Water-based gel casting method for structural ceramics

A technology of water-based gel injection molding and molding method, which is used in ceramic molding machines, manufacturing tools, etc., can solve the problems of large residual stress of ceramic blanks, poor processing performance, easy to wear tools, etc., and achieves high density and reduced Residual stress, the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The experimental process is as follows:

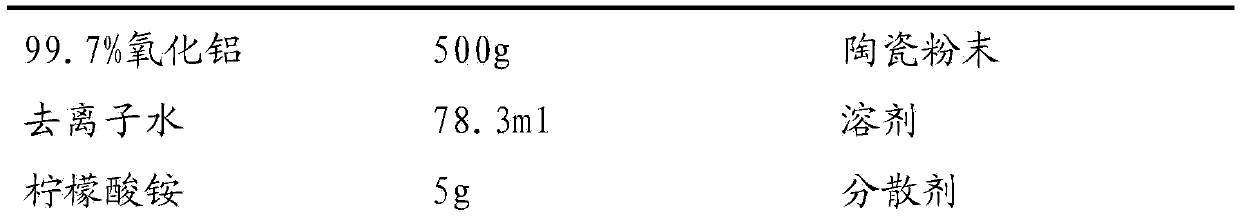

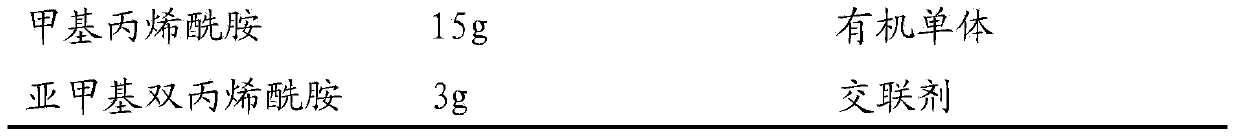

[0026] (1) Put the organic monomer and crosslinking agent accounting for 1wt% of the raw material solution into a beaker, the mass ratio between the organic monomer and the crosslinking agent is 5:1, and then add 8wt% deionized Fully dissolve the organic matter in water to prepare an organic matter solution, then add a dispersant accounting for 0.5wt% of the raw material solution to the prepared organic matter solution, stir and mix thoroughly, and adjust the pH value between 8-11 with ammonia water and acetic acid. Wherein, the organic monomer is acrylamide or methacrylamide, the crosslinking agent is methylene bisacrylamide or poly(vinyl glycol) dimethacrylic acid, and the dispersant is Ammonium citrate, polyacrylic acid and its copolymers (PAA) or polyethyleneimine.

[0027] (2) Add a plasticizer accounting for 20wt% of organic monomers to the above solution, and stir evenly to make a raw material solution. The plasticizer ...

Embodiment 2

[0033] In this example, the organic monomer and the crosslinking agent accounted for 2wt% of the raw material solution, the weight ratio of the organic monomer to the crosslinking agent was 10:1, and the others were the same as in Example 1.

Embodiment 3

[0035] In this example, the organic monomer and the crosslinking agent account for 3 wt% of the raw material solution, the weight ratio of the organic monomer to the crosslinking agent is 20:1, and the others are the same as in Example 1.

PUM

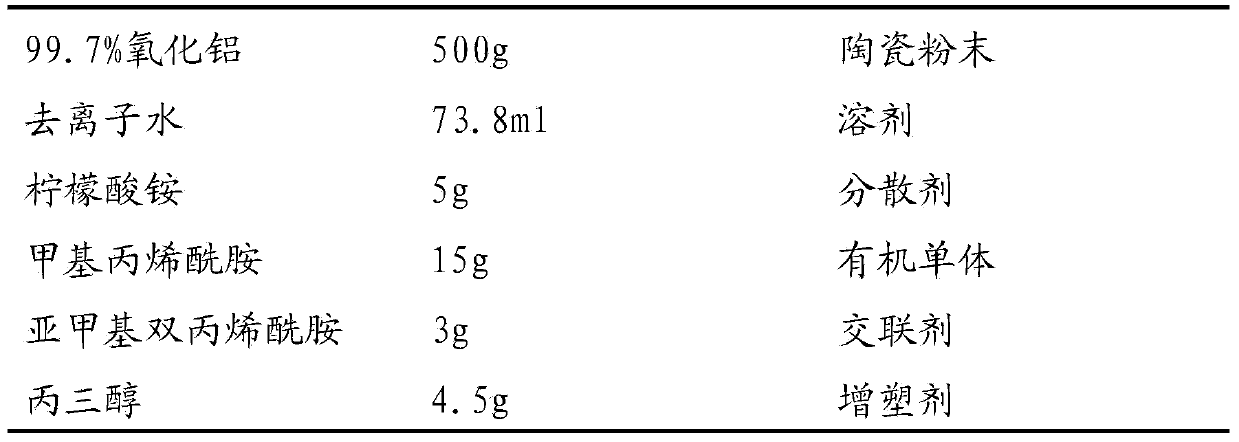

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com