Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Increase the speed of oxidation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation

ActiveCN102527205AAvoid preparationImprove safety and economyDispersed particle separationEnvironmental chemistryDust control

The invention discloses a method for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation. The method is characterized by comprising the following steps of: (1) arranging a catalytic reactor in a dust-removed smoke duct, wherein a catalyst for promoting oxidizing reaction of NO and HgO is filled in the catalytic reactor; (2) allowing the dust-removed smoke to pass through the catalytic reactor, wherein under catalysis of the catalyst, the reaction speed of the NO, the HgO and O2 is increased and the NO and the HgO are oxidized into NO2 and Hg<2+>; and (3) introducing the smoke subjected to catalytic oxidation into an absorber with an absorption solution, wherein the absorption solution is used for absorbing NO2, Hg<2+> and SO2 from the smoke. The invention also discloses a system applicable to the method. According to the method and the system, the sulfur, the niter and the mercury are removed from the smoke; external oxidant is not required to be added; preparation, transportation and storage of strong oxidant are avoided; operating cost is reduced; and economy and safety of the system are improved.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Method for regenerating alkali liquor containing sodium thioalcohol

InactiveCN101077981AIncrease the speed of oxidation reactionSave working spaceHydrocarbon oils refiningSulfideAqueous sodium hydroxide

The method of regenerating alkali solution containing sodium mercaptide is to oxidize sodium mercaptide in alkali solution with oxygen-rich air with oxygen concentration of 26-99.99 vol% intelligent presence of catalyst, such as cobalt phthalcyanide sulfonate, into disulfide. Sodium mercaptide including sodium methyl mercaptide, sodium ethyl mercaptide, etc in alkali solution, such as water solution of sodium hydroxide, is mixed with oxygen-rich air and reacted under the action of catalyst, such as cobalt phthalcyanide sulfonate, to produce sodium hydroxide and disulfide, such as dimethyl disulfide, diethyl disulfide, etc., so that the alkali solution has lowered sodium mercaptide concentration and raised sodium hydroxide concentration. The regenerated alkali solution after eliminating the disulfide may be reused in the mercaptide eluting process of liquefied alkali.

Owner:NINGBO ZHONGYI PETROCHEM TECH

Smokeless coal gasification micro grease gun igniting pulverized coal burner

ActiveCN101012928APromote combustionAchieve staged combustionPulverulent fuel combustion burnersCombustion chambersCombustorStaged combustion

The invention relates to a non-smoke gasify micro oil gun ignition powder coal burner, wherein, the cooling air cylinder (7) is arranged outside the outer tube (9) of burner; the cooling air cylinder (7) and the outer tube (9), the secondary burning room reducing section (10) and the cooling air reducing section (12) are formed by the cooling air channels (5) between them; one end of oxygen tube (6) is communicated with the secondary burning straight section (8), while another end is communicated with outer space. The invention mounts an oxygen tube to feed oxygen into the secondary burning room, to improve the oxidization speed, improve the burnt degree, and realize non-smoke burning.

Owner:STATE GRID CORP OF CHINA +2

Catalytic wet oxidation method of flue gas desulfurization waste liquor

ActiveCN103043773AIncrease the speed of oxidation reactionImprove processing efficiencyWaste water treatment from gaseous effluentsWater/sewage treatment by oxidationSulfite saltWet oxidation

The invention relates to a catalytic wet oxidation method of flue gas desulfurization waste liquor. In the presence of a catalyst, flue gas desulfurization waste liquor contacts air to oxidate sulfite into sulfate, wherein the catalyst uses nano TiO2 as a supporter, the active component of the catalyst is one or more of noble metal elements Pt, Pd, Ru and Rh, and the assistant is one or more of rare earth metal elements La, Ce, Pr and Nd. The catalyst comprises the following components in percentage by weight: 0.05-0.5% of noble metal element and 1-10% of rare earth metal element. The mass ratio of the rare earth metal element to the noble metal element is 10-200. By adopting the proper catalyst, the method provided by the invention lowers the cost of the catalyst on the premise of enhancing the reactivity; and the catalyst has the advantages of high stability and no secondary pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regeneration method of flue-gas demercuration absorbent

ActiveCN104437377AIncrease the speed of oxidation reactionImprove Chlorine RemovalOther chemical processesDispersed particle separationEnvironmental chemistryOxide

The invention discloses a regeneration method of a flue-gas demercuration absorbent composition. The regeneration method comprises the following steps: (a) washing an inactivated absorbent by using hydrogen peroxide solution, removing impurities such as flying ash on the surface of the absorbent, and converting elemental mercury absorbed on the surface of the absorbent into mercury in an oxidation state; (b) treating reacted mercury absorbent by using supercritical water and washing out the mercury absorbed; (c) further treating aqueous solution obtained in the step (b) by using sulfide solution, so as to obtain mercuric sulfide precipitate, and recovering the mercuric sulfide precipitate; (d) dipping and activating the absorbent in ferric chloride solution with the concentration being 1-3mol / L; and (e) drying, then roasting for 1-3 hours, thus obtaining the regeneration absorbent. The regeneration method disclosed by the invention is applicable to regeneration of the modified-metal-oxide-based mercury absorbent, and the recovery of the absorbing performance of the regenerated absorbent is good, so that the service life of the absorbent is prolonged and the economic and social benefits are good.

Owner:浙江大业新材料股份有限公司

Fuel battery unit cell, fuel battery unit cell array, fuel battery module, and fuel battery system

InactiveCN101278428ACatalytic activationIncrease the speed of oxidation reactionElectrolyte holding meansFuel cells groupingPtru catalystFuel cells

This invention provides a fuel battery unit cell, which can realize a size reduction and a cost reduction, a fuel battery unit cell array, a fuel battery module, and a fuel battery system. The fuel battery unit cell has a pin structure comprising a fuel electrode (11) formed of a p-type semiconductor, an oxygen electrode (13) formed of an n-type semiconductor, and an intermediate layer (12) interposed between the fuel electrode (11) and the oxygen electrode (13) and formed of an authentic semiconductor. The fuel electrode (11) and the oxygen electrode (13) are porous and permeable to a fluid. A metal-base catalyst layer is provided on the inner surface of pores in the porous part. The intermediate layer (12) is porous and permeable to a hydrogen ion produced in the fuel electrode (11) and is impermeable to electrons. A hydrogen-containing fuel is supplied on the surface of the fuel electrode (11), and an oxygen-containing oxidizing fluid is supplied on the surface of the oxygen electrode (13). Connecting terminals electrically connected respectively to the fuel electrode (11) and the oxygen electrode (13) are provided.

Owner:MICRO SILITRON INC

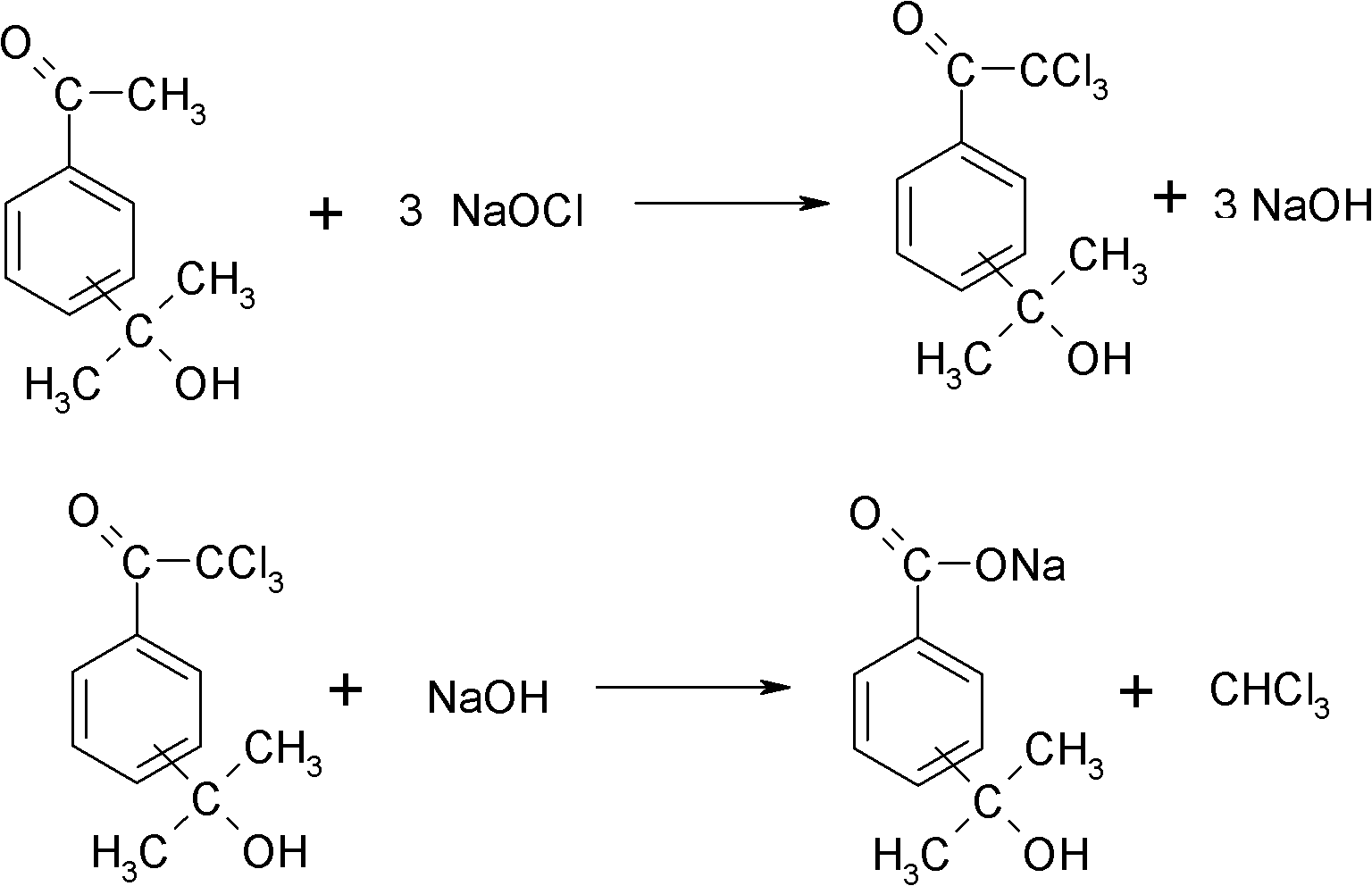

Production method for bis-(2-hydroxyl isopropyl)benzene

ActiveCN103159592AIncrease the speed of oxidation reactionPreparation by oxygen reductionBenzeneReaction temperature

The invention relates to a production method for bis-(2-hydroxyl isopropyl)benzene, and mainly solves the problem that continuous accumulation of impurity of acetyl dimethyl-benzyl alcohol in recycling diisopropylbenzene influences the speed of an oxidation reaction in the prior art. The problem is relatively well solved by a technical solution comprising the following steps of a) contacting a material flow I containing the diisopropylbenzene and air with a catalyst to carry out the oxidation reaction for 10-24 hours under a condition with a reaction temperature of 85-105 DEG C and a reaction pressure of 0.20-0.35 MPa, so as to obtain a material flow II, wherein the weight content of the acetyl dimethyl-benzyl alcohol in the material flow I is smaller than 3%; and b) carrying out a reduction reaction on the material flow II and a reducing agent Na2S for 5-7 hours under the condition with the reaction temperature of 85-105 DEG C and the reaction pressure of 0.20-0.35 MPa, so as to obtain the bis-(2-hydroxyl isopropyl)benzene. The production method can be applied in industrial production of the bis-(2-hydroxyl isopropyl)benzene.

Owner:CHINA PETROCHEMICAL CORP

Method for preparing cumene hydroperoxide through oxidation of cumene

ActiveCN110437117AHigh yieldInhibit moving to the rightOrganic compound preparationPeroxy compound preparationBy-productCumene hydroperoxide

The present invention relates to a method for preparing cumene hydroperoxide through oxidation of cumene. The method comprises: in the presence of an alpha-methyl styrene dimer, preparing cumene hydroperoxide through oxidation of cumene, wherein preferably the method can be performed in the presence of a by-product inhibitor. According to the present invention, the conversion rate of cumene is improved when the reaction solution contains a certain amount of alpha-methylstyrene dimmers; and after the alpha-methylstyrene dimer and the by-product inhibitor are simultaneously added, the conversionrate of cumene can be increased while the selectivity of methyl phenyl ketone can be effectively reduced.

Owner:WANHUA CHEM GRP CO LTD +1

Method for producing pig iron and phosphate using ferro-phosphorus

InactiveCN102796838AIncrease the speed of oxidation reactionSave heating energyPhosphoric acidPhosphateReaction temperature

A method for producing pig iron and phosphate using ferro-phosphorus is characterized in that: the ferro-phosphorus is arranged in a reverberatory furnace, and performs quick air refining reaction with air or oxygen-rich air, thus the phosphor in the ferro-phosphorus is oxidized into P2O5 gas, and the reaction furnace gas is subjected to heat exchange, dust removal, and P2O5 hydration absorption to obtain rough phosphoric acid, and the rough phosphoric acid is refined and purified to obtain a technical grade phosphoric acid product. While the phosphorus element is oxidized, part of the ferro element is oxidized into ferric oxide, and then the ferric oxide is reacted with the newly-added ferro-phosphorus, thus the phosphorus element is oxidized into the P2O5 gas, and the ferric oxide is reduced into the ferro by phosphorus; when the phosphorus content in the iron solution in the reverberatory furnace is smaller than 4%, the iron solution is arranged in a converter and processed by pig iron smelting after adding refining agent such as burned lime powder as dephosphorization agent, and the eligible pig iron solution is then processed by injection moulding to obtain a pig iron product. The best material reaction temperature in the reverberatory furnace is 1300-1600 DEG C.

Owner:黄靖元

Method for synthesizing vanillin

InactiveCN102030625AAvoiding Explosion HazardsAvoid deep oxidationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSlurry reactorVanillin synthesis

The invention relates to a method for synthesizing vanillin, comprising the following steps of: carrying out material thermal pretreatment by adopting a pressured reaction axe, and then pouring the materials into a cannular slurry reactor for vanillin synthetic oxidation reaction; and by using 4-methyl-2-metoxyphenol as a raw material, using ethylene glycol monomethyl ether or ethylene glycol monoethyl ether as a solvent and using oxygen as an oxidant, carrying out the oxidation reaction for synthesizing vanillin in a way of intermittently feeding oxygen. The conversion rate of the 4-methyl-2-metoxyphenol as the raw material reaches more than 99%, the selectivity of the vanillin reaches more than 93%, and the separation yield reaches about 82%. The oxidation test carried out in the cannular slurry reactor proves that the oxidation reaction of the 4-methyl-2-metoxyphenol can be successfully carried out in the reactor under a milder condition to synthesize vanillin, and the method avoids a danger of easy explosion of the traditional axe type oxidation technology process for synthesizing vanillin by using methanol as the reaction solvent and has the advantages of environmental-protection process and high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

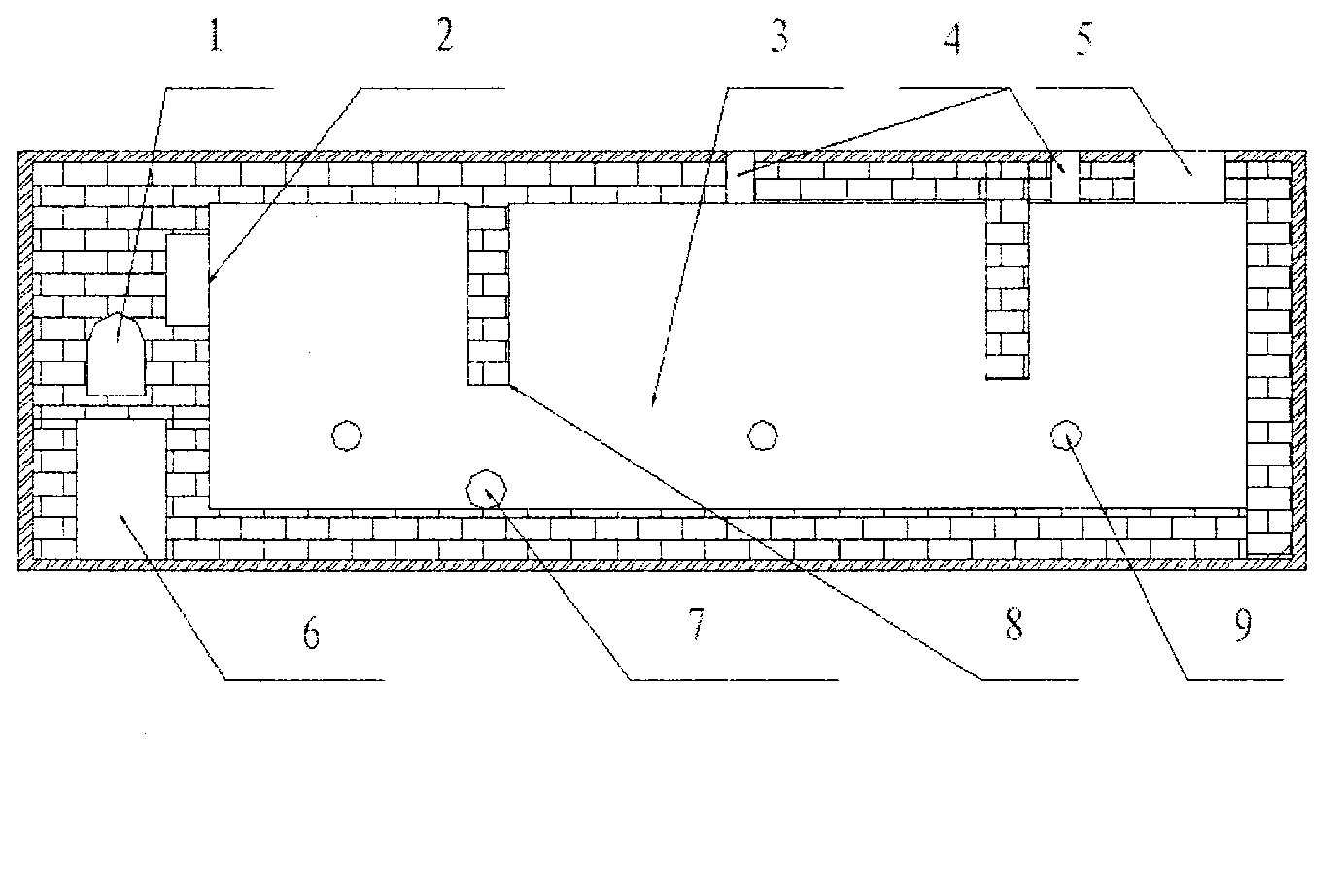

Rich-oxygen and pure oxygen burning tunnel kiln

InactiveCN101182218AReduce total powerEmission reductionFurnace typesCeramic materials productionTunnel kilnHigh concentration

The invention provides an oxygen-enriched and total-oxygen burning tunnel kiln, comprising a preheating area (2), a sintering area (3), a fuel and combustion-supporting medium feeding system (4), a smoke exhaust system (5), a quench area, a cooling area, a temperature control system, a burning system and a waste heat system. The tunnel kiln is used for a combustion-supporting medium with the volume concentration of at least 21 percent of oxygen and the fuel to burn together inside a burner (6), no air combustion-supporting fan is required, the burner (6) is installed at the position of a burner brick (7). In order to solve the problem that the exhaust emission quantity of a ceramic tunnel kiln is large, the invention adopts the high concentration oxygen burning tunnel kiln which has high thermal efficiency, so compared with the combustion which considers the air as the combustion-supporting medium, the burning product quantity is reduced more than 50 percent, the nitrogen oxide produced by the invention is reduced greatly, the invention can reduce the energy consumption more than 10 percent, and the harmful substance emission can be reduced to the minimum.

Owner:WUHAN UNIV OF TECH

Preparation method of nano-cellulose

The invention discloses a preparation method of nano-cellulose, comprising the following steps of: firstly, swelling the raw material cellulose by aqueous alkali, soaking for a while, centrifugally separating out cellulose, and washing by deionized water till the filter liquor is neutral; dispersing the separated cellulose in water, adding sodium bromide, 2, 2, 6, 6-tetramethyl piperidine-1-oxide and sodium hypochlorite solution, carrying out an oxidation reaction under sonic oscillation, centrifugally separating after reaction, and carrying out freeze drying treatment on suspension liquid to obtain the nano-cellulose powder. Compared with the prior art, the preparation method is incompact in cellulose structure, can enlarge the unit cell distance, and can improve the reaction accessibility after the raw material cellulose is pretreated, so that the oxidation reaction efficiency can be improved, and the product yield can be obviously improved; the oxidation reaction conditions are mild, and are easy to control, and the product quality can not be influenced due to the fact that only a small quantity of sodium chloride and minute quantity of oxidizing agent are mixed in a reaction system after the reaction; and the sonic oscillation is adopted in the process of reaction, so that the oxidation reaction speed can be accelerated, and the reaction time can be obviously shortened.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

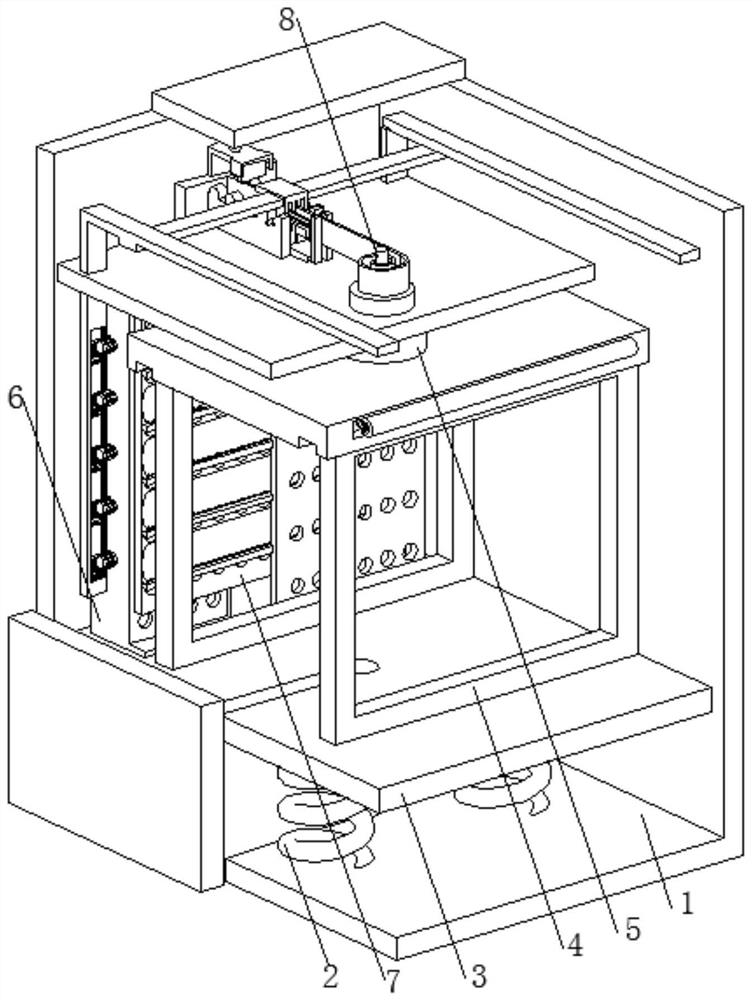

A wastewater treatment device for a paper mill

InactiveCN109422369AIncrease dissolved oxygen contentFully oxidizedWater treatment parameter controlWater/sewage treatment by irradiationCouplingWastewater

A wastewater treatment device for a paper mill is disclosed. The device includes a main body. The bottom of the inner cavity of the main body is fixedly connected to an aeration chamber the top of which is fixedly connected to a fixed base. A motor is fixedly mounted at one side of the fixed base. The rotating shaft of the motor is in transmission connection with a stirring shaft through a coupler. The bottom end of the stirring shaft penetrates the top of the aeration chamber and extends into the aeration chamber. The bottom of the stirring shaft is welded to stirring plates. The left side ofthe main body is fixedly connected to a water feeding pipe. Through arrangement of a water stopper ring, a water stop bolt, a shell, a Y-shaped ventilation screw and a cushion plate, the water stopper ring and the water stop bolt maintain structure leakproofness, air flows into the Y-shaped ventilation screw through a branch pipe and then is fed into wastewater from the top end of the Y-shaped ventilation screw, thus greatly increasing the content of dissolved oxygen in wastewater, accelerating oxidation reaction and making oxidation more thorough, and therefore organic matters are fully decomposed and sludge is discharged from a drainage pipe.

Owner:江苏佳鑫环保工程有限公司

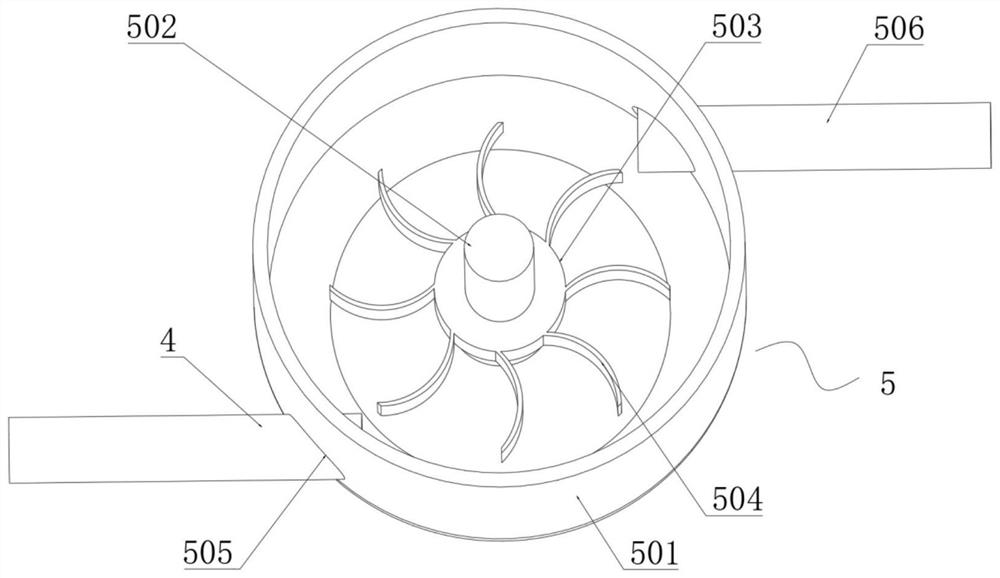

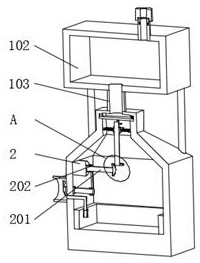

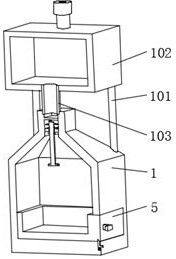

Process and device for preparing ferric chloride

The invention belongs to the technical field of waste liquid treatment, and provides a device for preparing ferric chloride. The device comprises a reaction groove, wherein the reaction groove comprises a reaction groove body, a stirring mechanism, an air inlet, an air outlet and a catalyst inlet; the air inlet and the air outlet are both formed in the upper part of the reaction groove body; the stirring mechanism extends into the reaction groove body; the stirring mechanism comprises a transmission shaft, a hollow shaft sleeve and an impeller; the hollow shaft sleeve is sleeved on the transmission shaft; the impeller is arranged below the hollow shaft sleeve; an air inlet pipeline is connected to the air inlet; and the air inlet pipeline is connected with the impeller. The invention further provides a process for preparing ferric chloride by adopting the device for preparing ferric chloride. The process includes taking a pickling waste liquid as a raw material; adopting NH4Cl, NH4NO3,MnCl2 or HNO3 as cocatalysts, and cooperating with a main catalyst NaNO2 to jointly catalyze an oxidation reaction of ferrous chloride, hydrogen chloride and oxygen or air under normal pressure. Thedevice and the process solve the problems of high danger and high cost of adopting high-temperature high-pressure oxidation pickling waste liquid in the preparation of ferric chloride in the prior art.

Owner:唐山达润达危废处理有限公司 +1

Desulfurization and denitrification method and desulfurization and denitrification device

PendingCN108187474AGood value for moneyIncrease the speed of oxidation reactionDispersed particle separationAir quality improvementFlue gasX-ray

The invention discloses a desulfurization and denitrification method and a desulfurization and denitrification device, relates to the field of separation and aims to provide a desulfurization and denitrification method and a desulfurization and denitrification device which are low in temperature requirement, rapid in oxidation speed and relatively low in cost, and meet the purposes of reducing difficulties and cost of desulfurization and denitrification and improving desulfurization and denitrification efficiency. According to the main technical scheme of the invention, the desulfurization anddenitrification method comprises the following steps: (1) mixing a flue gas with H2O2, catalyzing reactions with short-wave rays, oxidizing SO2 and aNOX in the flue gas to generate H2SO4 and HNO3, and collecting a flue gas after the reaction is completed, wherein the shortwave rays comprise one or more of ultraviolet rays, X rays and gamma rays; (2) collecting H2SO4 and HNO3 in the flue gas afterthe reactions, or converting H2SO4 and HNO3 into other products.

Owner:TIANZHILAN ENVIRONMENT ENG

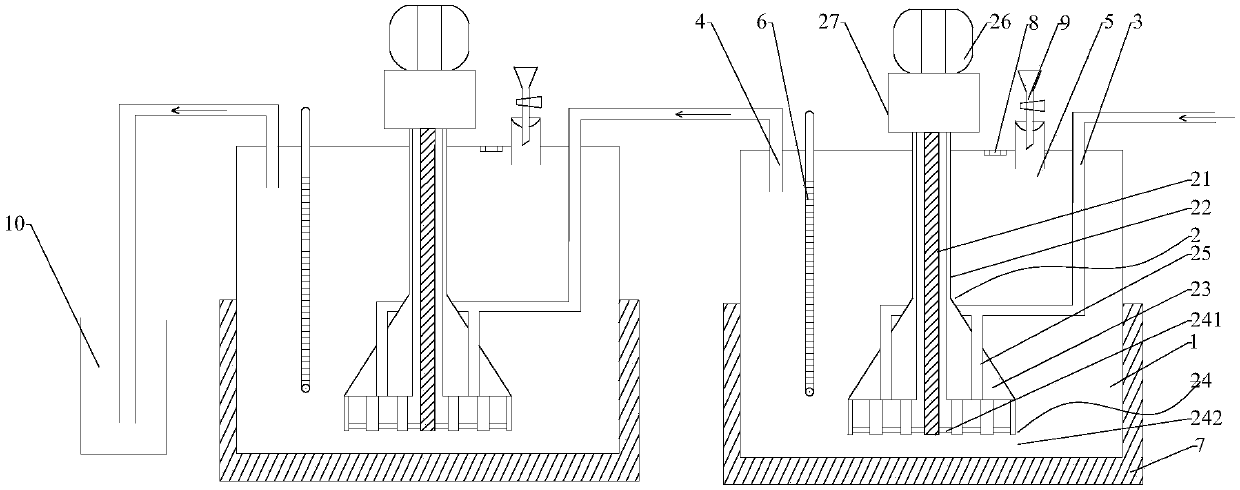

Method for efficiently extracting vanadium from vanadium containing ore

ActiveCN108866354ASmall particle sizeUniform particle sizeProcess efficiency improvementIon exchangeMaterials science

The invention discloses a method for efficiently extracting vanadium from vanadium containing ore. The method comprises the steps of pretreatment, leaching, ion exchange, vanadium precipitation and post-treatment. According to the disclosed preparing method, the metal vanadium in the vanadium containing ore can be sufficiently extracted, and the extraction efficiency is high; a large amount of concentrated sulfuric acid does not need to be consumed in the preparing process, the high-temperature extraction process does not need to be conducted, and the production cost can be reduced; and meanwhile, the production technology can be simplified, and more excellent development prospects are achieved.

Owner:古丈祥丰建筑材料工程有限公司

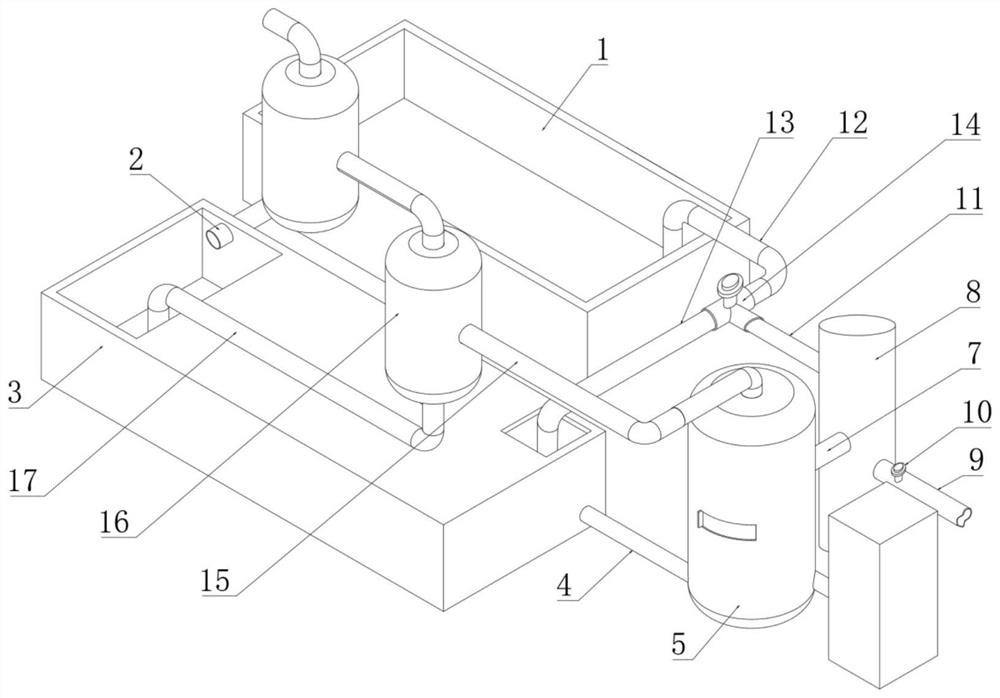

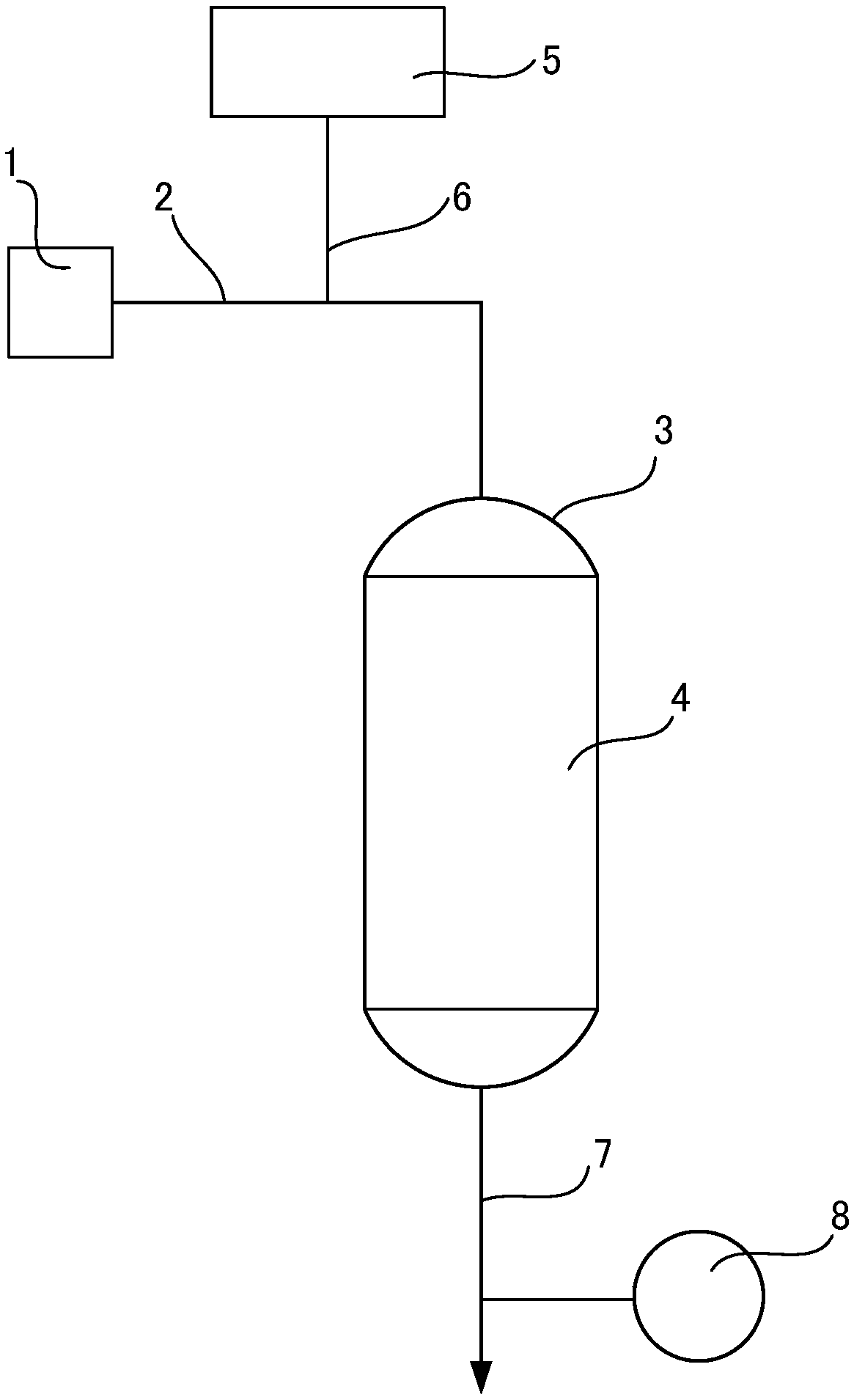

Catalytic ozonation reactor for sewage treatment and sewage circulation treatment method

PendingCN111646561AIncrease the speed of oxidation reactionIncrease speedWater contaminantsMultistage water/sewage treatmentPre treatmentSewage treatment

Owner:深圳市创飞格环保技术有限公司

Production method of L-glufosinate or salt thereof

ActiveCN112391438AFast dissolutionEasy to achieve dissolved oxygen saturation in solutionFermentationOxidative enzymeEnzyme catalysis

The invention discloses an enzyme catalysis technology for preparing L-glufosinate through deracemization. The enzyme catalysis technology is characterized in that oxygen subjected to in-situ generation and dissolving by added hydrogen peroxide under a function of catalase is taken as an oxygen source; DL-glufosinate is taken as a raw material, and the deracemization of the DL-glufosinate is realized under catalysis of D-amino-acid oxidase, amino acid dehydrogenase and a proper coenzyme recycling system; and through an in-situ oxygen supply technology, reaction time can be obviously shortened,and the concentration of a product is obviously improved.

Owner:SICHUAN LIER BIOTECHNOLOGY CO LTD

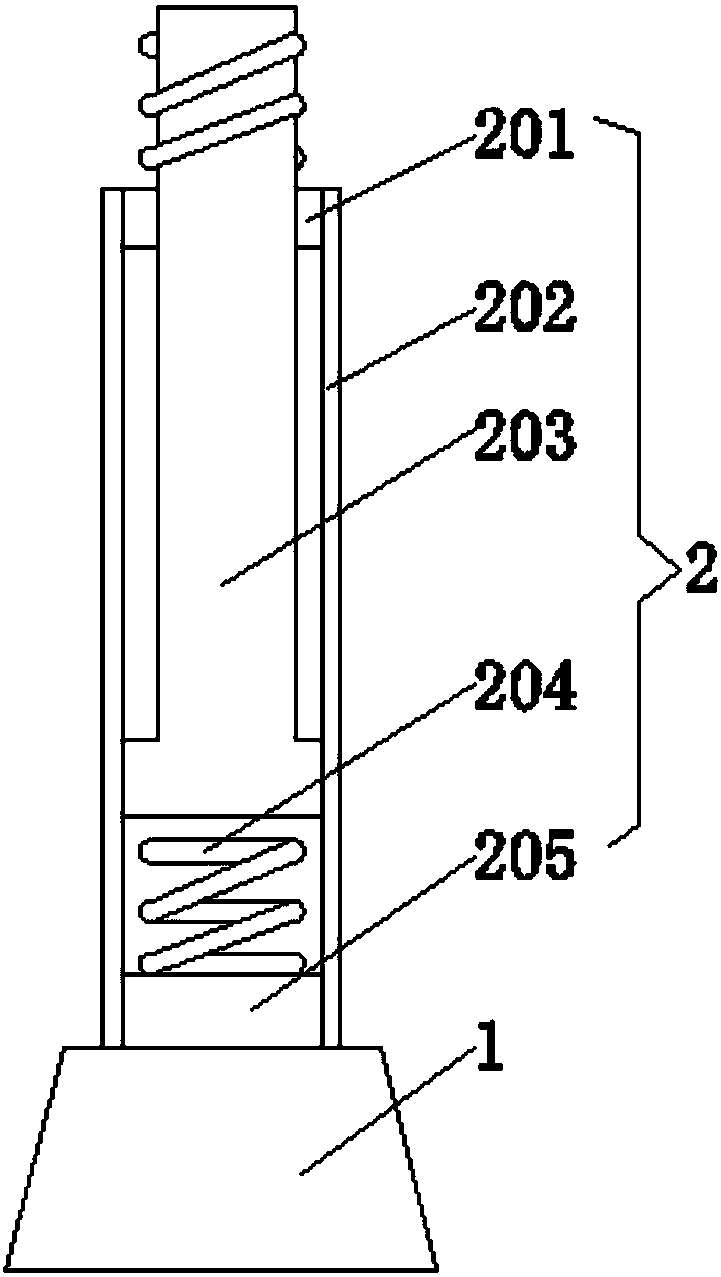

Fully-oxidizing oxygen injection calcining equipment for zinc oxide production

InactiveCN112378261AAvoid cloggingFully oxidizedMaintainance of heating chambersWaste heat treatmentSorbentPhysical chemistry

The invention discloses fully-oxidizing oxygen injection calcining equipment for zinc oxide production, and relates to the field of oxygen injection calcining equipment, the fully-oxidizing oxygen injection calcining equipment comprises a filter box body, four support rods are fixedly mounted at the top of the filter box body, and the same calcining box is fixedly mounted at the tops of the four support rods. A motor is started to drive a rotating shaft, a transmission wheel, a transmission belt and a rotating rod to rotate, the rotating rod rotates to drive air suction fan blades to rotate, the air suction fan blades rotate to suck air, then the air enters a liquid storage box through an L-shaped guide pipe and a movable pipe, other gases in the air are filtered out through the liquid storage box, and remaining oxygen enters the filter box body. Then zinc powder can be fully subjected to oxidation reaction, so that the situation that the zinc powder cannot be fully oxidized due to thefact that other gases react with the zinc powder is avoided, oxygen enters the calcining box through an adsorbent layer and a connecting pipe, the oxidation reaction speed can be increased, and thusthe zinc oxide production speed is increased.

Owner:安徽省含山县锦华氧化锌厂

High-softening-point asphalt preparation method suitable for asphalt-based spherical activated carbon raw materials

ActiveCN109251759ARealize continuous productionSimple processWorking-up pitch/asphalt/bitumen by chemical meansHeptaneCoal

The invention relates to a high-softening-point asphalt preparation method suitable for asphalt-based spherical activated carbon raw materials, special asphalt with the softening point of 130-220 DEGC is used as a raw material, a synergistic effect of negative pressure extraction and thermal polymerization reaction is utilized, a double-screw extruder with a certain number of vacuumizing ports isadopted, and the molecular weight distribution, softening point, group composition and other physical and chemical properties of high-softening point coal asphalt can be adjusted by adjusting the temperature and the extrusion speed of each temperature zone of the double-screw extruder, the number, the setting positions and the vacuum degrees of the vacuumizing ports. The softening point of the prepared high softening point asphalt is 240-280 DEG C, the content of n-heptane soluble substances is lower than 10%, the content of toluene soluble substances is lower than 30%, the content of quinoline insoluble substances is higher than 35%, the content of pyridine insoluble substances is higher than 20%, and the ash content is 0.02-8%. The high-softening-point asphalt preparation method has important significance for promotion of resource reutilization of the special asphalt and the asphalt-based spherical activated carbon and related materials (such as asphalt-based foam carbon).

Owner:湖南曦威新材料有限公司

Method and system for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation

ActiveCN102527205BIncrease the speed of oxidation reactionPromote absorptionDispersed particle separationPtru catalystCatalytic oxidation

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Ozone oxidative decomposition treatment method for vocs and/or gaseous inorganic reducing compounds in gas

ActiveCN108136326AEfficient oxidationReliable conversionGas treatmentOther chemical processesAir volumeSorbent

An ozone oxidative decomposition treatment method for VOCs and / or gas phase inorganic reducing compounds in gas is provided which, being a method that uses a high silica adsorbent to perform oxidativedecomposition treatment of VOCs, etc., with ozone, further improves efficiency of oxidative decomposition reaction with ozone, can perform efficient decomposition treatment even of substances at lowconcentrations such as VOCs and malodorous substances in a high air-flow discharge gas, and which can also reduce the amount of ozone used. When adding and mixing an ozone gas with a gas containing VOCs, then contacting the mixture with a high silica adsorbent, which is a filled porous body, and performing decomposition treatment on the VOCs by ozone oxidation, the aforementioned high-silica adsorbent is the base material in the fill material, and as the base material, a porous substance is used which supports fine particulate powder of a transition metal-containing oxide having a BET specificratio surface area of 80m<2> or greater.

Owner:FUTAMURA CHEM +1

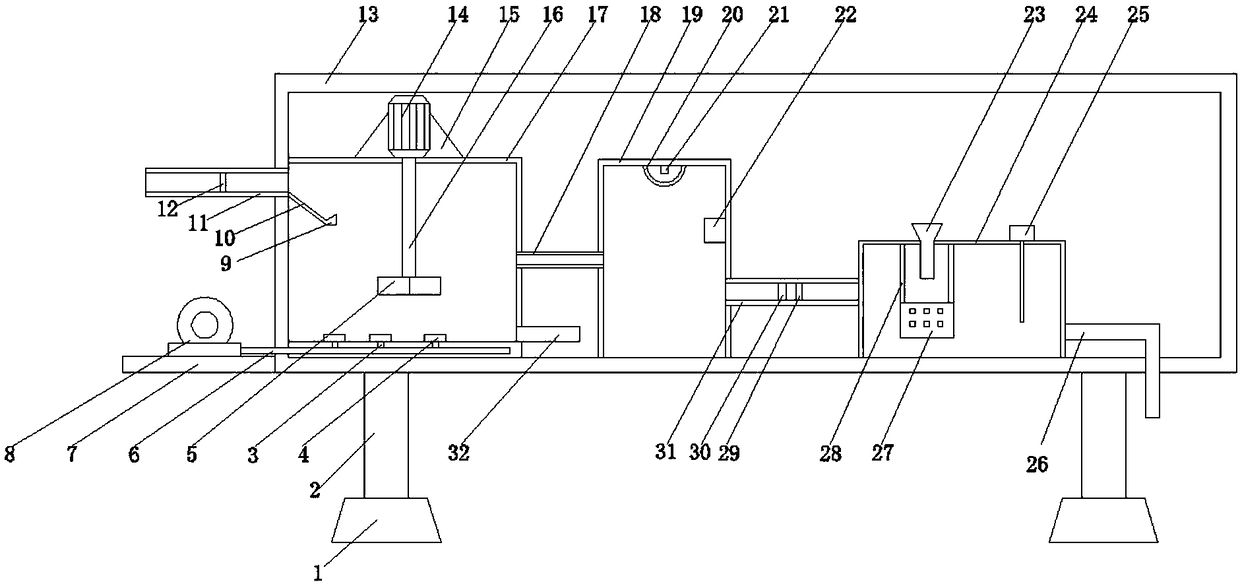

Kiln catalytic combustion method and device

InactiveCN105783022AIncrease the speed of oxidation reactionIncrease burn rateIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyHydrogenFuel oil

The invention discloses a kiln catalytic combustion method and device which can be applied to kilns taking heavy oil, or pulverized coal or biomass as fuel. The method is characterized in that a water electrolyzing oxyhydrogen gas pipeline is additionally arranged on a blast pipeline of a kiln, oxyhydrogen gas generated by a water electrolyzing oxyhydrogen generator is mixed with air according to the proportion of 0.1% to 0.3%, and the mixture is blown into a kiln hearth to serve as a combustion catalyst from the bottom and one side surface of the kiln hearth. The device comprises the kiln hearth, wherein a grate is arranged in the kiln hearth; the blast pipeline is mounted under and on one side face of the grate; a blower is arranged at the tail end of the blast pipeline; the water electrolyzing oxyhydrogen gas pipeline is arranged in the middle section of the blast pipeline; a valve is arranged at the front end of the water electrolyzing oxyhydrogen gas pipeline; and the water electrolyzing oxyhydrogen generator is arranged at the tail end of the water electrolyzing oxyhydrogen gas pipeline. As the mixture obtained by mixing the oxyhydrogen gas generated by the water electrolyzing oxyhydrogen generator and air according to the proportion is added in the combustion process of the kiln to serve as the combustion catalyst, and enters the combustion space of heavy oil, or pulverized coal or biomass for mutual combustion, the combustion efficiency of the fuel can be improved.

Owner:湖南冠拓科技股份有限公司

Pyrolysis gasification tar conversion and utilization device and method

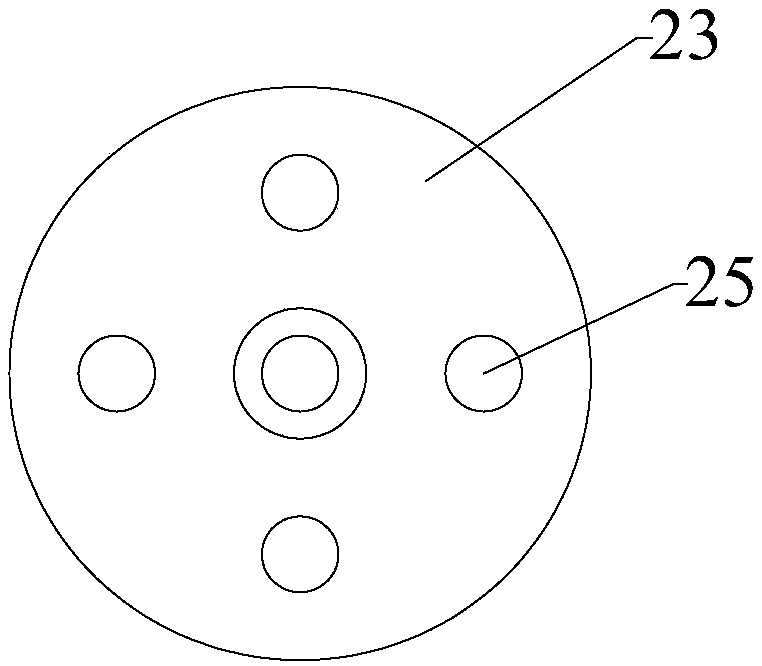

ActiveCN113025383AReduce washingReduce drynessGranular/pulverulent flues gasificationEngineeringMechanical engineering

The invention relates to a pyrolysis gasification tar conversion and utilization device and method. The device comprises a reaction cavity (1), an airflow mixer (2), a heat exchange unit (15) and a deslagging unit (16), The section of the reaction cavity is gradually expanded, and a pore plate (11) is arranged in the reaction cavity and extends downwards along the tube wall of the reaction cavity; A Brown gas channel (12) and a Brown gas nozzle (13) are arranged at the upper end of one side of the reaction cavity; The airflow mixer is arranged below the Brown gas channel and comprises a to-be-treated gas inlet, an oxidant inlet and a mixed gas outlet; A baffle plate (14) is arranged at the rear end of the pore plate and extends downwards along with the pore plate; A heat exchange unit (15) is arranged between the baffle plate and the side wall of the other side of the reaction cavity; And the lower end of the other side of the reaction cavity is connected with a deslagging unit (16). The problem that tar in the pyrolysis gasification gas is not easy to remove and purify can be solved, the tar content of the pyrolysis gasification gas can be reduced, and the energy utilization rate can be increased.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

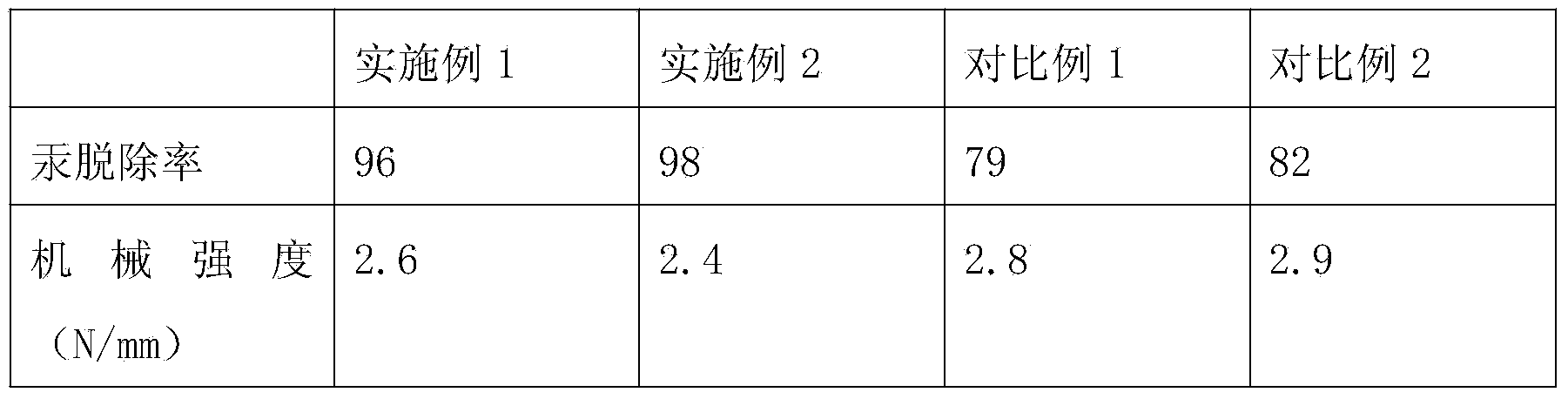

Adsorbent for adsorbing mercury in smoke and preparation method of adsorbent

InactiveCN104399432AIncrease the speed of oxidation reactionImprove Chlorine RemovalGas treatmentOther chemical processesSorbentCopper oxide

The invention discloses an adsorbent for adsorbing mercury in smoke and a preparation method of the adsorbent. The adsorbent comprises the following components in parts by weight: 20-30 parts of semicoke powder, 5-10 parts of ferric trichloride, 10-25 parts of copper oxide, 40-60 parts of aluminium oxide and 1-5 parts of titanium dioxide. The preparation method comprises the following steps: (a) grinding the semicoke powder into particles of 100-200 meshes, preparing ferric trichloride into a water solution, soaking the semicoke powder into the ferric trichloride water solution for 10-15h; (b) pulping pseudo-boehmite, titanium dioxide precursor and copper oxide precursor according to the weight parts for mixing; (c) sufficiently mixing the semicoke particles obtained by the step (a) with the pulp obtained by the step (b), and drying the obtained mixture; and (d) roasting the dried particles at temperature 300-500 DEG C, and cooling to obtain the adsorbent, wherein the adding amount of pseudo-boehmite is calculated on the basis of that of aluminium oxide, and the adding amount of the titanium dioxide precursor and the copper oxide precursor is calculated on the basis of that of titanium dioxide and copper oxide respectively. The mercury adsorbing rate of the adsorbent can reach 95%, and good regenerability is obtained.

Owner:YANCHENG INST OF TECH

Method for producing mono-hydrogen peroxide diisopropylbenzene

ActiveCN102911098ALow costIncrease the speed of oxidation reactionOrganic compound preparationPeroxy compound preparationReaction temperatureRaw material

The invention relates to a method for producing mono-hydrogen peroxide diisopropylbenzene, which solves problems of high additive cost and low product yield in the prior art. According to the invention, the problems are preferably solved through the adoption of the technical scheme as follows: raw materials diisopropylbenzene and air react with each other under conditions that the reaction temperature is 60-240 DEG C, the reaction pressure is 0.2-1.6 MPa, the weight ratio between the diisopropylbenzene and the air is (10-20):3 and the pH value of the reaction materials is 1.0-3.0 or 10.0-13.8, so as to obtain the mono-hydrogen peroxide diisopropylbenzene; and the method for producing the mono-hydrogen peroxide diisopropylbenzene, provided by the invention, can be used for the industrial production of the mono-hydrogen peroxide diisopropylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nursing device for intravenous drip injection in department of cardiology

InactiveCN114099851AAchieve heating effectAvoid discomfortMedical devicesFlow monitorsActivated carbonNursing techniques

The invention relates to the technical field of intravenous drip nursing in the department of cardiology, and discloses a nursing device for intravenous drip injection in the department of cardiology, which comprises a frame body, a gravity spring is fixedly connected to the bottom of the inner wall of the frame body, a bottom plate is fixedly connected to the top end of the gravity spring, and a medicine bag hanger is fixedly connected to the top of the bottom plate. Warming boxes are fixedly connected to the positions, located on the two sides of the medicine bag hanging frame, in the frame body, the interiors of the warming boxes are slidably connected with air inlet plates, and a ringing device used for alarming and prompting is arranged at the position, located above the telescopic column, in the frame body. According to the nursing device for intravenous drip injection in the cardiology department, the height of a lower bottom plate of a medicine bag hanging frame is controlled through the gravity of a medicine bag, an air inlet plate and a ringing device are satay, and when the air inlet plate moves in an incubator, iron powder in the air inlet plate and activated carbon make contact reaction with oxygen with different contents, so that the effect of heating the medicine bag is achieved; the problem that ice-cold liquid enters a human body to cause discomfort is avoided.

Owner:马少俊

Microbiological fuel cell composite material anode and its manufacturing method

The invention provides a microbiological fuel cell composite material anode and a manufacturing method thereof, and relates to a fuel cell composite material anode and a manufacturing method thereof, so that the problems of low electricity generation capacity and low removal rate of organic pollutant in water body or deposit can be solved. The anode is a compressing piece, the anode comprises a first wire mesh layer, a first non-metal sheet layer, a second wire mesh layer, a second non-metal sheet layer and a third wire mesh layer, the second non-metal sheet layer is positioned between the first wire mesh layer and the second wire mesh layer, the second non-metal sheet layer is arranged between the second wire mesh layer and the third wire mesh layer. The main steps for manufacturing the microbiological fuel cell composite material anode comprise: 1) irregularly etching the wire mesh, 2) performing a nitrocementation to liquid phase plasma, 3) compacting the material, 4) performing a carburization to liquid phase plasma, and 5) treating the composite material. The invention is used for power generation of the microbiological fuel cell and the organic pollutant in water body deposit removal.

Owner:哈尔滨佳泰达微生物燃料电池科技有限公司

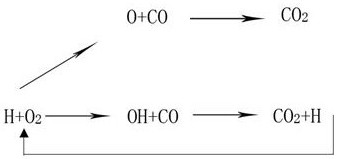

Industrial organic waste gas treatment method and device based on oxyhydrogen gas combustion

InactiveCN111059554ASolve the disadvantages of easy poisoningPromote lysisIncinerator apparatusPtru catalystElectrolysis

The invention discloses an industrial organic waste gas treatment method and device based on oxyhydrogen gas combustion. According to the method, water electrolysis oxyhydrogen gas is introduced intoa waste gas treatment pipeline through a three-way pipeline, one path of oxyhydrogen gas is used as a catalyst to be fully mixed with to-be-treated industrial organic waste gas in advance, the other path of oxyhydrogen gas serves as fire source fuel, and is delayed in ignition under the control of an automatic ignition device, so that combustible gas components in the waste gas are combusted underthe catalytic action of the oxyhydrogen gas, due to the chain propulsion of the water electrolysis oxyhydrogen gas to oxidation reaction of the combustion intermediate product, the combustion speed of a large amount of hydrocarbons, alcohols, aldehydes and other substances in the waste gas can be significantly improved, and in addition, the pyrolysis effect of dioxin in the waste gas in a hydrogenation environment is also superior to that of chemical pyrolysis. The waste gas treated by the method can meet the emission requirement. The device comprises a water electrolysis oxyhydrogen gas system, an automatic igniter, a waste gas treatment pipeline temperature detection and control system, and a combustion and oxyhydrogen gas production interlocking control circuit.

Owner:湖南冠拓科技股份有限公司

A method for efficiently extracting vanadium from vanadium-containing ores

ActiveCN108866354BSmall particle sizeUniform particle sizeProcess efficiency improvementPhysical chemistryIon exchange

The invention discloses a method for efficiently extracting vanadium from vanadium containing ore. The method comprises the steps of pretreatment, leaching, ion exchange, vanadium precipitation and post-treatment. According to the disclosed preparing method, the metal vanadium in the vanadium containing ore can be sufficiently extracted, and the extraction efficiency is high; a large amount of concentrated sulfuric acid does not need to be consumed in the preparing process, the high-temperature extraction process does not need to be conducted, and the production cost can be reduced; and meanwhile, the production technology can be simplified, and more excellent development prospects are achieved.

Owner:古丈祥丰建筑材料工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com