Water tank and horizontal single-cylinder evaporative diesel engine with same

A diesel engine, evaporative technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems affecting the appearance of the water tank, save material costs, and improve the overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

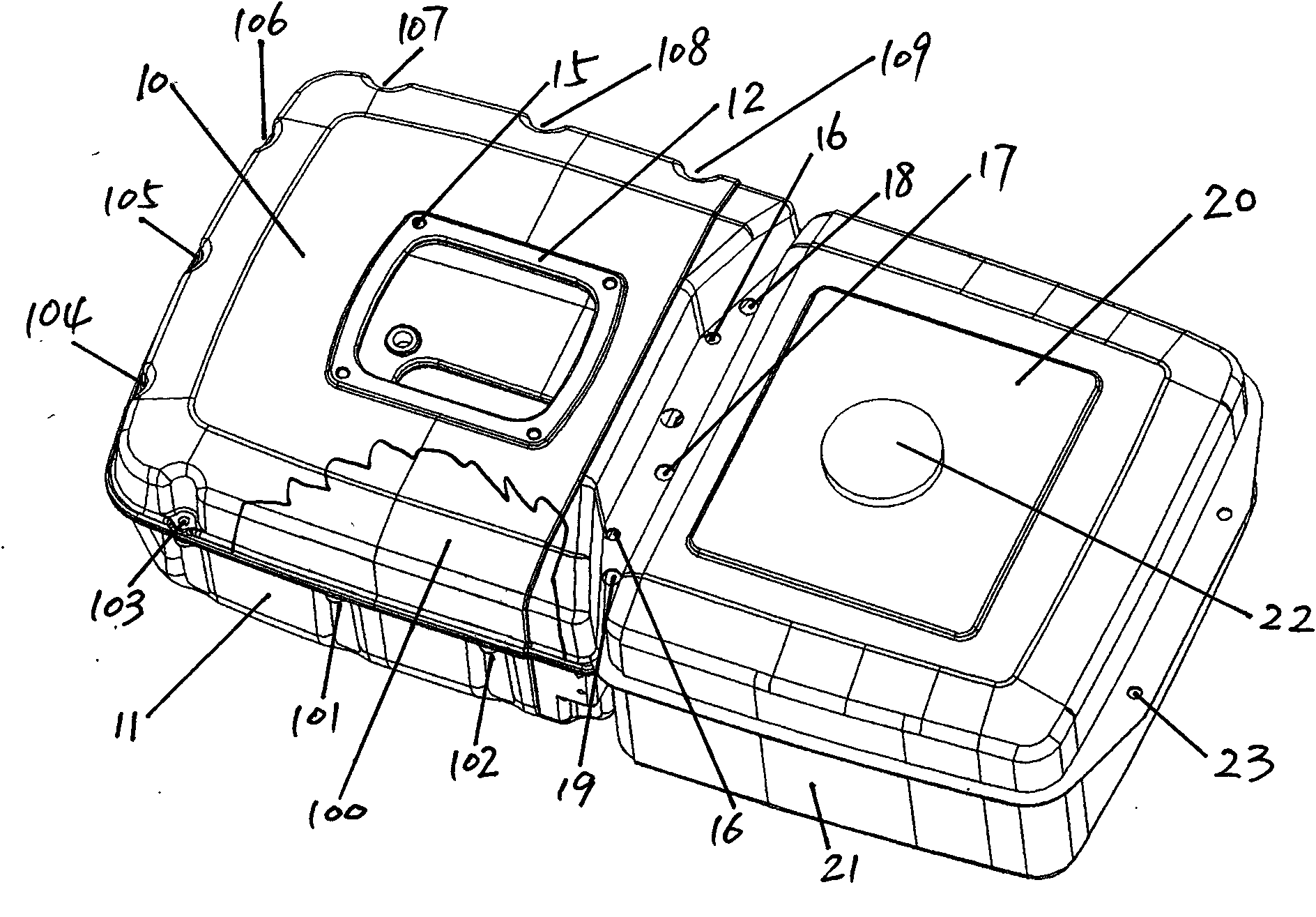

[0023] exist figure 1 In , the three-dimensional top view expresses the state of assembly and connection of the water tank and the fuel tank on the single-cylinder horizontal evaporative diesel engine. The part of the upper body of the water tank (100) without vertical grooves expresses the smooth effect of the connection between the water tank and the fuel tank, because the vertical surface shell of the upper body of the water tank (10) corresponding to the boss (118) is located in the connection hole (1180) On the outside, the overall outline of the water tank and the fuel tank are smoothly connected.

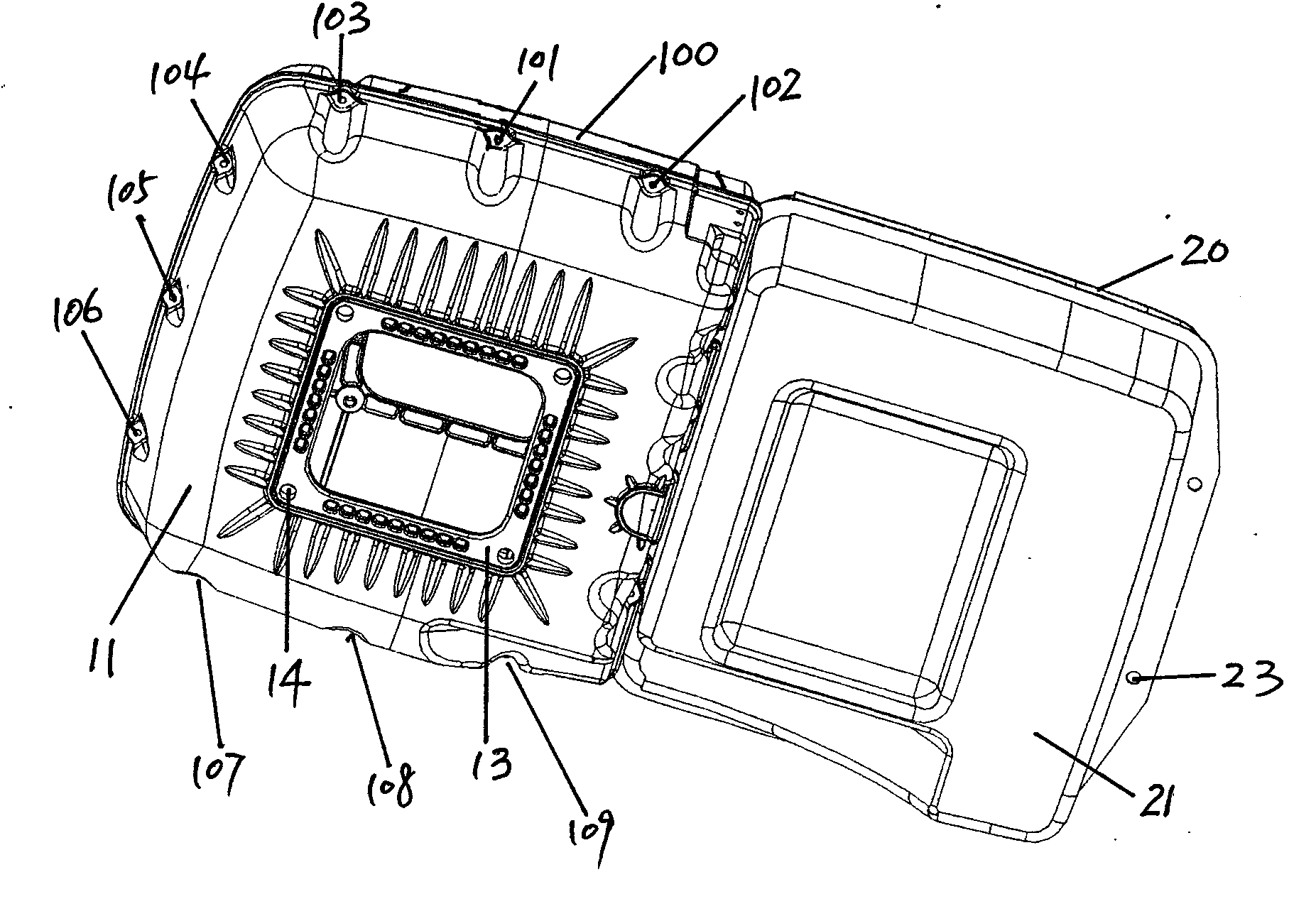

[0024] exist figure 2 In , the three-dimensional bottom view expresses the connection mode between the water tank and the body. The holes (101) and holes (102) on the edge of the lower body of the water tank can be threaded into the local upper body (100) of the water tank without vertical grooves on the upper body of the water tank. .

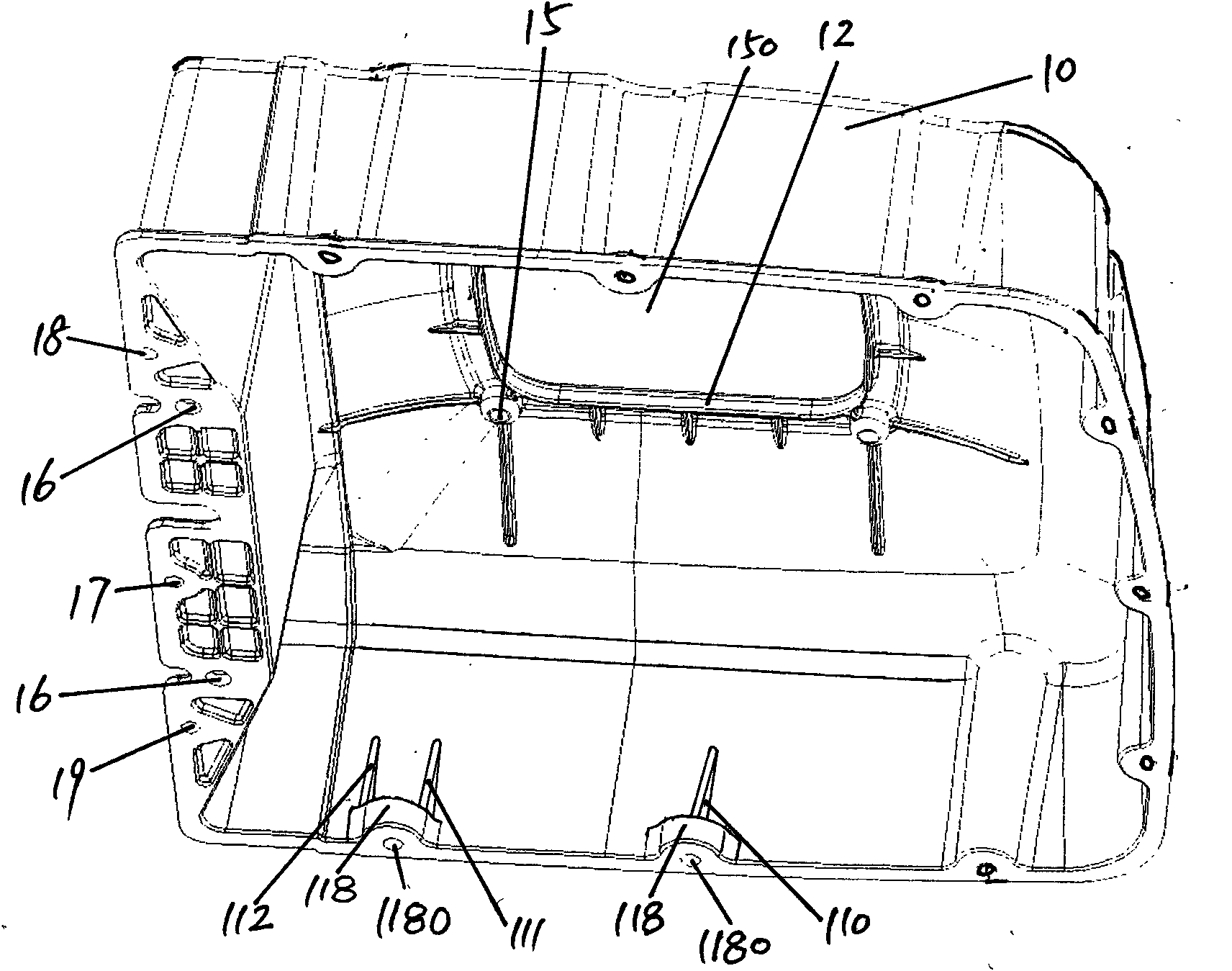

[0025] exist image 3 Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com