Method for preparing ternary complex anode material (LiNixCoyMn1-x-yO2)

A positive electrode material and ternary composite technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of uniform mixing of difficult elements, limited mechanical mixing uniformity, agglomeration and excessive particle growth, etc., to achieve the suppression of particle agglomeration and Effects of overgrowth, excellent electrochemical performance, and increased particle surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

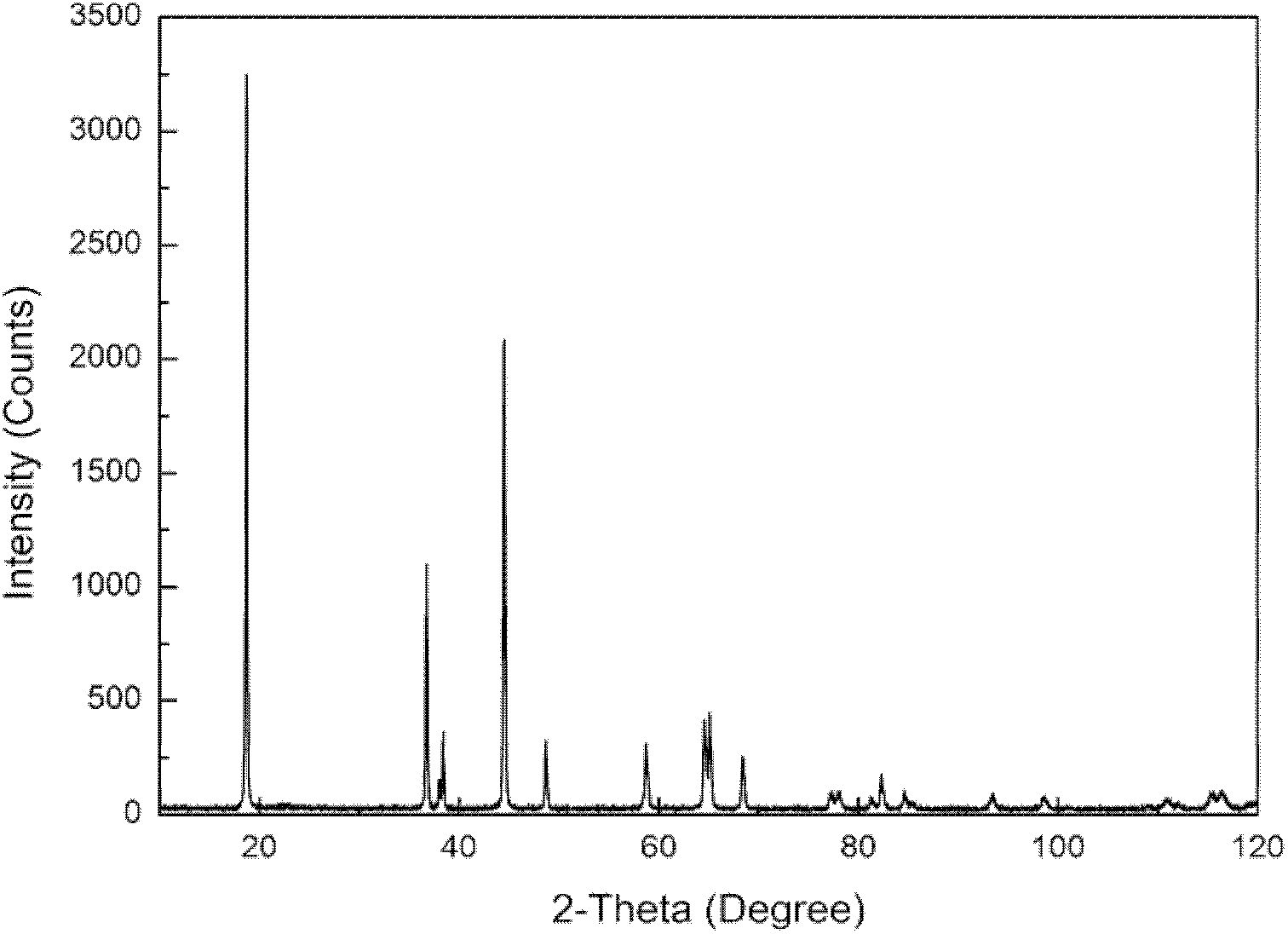

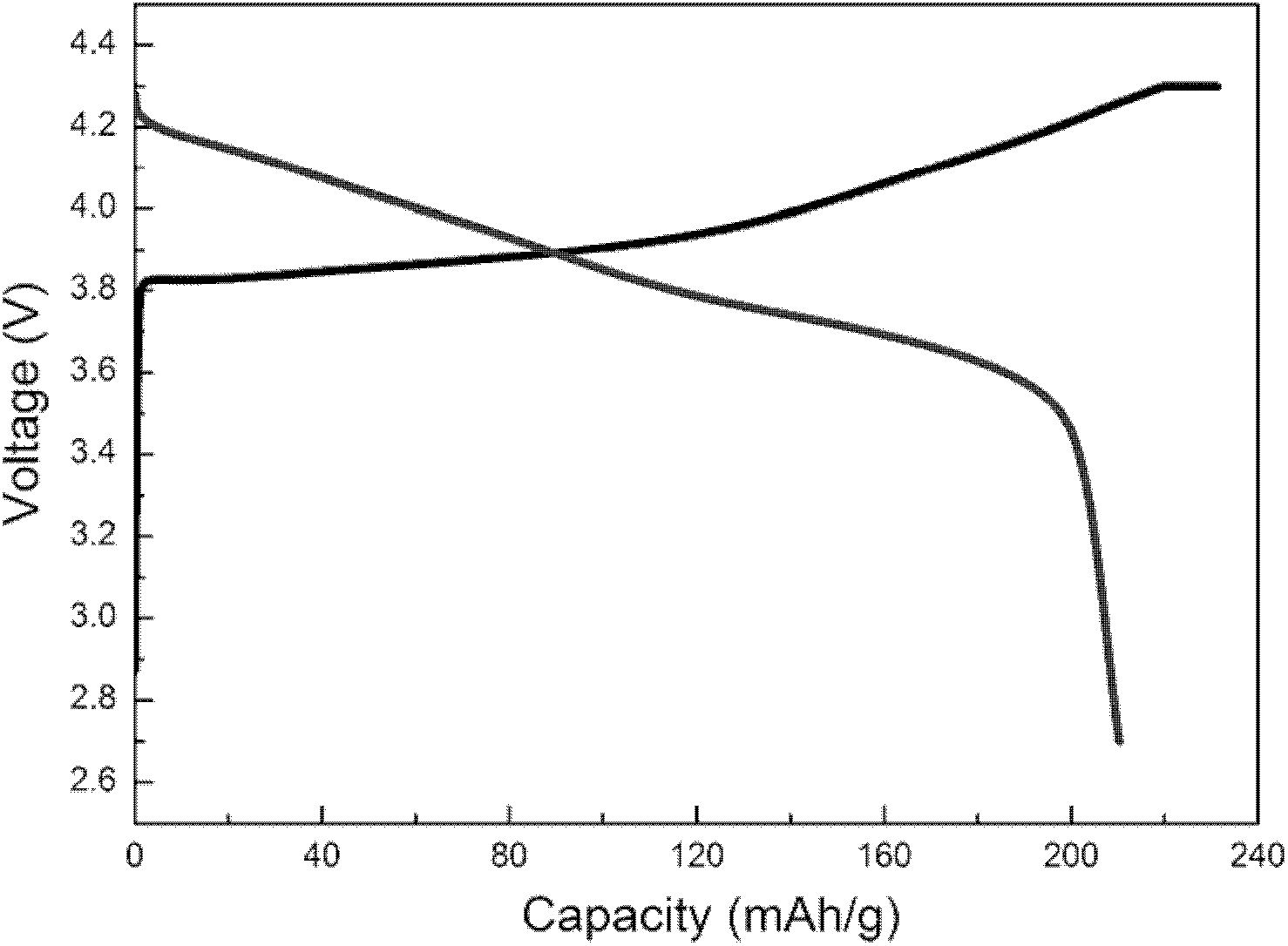

Embodiment 1

[0020] NiCl 2 ·6H 2 O, CoCl 2 ·6H 2 O, MnCl 2 4H 2 O is the raw material, and the molar ratio of Ni, Co, and Mn is 9:0.5:0.5. Add deionized water to make a solution with a total metal ion concentration of 2mol / L. Add ammonia water and NaOH solution to adjust the pH value to 12.5. Stir at constant temperature 1min, get the hydroxide precipitate, filter, wash, utilize 10% polyvinylpyrrolidone and tetraethyl orthosilicate (15% by Si amount), stir, filter, the gained precipitate is dried in 110 ℃ of forced air ovens, and then The obtained powder was added with LiOH·H according to the stoichiometric ratio 2 O (excess 5%), calcined at 950°C for 2h in an air atmosphere, and the obtained product was removed with a sodium hydroxide solution in an ultrasonic oscillator to obtain a nanoscale, high specific surface area composite cathode material LiNi 0.9 co 0.05 mn 0.05 o 2 , its first discharge specific capacity is as high as 210.3mAh / g.

Embodiment 2

[0022] Use nickel acetate, cobalt acetate, and manganese acetate as raw materials, mix according to the molar ratio of Ni, Co, and Mn as 1:1:8, add deionized water to make a solution with a total metal ion concentration of 0.5mol / L, and keep the temperature at 50°C Add ammonia water and NaOH mixed solution (NH 3 ·H 2 O, NaOH molar ratio 1: 1), adjust the pH to be 9, stir at constant temperature for 24h, obtain hydroxide precipitate, filter, wash, utilize 0.2% polyvinylpyrrolidone and dimethyl dichlorosilane (0.5% by Si amount) ), stirred, filtered, and the obtained precipitate was dried in a blast drying oven at 110°C, then the obtained powder was added with lithium acetate according to the stoichiometric ratio, and calcined at 450°C for 24 hours in an oxygen atmosphere, and the obtained product was treated with sodium hydroxide solution in ultrasonic Removing the surface Si in the oscillator, that is, nano-scale, high specific surface area composite cathode material LiNi 0....

Embodiment 3

[0024] Using nickel nitrate, cobalt nitrate, and manganese nitrate as raw materials, the molar ratio of Ni, Co, and Mn is 6:2:2, and deionized water is added to make a solution with a total metal ion concentration of 1mol / L. Ammonia, add NaOH solution, adjust the pH value to 10, stir at constant temperature for 1h, obtain hydroxide precipitate, filter, wash, utilize 5% pvp and methyl trichlorosilane (5% by Si amount), stir, filter, The obtained precipitate was dried in a blast drying oven at 110°C, and then the obtained powder was added with lithium carbonate (2% excess) according to the stoichiometric ratio, calcined at 750°C for 12 hours in an oxygen atmosphere, and the obtained product was vibrated with sodium hydroxide solution in ultrasonic Remove the surface Si in the device, and then get the quasi-nanoscale composite cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 . Its primary particle size can reach 160-180nm, and its initial discharge specific capacity can reach 194....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com