sodium aluminate, 5-10 parts of pyrophyllite, 2-5 parts of calcined talc and 5-8 parts of an inorganic reinforcing agent; and the inorganic reinforcing agent is a needle-shaped or fibrous inorganic reinforcing agent. The ceramic body and the ceramic plate have higher strength and toughness, and can meet the toughness requirements in the states of daily production, processing and cutting, transfer transportation, application, paving and the like.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD +4

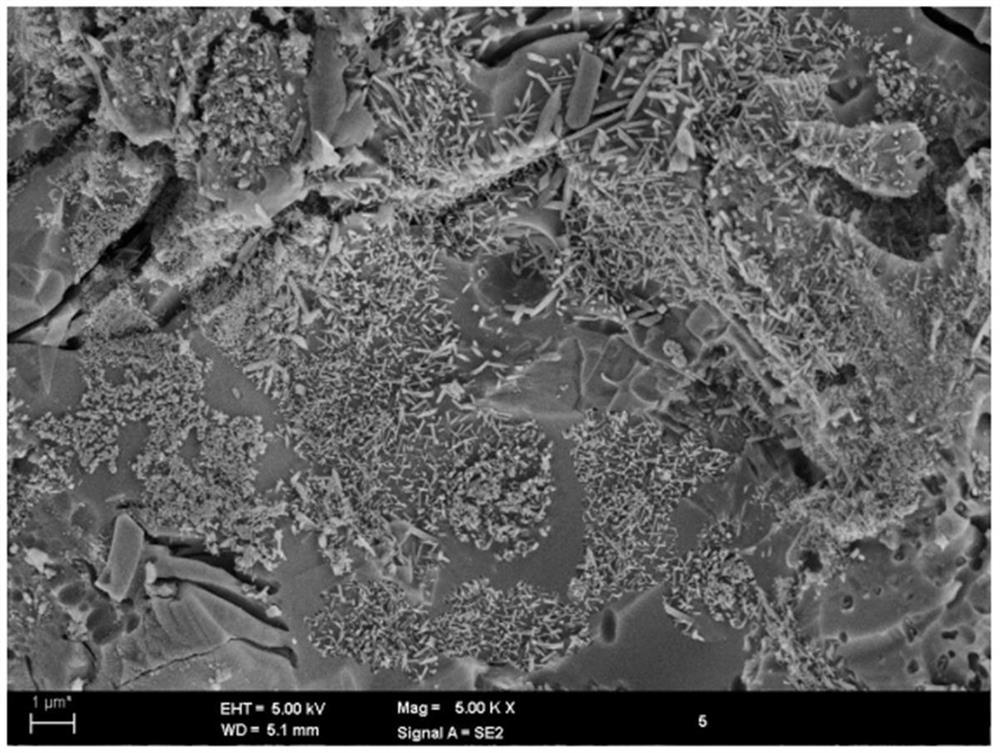

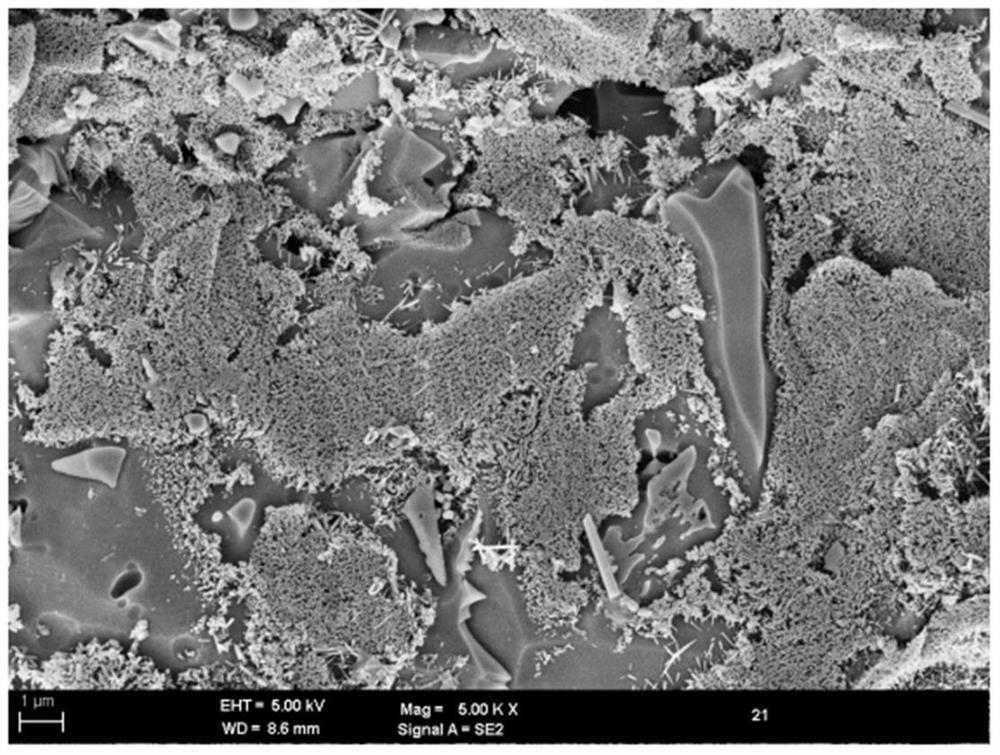

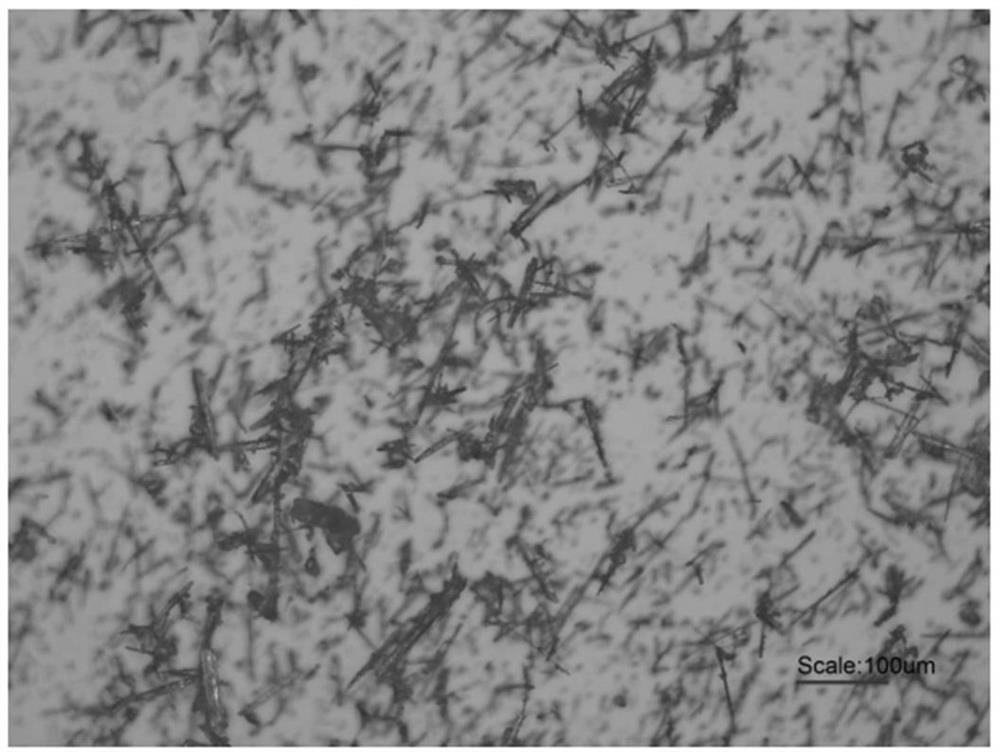

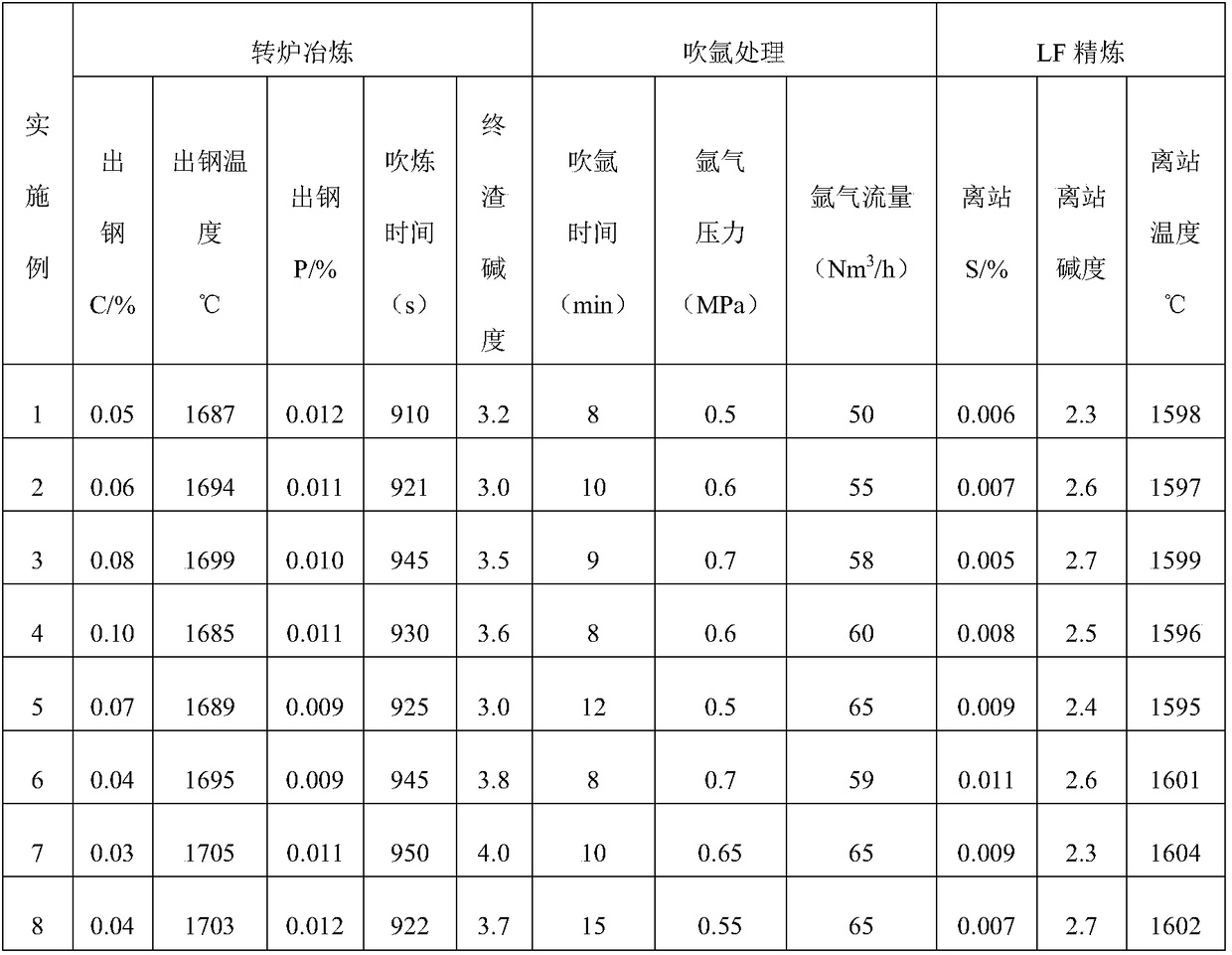

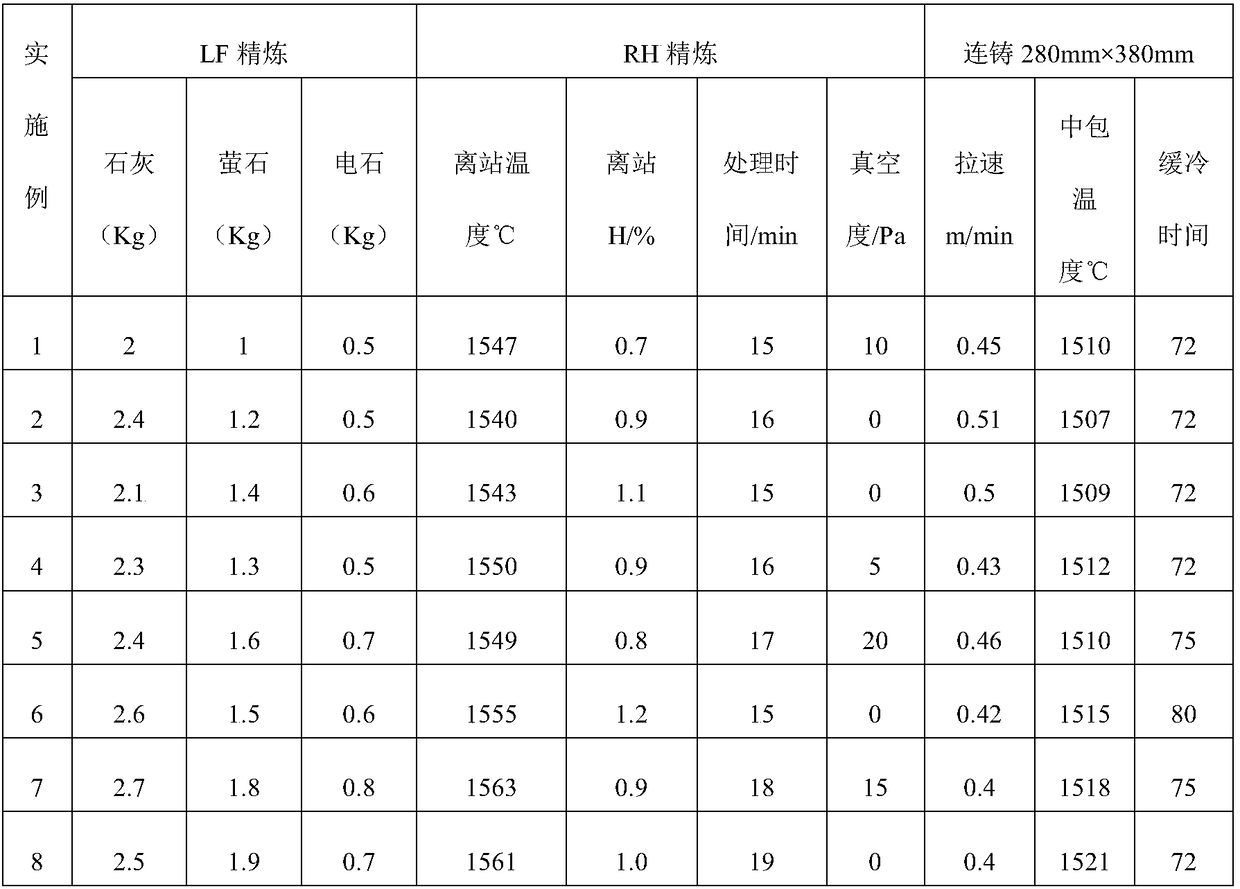

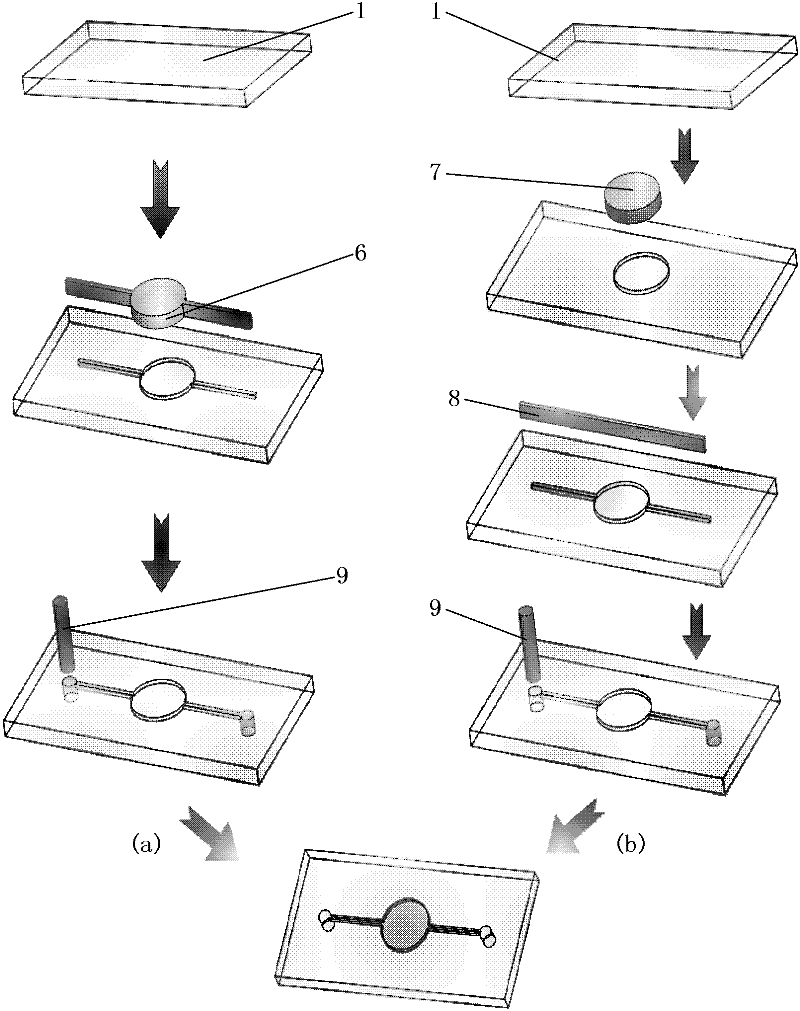

Bainite rail steel with ultra-low aluminium content and high strength and production method thereof

InactiveCN109023035AImprove fatigue resistance and service lifeImprove purityManufacturing convertersAluminiumSmelting

The invention discloses bainite rail steel with an ultra-low aluminium content and high strength and a production method thereof. The rail steel comprises the chemical components of, by weight, 0.10%-0.25% of C, 1.50%-1.90% of Si, 1.40%-1.90% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 1.10%-1.50% of Cr, 0.40-0.70% of Mo, 0.40%-0.75% of Ni, 0.04%-0.15% of V, less than or equal to 0.004% of Alt and the balance Fe and unavoidable impurities. The production method adopts top-bottom combined blowing converter smelting, LF refining and RH vacuum treatment, the totalaluminum content of the bainite rail steel can be effectively controlled below 40*10<-4>%, and the harm of alumina inclusions in the steel is effectively reduced.

Owner:武汉钢铁有限公司

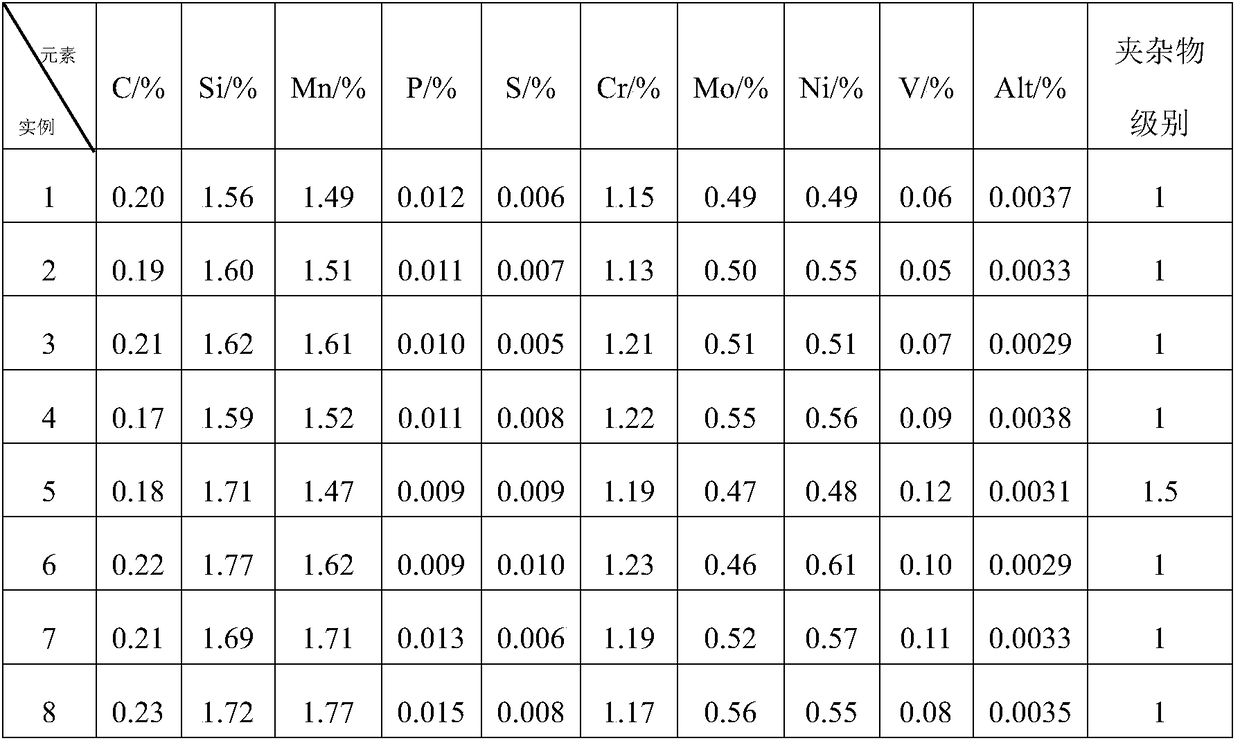

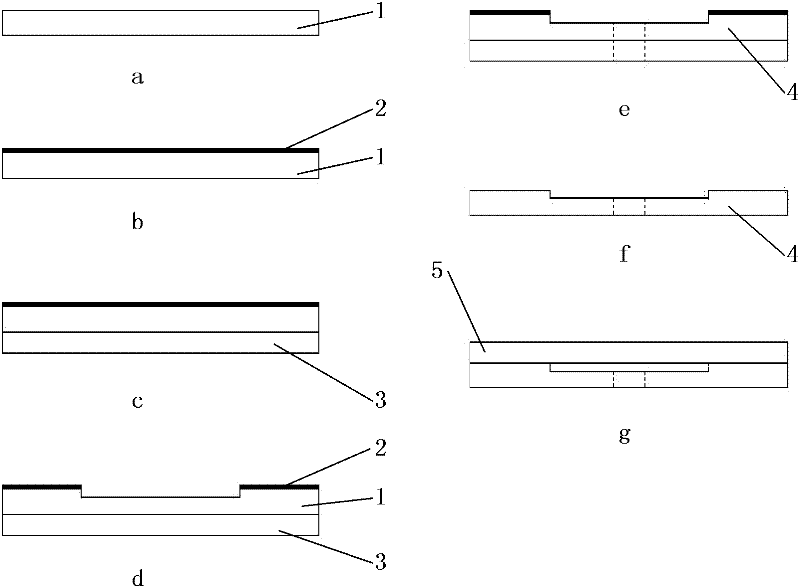

Supersonic wave processing method of glass base microfluidic chip

InactiveCN102398890AImprove processing qualityAvoid defects such as crackingDecorative surface effectsChemical vapor deposition coatingGlass chipSupersonic waves

A supersonic wave processing method of a glass base microfluidic chip comprises steps of: processing a probe; pasting a paste adhesive tape on an upper surface of a glass substrate and a piece of glass flake on a lower surface of the glass substrate; carrying out supersonic wave processing; polishing by chemical attack; and finally completing preparation of the chip. The invention can be widely applied to manufacture of glass base microfluidic chip and other hard material biological chip and has characteristics of simple operation, high precision, high machining efficiency and reduced processing cost.

Owner:XI AN JIAOTONG UNIV

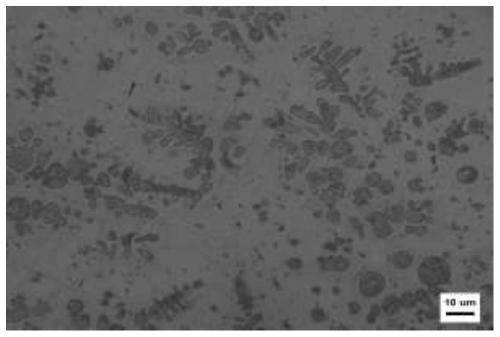

Cu based-flux-cored wire and method thereof for low-carbon surface modification

ActiveCN111558794AImprove wear resistanceAccelerated corrosionArc welding apparatusWelding/cutting media/materialsMetallurgyCarbon steel

The invention discloses a Cu based-flux-cored wire. The Cu based-flux-cored wire comprises a flux core and a welding scale, wherein the flux core is prepared from the following components in percentage by mass: 20%-35% of Ni powder, 10%-15% of Sn powder, 1%-2% of Zn powder, 8%-15% of Pb powder, 2%-6% of Ag powder, 1%-4% of Si powder, the balance of Cu, and the sum of the mass percentage of the components is 100%. The abrasive resistance, corrosion resistance and electrical conductivity and thermal conductivity of the surface of low-carbon steel can be improved, and the performance of multi-functionalization of low-carbon steel parts is sufficiently developed. The invention further provides a method for low-carbon surface modification by adopting the Cu based-flux-cored wire. The problem ofthe low-carbon surface modification is solved, the corrosion resistance, the abrasive resistance, the electrical conductivity and the thermal conductivity of the surface of the low-carbon steel can be improved, and thus the steel parts meet the service condition in specific fields.

Owner:XIAN UNIV OF TECH

Adhesion technology for transverse stabilizer bar and stabilizer bar bushing of automobile

InactiveCN106217751AAvoid defects such as crackingGood gate qualityInterconnection systemsHot runnerVulcanization

The invention provides an adhesion technology for a transverse stabilizer bar and a stabilizer bar bushing of an automobile. The adhesion technology comprises the steps that 1, the transverse stabilizer bar is subjected to medium-frequency induction and moderate temperature rolling molding, and the stabilizer bar bushing is subjected to hot runner injection molding; 2, the inner surface of the stabilizer bar bushing is coated with adhesives with uniform thickness and dried in the air; 3, the bushing coated with the adhesives in the step 2 is subjected to vulcanization treatment, and a pre-vulcanized bushing is obtained; 4, the surface of the stabilizer bar is subjected to sand blasting treatment, and the pre-vulcanized rubber bushing obtained in the step 3 adheres to the surface of the stabilizer bar; and 5, compressing force is uniformly applied to the bushing in the direction perpendicular to the axis of the stabilizer bar. According to the adhesion technology, the operation steps are simple, the cost is low, the adhesion quality can be ensured, and abrasion and abnormal sound between the stabilizer bar and the bushing are effectively relieved.

Owner:ANHUI RUNKANG RUBBER & PLASTIC TECH CO LTD

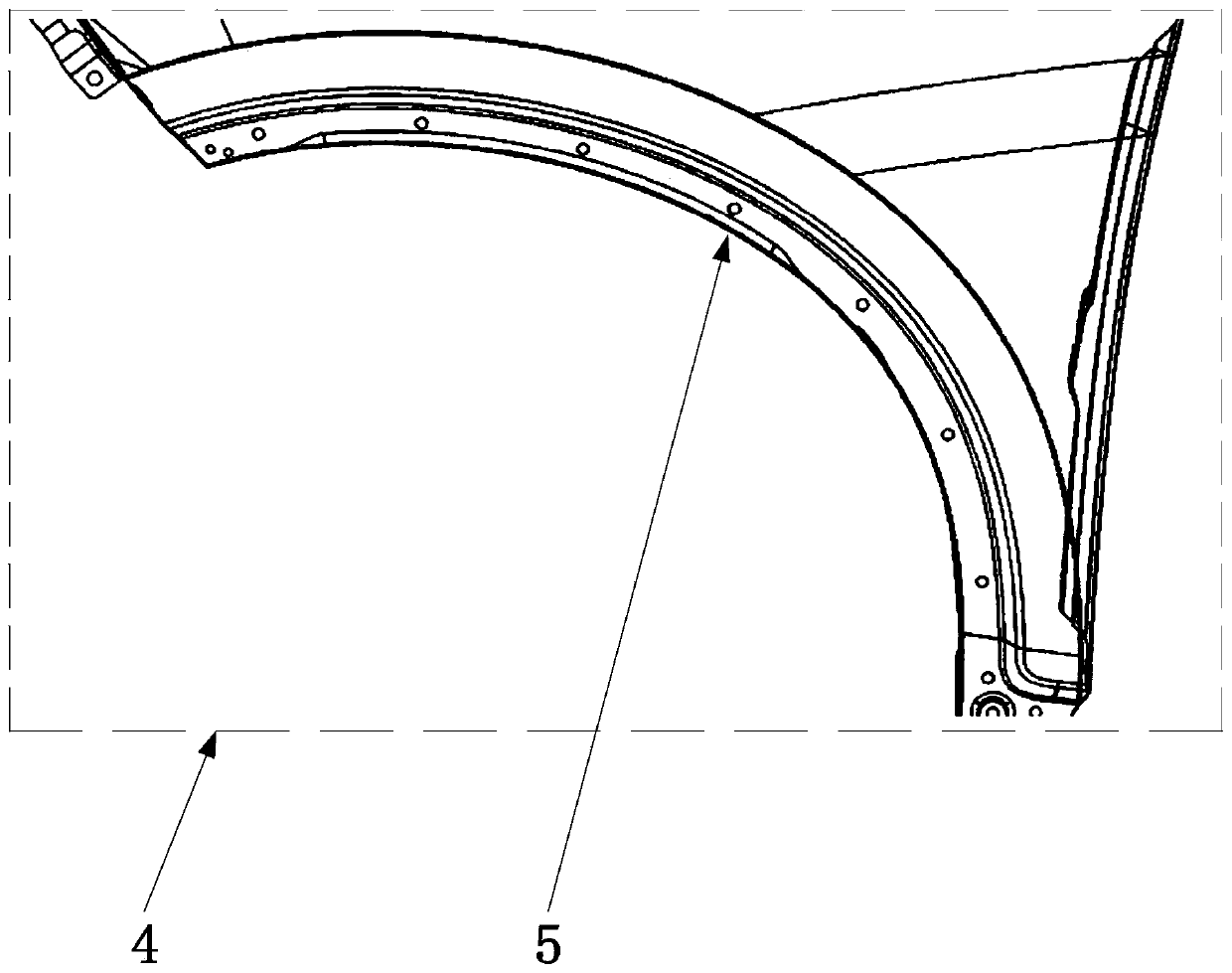

Outer panel piece and formation method thereof

The invention provides an outer panel piece and a formation method of the outer panel piece. The formation method of the outer panel piece comprises the steps that S1, a technology addendum face is pre-arranged on an outer panel piece to be stamped and formed; S2, a trimming line is pre-arranged on the technology addendum face; S3, a protrusion structure is formed on the technology addendum face through stamping. The formation method of the outer panel piece relieves the material lack tendency during drawing and flanging of the outer panel piece and protects the outer panel piece against deformation, rebound and even crack.

Owner:上海赛科利汽车模具技术应用有限公司

Supercritical fluid process for dewaxing hot-press ceramics

A supercritical fluid dewaxing process for hot-pressed ceramics includes mixing the raw ceramic slurry with polar on non-polar mixed paraffine adhesive and low-temp deoxing in supercritical CO2 fluid. Its advantages are short period, and no deformation and crack.

Owner:TSINGHUA UNIV

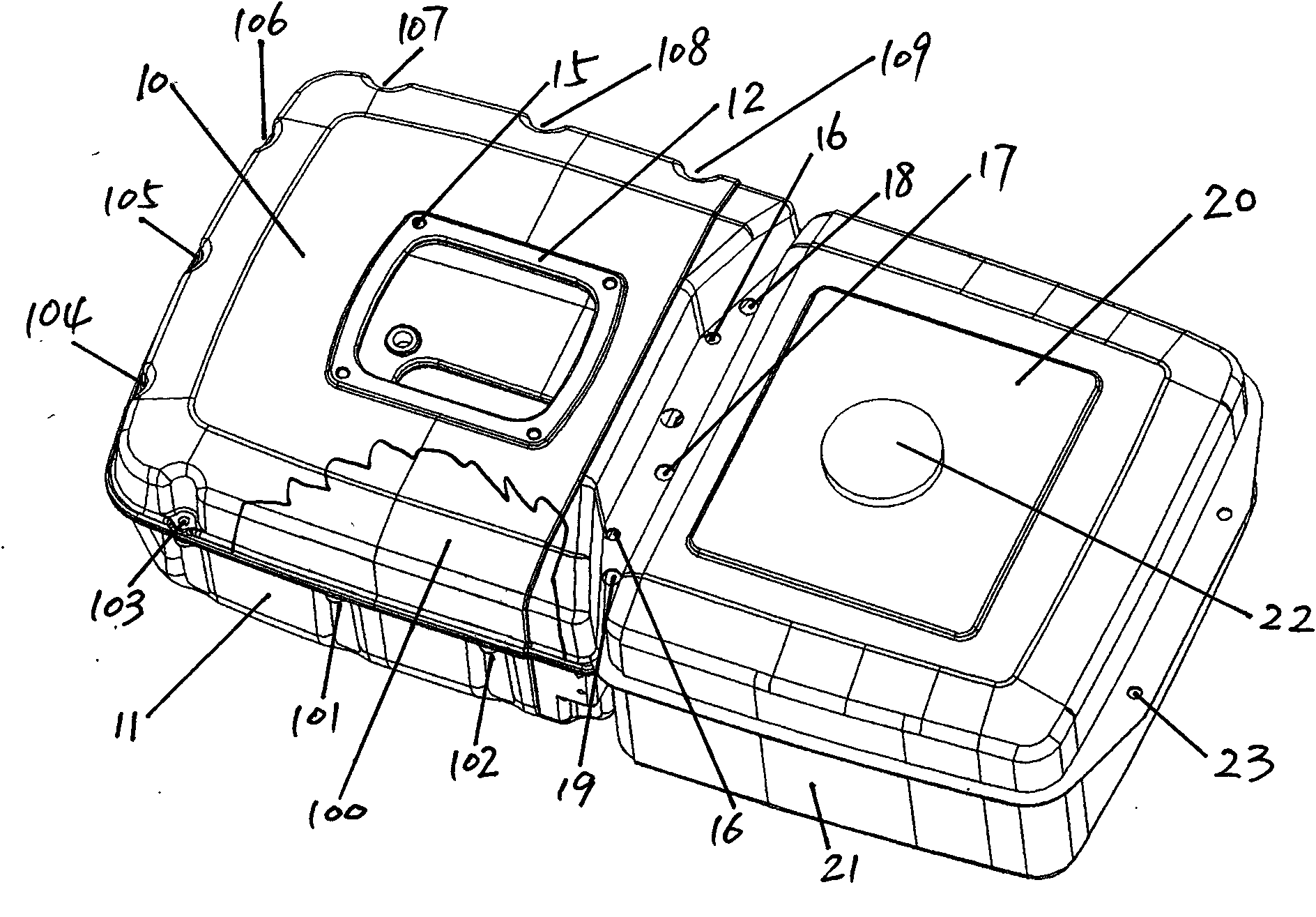

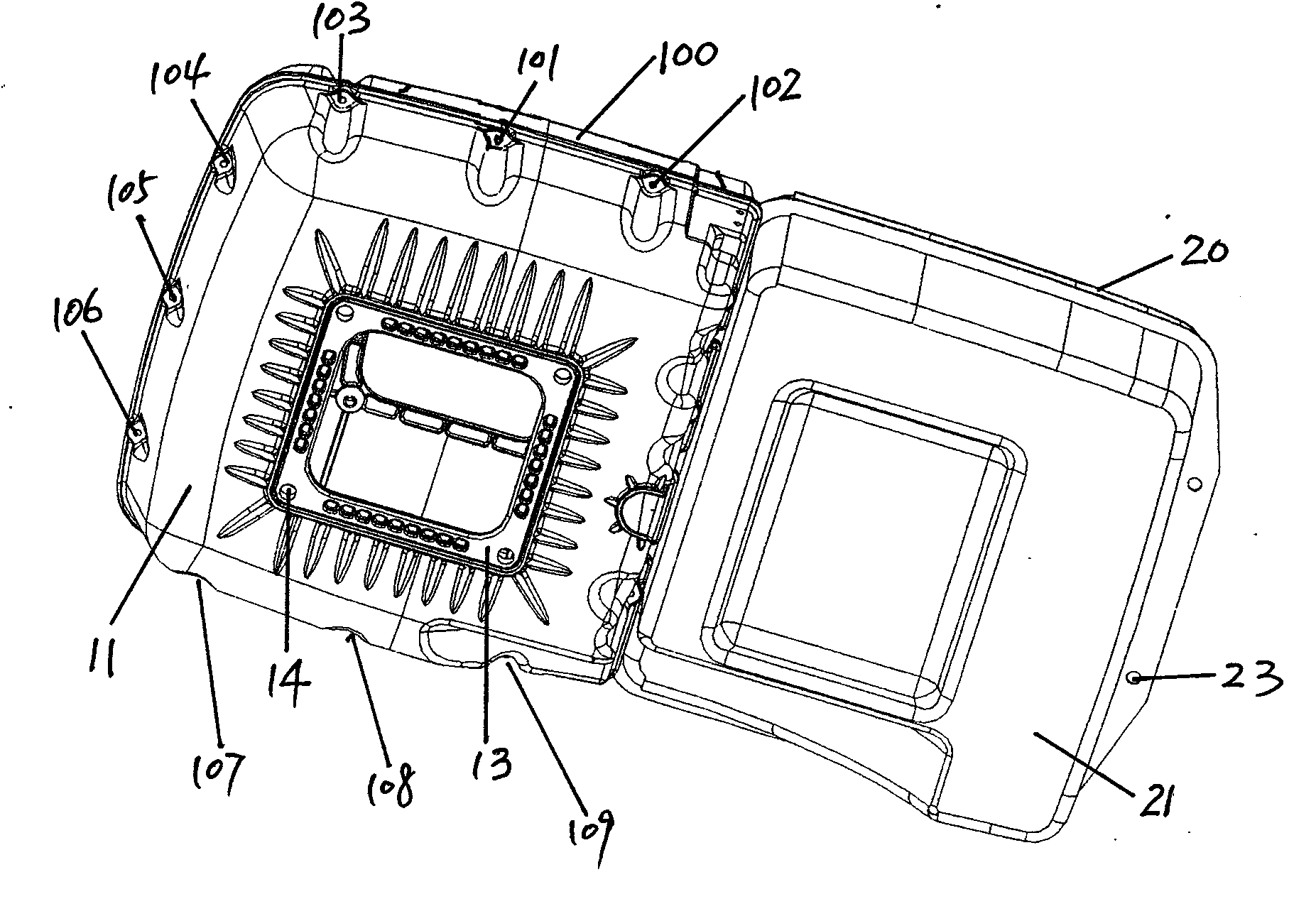

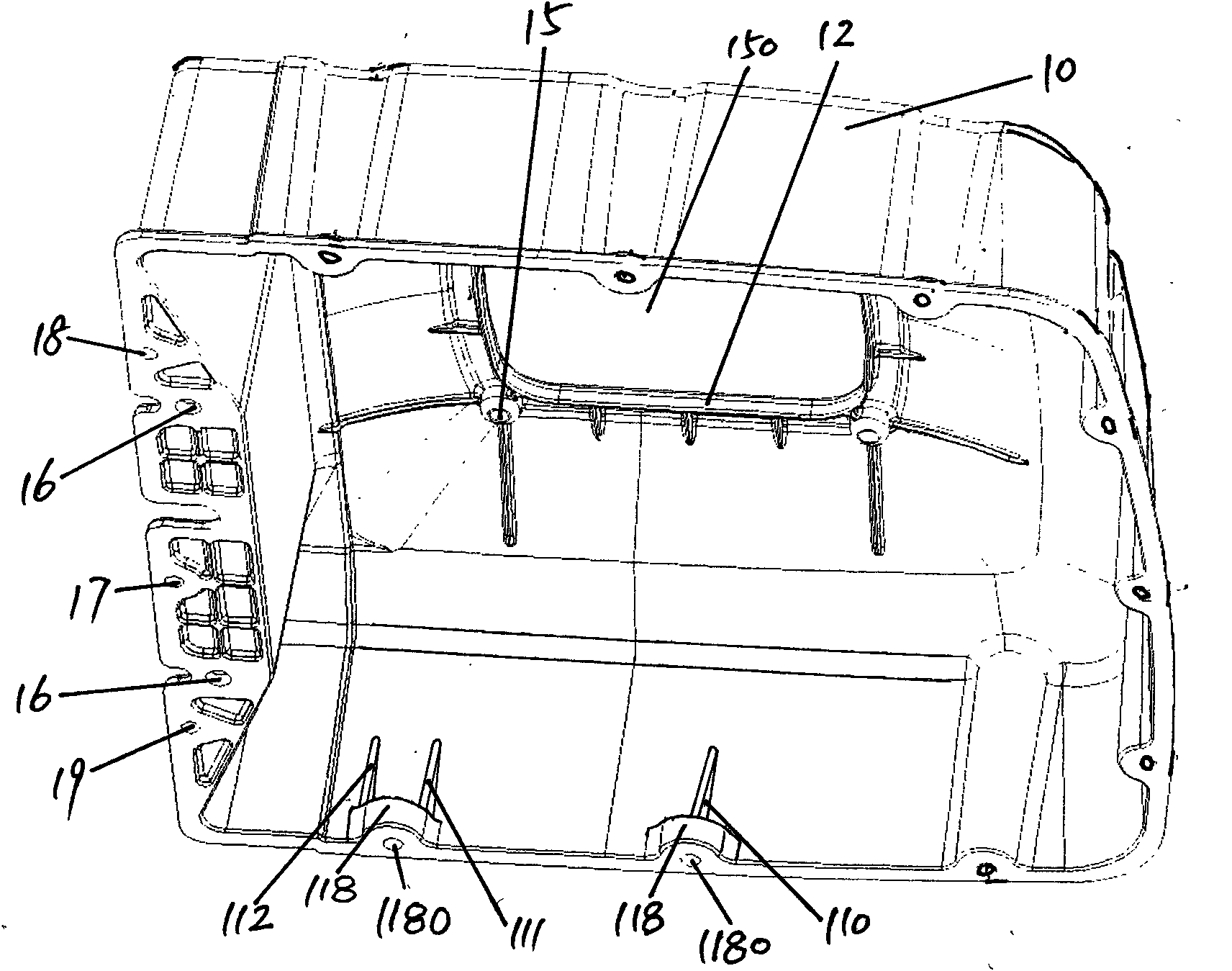

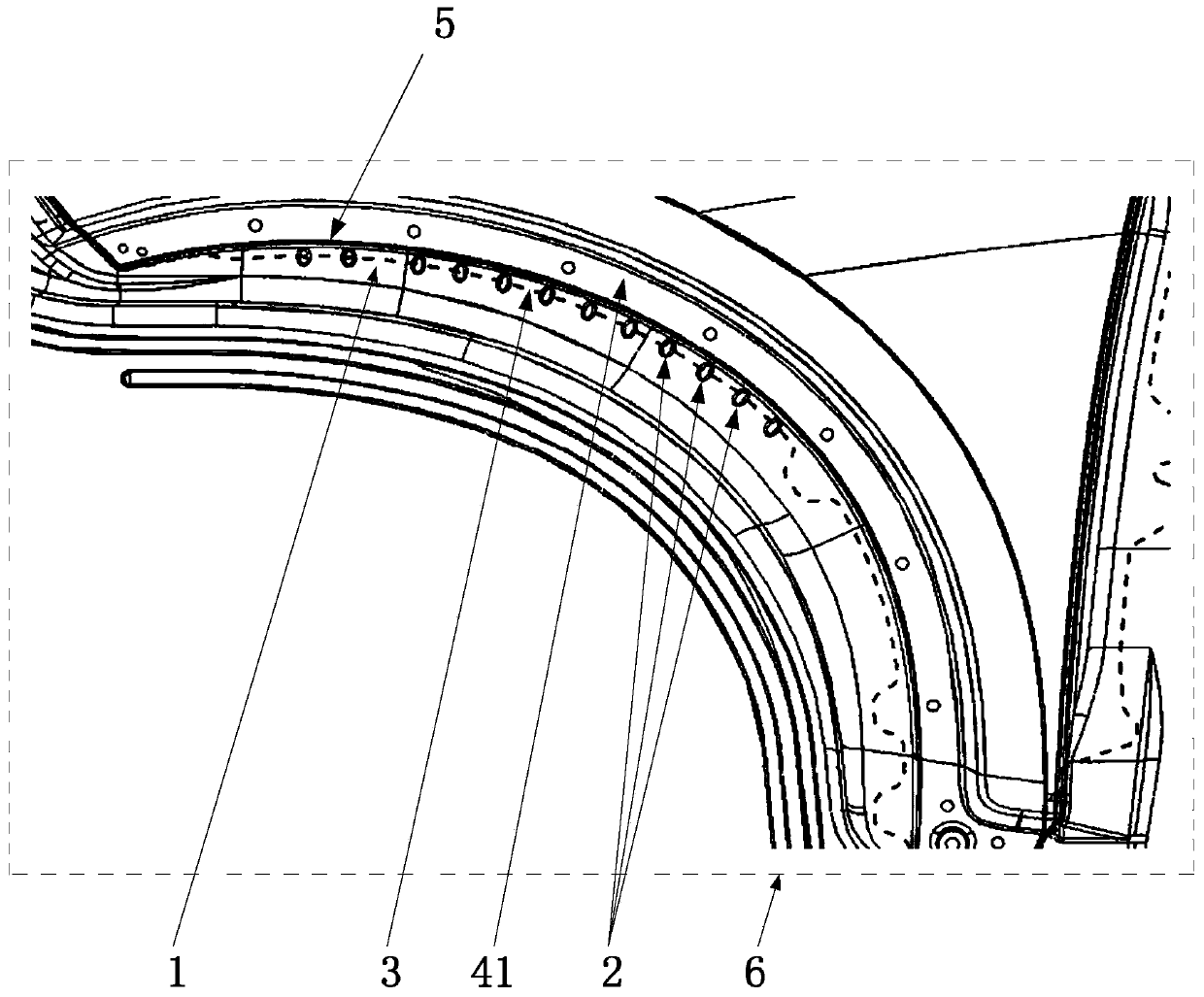

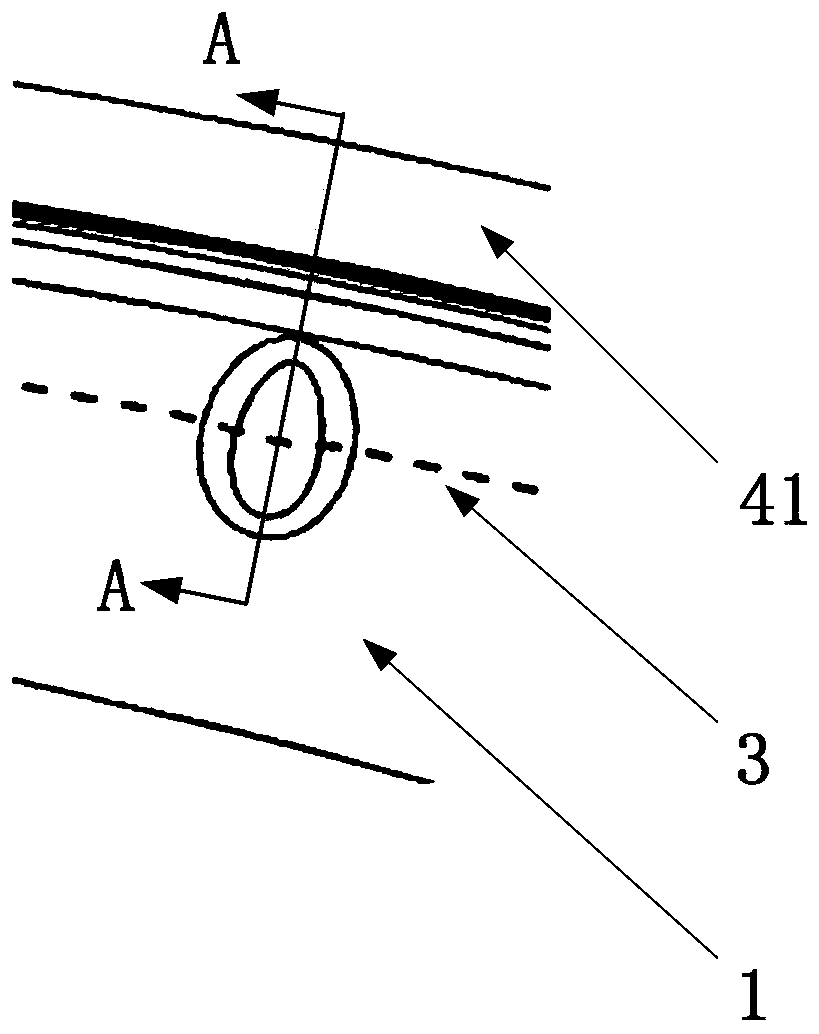

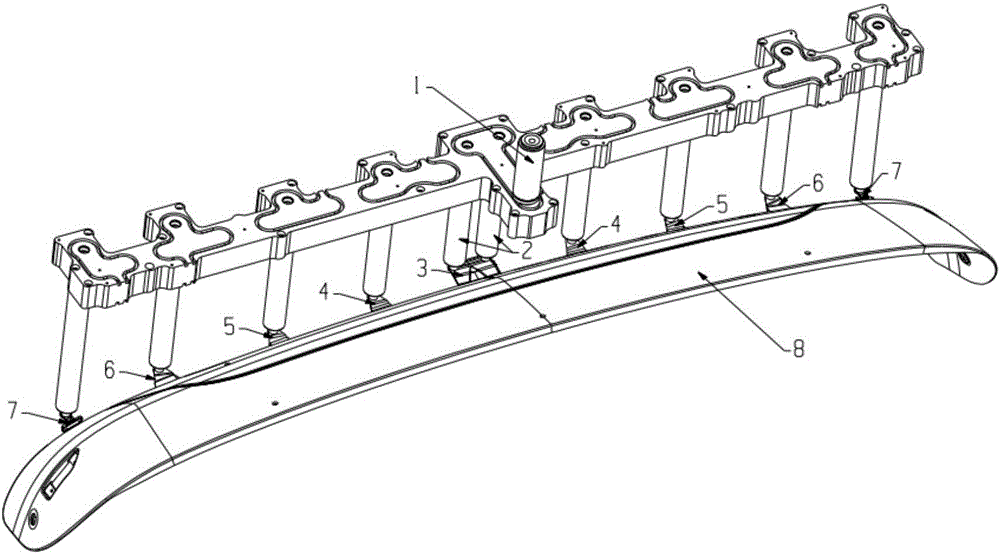

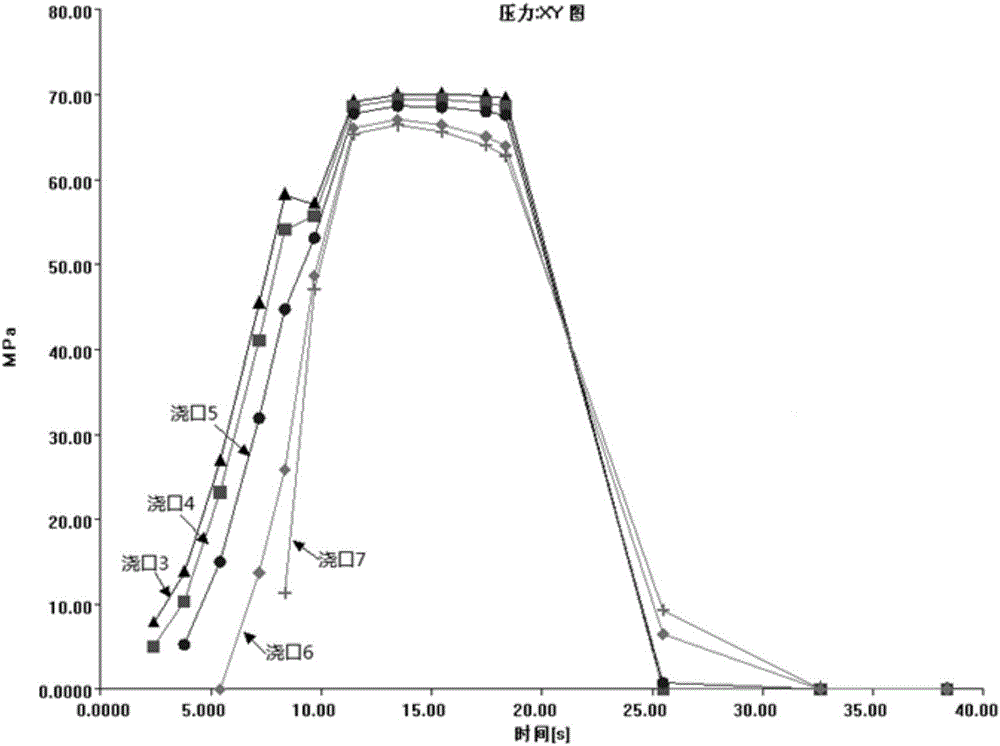

Injection molding method for commercial vehicle sun shade

The invention relates to a manufacturing process of vehicle decoration pieces, in particular to a molding process for a commercial vehicle sun shade product. The process aims at solving the problem that the shearing rate in a traditional injection mold gating system is too high, and the product quality can be effectively improved through an injection molding method for a commercial vehicle sun shade. The injection molding method for the commercial vehicle sun shade particularly comprises the following steps that (1) melted plastic passes through a middle position hot runner main spraying nozzle, passes through two-point hot runners and then passes through a middle-position cold runner sprue to enter a product cavity; (2) a second cold runner sprue, a third cold runner sprue, a fourth cold runner sprue and a fifth cold runner sprue which are symmetrically arranged on the two sides of the middle-position cold runner sprue are opened in sequence, and the melted plastic is injected into the product cavity; and (3) the injection pressure at all sprues is kept until the product cavity is filled with the melted plastic.

Owner:JIANGSU XINQUAN AUTOMOTIVE TRIM

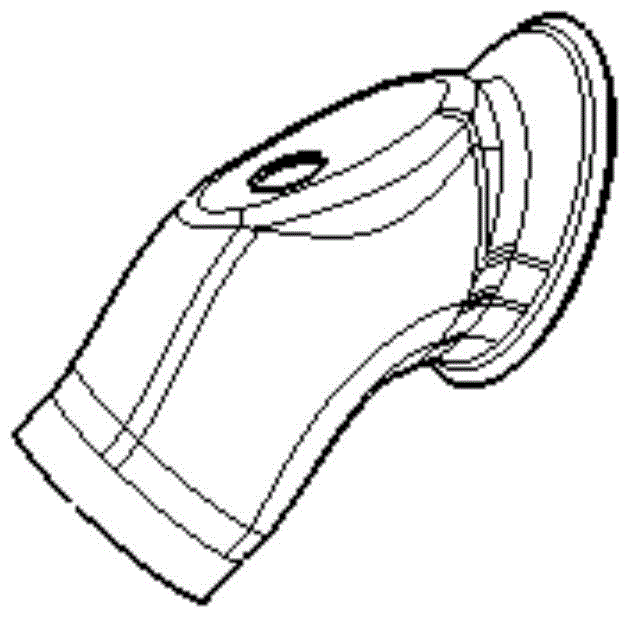

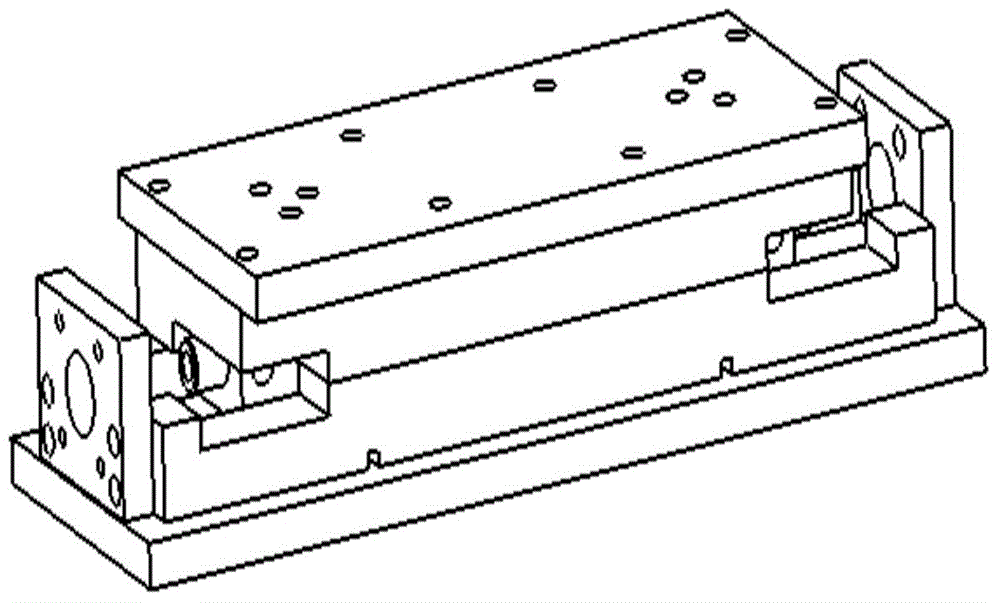

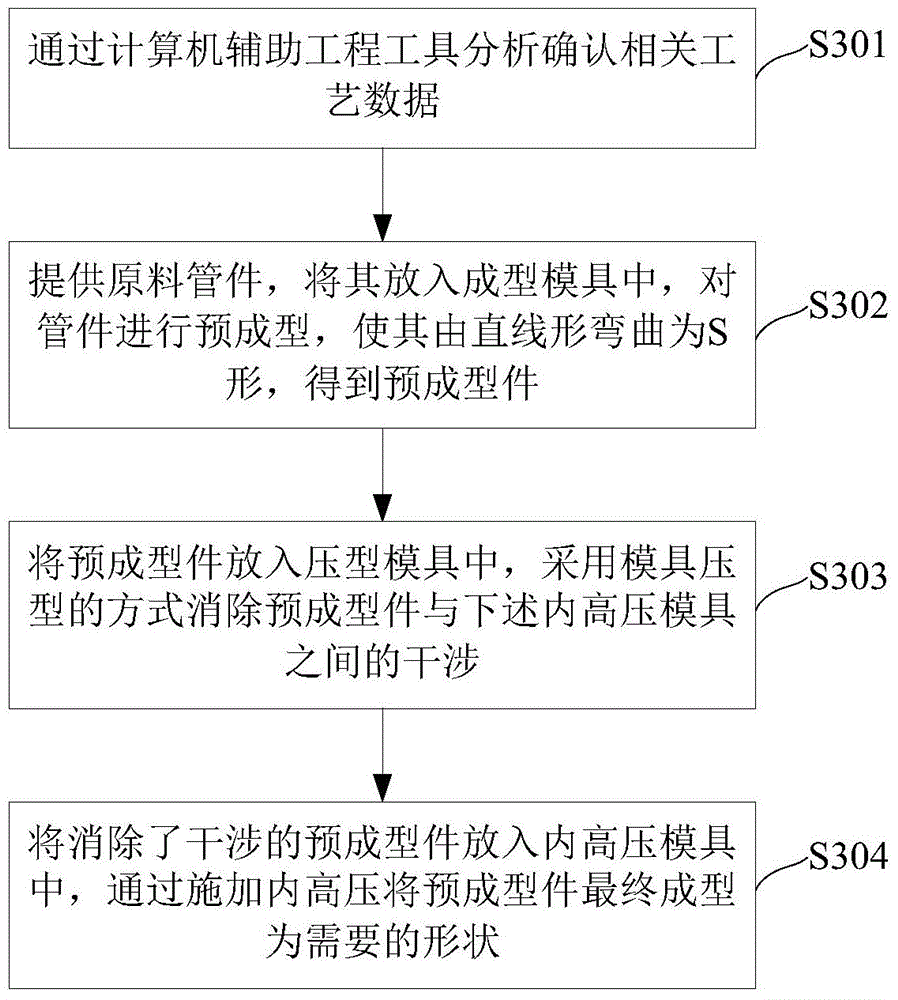

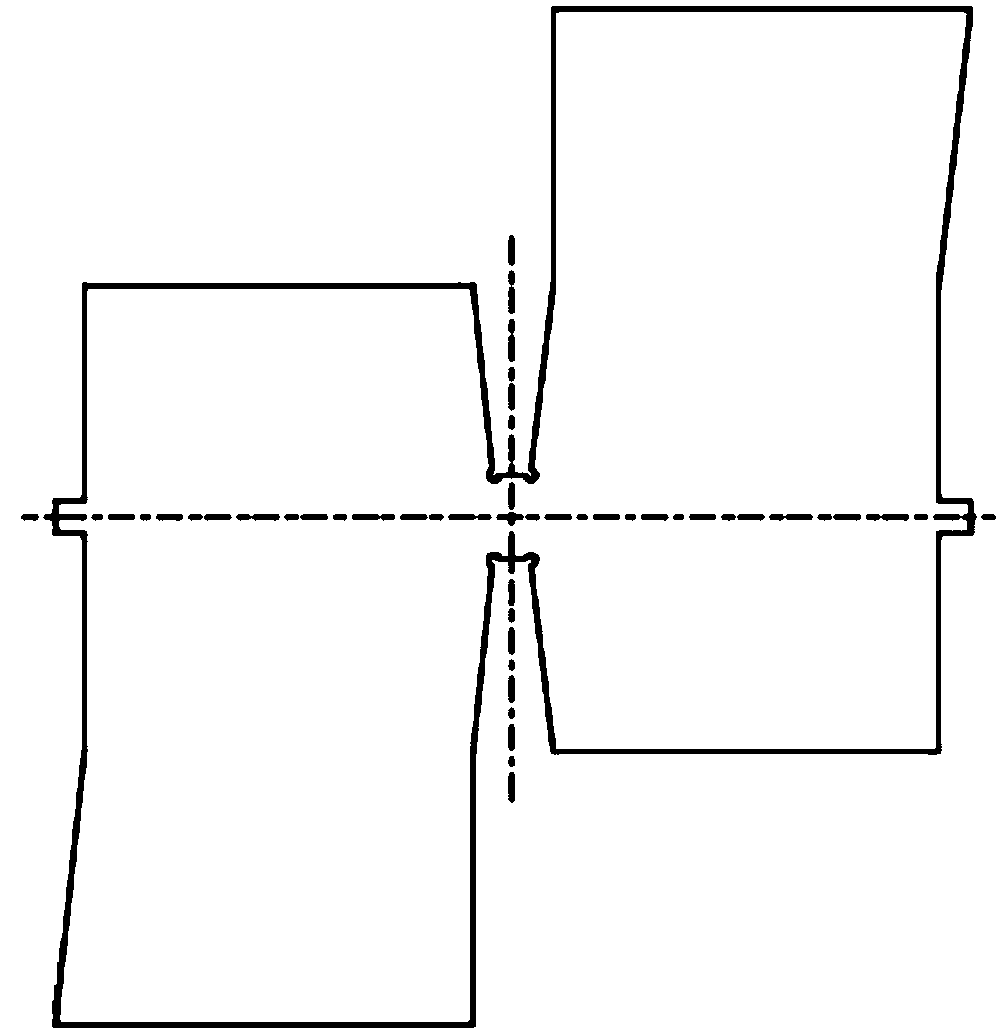

Internal high pressure-forming method for special-shaped tube

The invention provides an internal high pressure-forming method for a special-shaped tube, which adopts a one-die multi-tube manner. The method includes the following steps: analyzing and affirming relevant technique data through a computer-aided emerging tool; providing a raw tube, arranging the raw tube in a forming die, performing pre-forming on the raw tube, allowing the linear tube to be bent into the S-shaped tube, and obtaining a pre-forming tube; putting the pre-forming tube in a compression die, and eliminating interference between the pre-forming tube and an internal high pressure die; putting the pre-forming tube without interference in the internal high pressure die, applying the internal high pressure on the pre-forming tube and allowing the pre-forming tube to form a tube with a desired shape. The method can stably and reliably form the special-shaped tube through the one-die multi-tube manner, wherein the special-shaped tube has a serious demand for the wall thickness and has a big end and a small end, the diameter change between the big end and the small end is large. The method can effectively overcome the defects of large wall thickness change and cranks during forming, can save cost, and can improve benefits.

Owner:BAOLONG ANHUI AUTO PARTS

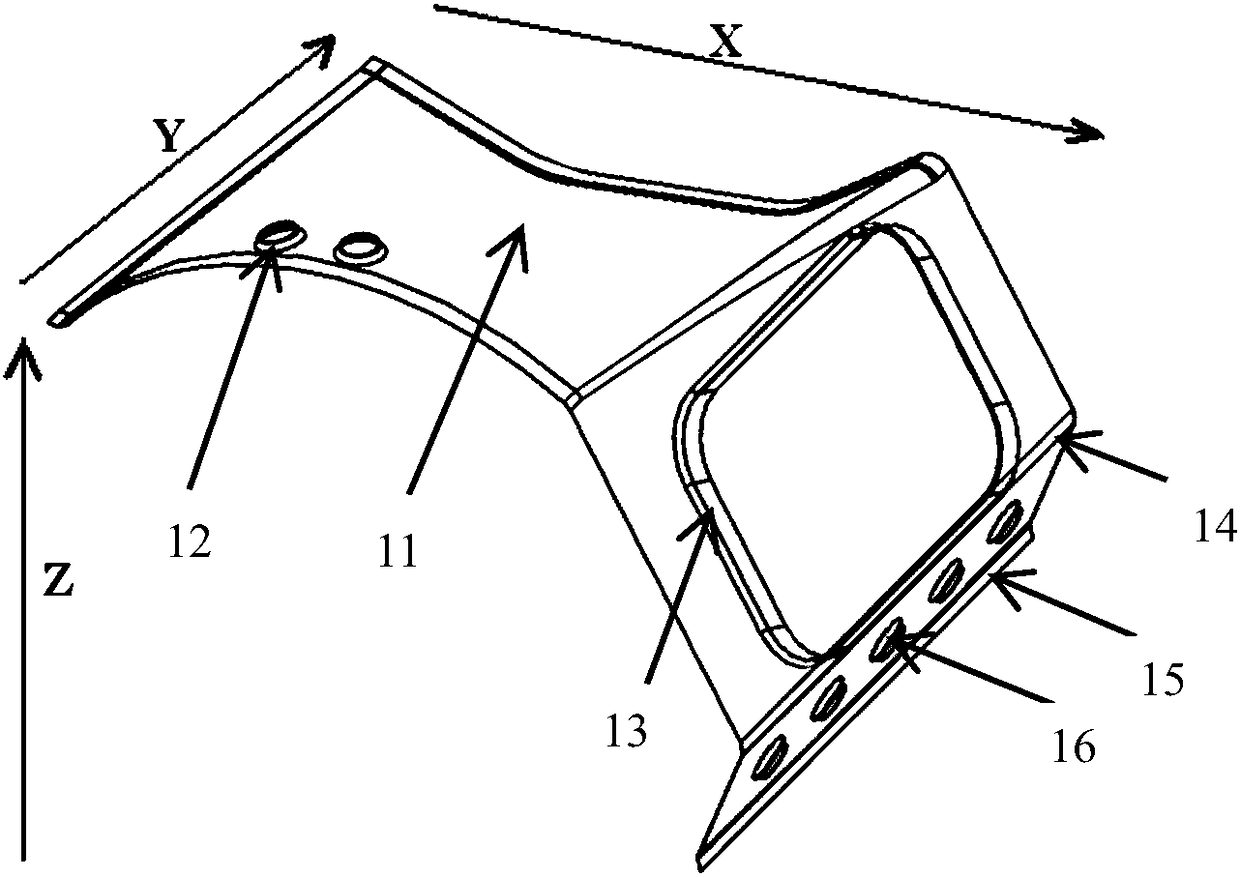

Precise plastic formation method for aluminum alloy complicated special-shaped curved structure part

The invention provides a precise plastic formation method for an aluminum alloy complicated special-shaped curved structure part and belongs to the field of precise sheet metal machining. The preciseplastic formation method is applicable to the aluminum alloy complicated special-shaped curved structure part which has relatively high requirements on dimensional precision, profile surface precisionand surface quality after formation. The method provided by the invention comprises the following steps of: (1) designing and manufacturing an aluminum alloy special-shaped curved thermo-forming mold, a flanging-hole flanging mold and a right side window thermal-flanging mold; (2) calculating the boundary dimension of a blank material and carrying out blanking; (3) carrying out top special-shapedcurved thermo-formation; (4) removing the process allowance and forming a flanging-hole flanging bottom hole and a flanging window flanging front window; (5) carrying out flanging formation of a flanging hole; (6) carrying bending formation of a bent edge; and (7) carrying thermo-flanging formation of the window. The method provided by the invention can overcome the shortcomings that a part machined by the prior art is poor in integrity, difficult in boundary dimension control or the cost is relatively high, and can effectively guarantee precise formation of the aluminum alloy complicated special-shaped curved structure part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

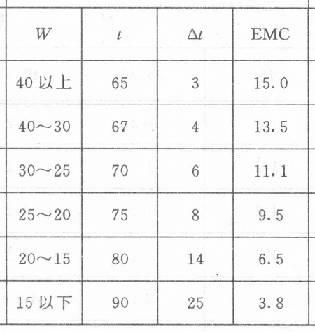

Cypress defatting method

The invention discloses a cypress defatting method, and relates to the technical field of modified treatment on wood in wood processing. Cypress log is firstly processed into boards of different thickness according to requirements, then the boards are placed in a closed dry kiln to be heated by steam and then to be steamed by saturated steam, so that the resin in the board is liquefied into cedar oil, the cedar oil is heated to be azeotropic with the water vapor, the cedar oil of the board is volatilized constantly and is discharged out of the board along with water and water vapor, so that he purpose of seeping resin is achieved. According to the method, the defatting effect is good, the method is easy to operate and can be widely used for cypress defatting, and the problems in the prior art that defatting treatment can not be carried out on a large scale and defatting treatment needs to be continued in the dry kiln after being carried out in a defatting tank are solved.

Owner:SICHUAN AGRI UNIV

Supersonic wave processing method of glass base microfluidic chip

InactiveCN102398890BImprove processing qualityAvoid defects such as crackingDecorative surface effectsChemical vapor deposition coatingSupersonic wavesUltrasonic machining

A supersonic wave processing method of a glass base microfluidic chip comprises steps of: processing a probe; pasting a paste adhesive tape on an upper surface of a glass substrate and a piece of glass flake on a lower surface of the glass substrate; carrying out supersonic wave processing; polishing by chemical attack; and finally completing preparation of the chip. The invention can be widely applied to manufacture of glass base microfluidic chip and other hard material biological chip and has characteristics of simple operation, high precision, high machining efficiency and reduced processing cost.

Owner:XI AN JIAOTONG UNIV

Slurry patting construction process for building construction

InactiveCN112376854ASimple structureReduce processing difficultyBuilding constructionsRough surfaceConstruction engineering

The invention discloses a slurry patting construction process for building construction. The construction process comprises the following steps of a, operation preparation, b, tool manufacturing, c, slurry preparation, d, wall treatment, e, slurry patting construction and f, maintenance construction. Slurry is flatly laid on a meshed bat through a mortar scraper, the meshed bat is flush with the wall surface in the slurry patting process, a thorn-shaped rough surface with a thick bottom and sharp tops is formed, the purpose of uniform and firm base layer treatment is achieved, the defects of hollowing, cracking and the like of a painting layer caused by base layer treatment are basically avoided, the rework rate is reduced, and the plastering quality is improved.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Large-size anti-warping 3D printing flexible bottom plate with easy-to-take part and using method thereof

PendingCN111660555ALow costAvoid wastingManufacturing platforms/substrates3D object support structuresMolten stateManufactured material

The invention discloses a large-size anti-warping 3D printing flexible bottom plate with an easy-to-take part and a using method thereof. According to the printing bottom plate, a cured flexible colloid is loaded in a container, printing material particles are laid on the surface of the cured flexible colloid, and an additive manufacturing process is carried out on the printing material particles.The whole printing bottom plate does not need to be heated, so that energy conservation and environmental protection are achieved; the surface material of the bottom plate and the printing material are the same material, and the surface particles and the surface material in a molten state have a good bonding effect; after printing is completed, the part is convenient to take; the base plate can be repeatedly repaired and used, and the cost is low; the shape of the base plate can be changed along with the shape of a workpiece 4, so that material waste is avoided to the maximum extent; the bottom plate is formed by compounding a plurality of materials, and the surface material of the bottom plate is a raw material consistent with the printing material so as to meet the requirements of materials with different printing temperatures; and the flexible bottom plate is beneficial to release of internal stress in the printing process, and cracking caused by stress concentration can be effectively prevented.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

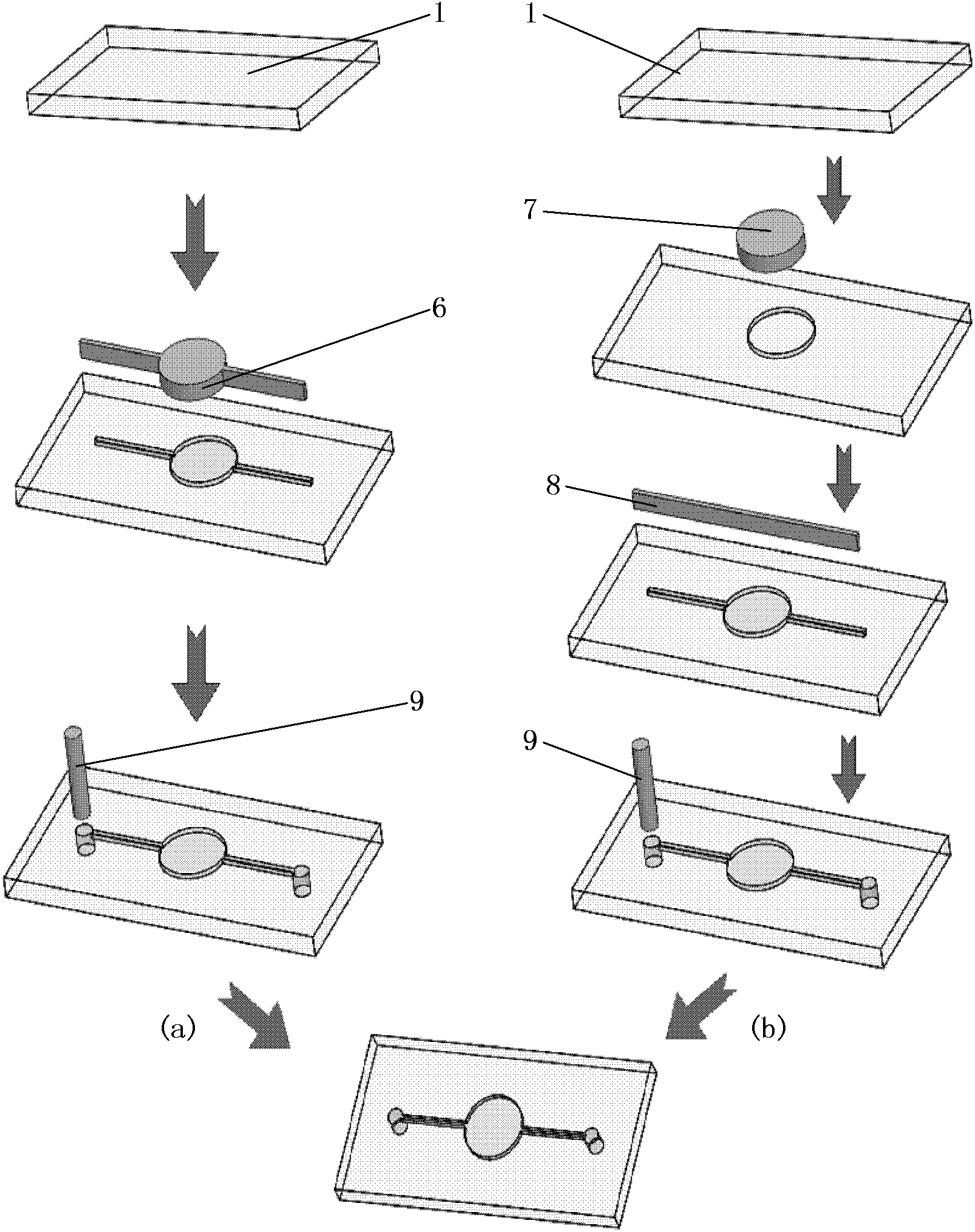

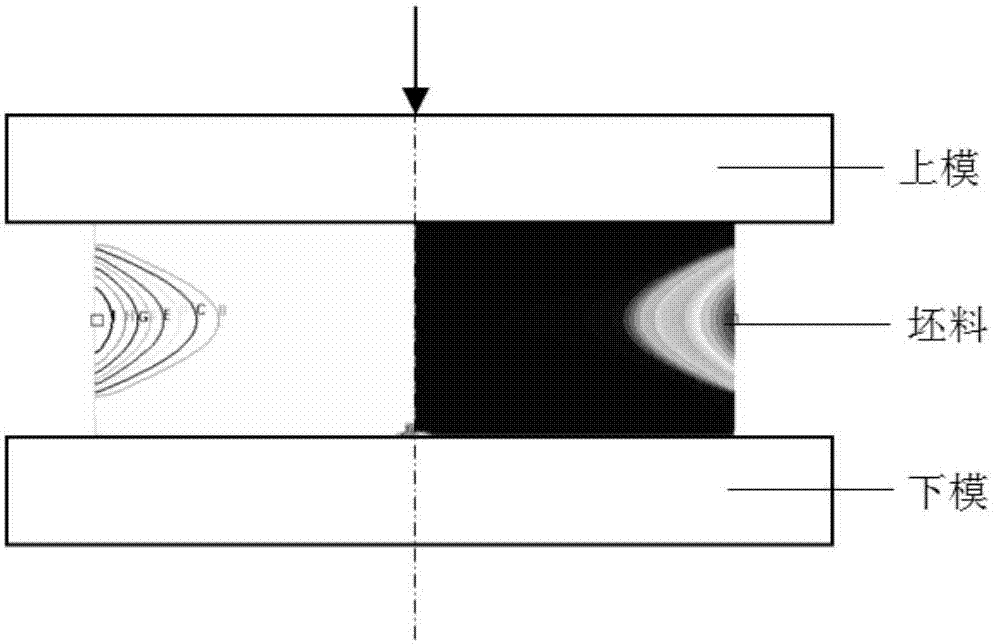

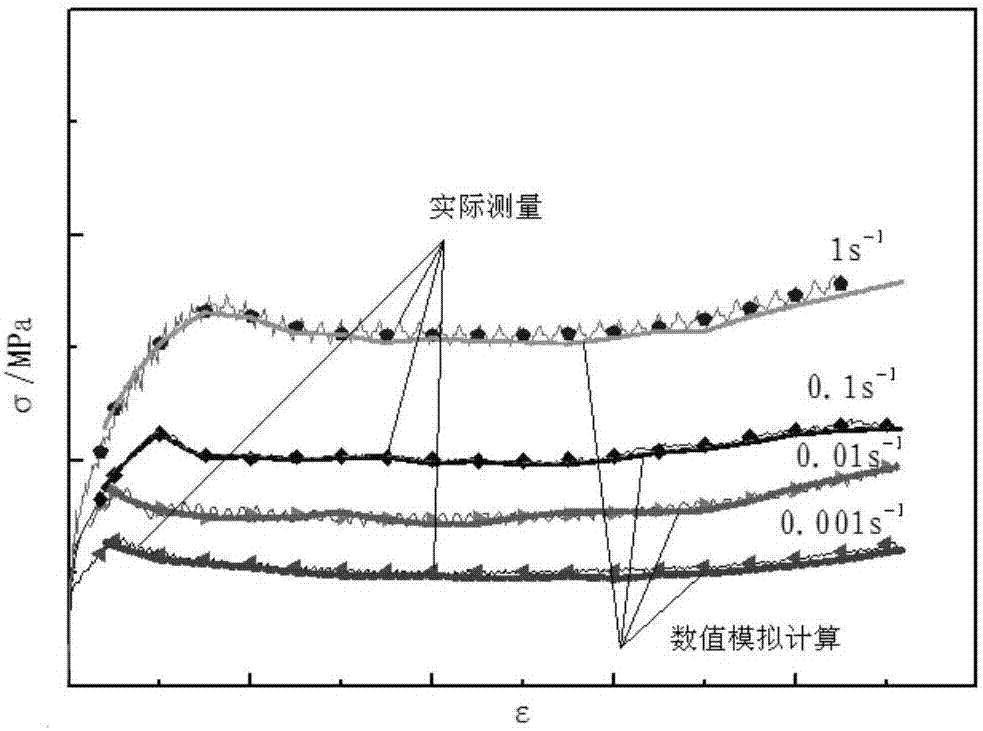

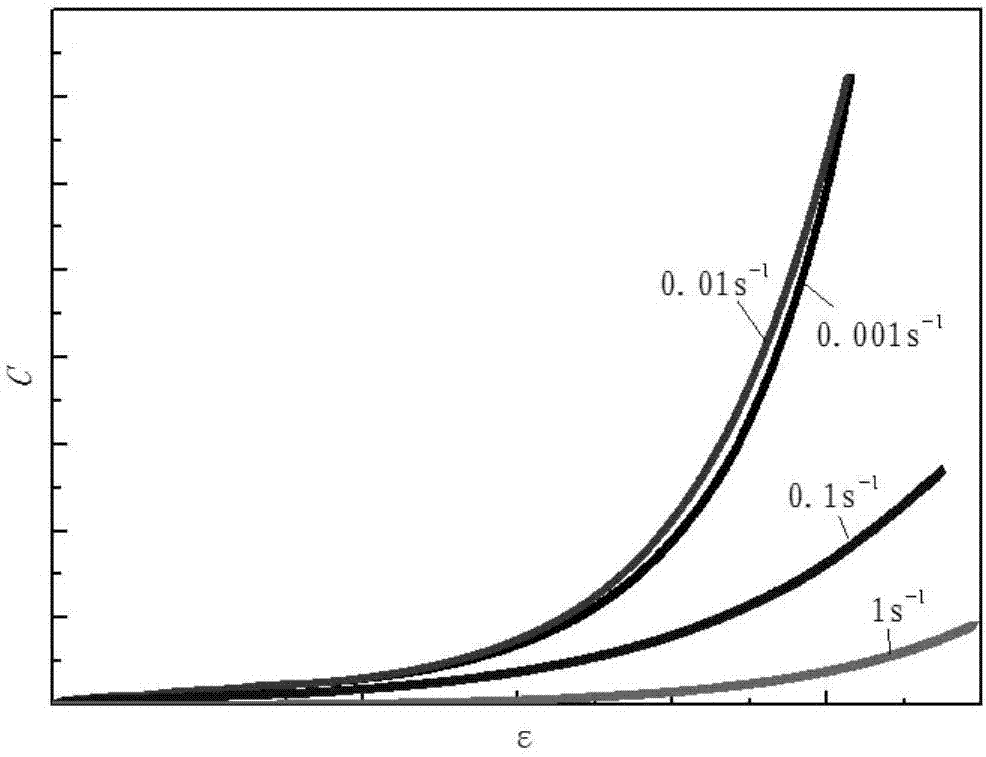

Identification method for plastic compression molding critical damage

ActiveCN108009379ASolve problems such as dispersionIdentify critical damageDesign optimisation/simulationSpecial data processing applicationsControl periodStrain rate

The invention discloses an identification method for plastic compression molding critical damage. The method comprises the following steps that: 1) under a condition of an equal temperature and a constant strain rate, carrying out compression molding on a round rod material through an upper die, and evenly dividing whole compression molding into N control periods; 2) extracting the internal stressof the material after compression molding is carried out, and carrying out calculation to obtain the cumulative damage value of each control period; 3) establishing the function of cumulative damageand macroscopic equivalent strain, on the basis, establishing the function of a damage sensitivity coefficient and the macroscopic equivalent strain, the corresponding macroscopic equivalent strain iscritical fracture strain when the damage sensitivity coefficient approaches to 0, and carrying out calculation to obtain a critical damage value; and 4) repeatedly adopting the above method to establish an association model of the critical damage value, the temperature and the strain rate. By use of the method, the critical damage of a plastic compression process can be effectively identified, defects including product cracking and the like due to blind forming technical design are avoided, and a scientific guidance is provided for the product technical design.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Forming method for improving wall thickness distribution of superplastic forming special-shaped cylinder body through predeformation

The invention discloses a forming method for improving wall thickness distribution of a superplastic forming special-shaped cylinder body through predeformation. The method comprises the following steps of (1), carrying out designing of an aluminum alloy special-shaped cylinder body blank; (2), carrying out designing of a superplastic forming upper mold and a superplastic forming lower mold of thealuminum alloy special-shaped cylinder body; (3), carrying out designing of an superplastic forming core mold of the aluminum alloy special-shaped cylinder body; (4), carrying out reverse superplastic forming on the aluminum alloy special-shaped cylinder body; and (5), carrying out forward superplastic forming on the aluminum alloy special-shaped cylinder body. Reverse superplastic forming is carried out and then forward superplastic forming is carried out so as to prepare the aluminum alloy special-shaped cylinder body, thus the problem that the size precision and the molded surface precision are difficult to control in conventional cold stamping or mechanical machining is solved, and the surface quality of a part is improved; and aluminum alloy special-shaped cylinder body reverse superplastic forming is adopted to carry out predeformation on the aluminum alloy special-shaped cylinder body blank, then aluminum alloy special-shaped cylinder body forward superplastic forming is adopted so as to carry out final forming, thus the defect that the wall thickness distribution of the aluminum alloy special-shaped cylinder body only subjected to forward superplastic forming is not uniform is overcome, and the requirements for size precision, molded surface precision and surface quality of the part are guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

A kind of manufacturing method of tantalum target material

ActiveCN104419901BIncrease deformation rateUniform structureVacuum evaporation coatingSputtering coatingIngotBismuth

The invention provides a method for manufacturing a tantalum target material. The method comprises the following steps: firstly, carrying out hot forging on a tantalum ingot and then carrying out first annealing on the hot-forged tantalum ingot to form a first tantalum target material billet; rolling the first tantalum target material billet to form a second tantalum target material billet; and carrying out second annealing on the second tantalum target material billet to obtain the tantalum target material. The tantalum target material formed according to the technical scheme has fine internal grains and uniform internal microstructure and thus the defects such as delamination inside the tantalum target material are effectively avoided, the sputtering rate of the tantalum target material and the quality of the formed tantalum film in the subsequent use process are improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

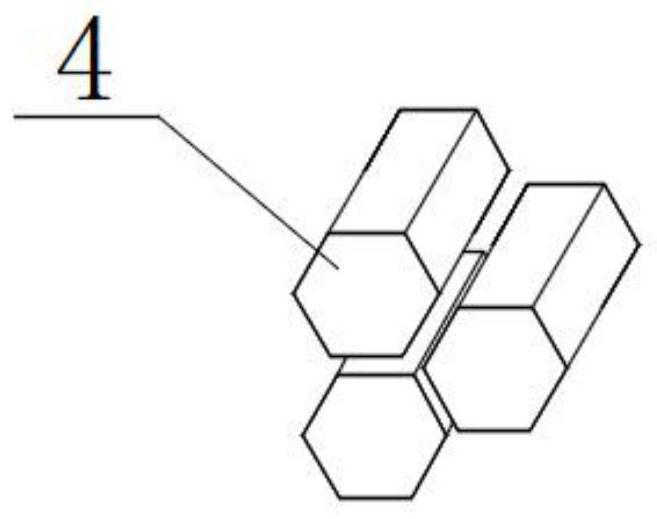

Hexagonal solid wood splicing structure and processing method thereof

InactiveCN113478592ABalance stressAvoid shrinkage and swellingDomestic upholsteryLaminationSolid woodEngineering

The invention relates to a hexagonal solid wood splicing structure and a processing method of the hexagonal solid wood splicing structure. The hexagonal solid wood splicing structure comprises density boards which are symmetrically arranged; solid wood veneers attach to light-seeing surfaces of the density boards, and a pressure-resistant board is arranged between the two density boards; the pressure-resistant board is formed by splicing a plurality of polygonal profiles; force rib plates are arranged on the periphery of the pressure-resistant board in a surrounding manner; and a veneer, a fireproof plate or a multi-layer board is arranged on the surface of each solid wood veneer. The technical scheme has the following beneficial effects that eucalyptus boards are rotationally cut into slices with the thickness of 1.5 mm through a rotary cutter, the remaining eucalyptus core sticks are fully utilized, therefore, the waste material core boards of the multi-layer board are recycled, meanwhile, stress release control through temperature and humidity and moisture absorption analysis of the wood are realized in the whole process through the rigorous and scientific processing technology, and thus the stability of the product is ensured; and all regular hexahedral rhombic materials (eucalyptus cores) are hexagons with the same size, and the same splicing area adopts the density boards made of the same material, so that balance stress can be released, and the defects that wood shrinks after being dried and expands after being wetted, cracks and the like are effectively overcome.

Owner:广东玛格家居有限公司

Method for forming special-shaped pipe fitting used in field of communication

ActiveCN112643984AGood dimensional stabilityAvoid deformationSievingScreeningPipe fittingEngineering

The invention discloses a method for forming a special-shaped pipe fitting used in the field of communication. The method comprises the following steps of (1) putting polytetrafluoroethylene (PTFE) dispersion resin on a vibrating screen, and separating out large impurities and agglomerates; (2) mixing the PTFE dispersion resin and an extrusion aid to obtain a mixture; (3) heating and standing the mixture to cure the mixture; (4) sieving the cured mixture by using the vibrating screen, and primarily compressing the sieved mixture to obtain a pre-pressed blank; (5) compressing the pre-pressed blank from a mouth model by using PTFE dispersion extrusion equipment, and extruding to obtain a special-shaped product; and (6) sintering the extruded special-shaped product. The method is used for forming the special-shaped pipe fitting used in the field of communication, the pipe wall of the prepared special-shaped pipe fitting is not prone to deformation, and the defects of air holes, cracking and the like do not exist.

Owner:NANJING COMPTECH COMPOSITES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com