Method for preparing high-purity vanadium from heteropolyacid impurity in amine extraction mode

A heteropoly acid and extraction technology, applied in the direction of improving process efficiency, can solve the problems of low purity and unsatisfactory vanadium products, and achieve significant economic benefits, low equipment requirements, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

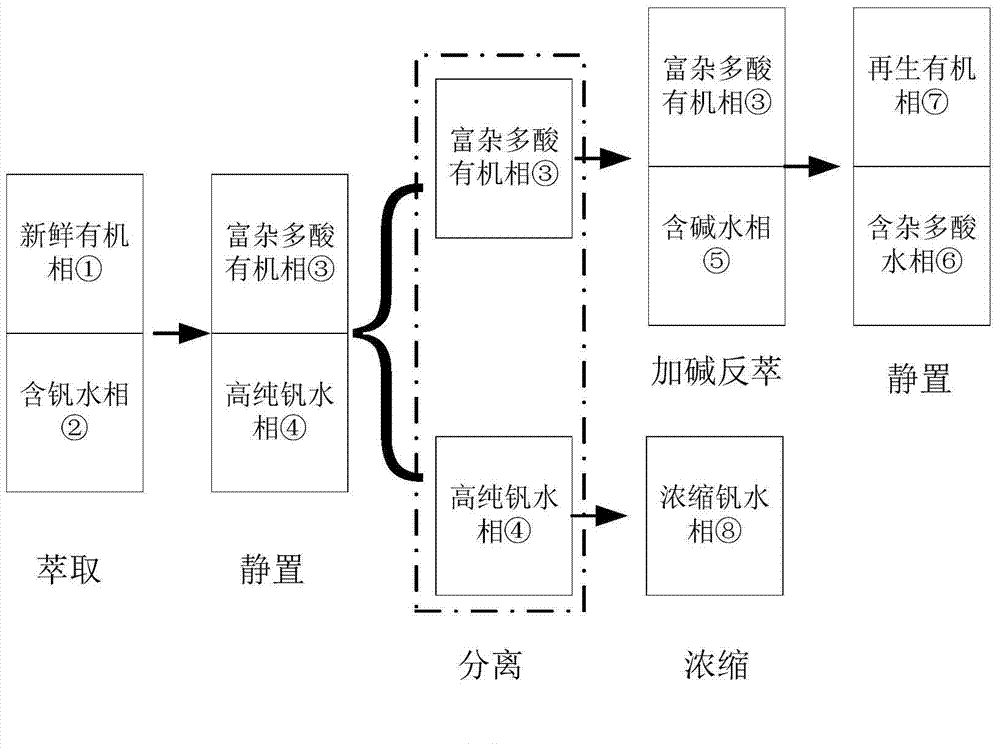

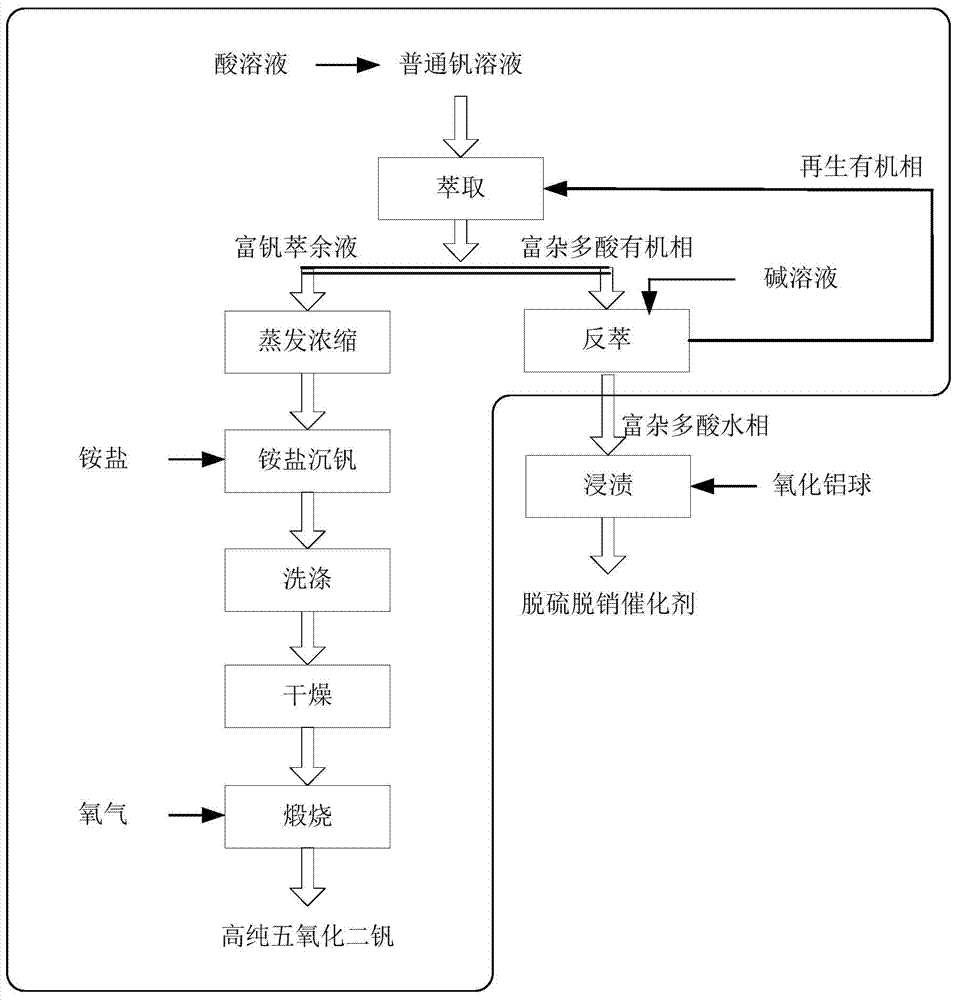

Method used

Image

Examples

Embodiment 1

[0021] The chromium-containing vanadium slag leaching liquid is used as the vanadium-containing solution after deep removal of impurities. The solution components are: 16 g / L vanadium, 0.5 g / L chromium, 0.5 g / L tungsten, 0.05 g / L silicon, 0.05 g / L Phosphorus, 0.5 g / L molybdenum, 0.1 g / L arsenic, primary amine N1923, oxime extractant LIX63, n-octanol and kerosene were used to form an organic phase for extraction and separation tests, and the pH value of the feed liquid was adjusted to 6.00. The volume percentage concentration of primary amine is selected as 3%, the volume percentage concentration of LIX63 is 0.8%, and the volume percentage concentration of n-octanol is 0.8%. Minutes, remove the oscillator and let the layers stand for 20 minutes, back-extract the loaded organic phase with 5% sodium hydroxide to regenerate the organic phase, heat the raffinate to 105 degrees, evaporate to about 40g / L, ammonium chloride The solid-to-liquid ratio of the dosing amount and the evapor...

Embodiment 2

[0023] The chromium-containing vanadium slag leaching liquid is used as the vanadium-containing solution after deep removal of impurities. The solution components are: 16 g / L vanadium, 0.5 g / L chromium, 0.5 g / L tungsten, 0.05 g / L silicon, 0.05 g / L Phosphorus, 0.5 g / L molybdenum, 0.1 g / L arsenic, quaternary ammonium salt N263, trialkylphosphorous oxide TRPO, n-hexanol and toluene are used to form an organic phase, and the extraction and separation test is carried out. The pH value of the feed solution is adjusted to 6.50, and the extraction The volume percentage concentration of primary amine is 4%, the volume percentage concentration of LIX63 is 1.0%, and the volume percentage concentration of n-octanol is 1.0%. The extraction temperature is room temperature 25°C. After 20 minutes, remove the shaker and let it stand for 10 minutes to separate the layers. The loaded organic phase is back-extracted with 5% potassium hydroxide to regenerate the organic phase. The raffinate is heat...

Embodiment 3

[0025] The chromium-containing vanadium slag leaching liquid is used as the vanadium-containing solution after deep removal of impurities. The solution components are: 16 g / L vanadium, 0.5 g / L chromium, 0.5 g / L tungsten, 0.05 g / L silicon, 0.05 g / L Phosphorus, 0.5 g / L molybdenum, 0.1 g / L arsenic, tertiary amine Alamine336, dioctyl sulfoxide, 4-methyl-1-pentanol and o-xylene were used to make the organic phase, and the extraction and separation test was carried out to adjust the pH value of the feed solution 4.5, the volume percentage concentration of the extraction agent primary amine is 3.0%, the volume percentage concentration of LIX63 is 0.3%, the volume percentage concentration of n-octanol is 0.3%, the extraction temperature is room temperature 25 ° C, and the aqueous phase and the organic phase are mixed in a stirring tank Mix, stir and extract for 20 minutes, remove the oscillator and let it stand for 10 minutes to separate the layers, back-extract the loaded organic phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com