Technology of hydrogenatioin to produce iso octanol using iso octaldehyde mixture and its catalyst

A catalyst and process technology, applied in the field of the process and the catalyst used, can solve the problem that the catalyst has no literature report, and achieve the effects of strong ability, improved purity and color, and high hydrogenation activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh industrial grade Ni(NO 3 ) 2 ·6H 2 O198 grams, be dissolved in 0.5 liters of water, be mixed with solution; Join in the industrial grade sodium carbonate solution, wherein 25 grams of diatomite, 90ml water glass (Na 2 SiO 3 , SiO 2 Content is 250g / l) and 7 grams of bauxite, mixed and beaten into the reaction solution, fully stirred to mix the materials evenly, until the reaction is complete, the nickel is fully precipitated, and the pH value is 7.0; filtered; dried; at a temperature of 600 ° C Roasting; adding extrusion aids, kneading, extrusion molding (or tableting, balling, pressing into Raschig rings) to obtain catalyst A-1. The strength data of catalyst A-1 prepared by different molding methods are listed in Table-1. The content of each component in catalyst A-1, the main process parameters in the preparation process and the pore structure data are shown in Table-2.

[0029] Change the add-on of each component in the above-mentioned preparation process, ...

Embodiment 2

[0033] Weigh industrial grade Ni(NO 3 ) 2 ·6H 2 O198 grams and industrial grade Mg (NO 3 ) 2 ·6H 2 O130 grams, dissolved in 0.5 liters of water, prepared into a solution; added to industrial grade sodium carbonate solution, during which 27.5 grams of diatomaceous earth and 7 grams of bauxite were mixed and beaten into the reaction solution, fully stirred to make the materials evenly mixed , until the reaction is complete, the nickel is fully precipitated, and the pH value is 7.5; filtering; drying; roasting at a temperature of 560 ° C; adding extrusion aids, kneading, and extruding to obtain catalyst B-1. The content of each component in catalyst B-1, the main process parameters in the preparation process, pore structure data and strength data are shown in Table-3.

[0034]Change the addition amount of each component in the above preparation process and the main process condition parameters to prepare catalysts B-2, B-3, B-4, B-5 respectively, the content of each compon...

Embodiment 3

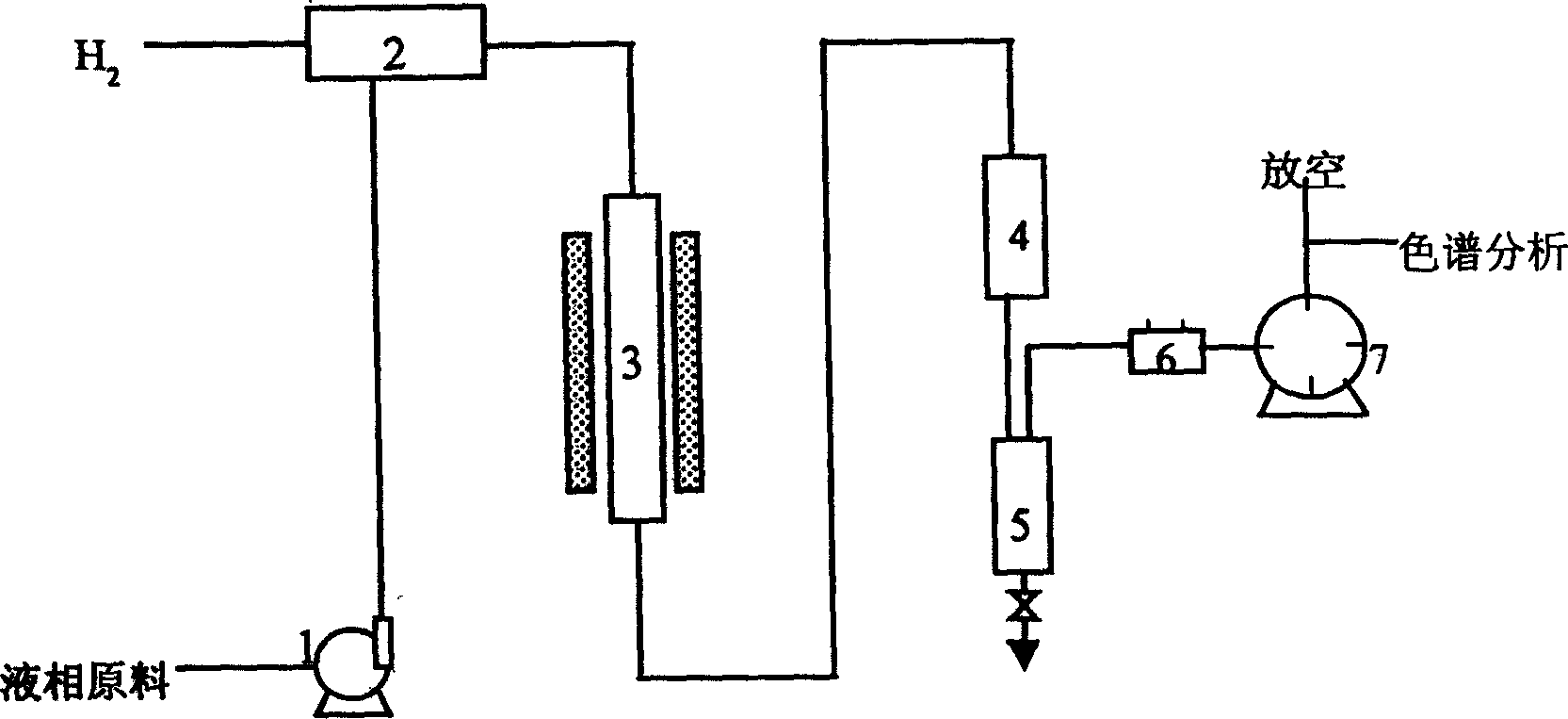

[0037] The schematic diagram of the liquid phase hydrogenation reaction device for isooctyl aldehyde mixture is shown in the accompanying drawing.

[0038] The reaction tube is a tube with an inner diameter of Φ19mm, and a thermocouple tube of Φ3mm is inserted. The particle size of the catalyst is 10-20 mesh, the loading capacity is 45ml, the reducing medium is hydrogen, the reducing temperature is 400°C-750°C, and the reducing pressure is 0.5MPa. The operating liquid space velocity is 5.0h -1 , H 2 / liquid (mol / mol)=8:1, operating pressure 2.6 MPa, temperature 100°C, 110°C, 120°C, each condition was operated for 4 hours.

[0039] The compositional data of the raw materials used in the reaction are shown in Table-4. (The following contents are all by weight%)

[0040] Composition name

Content (weight%)

0.05

1.03

Isooctane

0.01

Isooctene

0.03

Isooctylaldehyde

0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com