Polyphosphazene composition, solar cell back film with polyphosphazene coatings and preparation method of solar cell back film

A solar cell and polyphosphazene technology, which is applied in coatings, circuits, photovoltaic power generation, etc., can solve problems such as poor weather resistance and complicated preparation process, and achieve easy operation, simple process, excellent flexibility and ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

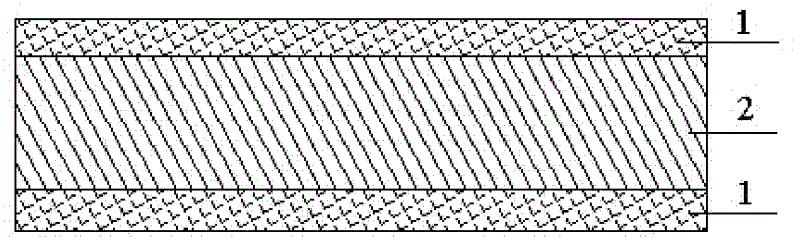

[0032] The present invention provides a kind of preparation method of above-mentioned polyphosphazene coating solar cell back film, comprises the following steps:

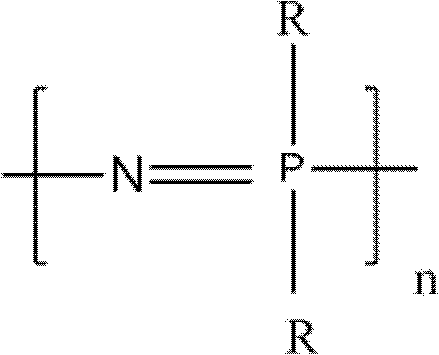

[0033] (1) According to 100 parts by weight of the polyphosphazene composition, add 10-30 parts by weight of solvent, 1-15 parts by weight of polyphosphazene micro-nano material and 55-89 parts by weight of polyphosphazene material in the container , after uniform stirring at room temperature, the above-mentioned polyphosphazene composition was obtained.

[0034] (2) Prepare a polyester base film by a biaxial stretching process, apply the polyphosphazene composition obtained in the above step (1) on the base film, bake and dry to obtain the polyphosphazene coating Solar cell back film.

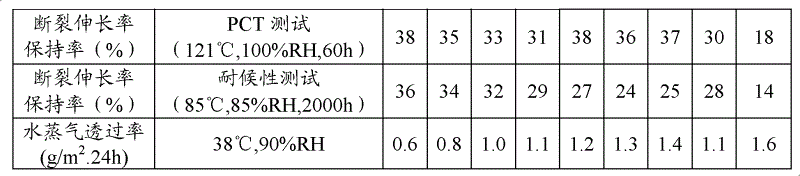

[0035] Prepare polyphosphazene-coated solar cell back film according to the above method, and the gained back film carries out elongation at break, water vapor transmission rate, weather resistance and PCT test.

[0036]Elongatio...

Embodiment 1

[0041] Add 10 parts by weight of tetrahydrofuran into the container, then add 1 part by weight of polyphosphazene microspheres and 89 parts by weight of polyphenoxyphosphazene, and stir evenly at room temperature to obtain polyphosphazene composition 1.

[0042] The above-mentioned composition 1 is coated on a 100-micron PET base film (also known as a substrate), and the specific coating process is as follows: the substrate is unwound by an unwinder, and then automatically loaded, and the polyphosphazene composition is coated on The two surfaces of the base material are then baked in a three-stage oven. The temperature of the oven is set at 90°C, 80°C, and 70°C respectively. The length of the drying tunnel is 10-30m, and the line speed is 5-40m / min. Finally, it is wound up by a winder, baked and dried to obtain a polyphosphazene-coated solar cell back film A1 with a weather-resistant barrier layer thickness of 20 microns;

Embodiment 2

[0044] Add 10 parts by weight of acetone into the container, then add 5 parts by weight of polyphosphazene microspheres and 85 parts by weight of polyphenoxyphosphazene, and stir evenly at room temperature to obtain polyphosphazene composition 2.

[0045] The above-mentioned composition 2 is coated on a 150-micron PBT substrate, and the specific coating process is as follows: the substrate is unwound by an unwinder, and then automatically loaded, and the polyphosphazene composition is coated on both surfaces of the substrate , and then baked in a three-stage oven. The temperature of the oven is set at 90°C, 80°C, and 70°C respectively. The length of the drying tunnel is 10-30m, and the line speed is 5-40m / min. Finally, it is wound up by a winder. roll, baked and dried to obtain a polyphosphazene-coated solar cell back film A2 with a weather-resistant barrier layer thickness of 15 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com