Supersonic wave processing method of glass base microfluidic chip

A technology of microfluidic chips and processing methods, applied in the fields of technology for producing decorative surface effects, microstructure technology, microstructure devices, etc., which can solve problems that are not suitable for large-scale processing, low processing environment requirements, complex processing equipment, etc. problems, to avoid surface scratches, improve processing quality, and improve surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

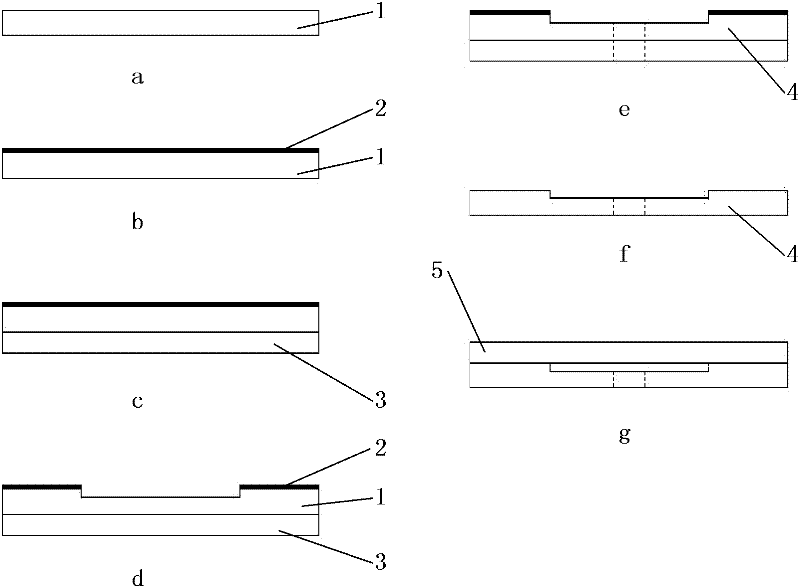

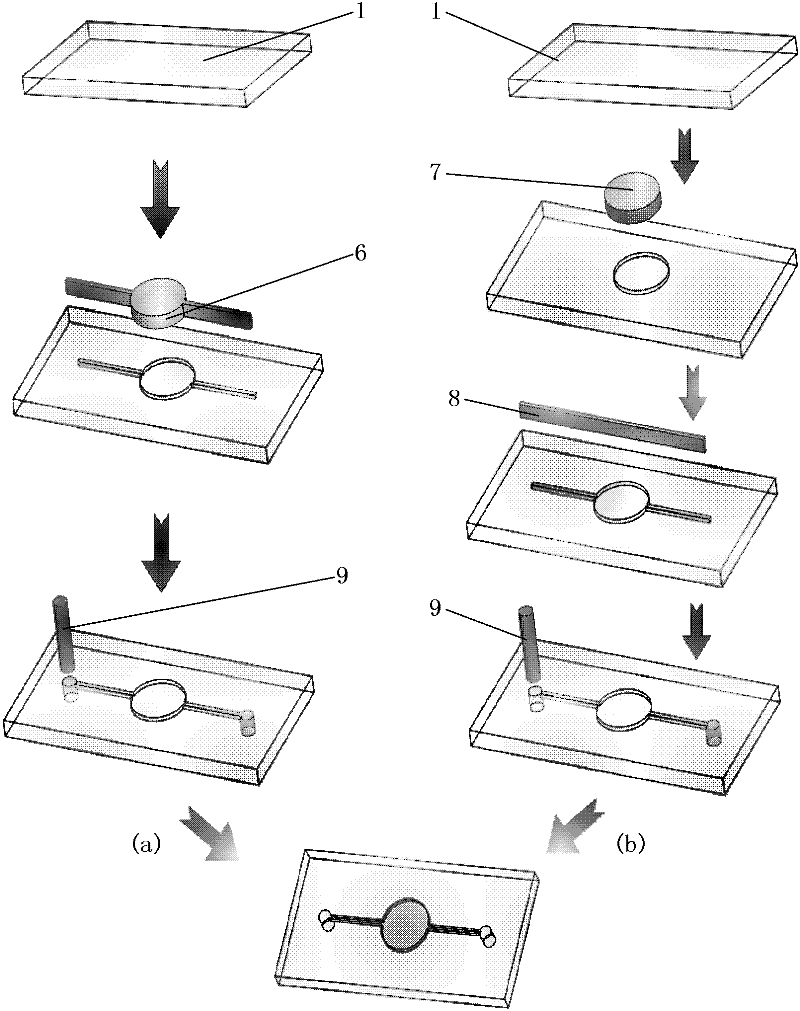

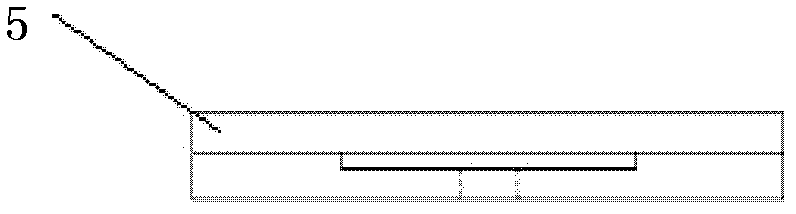

[0029] A kind of ultrasonic processing method of glass base microfluidic chip, refer to figure 1 , including the following steps:

[0030] Step 1. Make a processing probe consistent with the structure of the microfluidic chip, and then weld the processing probe and the ultrasonic probe together by soldering. During the welding process, pay attention to clean the oil and rust on the surface of the processing probe to avoid false positives. weld.

[0031] The design method of the processing probe in step 1 includes two processing schemes of integrated processing and multi-module step-by-step processing, and adopts traditional mechanical cutting processing or wet corrosion processing of metals. The difference between the two processing schemes lies in the fact that when designing and manufacturing the processing probe, the integrated processing sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com