Special repair mortar for structure and preparation method thereof

A technology for repairing mortar and quartz sand, which is applied in the field of building materials, can solve the problems of undisclosed mortar bond strength, tensile and compressive strength, etc., and achieve the effect of increasing van der Waals force, improving flexural strength, and maintaining later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

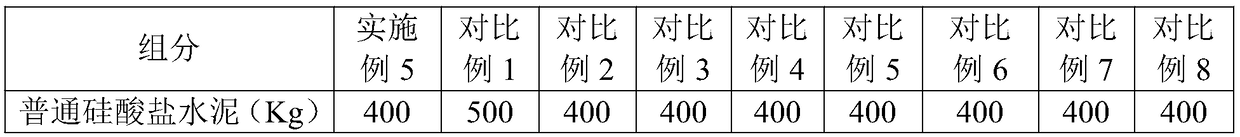

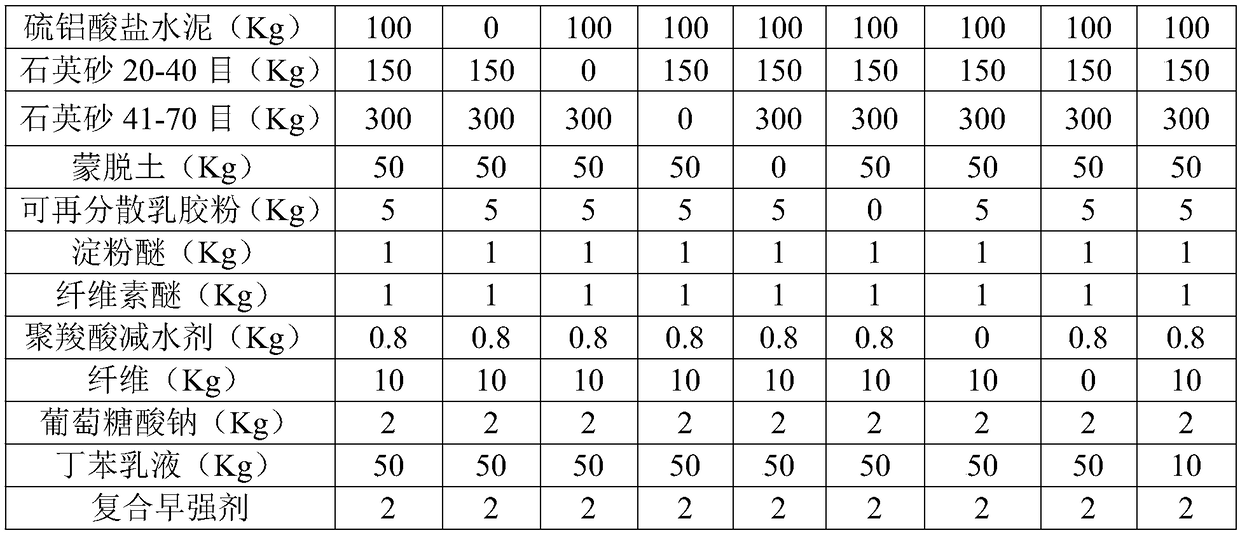

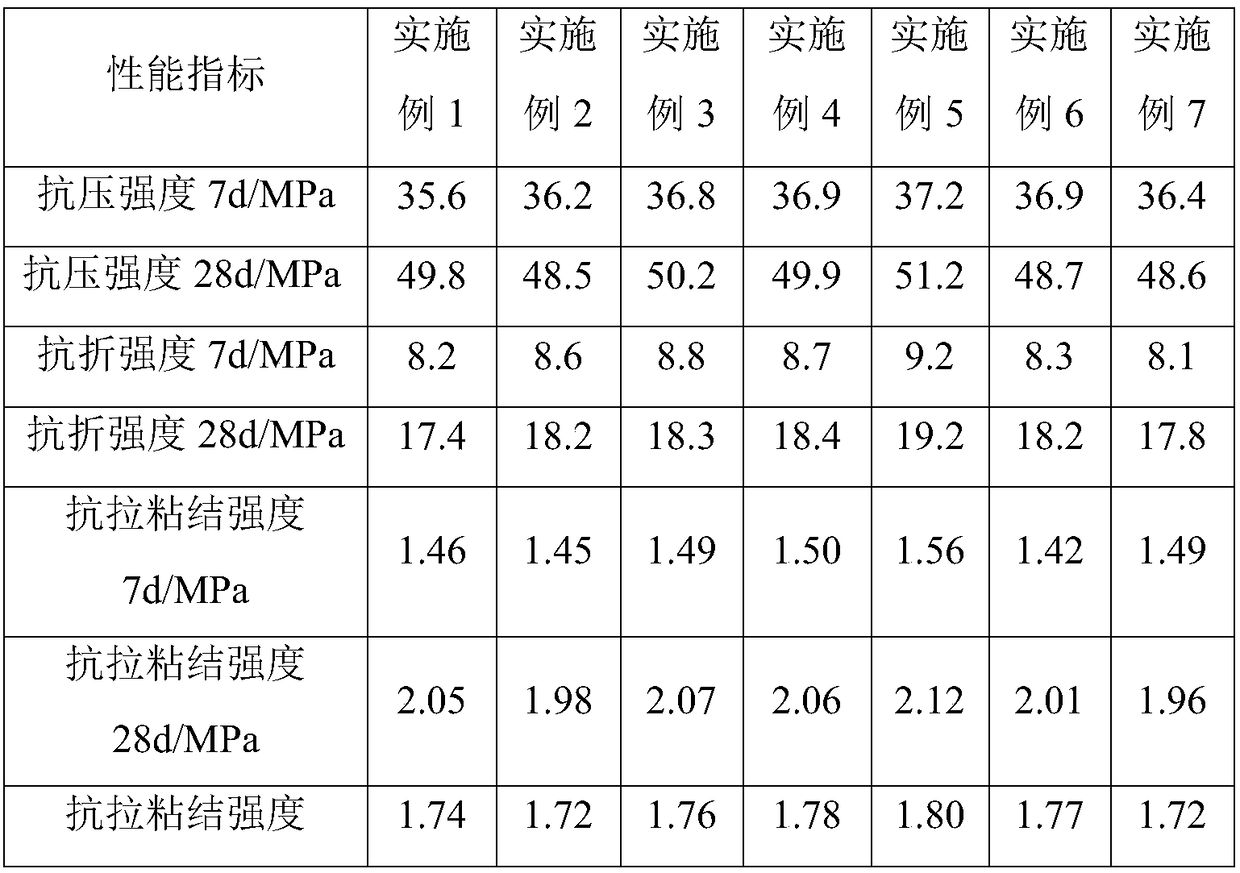

Examples

Embodiment 1

[0061] S1. Weigh 350Kg of ordinary Portland cement, 50Kg of sulphoaluminate cement, 100Kg of quartz sand (20-40 mesh), 300Kg of quartz sand (41-70 mesh) and 20Kg of montmorillonite according to parts by weight, and mix Uniform;

[0062] S2. Add 1Kg of redispersible latex powder, 1Kg of starch ether, 1Kg of cellulose ether, 0.5Kg of polycarboxylate superplasticizer, 1Kg of sodium gluconate, and mix well;

[0063] S3. Add 30Kg of styrene-butadiene emulsion, 1Kg of fiber (mixture of polypropylene fiber, wood fiber and polyvinyl alcohol fiber, the mass ratio is 1:3:2), 1Kg of composite early strength agent (boric acid, ferrous sulfate, gypsum, mass The ratio is 0.02:1:0.2), mix evenly, then add tap water accounting for 15%-25% of the dry powder weight to adjust the consistency of the mortar, stir for 3 to 5 minutes, and the product is ready.

Embodiment 2

[0065] S1. Weigh 500Kg of ordinary Portland cement, 150Kg of sulphoaluminate cement, 200Kg of quartz sand (20-40 mesh), 350Kg of quartz sand (41-70 mesh) and 50Kg of montmorillonite according to parts by weight, and mix Uniform;

[0066] S2. Add 10Kg of redispersible latex powder, 5Kg of starch ether, 5Kg of cellulose ether, 2Kg of polycarboxylate superplasticizer, 3Kg of sodium gluconate, and mix well;

[0067] S3. Add 50Kg of styrene-butadiene emulsion, 10Kg of fiber (the mixture of polypropylene fiber, wood fiber and polyvinyl alcohol fiber, the mass ratio is 1:3:3), 5Kg of composite early strength agent (boric acid, ferrous sulfate, gypsum, mass The ratio is 0.02:1:0.3), mix evenly, then add tap water accounting for 15%-25% of the dry powder weight to adjust the consistency of the mortar, and stir for 3-5 minutes to obtain.

Embodiment 3

[0069] S1. Weigh 400Kg of ordinary Portland cement, 100Kg of sulphoaluminate cement, 150Kg of quartz sand (20-40 mesh), 300Kg of quartz sand (41-70 mesh), and 50Kg of montmorillonite according to parts by weight, and mix Uniform;

[0070] S2. Add 5Kg of redispersible latex powder, 1Kg of starch ether, 1Kg of cellulose ether, 0.8Kg of polycarboxylate superplasticizer, 2Kg of white sugar, and mix well;

[0071] S3. Add 50Kg of styrene-butadiene emulsion, 10Kg of fiber (mixture of polypropylene fiber, wood fiber and polyvinyl alcohol fiber, the mass ratio is 1:4:2), 4Kg of composite early strength agent (boric acid, ferrous sulfate, gypsum, mass The ratio is 0.05:1:0.3), mix evenly, then add tap water accounting for 15%-25% of the dry powder weight to adjust the consistency of the mortar, and stir for 3-5 minutes to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com