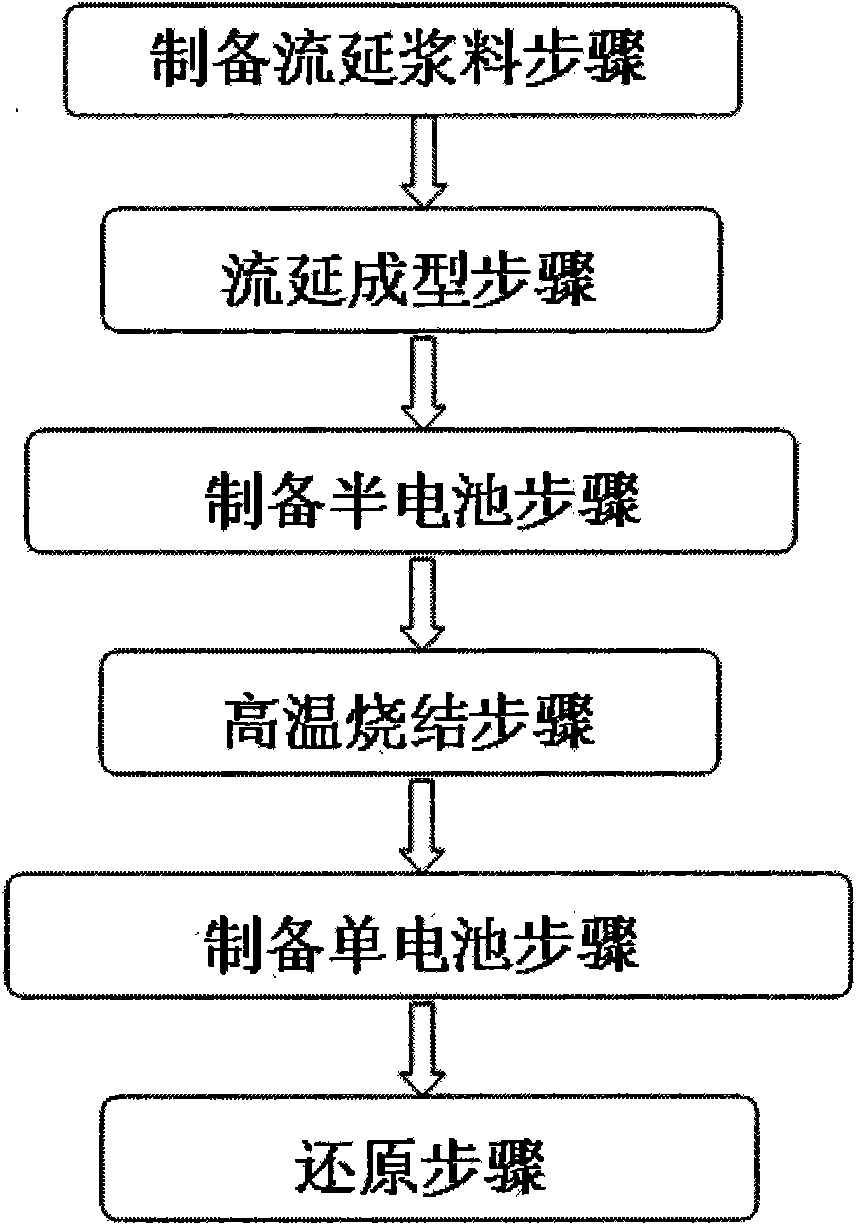

Method for preparing metallic support type solid oxide fuel cell

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of complex process, high equipment requirements, cracking of the electrolyte layer, etc., to achieve simple preparation process, Simple equipment, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: comprise the steps:

[0033] (1) Preparation of casting slurry step: according to weight ratio: nickel oxide 230g, pore-forming agent carbon powder 15g, binder polyvinyl butyral (PVB) 25g, plasticizer butyl benzyl phthalate ( BBP) / polyalkylene glycol (PAG) (weight ratio, 1:1) 25g, dispersant fish oil 4g, organic solvent xylene / dehydrated alcohol (weight ratio, 1:1) 104g, nickel oxide, pore-forming Agent, binding agent, plasticizer and dispersant are dissolved in the organic solvent, add 7 drops of defoaming agent cyclohexanone, ball mill to make casting slurry;

[0034] (2) Tape casting step: tape cast the obtained tape casting slurry, and obtain a nickel oxide green body with a thickness of about 1 mm after natural drying; the nickel oxide green body is cut into a nickel oxide support body green body with a diameter of 26 mm ;

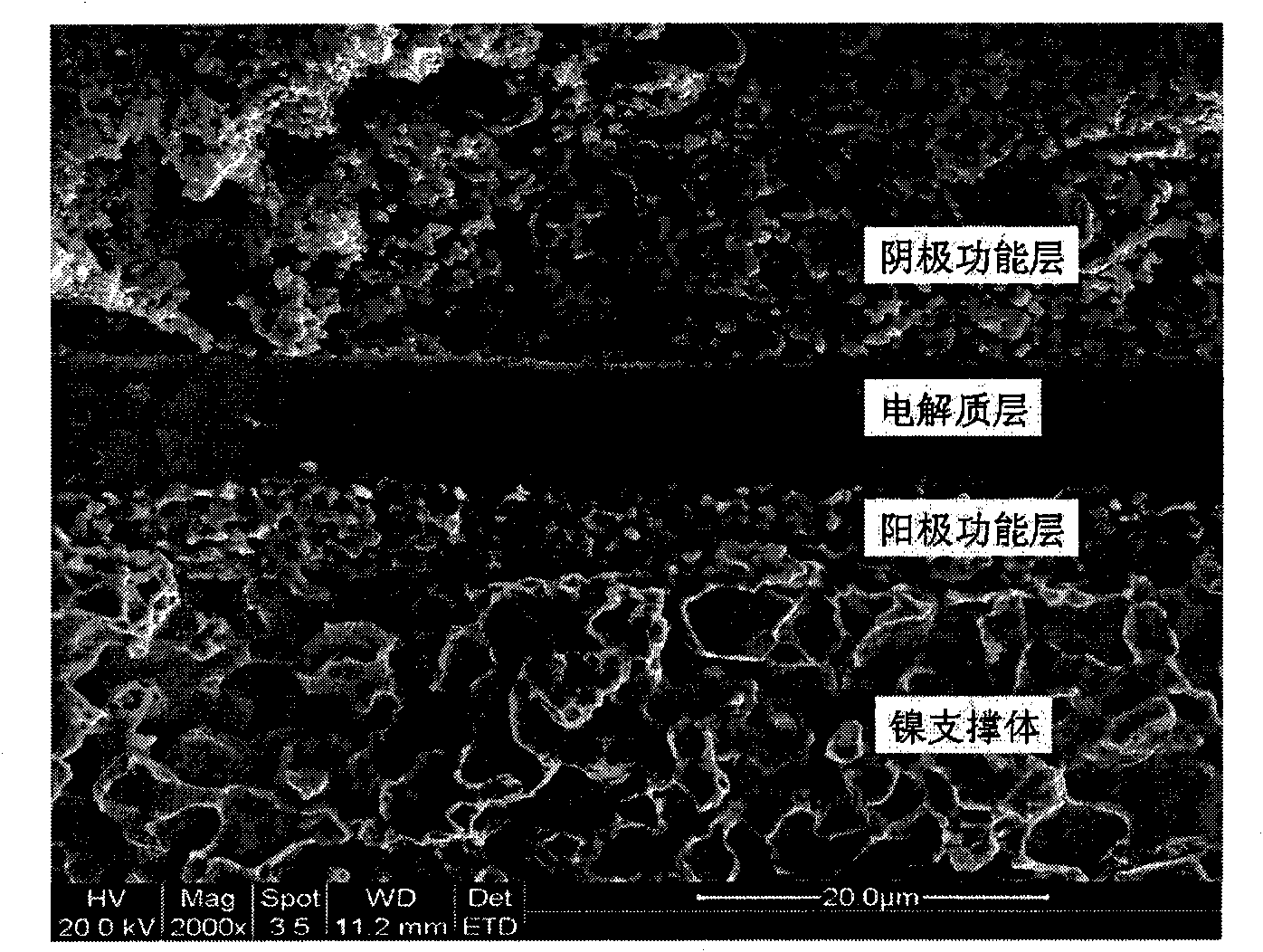

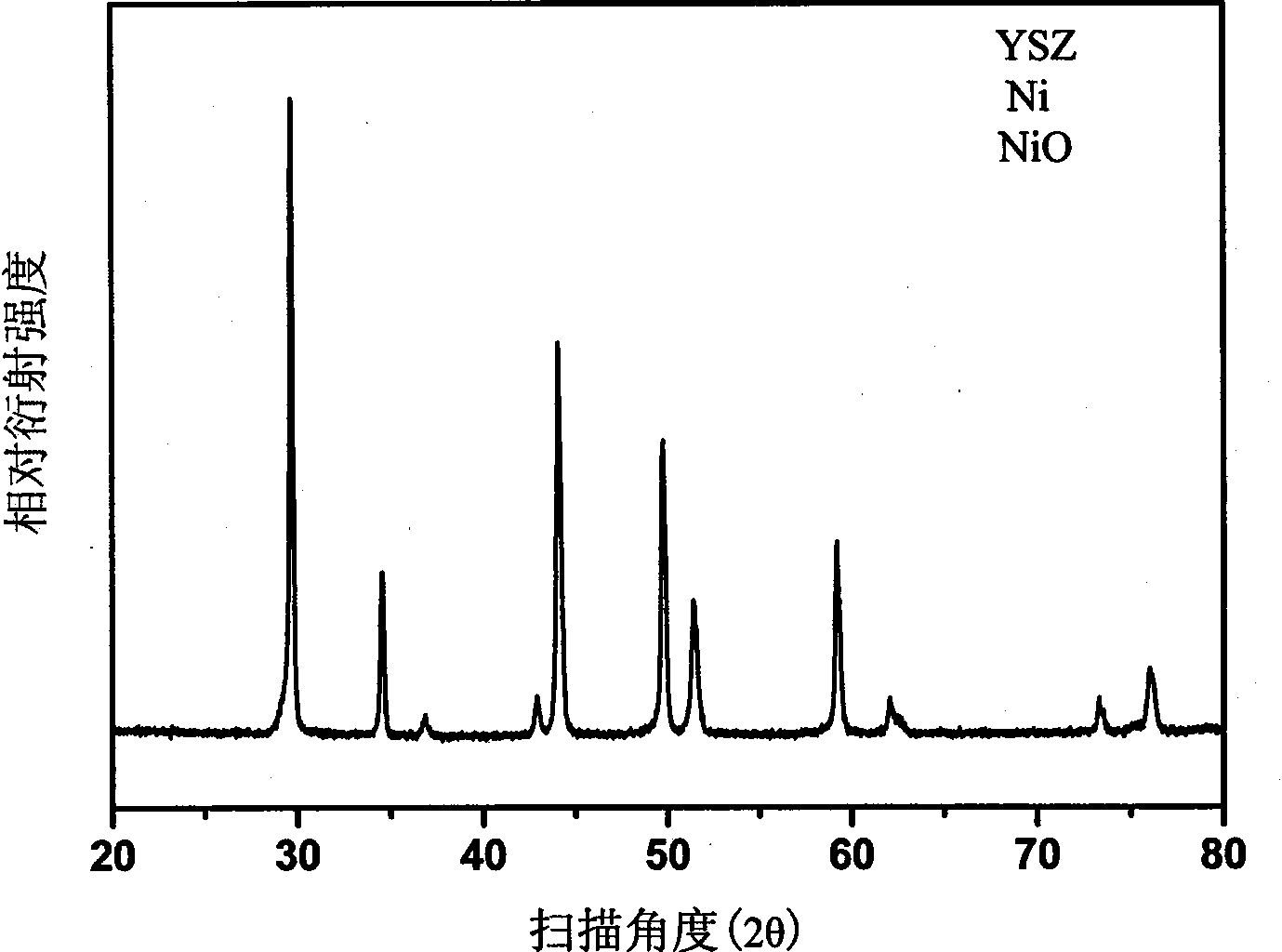

[0035] (3) Preparation of half-cell step: use screen printing process to sequentially print NiO-YSZ anode functional layer and...

Embodiment 2

[0042] Embodiment 2: comprise the steps:

[0043] (1) Preparation of casting slurry step: according to weight ratio: nickel oxide 200g, pore-forming agent carbon powder 10g, binder polyvinyl butyral (PVB) 22g, plasticizer butyl benzyl phthalate ( BBP) / polyalkylene glycol (PAG) (weight ratio, 1:1) 22g, dispersant fish oil 3g, organic solvent xylene / dehydrated alcohol (weight ratio, 1:1) 96g, nickel oxide, pore-forming Dissolve the agent, binder, plasticizer and dispersant in the organic solvent, add 4 drops of defoaming agent cyclohexanone, and ball mill to make casting slurry;

[0044] (2) Tape casting step: tape cast the obtained tape casting slurry, and obtain a nickel oxide green body with a thickness of about 1 mm after natural drying; the nickel oxide green body is cut into a nickel oxide support body green body with a diameter of 26 mm ;

[0045] (3) Preparation of half-cell step: use screen printing process to print anode functional layer NiO-YSZ and YSZ electrolyte l...

Embodiment 3

[0050] Embodiment 3: comprise the steps:

[0051] (1) Preparation of cast slurry step: according to weight ratio: nickel oxide 200g, pore-forming agent starch 10g, binder methyl cellulose 22g, plasticizer propylene glycol adipate polyester / polyalkylene glycol (PAG ) (weight ratio, 1: 1) 22g, dispersant tristearin 3g, organic solvent styrene / dehydrated alcohol (weight ratio, 1: 1) 96g, nickel oxide, pore forming agent, binding agent , Dissolve plasticizer and dispersant in organic solvent, add 6 drops of defoaming agent cyclohexanone, and ball mill to make casting slurry;

[0052] (2) Tape casting step: tape cast the obtained tape casting slurry, and obtain a nickel oxide green body with a thickness of about 1 mm after natural drying; the nickel oxide green body is cut into a nickel oxide support body green body with a diameter of 26 mm ;

[0053] (3) Preparation of half-cell step: use screen printing process to sequentially print NiO-YSZ anode functional layer and YSZ electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com